Noodle conveyer belt convenient for noodle scrap recovery

A conveyor belt and convenient technology, applied in the field of noodle processing equipment, can solve the problems of noodle crumbs that cannot be recycled, discarded, wasted, etc., and achieve the effect of simple structure, realizing recycling, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

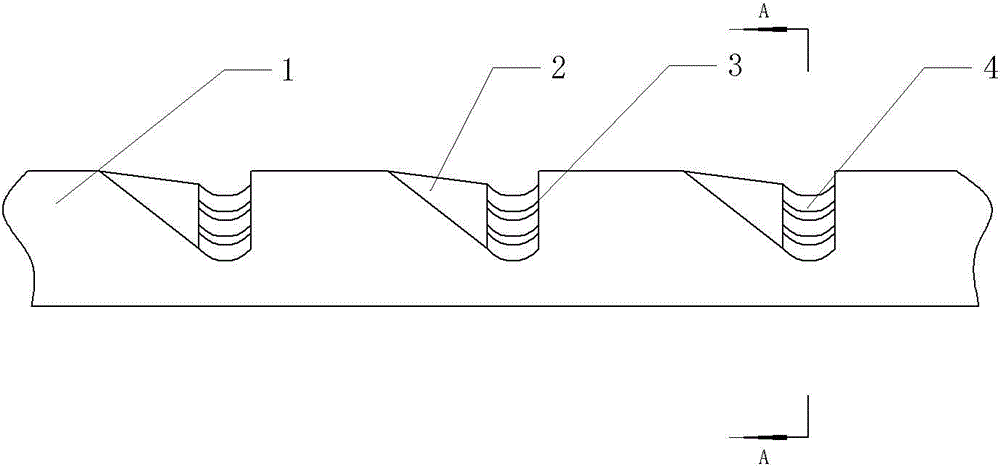

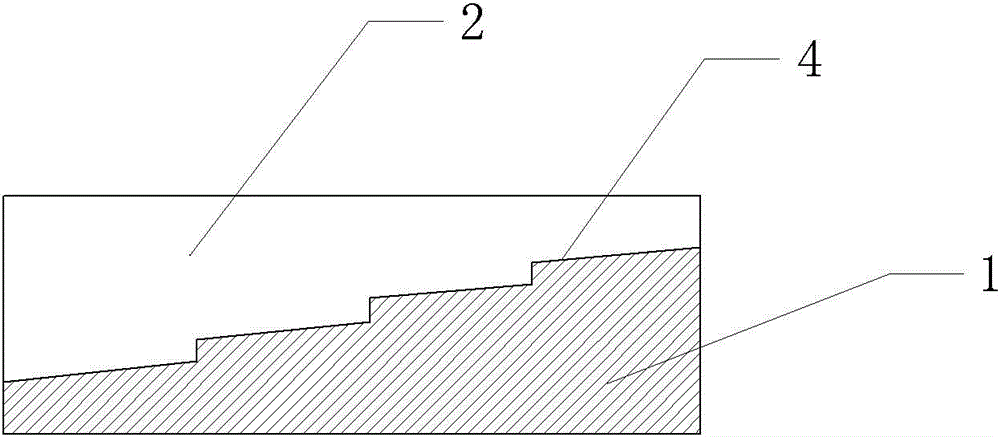

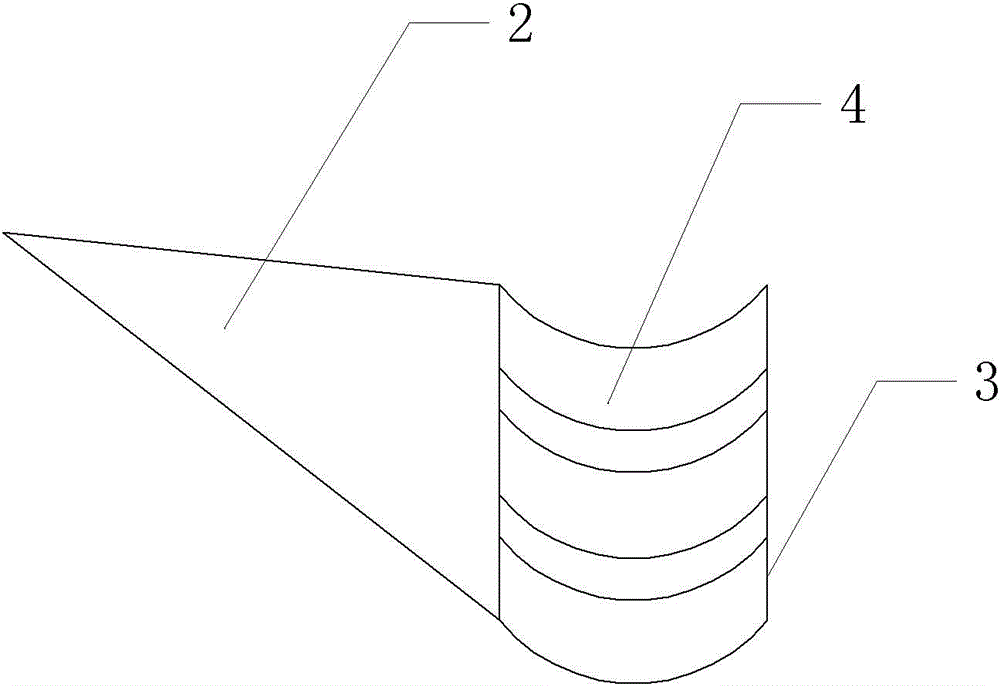

[0024] Such as figure 1 , figure 2 As shown, the noodle conveyor belt for convenient recycling of flour crumbs includes a belt body 1, and the belt body 1 includes a feeding end and a discharging end; a group of grooves are arranged horizontally on the belt body 1, and the grooves are evenly distributed along the conveying direction of the belt body 1; The groove is a through groove, and the bottom of the groove is stepped towards the side of the belt body 1, and each step 4 at the bottom of the groove is inclined downward, and each step 4 is in a downwardly concave arc shape, The groove bottoms of one group of grooves have the same orientation; the side walls of the grooves near the feeding end are inclined toward the feeding end, that is, the left side wall 2 is inclined toward the feeding end, as image 3 As shown, the left side wall 2 is planar, and the groove is close to the side wall of the discharge end, that is, the right side wall 3 is vertical.

[0025] In the spe...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is that: Figure 4 As shown, the left side wall 2 is in the shape of an upwardly protruding arc, and the rest are the same as in Embodiment 1.

Embodiment 3

[0029] The difference between this embodiment and Embodiment 1 is that: Figure 5 As shown, the left side wall 2 is in a downward concave arc shape, and the rest are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com