Visible light photosensitive resistor and manufacturing method thereof

A technology of photosensitive resistors and manufacturing methods, applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of high scrap rate, poor stability, and reduced performance parameters of photosensitive resistors, and achieve reduced scrap rate and high stability , It is not easy to produce the effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

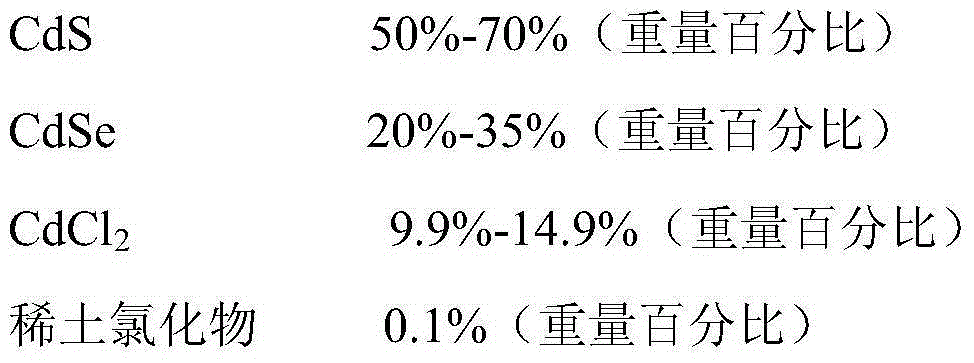

[0035] Embodiment 1: A visible light photoresistor, including a ceramic substrate, a photosensitive layer and two electrodes, the photosensitive layer is coated on the surface of the ceramic substrate, the photosensitive layer and the ceramic substrate form the main body of the visible light photoresistor, and the two electrodes are respectively installed on the visible light photoresistor At both ends of the main body, the photosensitive layer consists of the following components:

[0036]

[0037]

[0038] The rare earth chloride is one of europium chloride, cerium chloride and lutetium chloride or a mixture of two or more of holmium chloride, europium chloride, cerium chloride and lutetium chloride.

Embodiment 2

[0039] Embodiment 2: A visible light photoresistor, including a ceramic substrate, a photosensitive layer and two electrodes, the photosensitive layer is coated on the surface of the ceramic substrate, the photosensitive layer and the ceramic substrate form the main body of the visible light photoresistor, and the two electrodes are respectively installed on the visible light photoresistor At both ends of the main body, the photosensitive layer consists of the following components:

[0040]

[0041] The rare earth chloride is one of europium chloride, cerium chloride and lutetium chloride or a mixture of two or more of holmium chloride, europium chloride, cerium chloride and lutetium chloride.

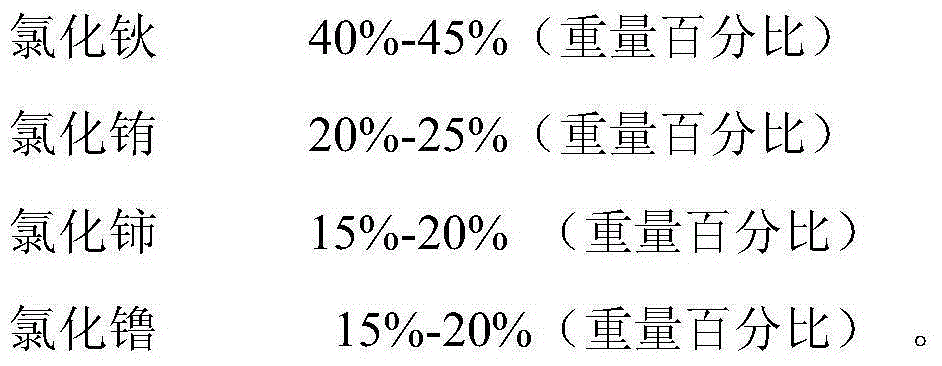

[0042] In this embodiment, the rare earth chloride is a mixture of holmium chloride, europium chloride, cerium chloride and lutetium chloride, and the rare earth chloride is composed of the following components:

[0043]

[0044] In this embodiment, the thickness of the photosensit...

Embodiment 3

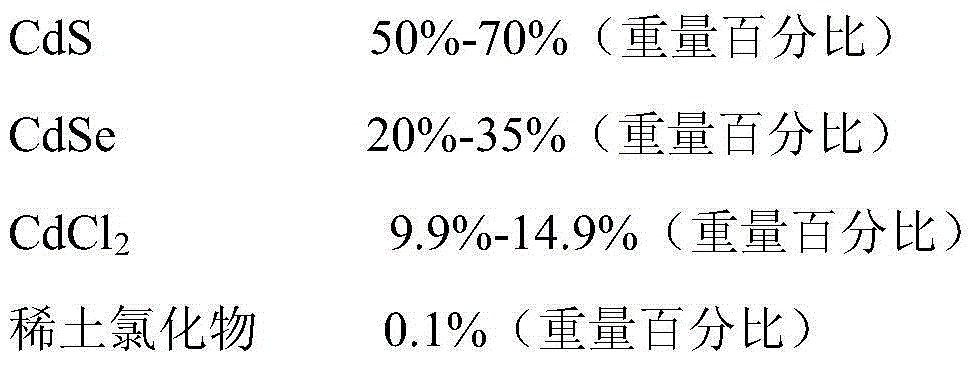

[0046] Embodiment 3: A visible light photoresistor, including a ceramic substrate, a photosensitive layer and two electrodes, the photosensitive layer is coated on the surface of the ceramic substrate, the photosensitive layer and the ceramic substrate form the main body of the visible light photoresistor, and the two electrodes are respectively installed on the visible light photoresistor At both ends of the main body, the photosensitive layer consists of the following components:

[0047]

[0048] The rare earth chloride is one of europium chloride, cerium chloride and lutetium chloride or a mixture of two or more of holmium chloride, europium chloride, cerium chloride and lutetium chloride.

[0049] In this embodiment, the rare earth chloride is a mixture of holmium chloride, europium chloride, cerium chloride and lutetium chloride, and the rare earth chloride is composed of the following components:

[0050]

[0051] In this embodiment, the thickness of the photosens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com