Centralized control system and control method for zinc stripping production line

A centralized control, production line technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of harsh working environment, low work efficiency, high work intensity, etc., achieve high work efficiency, realize automation, Process-accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

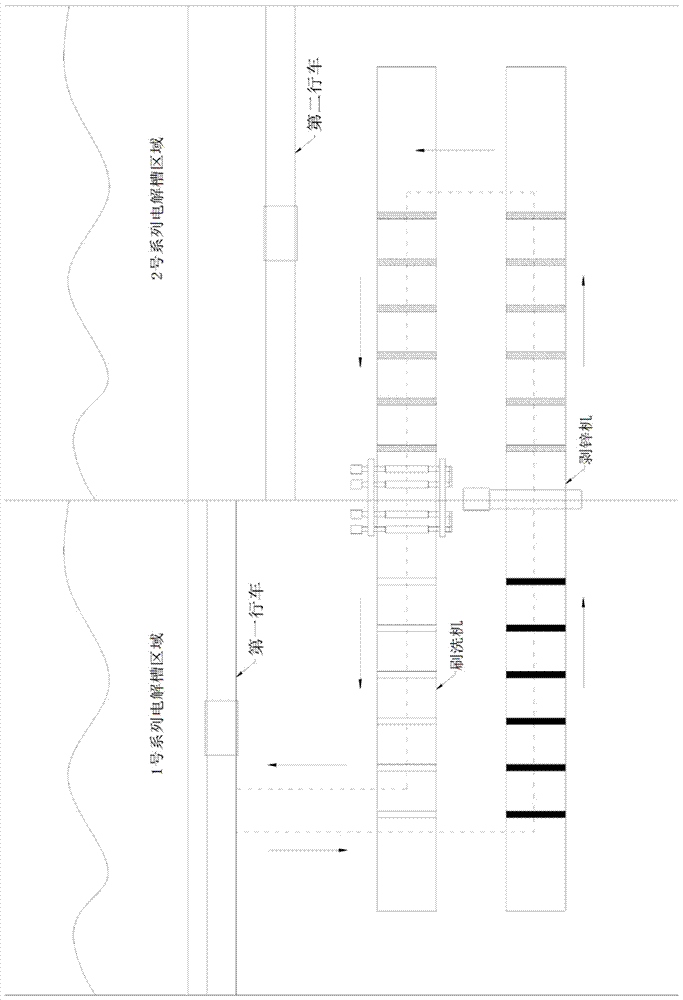

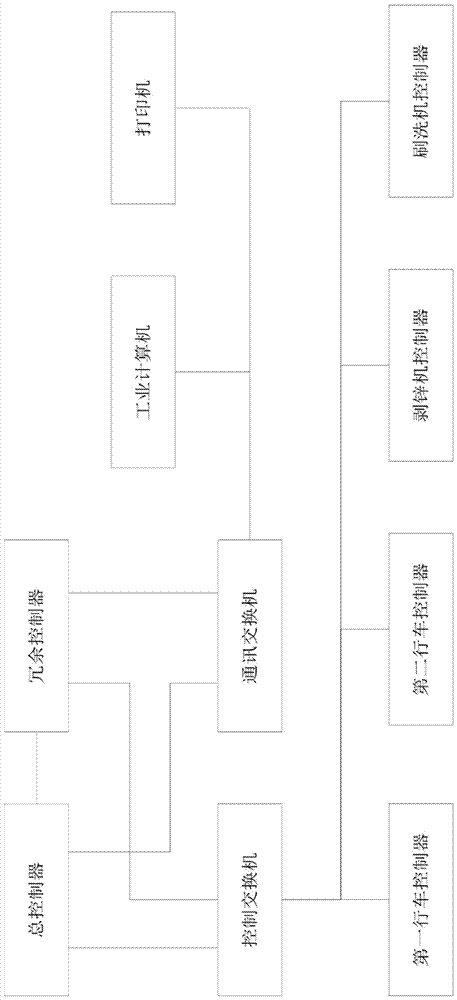

[0031] like figure 1 Shown is a schematic diagram of an embodiment of the zinc stripping production line of the present invention: the automatic zinc stripping production line of this embodiment includes a scrubbing machine, a zinc stripping machine, a first drive and a second drive. In the example in this picture, the first train lifts the cathode plate to be stripped from the No. 1 series electrolytic cell area and lifts it to the zinc stripper, and the second train lifts the stripped cathode plate from the zinc stripper to scrubbing machine, the first drive still needs to hoist the cathode plate that has been scrubbed back to the No. 1 series electrolytic cell area; the direction of the arrow in the figure is the running direction of the cathode plate, which is the workflow direction of the above-mentioned automatic zinc stripping production line. Similarly, the automatic stripping zinc production line can also use the second train to lift the cathode plate to be stripped f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com