Temperature Sensitive Particle Type Thermal Fuse

A technology of temperature-sensitive particles and thermal fuses, which is applied in the direction of heating/cooling contact switches, electrical components, circuits, etc., can solve the problems of deformation of the second fixed contact point, temperature-sensitive particles disconnecting the circuit, misoperation, failure, etc. Achieve high reliability, simple and accurate operation range, and improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the temperature-sensitive pellet type thermal fuse according to the present invention will be described in detail with reference to the accompanying drawings.

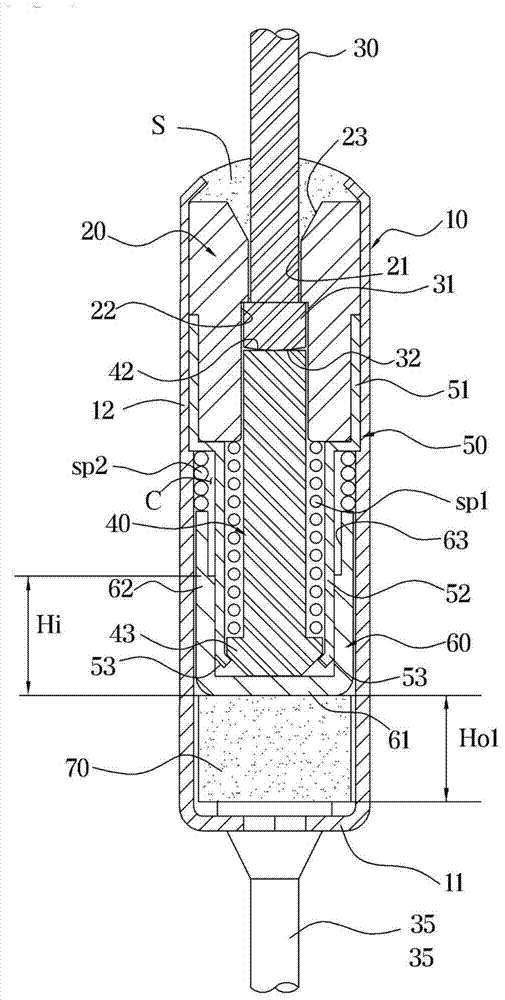

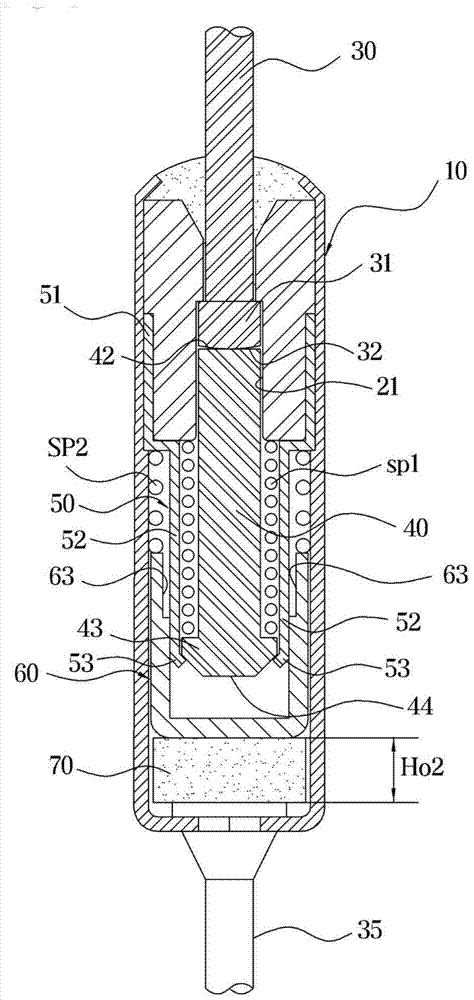

[0031] figure 1 It is a combined cross-sectional view showing that the temperature-sensitive particle type thermal fuse according to the present invention maintains the two lead wires in the energized state.

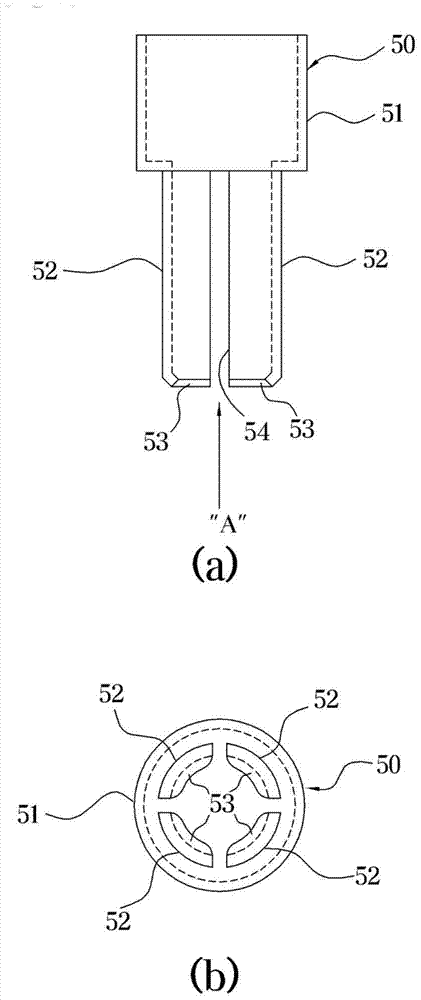

[0032] like figure 1 As shown, the temperature-sensitive particle type thermal fuse according to the present invention includes a cylindrical outer casing 10, an insulating sleeve 20, a first lead 30, a second lead 35, a temperature-sensitive particle 70, a movable terminal 40 and an operating device , wherein the cylindrical outer casing 10 is made of conductive metal material and has a bottom 11, a side wall 12 and an open end, an insulating sleeve 20 is bonded to one end of the outer casing 10, and the first lead 30 is penetratingly bonded to the insulating sleeve 20 and el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com