Contact oil spraying device

An oil-pointing and contact technology, which is applied to devices and coatings that apply liquid to the surface. It can solve problems such as poor efficiency and consistency, inconsistent oil application amount, and poor fluidity, and achieve good consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

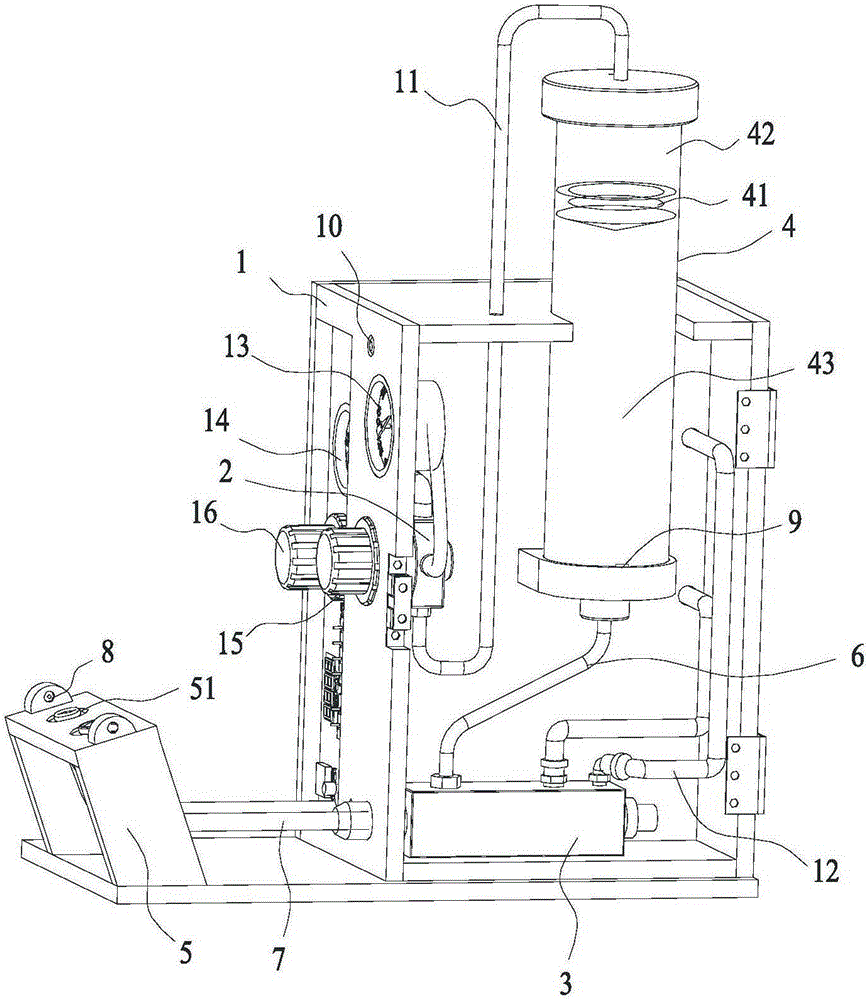

[0019] like figure 1 Shown a kind of oil coating device, comprises support 1 and glue dispensing machine 2, dispensing valve 3, dispensing cylinder 4 and oiling mold 5 that are all fixed on this support 1, and glue dispensing machine 2 has a device for adjusting air pressure Output size adjustment mechanism, the adjustment mechanism has a first air pressure output end and a second air pressure output end, a piston 41 is slidingly fitted in the dispensing cylinder 4, and the piston 41 divides the dispensing cylinder 4 into an air chamber 42 and an oil chamber 43 , the oil chamber 43 is filled with the grease used for oiling the rotating tail electrodes, the first air pressure output port communicates with the air chamber 42, and the oiling mold 5 has a socket 51 for inserting the rotating tail electrodes, and the oil chamber 43 passes through A first oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com