Sharp-knife ball making machine

The technology of a meatball machine and sharp knife is applied in slaughtering, oil/fat baking, food science, etc. It can solve the problems of complex manual processing, difficulty in one-time frying, and inability to make, so as to achieve convenient frying and low cost. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

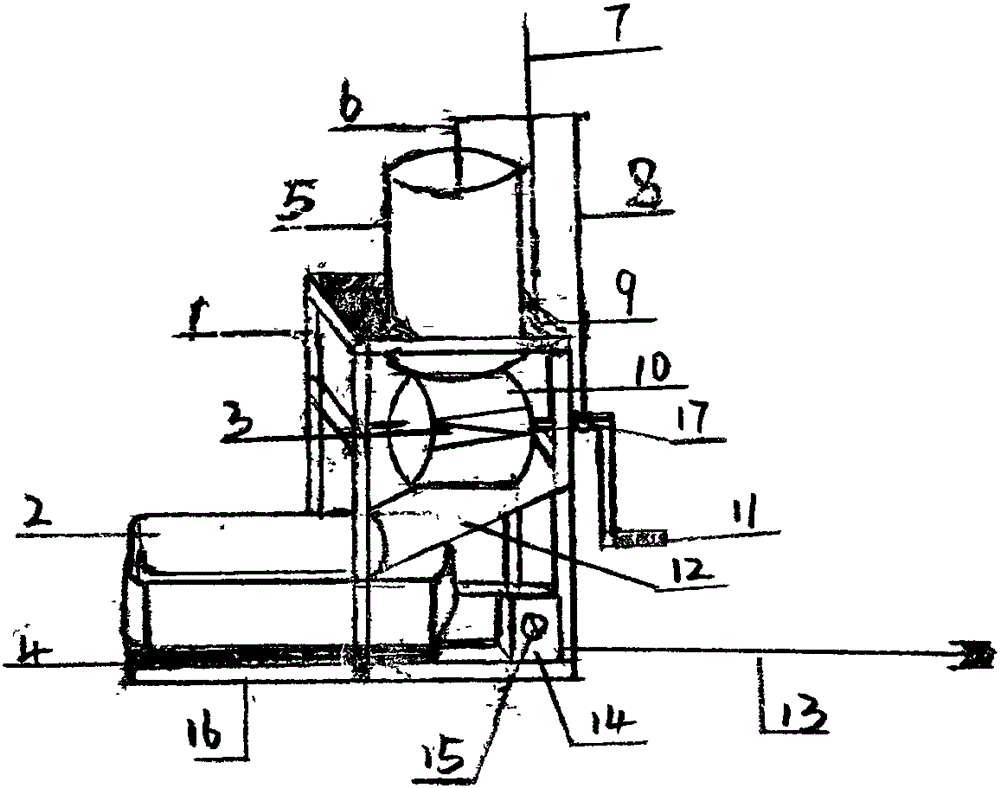

[0010] like figure 1 As shown, the sharp knife meatball machine of the present invention comprises a main frame (1), a hopper (5), a working wheel (10), a handle (11), a chute (12), a strip basin (2), a heating plate (4) , the control switch (14), the power cord (13), the hopper (5) is located at the top and fixed by the main frame (1), the working wheel (10) is located under the hopper (5), and is connected by the handle (11) and the main frame (1) Fixed, the chute (12) is below the working wheel (10), the lower end is on the top of the strip basin (2), the upper end is fixed with the main frame (10), and the strip basin (2) is positioned on the bottom heating plate (4) by The support (4) is fixed with the main frame (1), and the control switch (14) is connected with the power line (13) and the heating plate (4) at the lower right corner of the main frame (1).

[0011] Working process of the present invention is as follows:

[0012] Add a certain amount of edible oil into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com