Patents

Literature

75results about How to "Affect discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

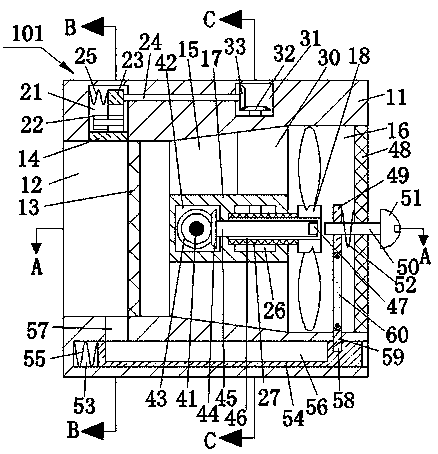

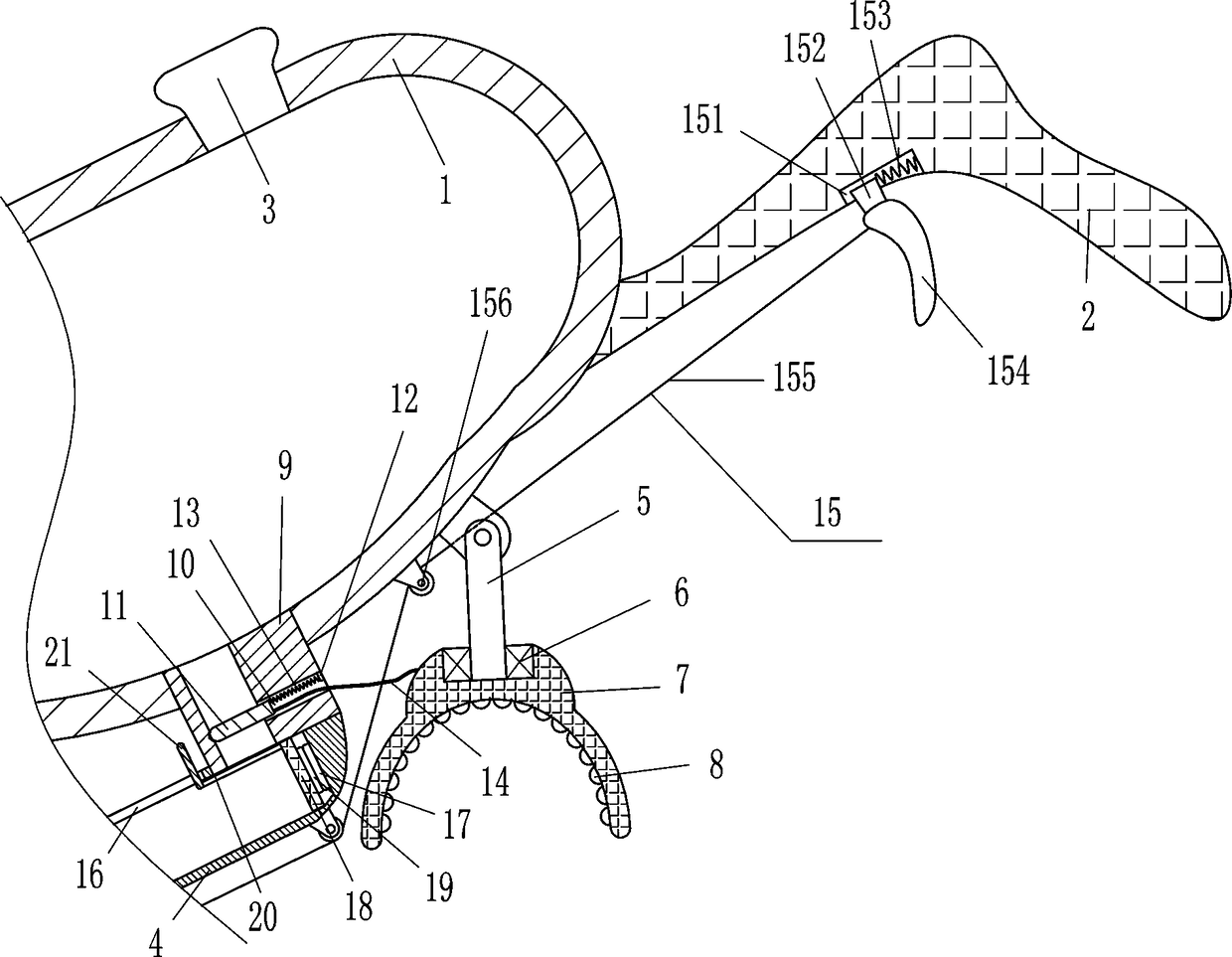

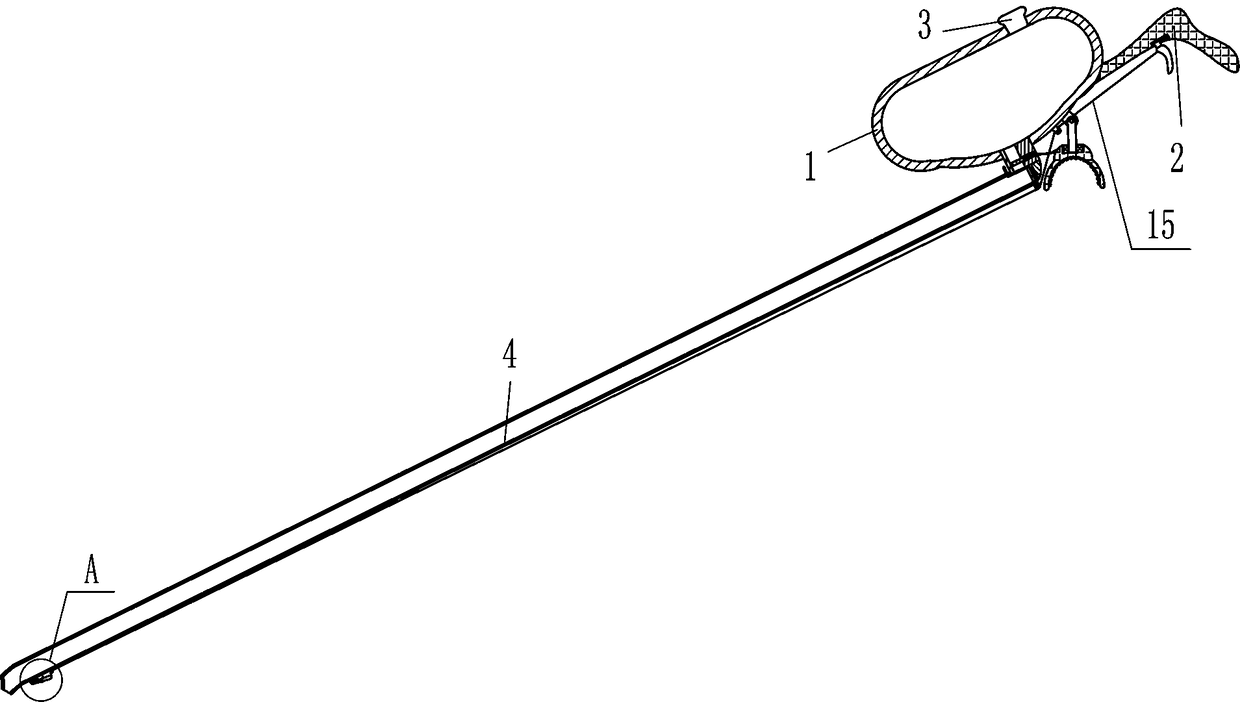

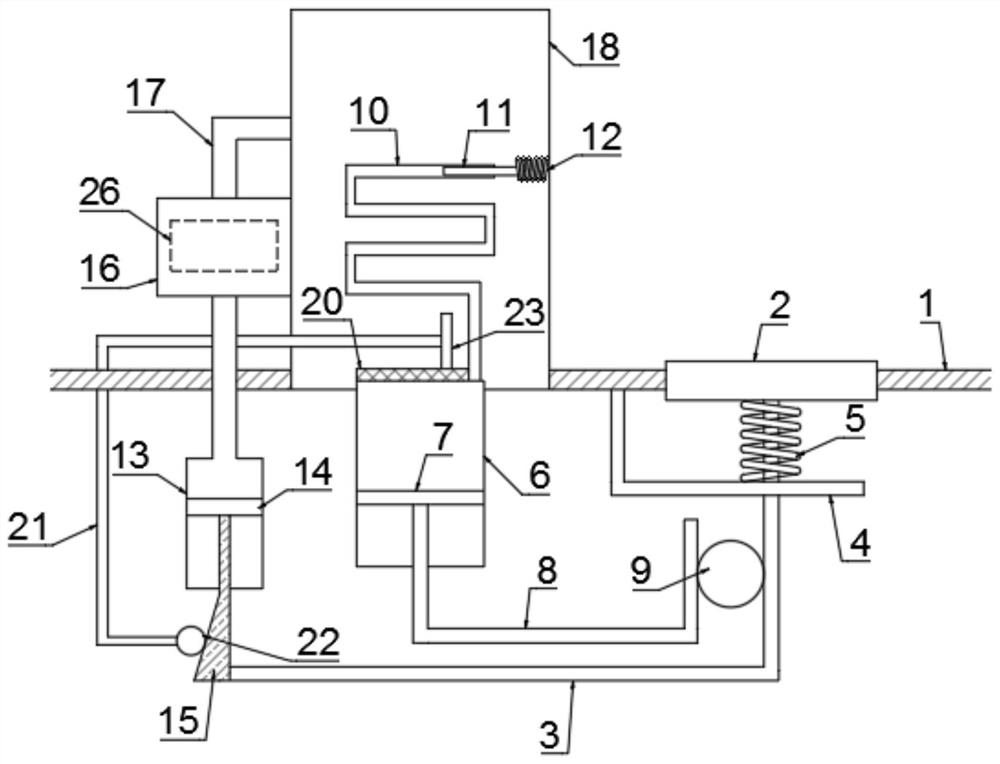

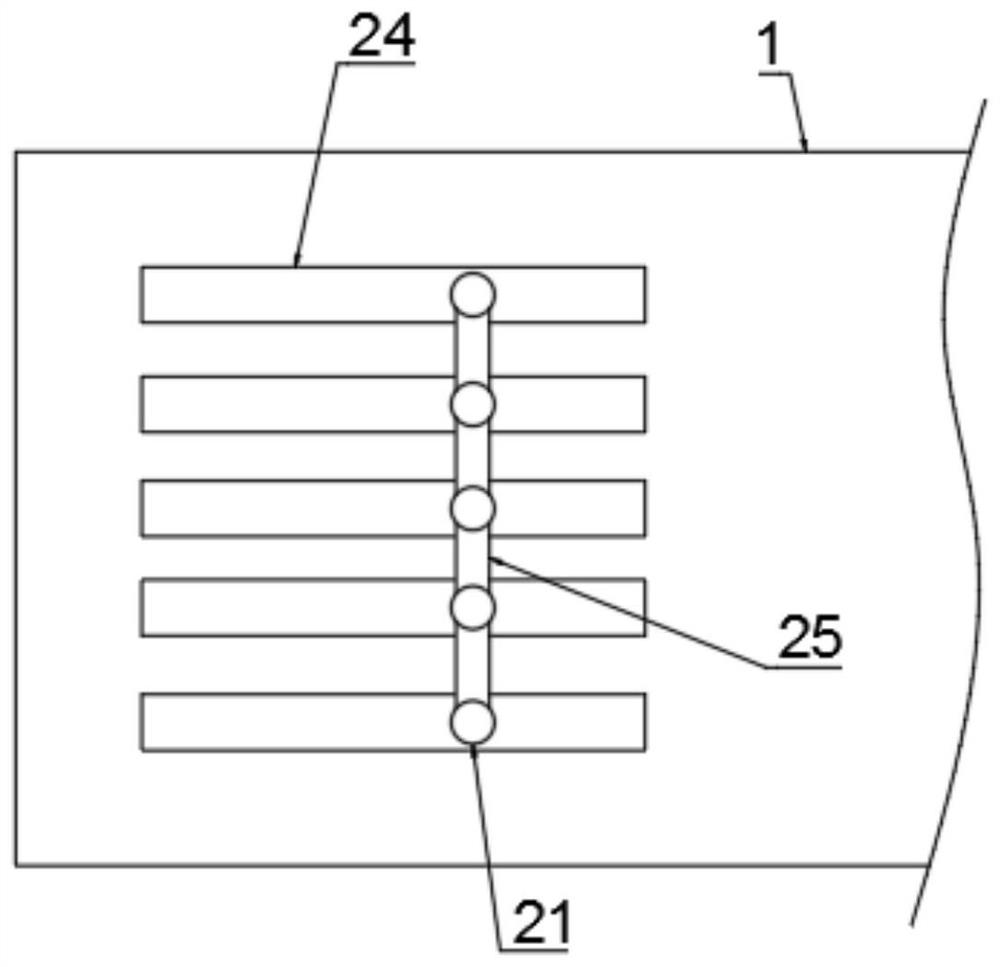

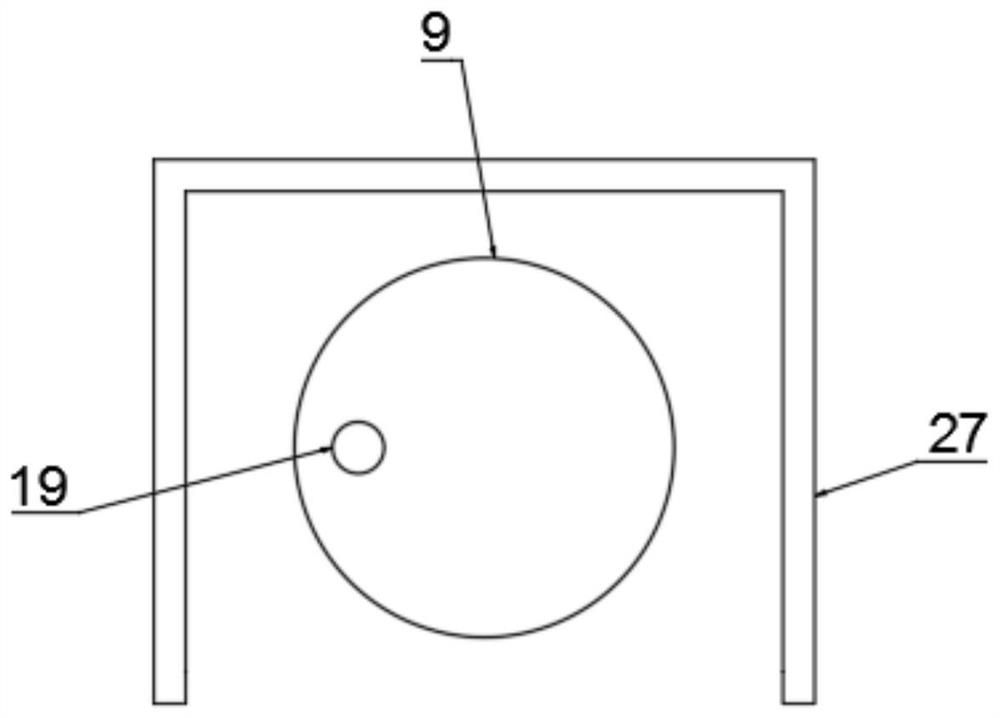

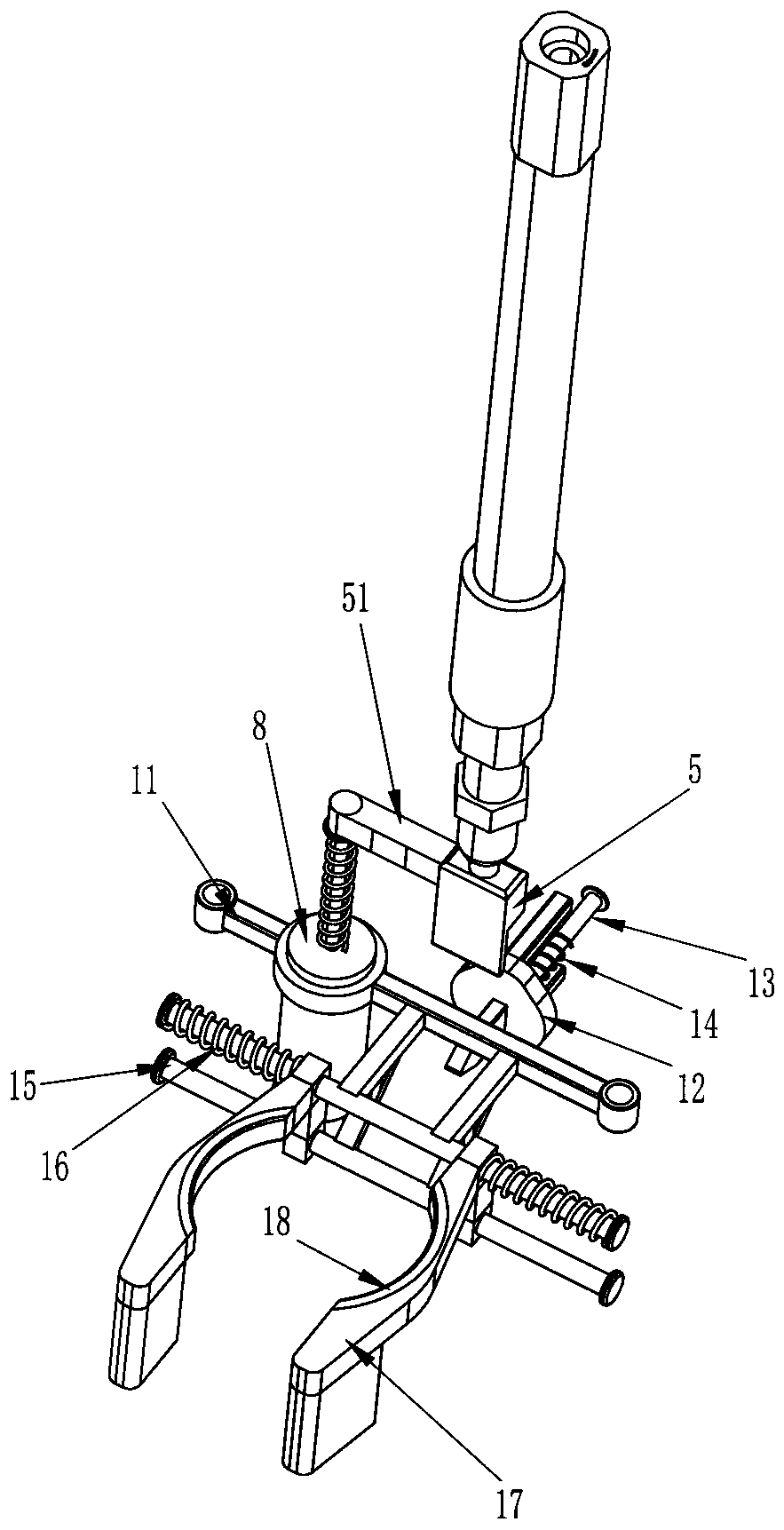

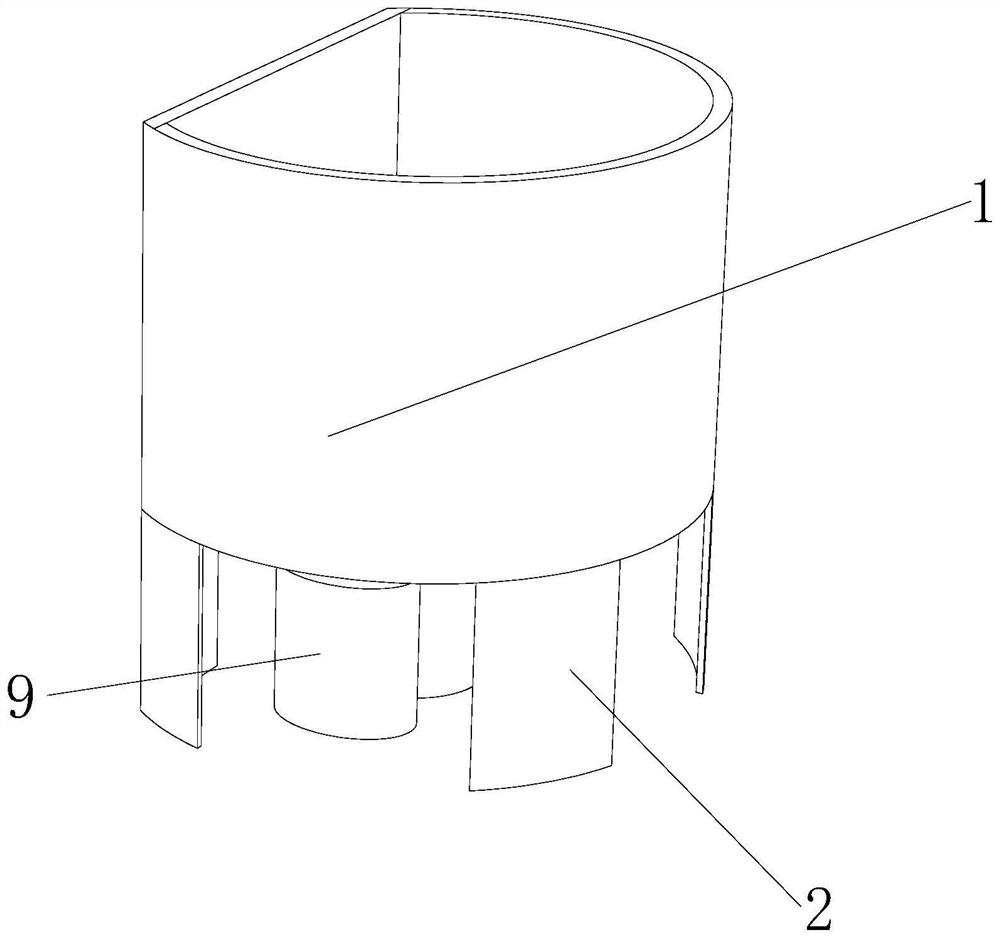

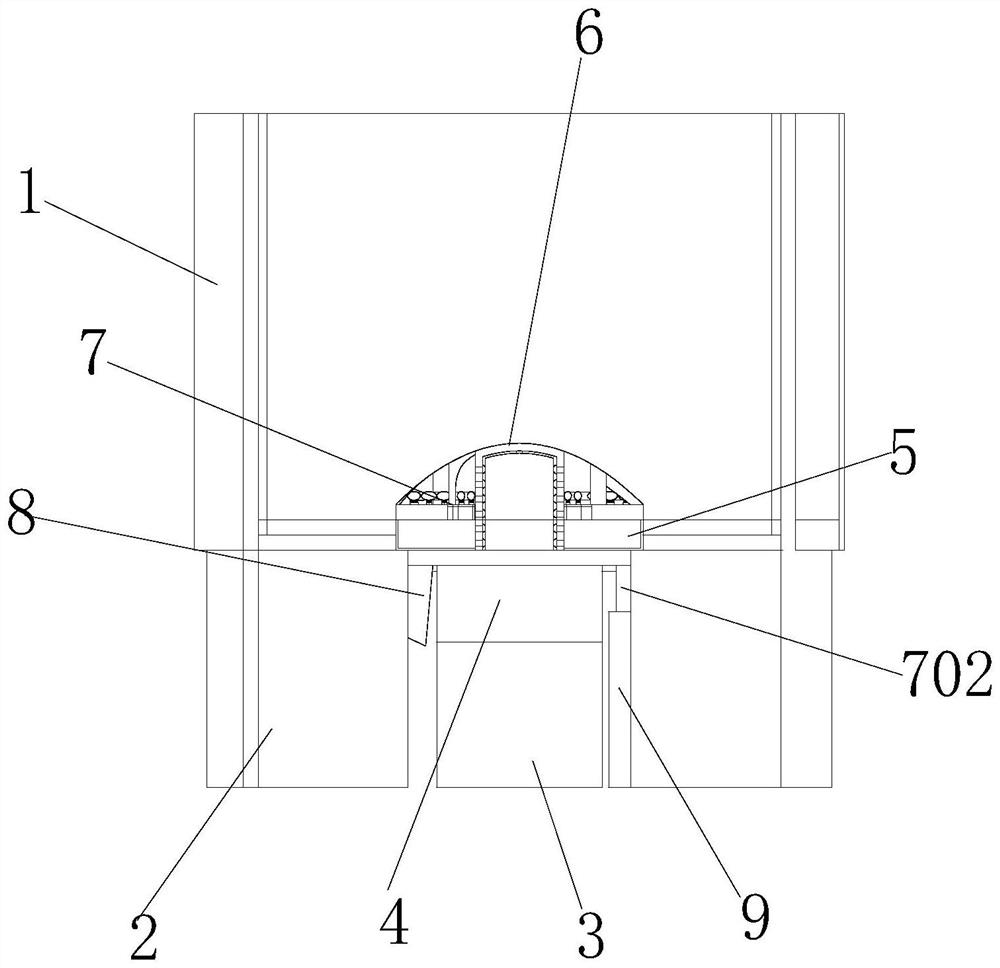

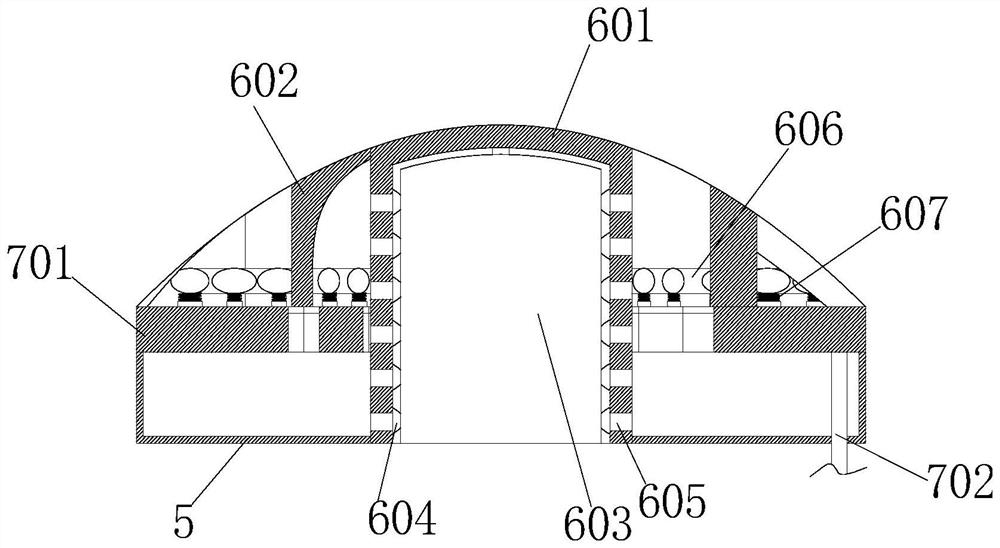

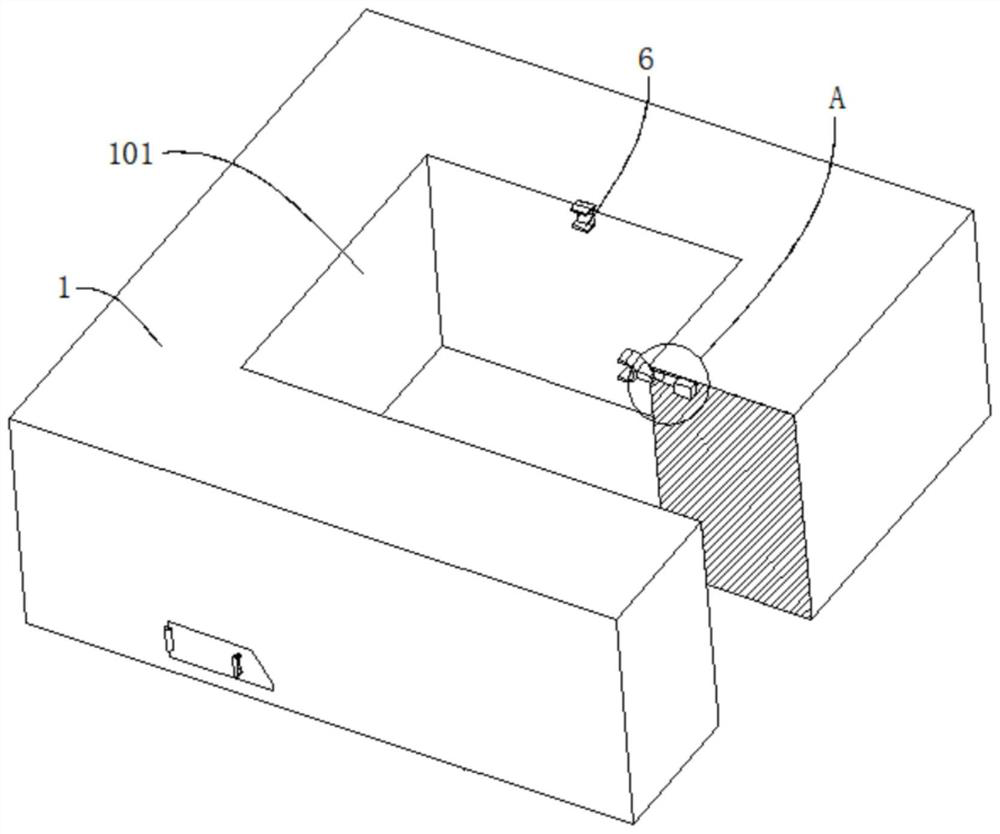

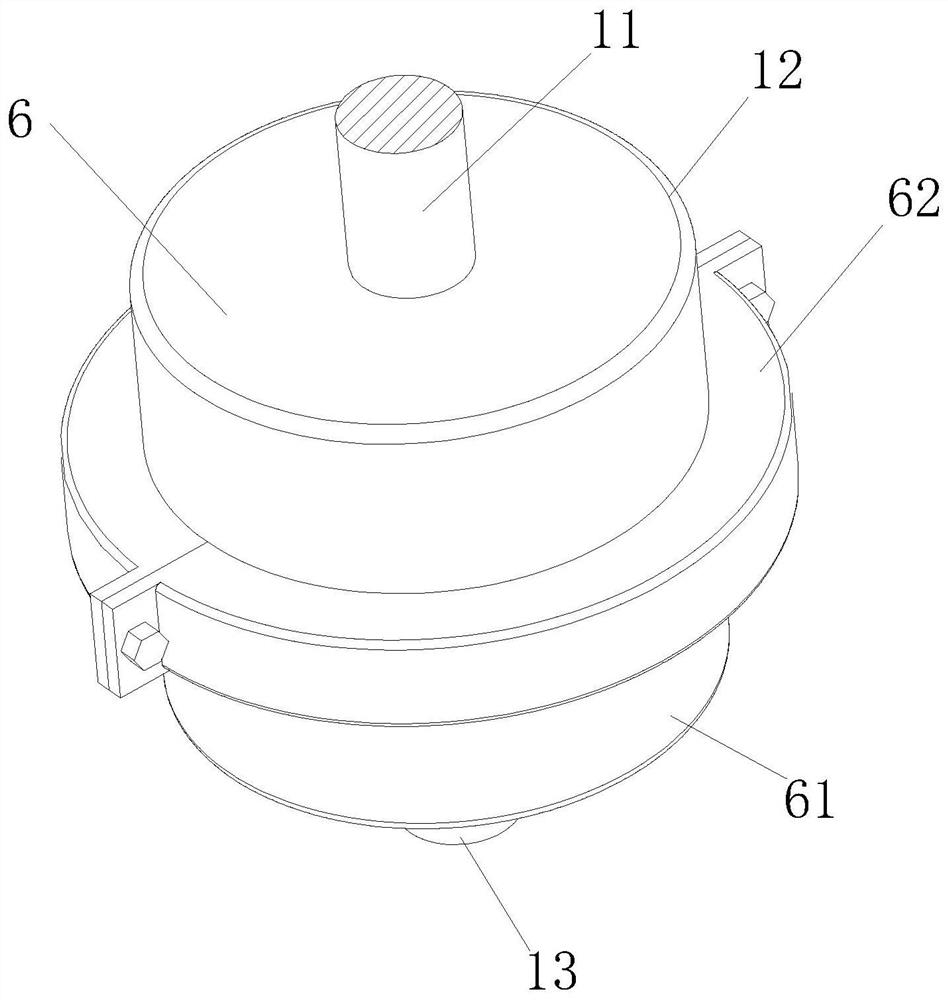

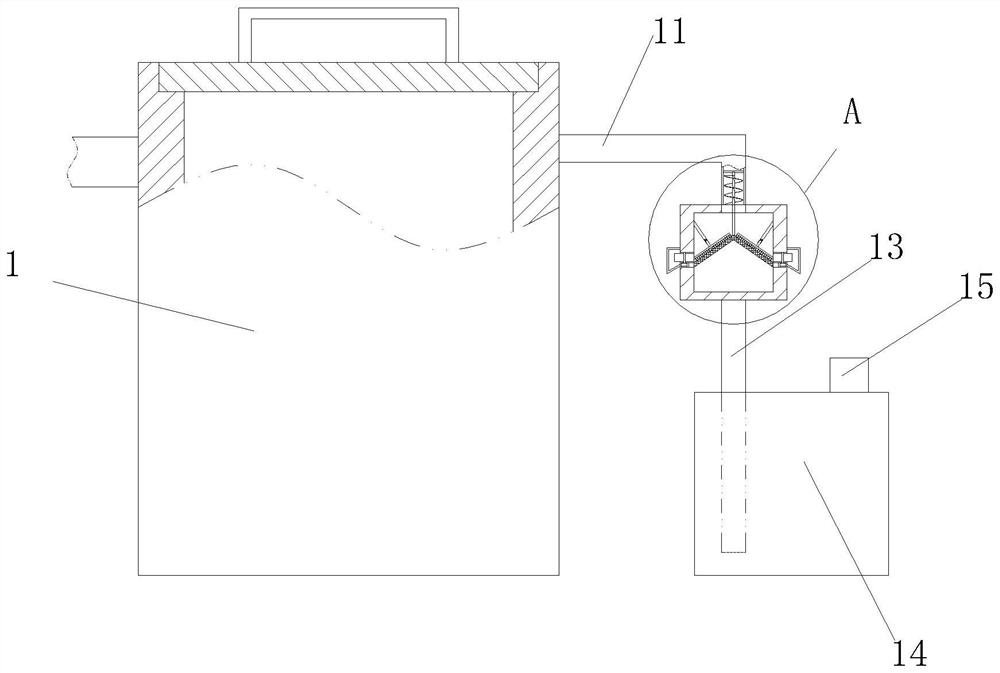

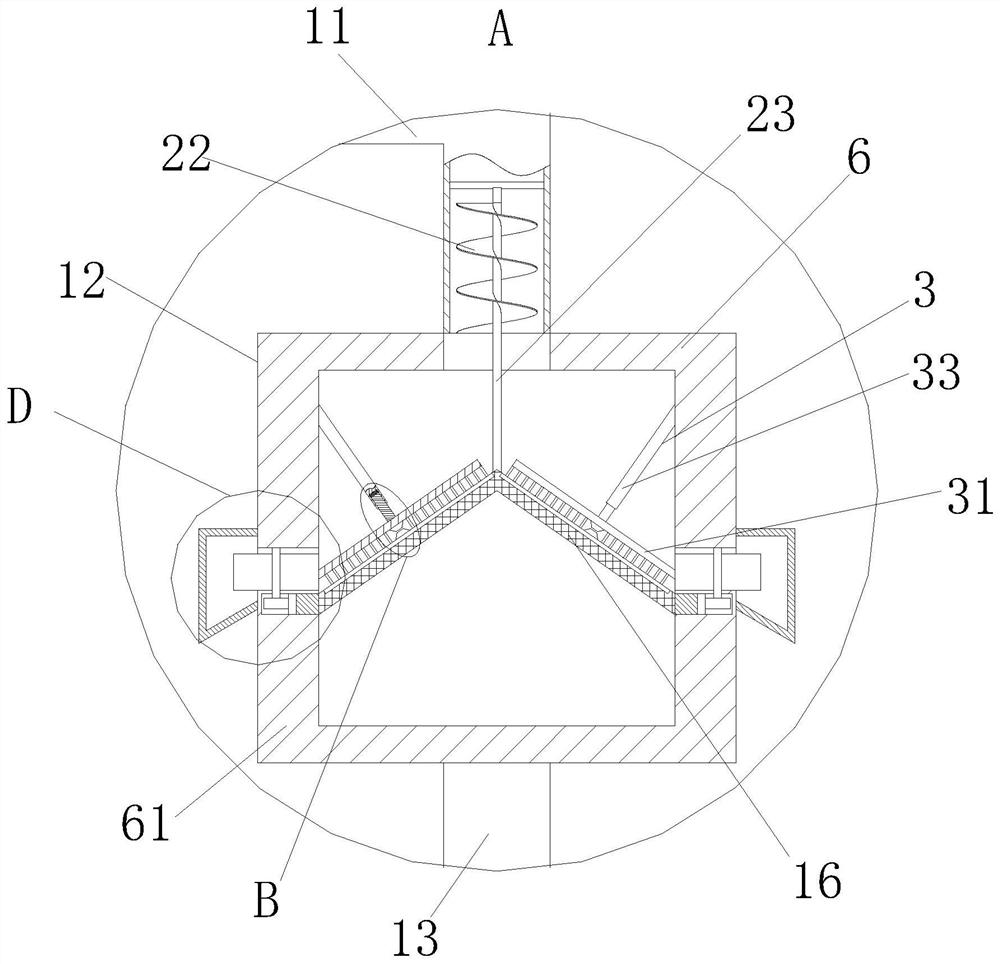

Automobile exhaust treatment device capable of being installed at tail end of exhaust pipe

InactiveCN110594001AGuaranteed stabilityGuaranteed effectInternal combustion piston enginesExhaust apparatusExhaust gasEngineering

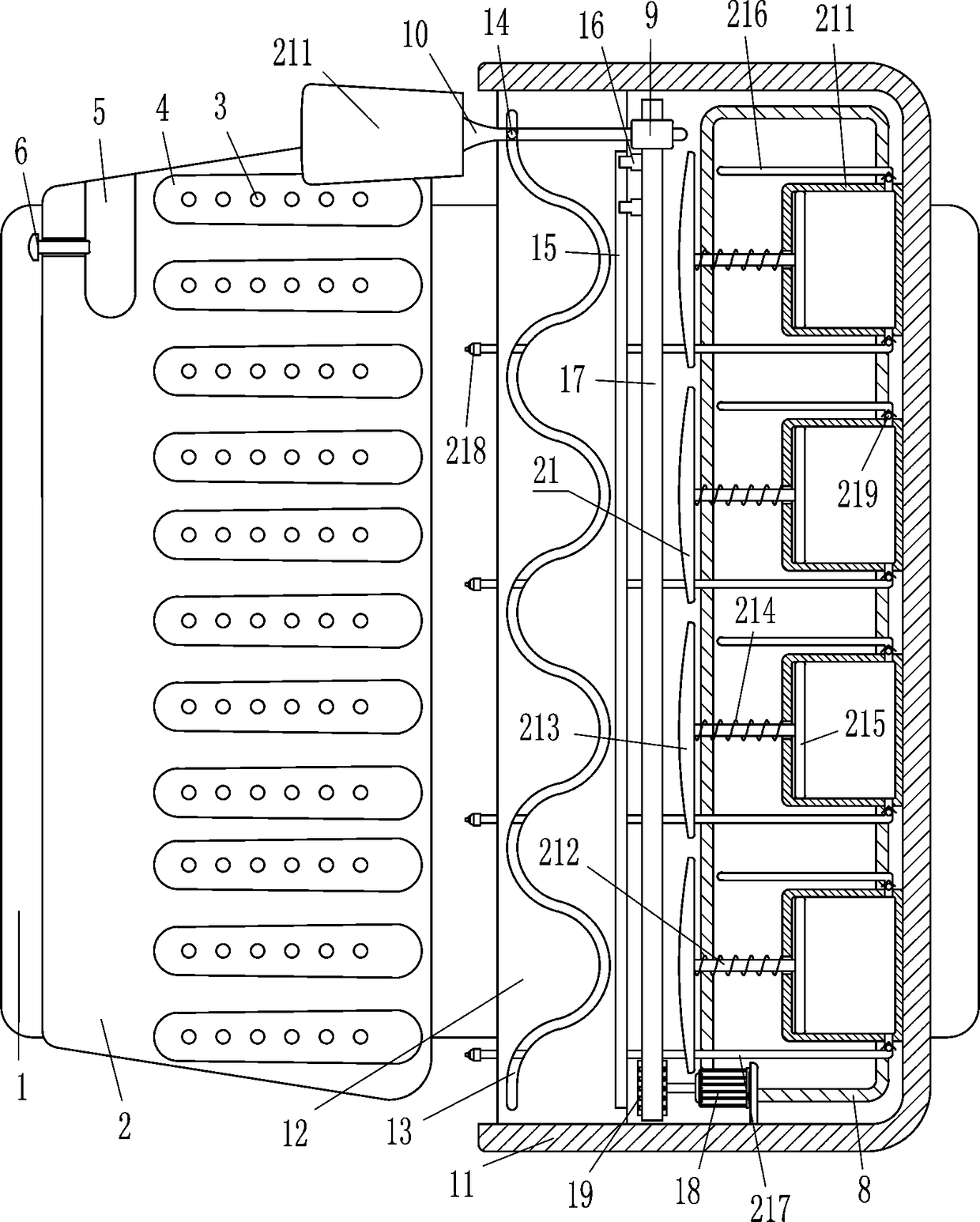

The invention discloses an automobile exhaust treatment device capable of being installed at the tail end of an exhaust pipe. The device comprises a mounting body, wherein a gas inlet with a leftwardopening is formed in the left side in the mounting body, a filter plate is fixedly arranged in the gas inlet, the filter plate can block carbon material in exhaust to the left side, a carbon scrapingdevice is arranged on the upper side of the gas inlet, a scraping plate is arranged in the carbon scraping device, the scraping plate can scrape off accumulated carbon on the left end face of the filter plate, the filtering effect of the filter plate is improved, and the right side of the gas inlet communicates with a ventilation cavity. By installing the device at the tail end of the exhaust pipe, the installation stability is ensured by internally pressing tightly the exhaust pipe and clamping the outer end surface of the exhaust pipe, the exhaust flow is utilized for continuously scraping off the accumulated carbon on the filter plate, the filtering effect is ensured, the phenomenon that blockage is caused, so that exhaust emission is influenced is avoided, and meanwhile, the installation and disassembly of the device are very convenient, so that the installation cost and maintenance cost are reduced.

Owner:嵊州塔木汽车尾气处理有限公司

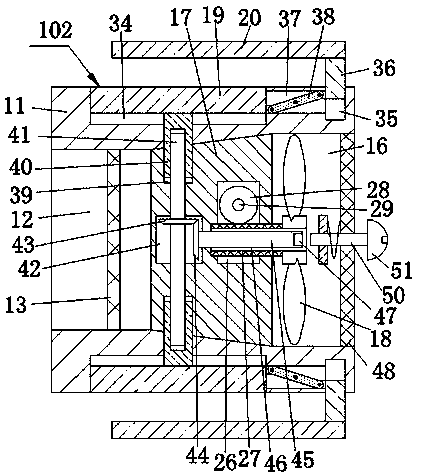

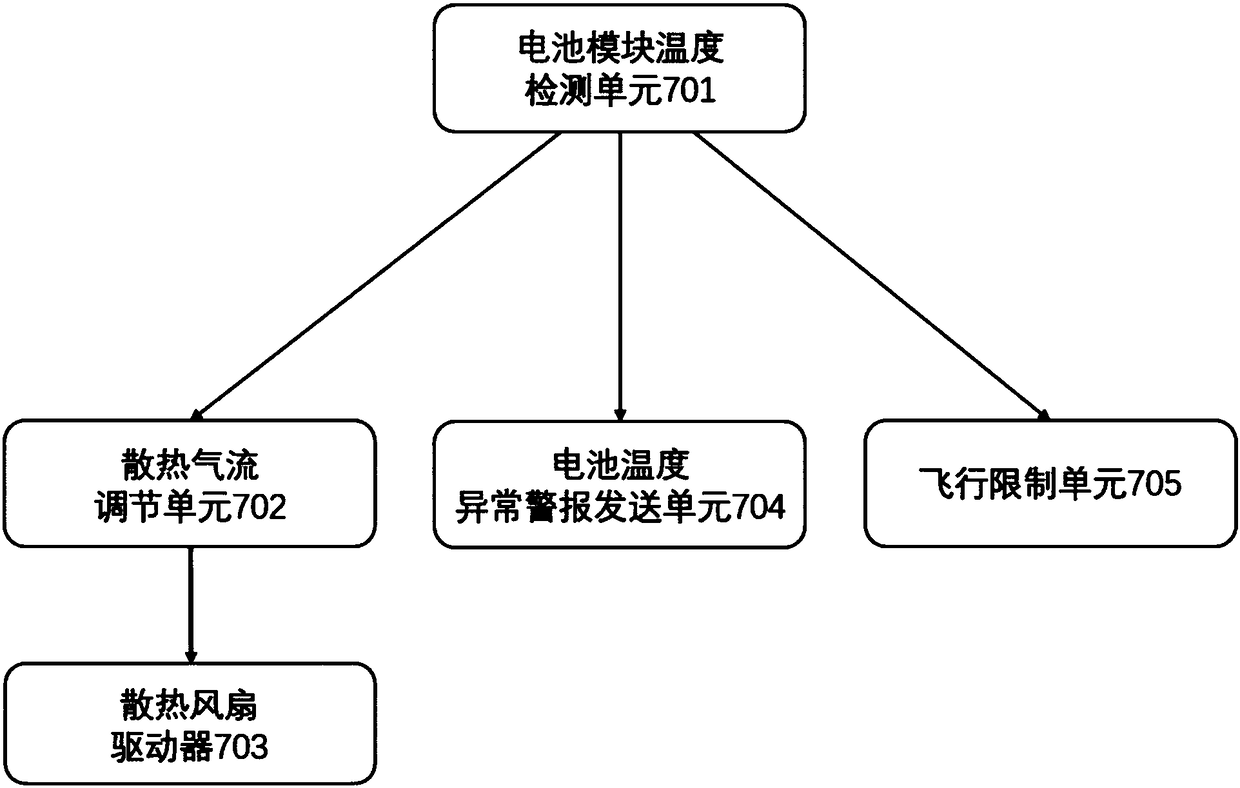

Unmanned aerial vehicle and battery temperature control system and method thereof

InactiveCN108312861AAffect dischargeAffect lifeVehicular energy storagePower plant typeTemperature controlControl system

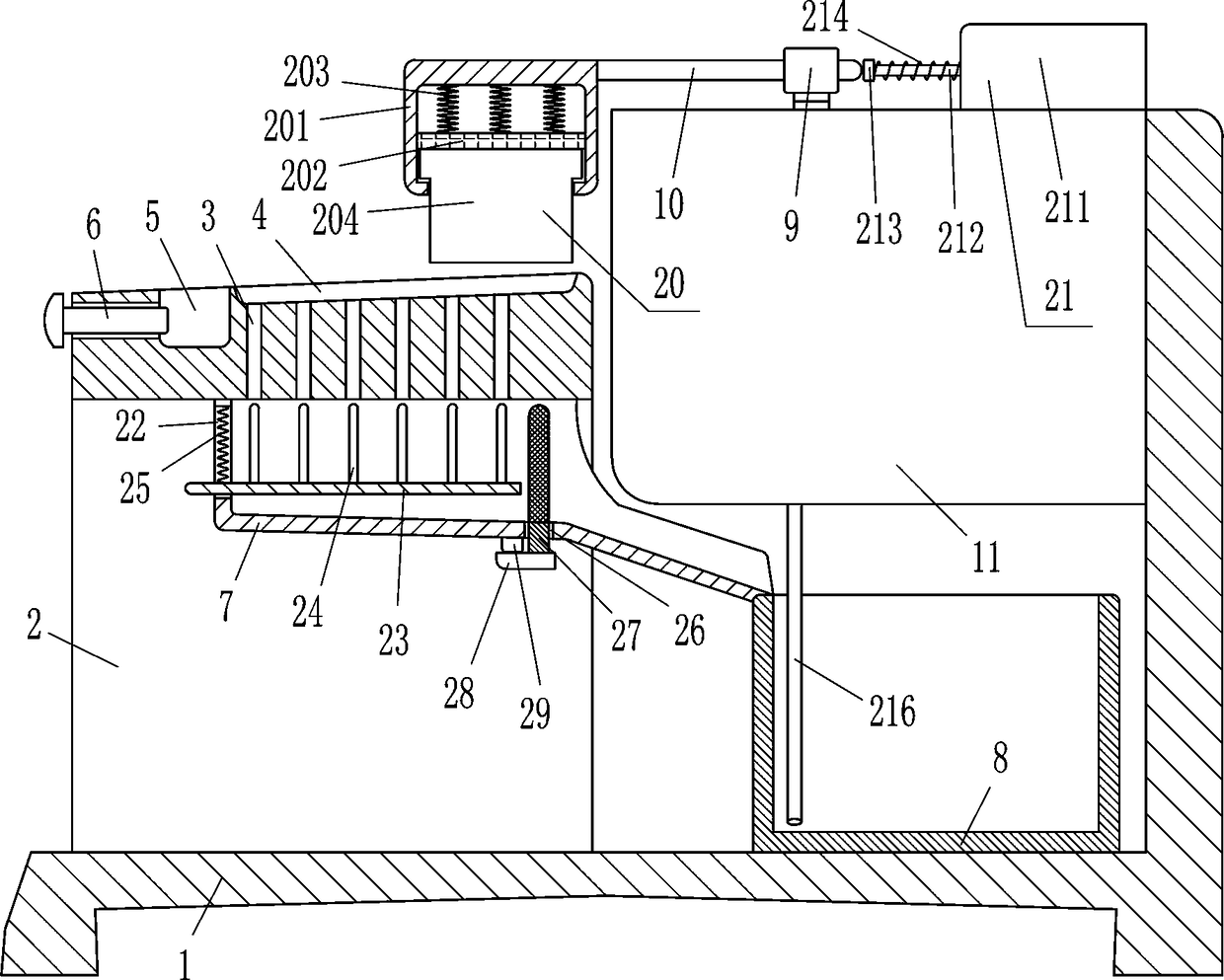

The invention belongs to the technical field of unmanned aerial vehicles, and particularly relates to an unmanned aerial vehicle and a battery temperature control system and method thereof. The temperature of a battery module under the working state of the unmanned aerial vehicle is monitored in real time, and the flow direction and the airflow intensity of the internal heat dissipation airflow ofthe unmanned aerial vehicle are controlled according to the monitored temperature value of the battery module. When the temperature value of the battery module is low, the battery module is heated bythe heat dissipation airflow of the unmanned aerial vehicle, and when the temperature value of the battery module is high, the heat dissipation airflow is increased to help the battery module to dissipate heat quickly; and when the temperature value of the battery module is too low or too high, the temperature abnormal alarm is reported back to an operator of the unmanned aerial vehicle, and theunmanned aerial vehicle is controlled to return or land when the battery module temperature value is too low to avoid air crash accidents.

Owner:GUANGZHOU EHANG INTELLIGENT TECH

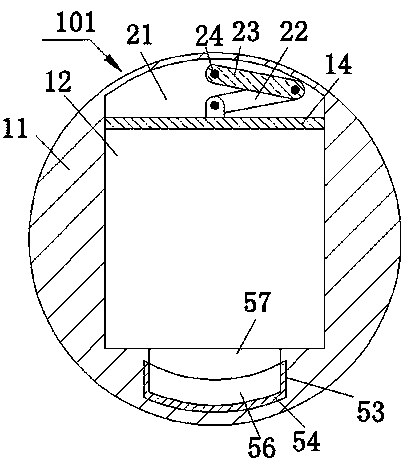

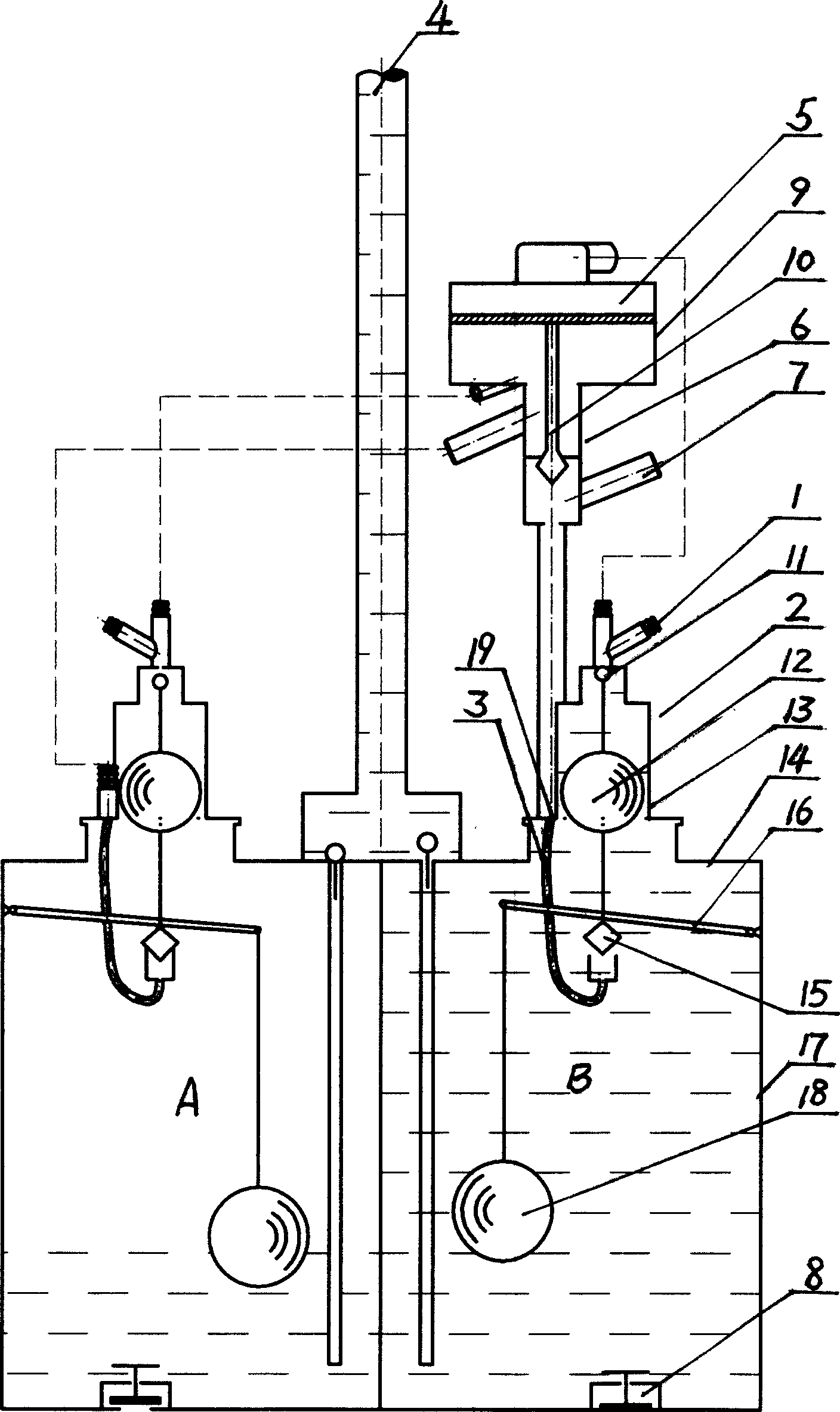

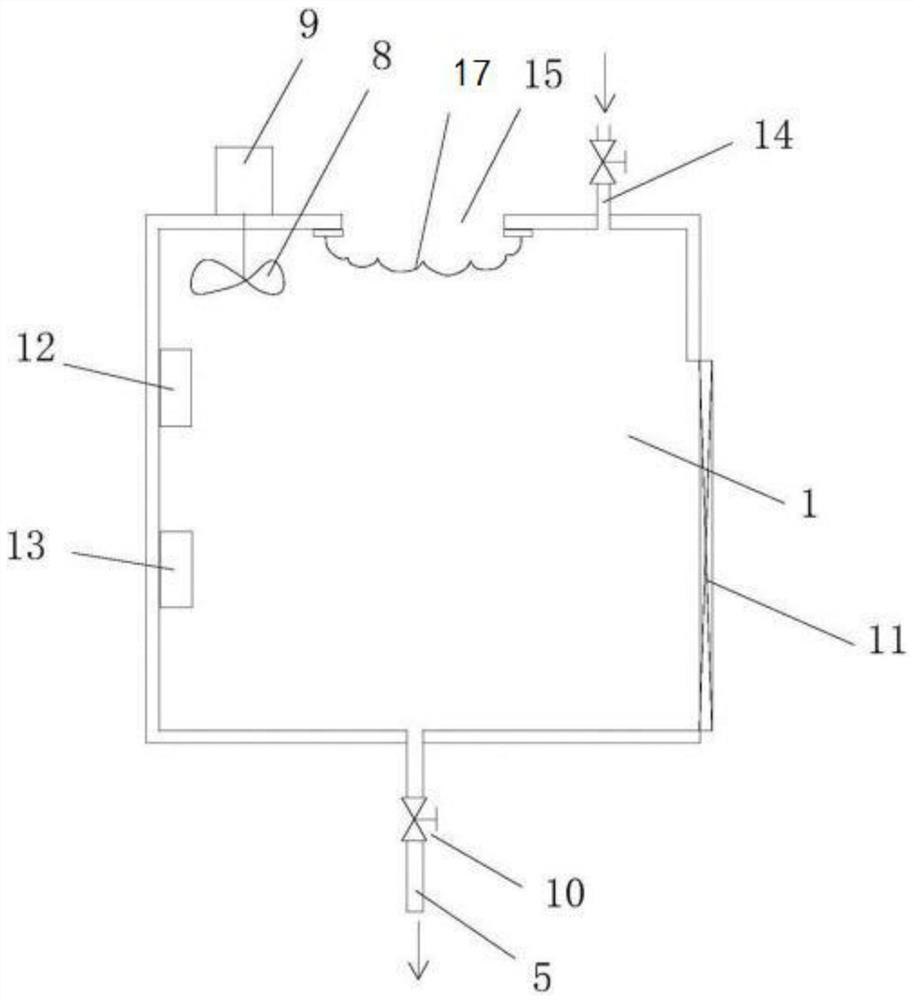

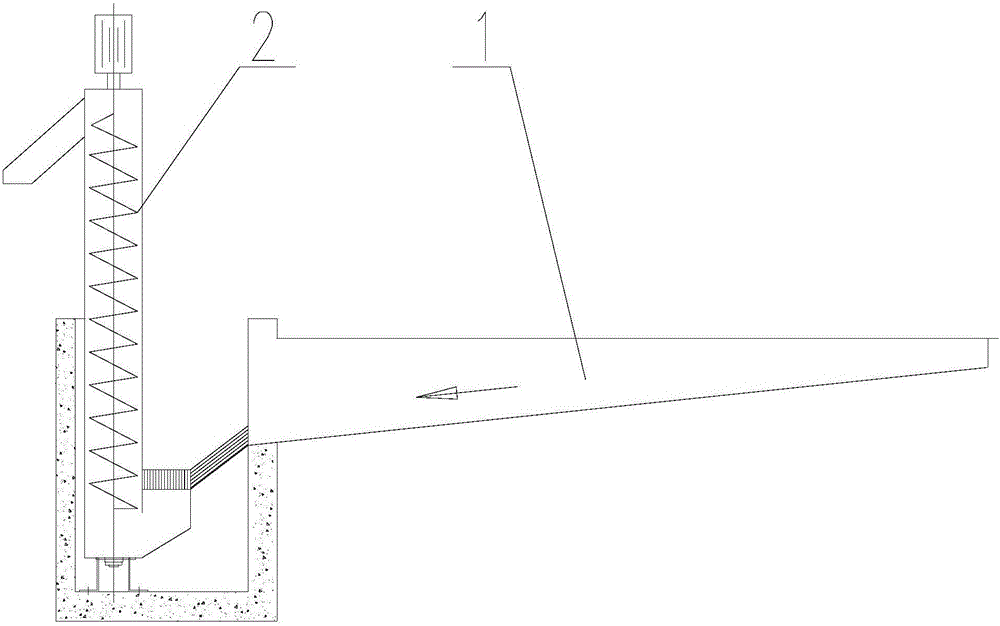

Air-pressure water raiser

InactiveCN1673551AEffective controlAchieve openPressure pumpsMachines/enginesInlet valveAerospace engineering

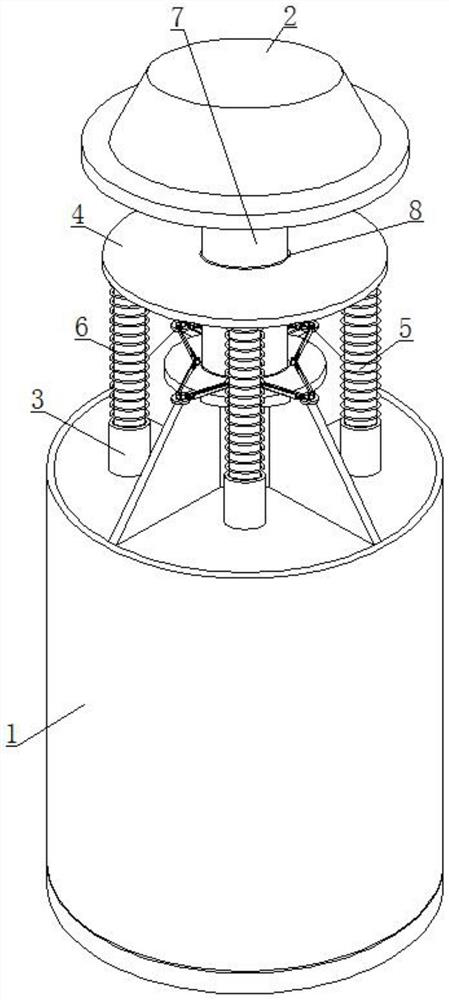

The present invention relates to air pressure water raiser, and aims at providing an air pressure water raiser with simple structure, low cost and effective control. The air pressure water raiser includes two boxes with water inlet, water outlet, air inlet, air outlet and air intake and exhaust controlling mechanism, and air intake pipe and air intake valve set in at least one of the air inlets. The air intake valve is connected to the exhaust controlling mechanism.

Owner:张传松

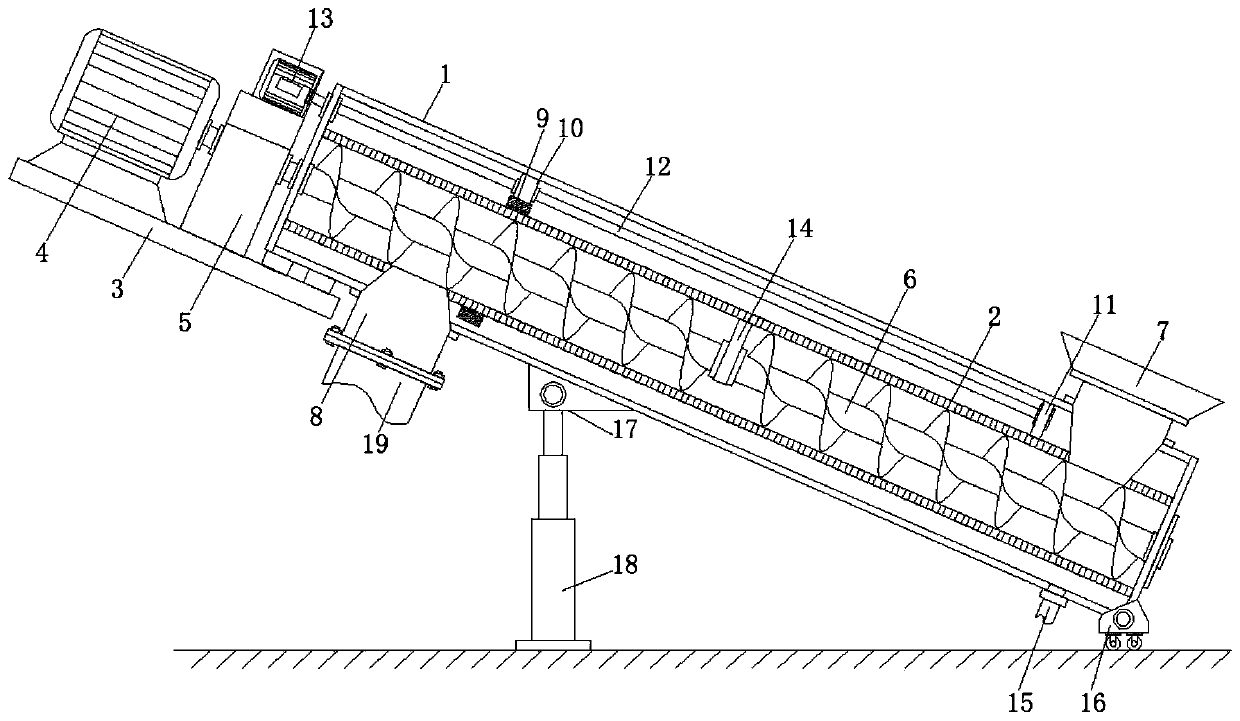

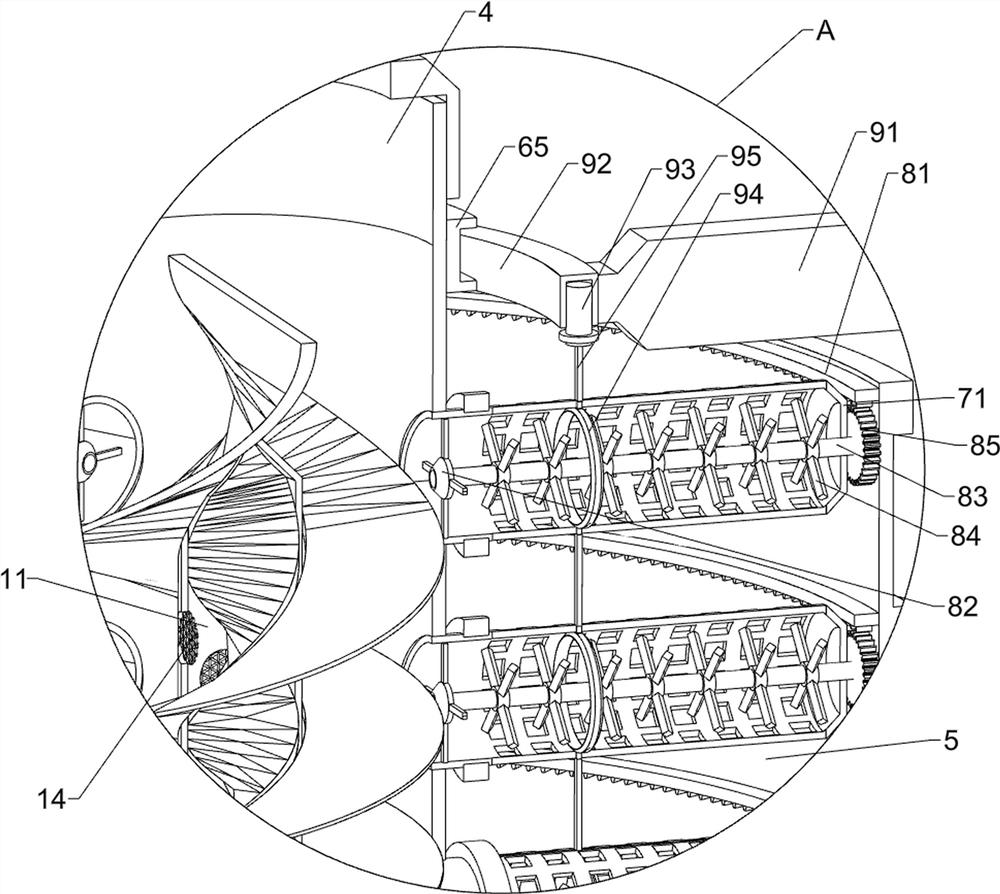

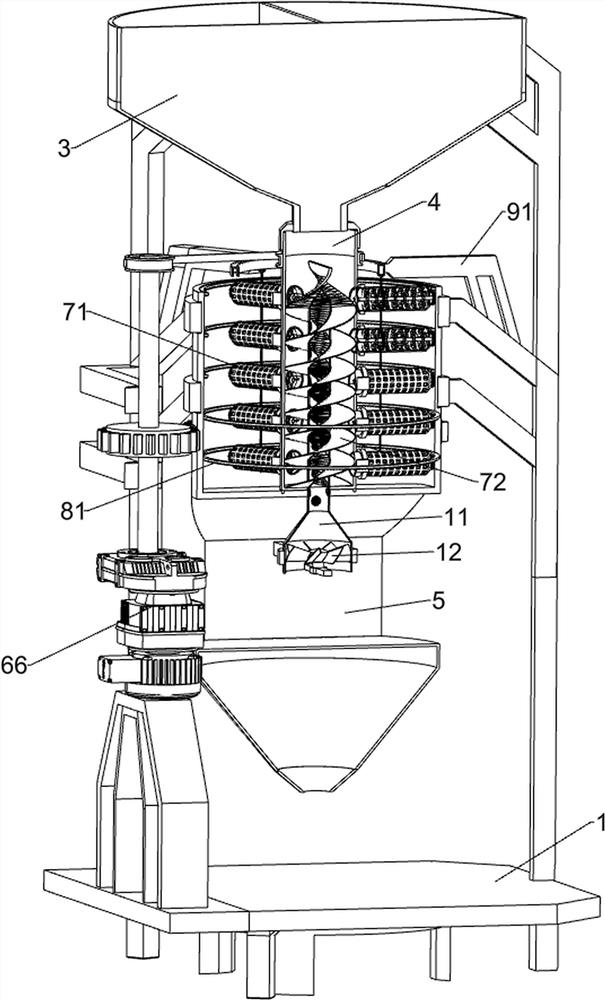

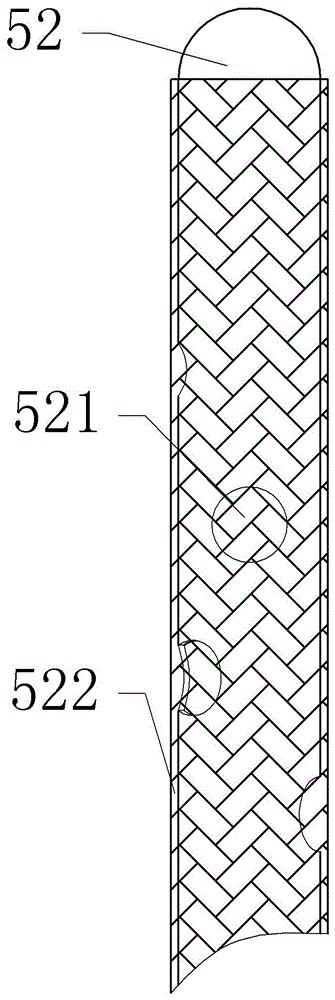

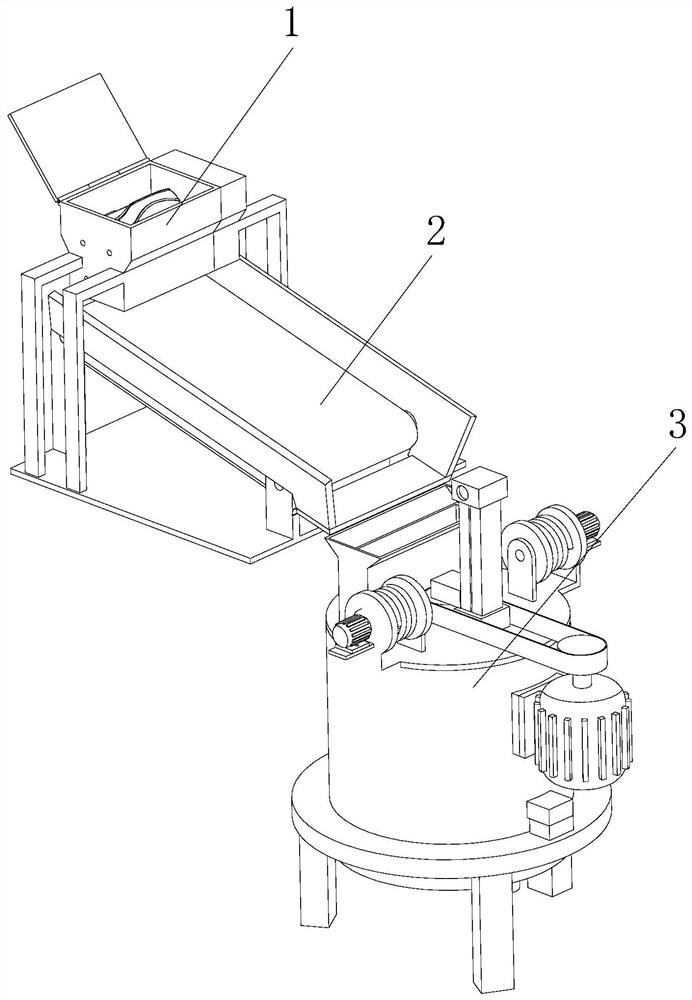

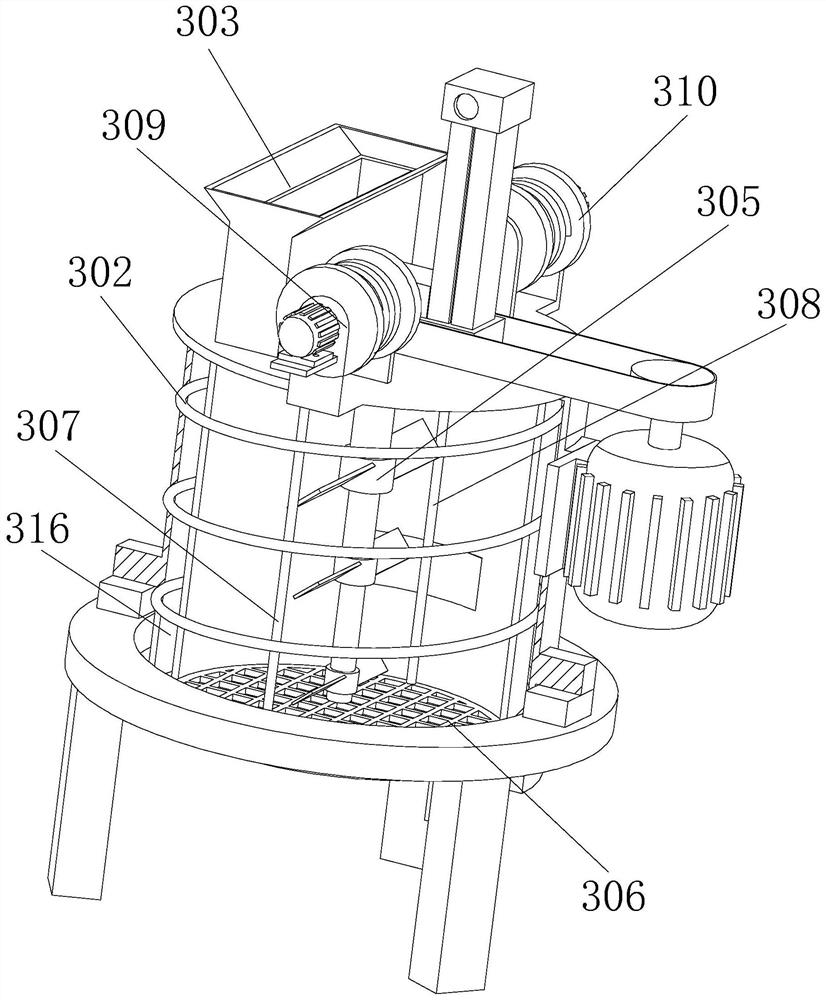

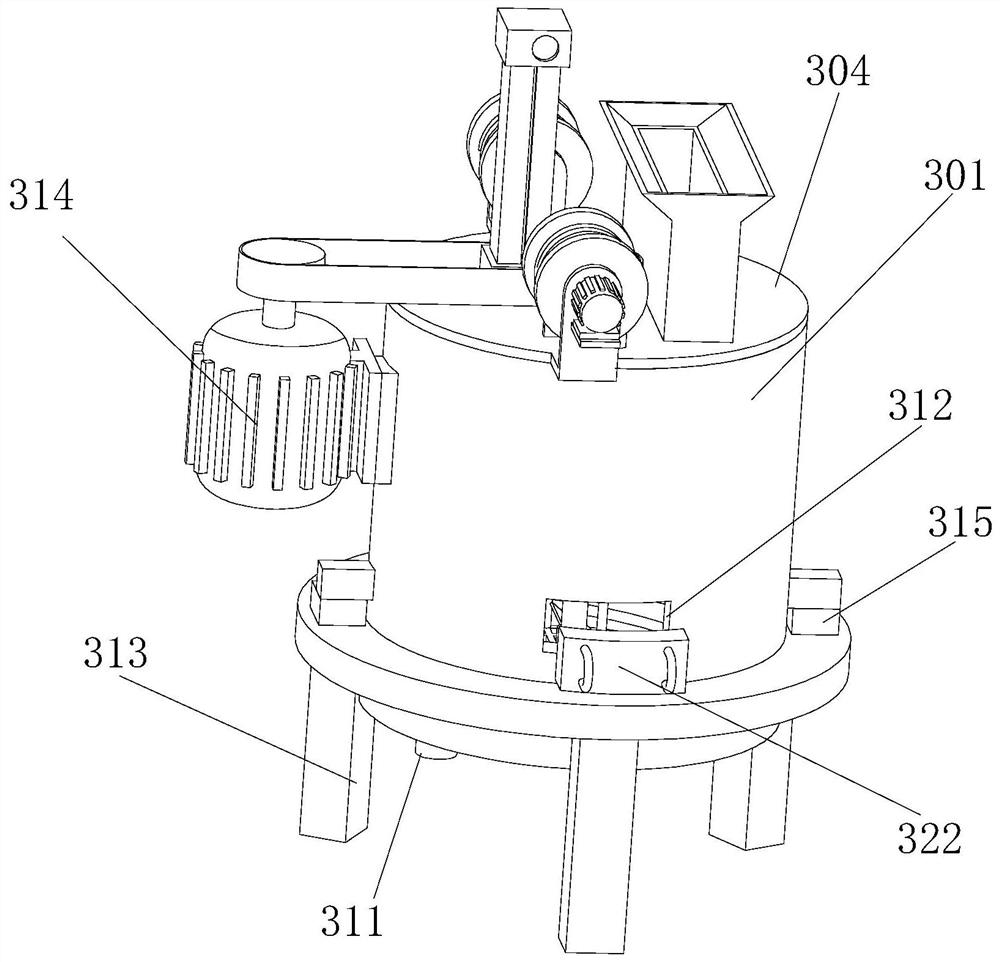

Vertical household garbage spiral conveyor

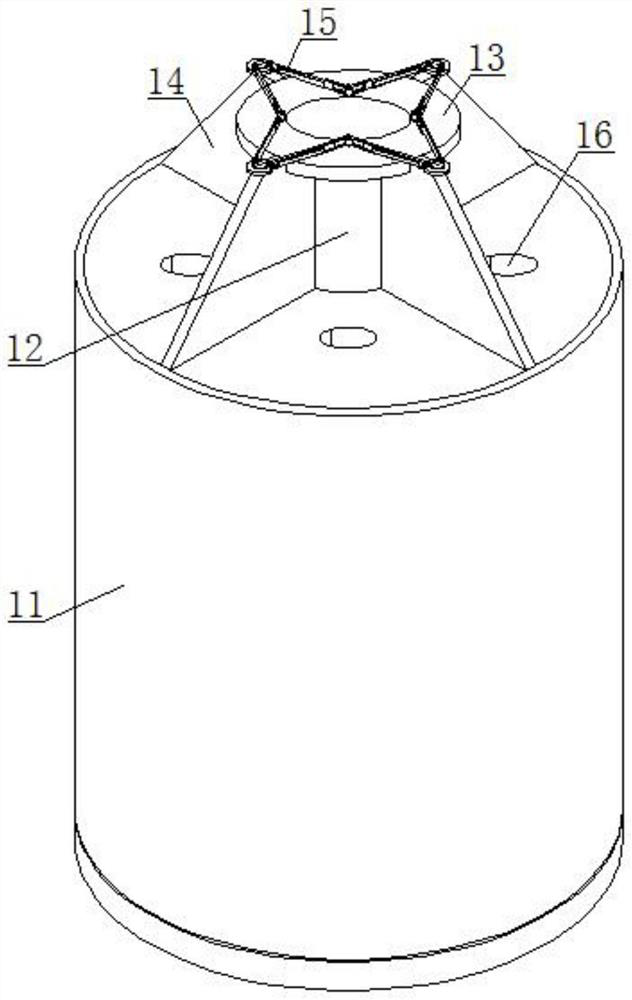

InactiveCN110980189ASolve the problem of high biodegradable organic contentSolving Difficult Shipping Handling ProblemsCleaningPackagingReduction driveElectric machine

An embodiment of the invention discloses a vertical household garbage spiral conveyor which comprises a conveying sleeve and a limiting sleeve. The limiting sleeve is fixedly sleeved with the inside of the conveying sleeve, a supporting plate is fixedly connected to one side of the bottom of the conveying sleeve through a connecting plate, and a driving motor and a speed reducer are fixedly installed at the top of the supporting plate from left to right. According to the vertical household garbage spiral conveyor, the driving motor is used as output power, garbage is conveyed to a centralizedtreatment position from a feeding opening through spiral blades, meanwhile, when the garbage enters the feeding opening, substances such as microbial decomposition bacteria are conveniently added, andthrough cooperation of the limiting sleeve and protrusions arranged on the limiting sleeve, the garbage insides can be rolled and extruded to enable water in the garbage to fall from a hole diameterof the limiting sleeve to fall to the inside of the conveying sleeve, then the water is collected and treated in a centralized mode through a liquid leakage pipe, and the problems that existing garbage contains more water and is difficult to transport and treat are effectively solved.

Owner:天津中科环境科技发展有限公司

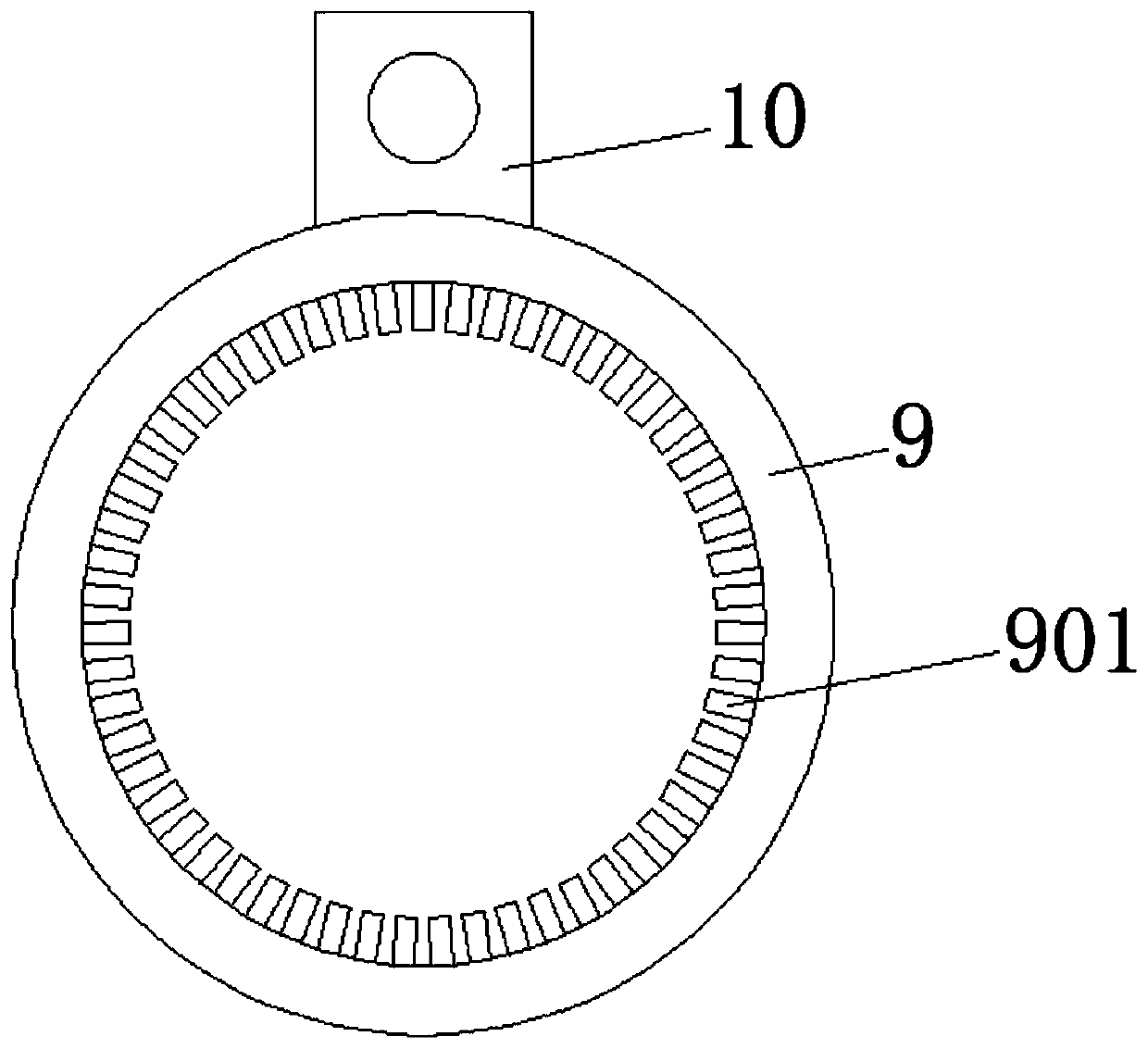

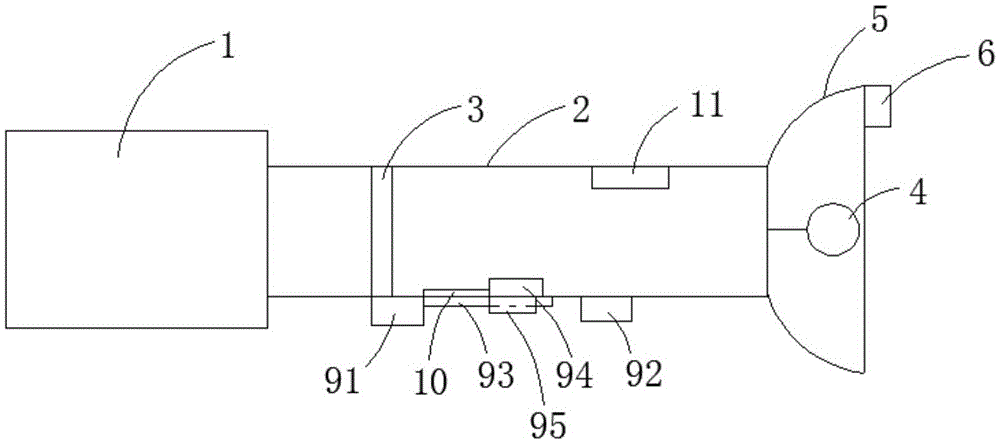

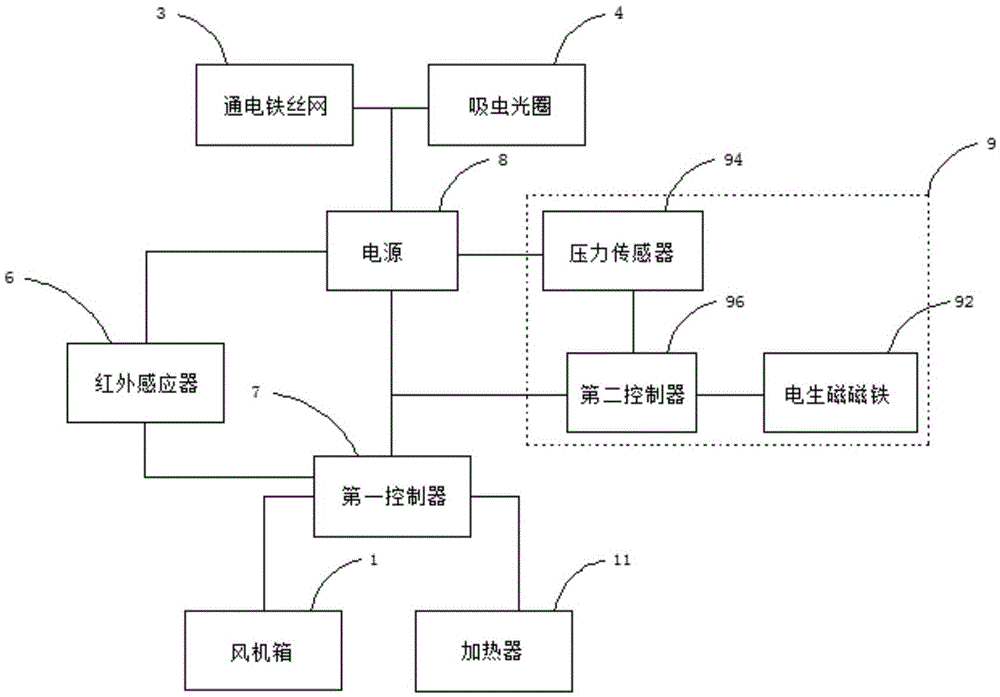

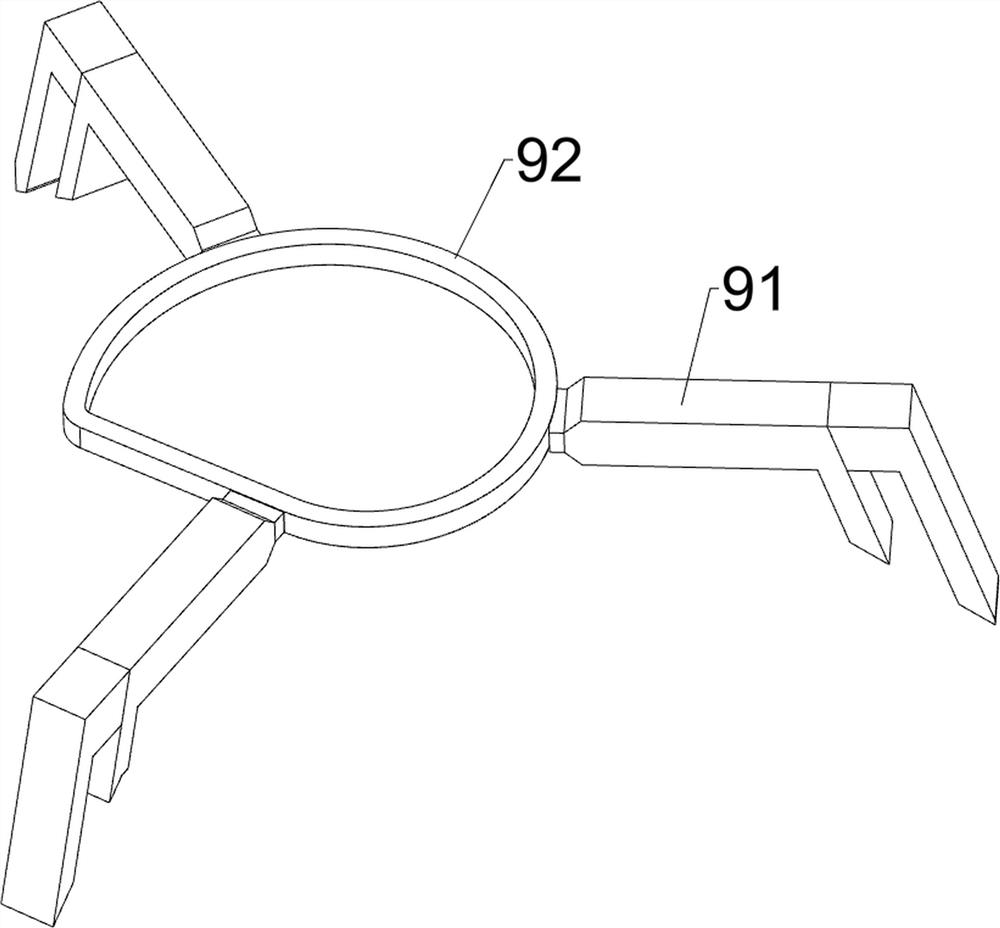

Inductive insect capturing device

InactiveCN105660571ANo pollutionEffective pest controlInsect catchers and killersPaleontologyInducer

The invention relates to an inductive insect capturing device which comprises a fan box, an insect collecting barrel, an electrified iron net and an insect attractive light ring, as well as a power supply, wherein the air sucking end of the fan box is communicated with one end of the insect collecting barrel; the electrified iron net is placed in the middle of the insect collecting barrel; the insect attractive light ring is placed at one end, far away from the fan box, of the insect collecting barrel; the insect attractive light ring is covered by a lampshade; one end of the lampshade is fixedly connected with the insect collecting barrel; an infrared inducer is arranged at one end, far away from the insect collecting barrel, of the lampshade; the infrared inducer is connected with a first controller through a wire; the control end of the first controller is connected with the fan box through another wire; the power supply is connected with the fan box, the electrified iron net, the infrared inducer and the first controller through wires respectively; an opening through which insect bodies can be discharged out is formed in the bottom on one side, close to the electrified iron net, of the insect collecting barrel; an automatic switch is arranged at the opening; the automatic switch is connected with the power supply through another wire. Compared with the prior art, the inductive insect capturing device is environment-friendly and energy-saving and high in insect capturing efficiency, and moreover the insect bodies can be automatically discharged out, so that the insect capturing efficiency can be maintained.

Owner:王晓春

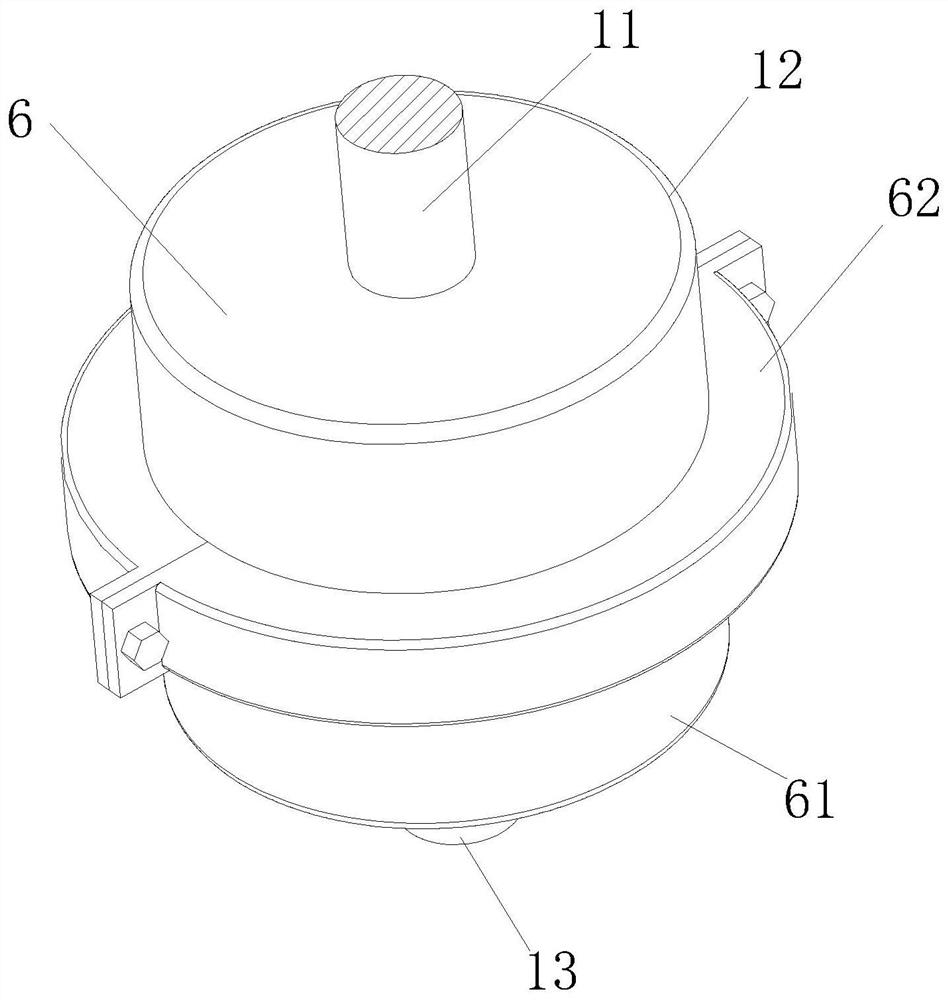

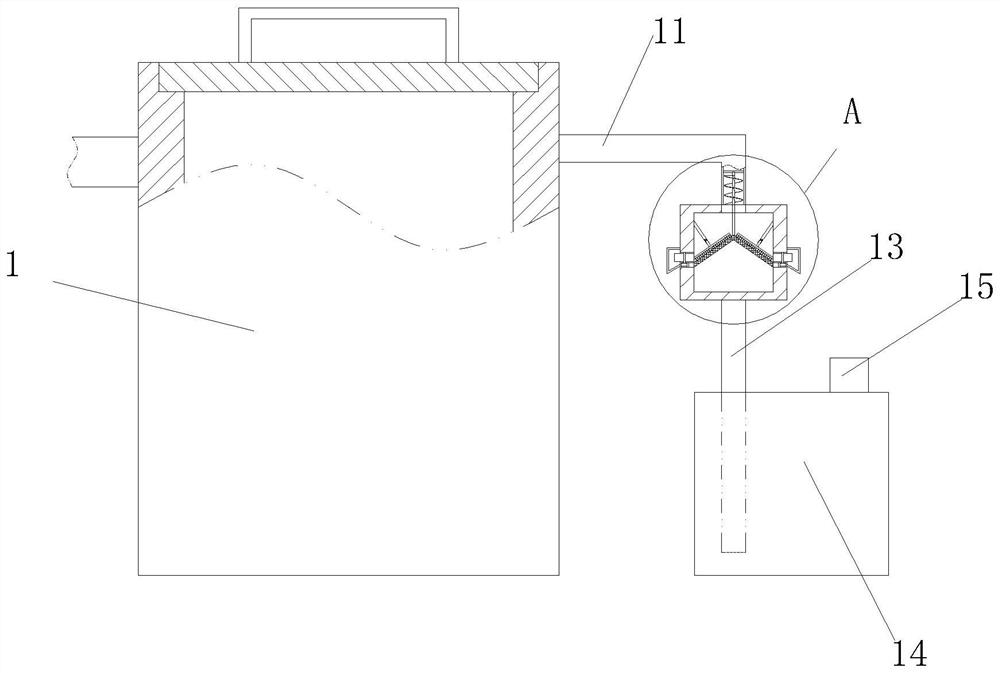

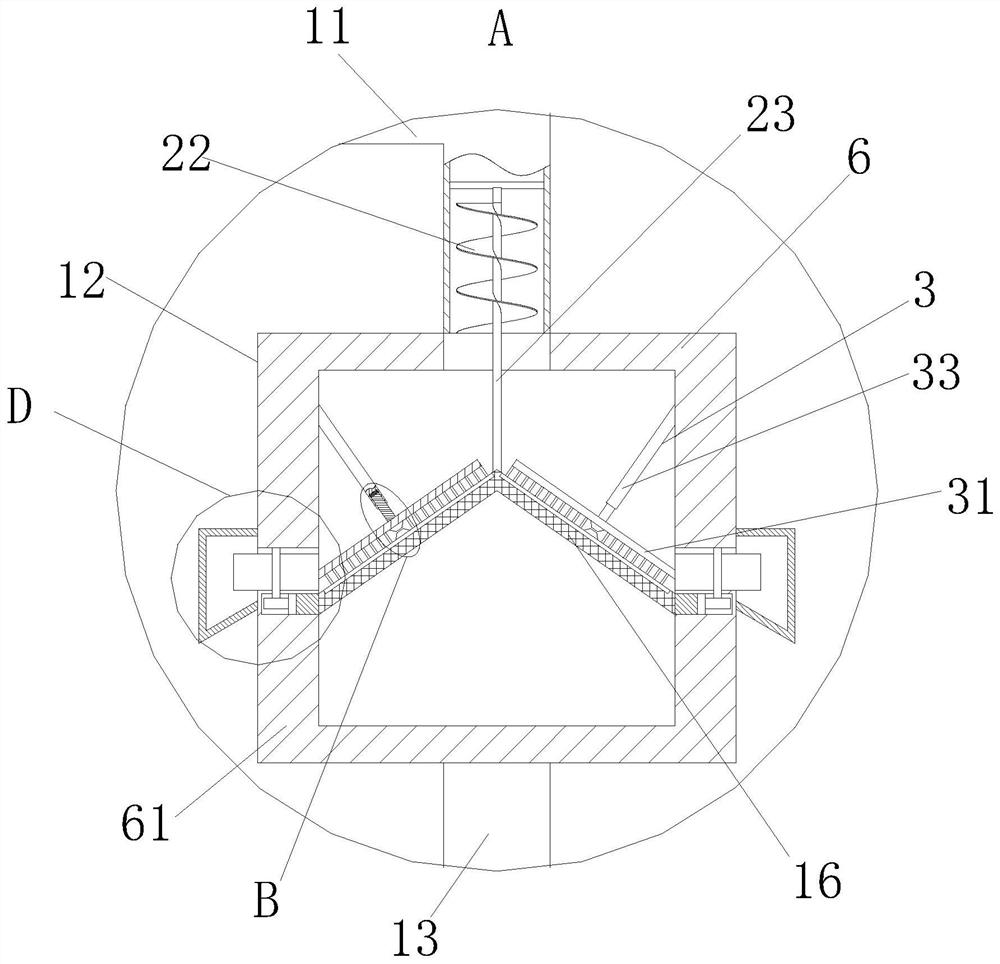

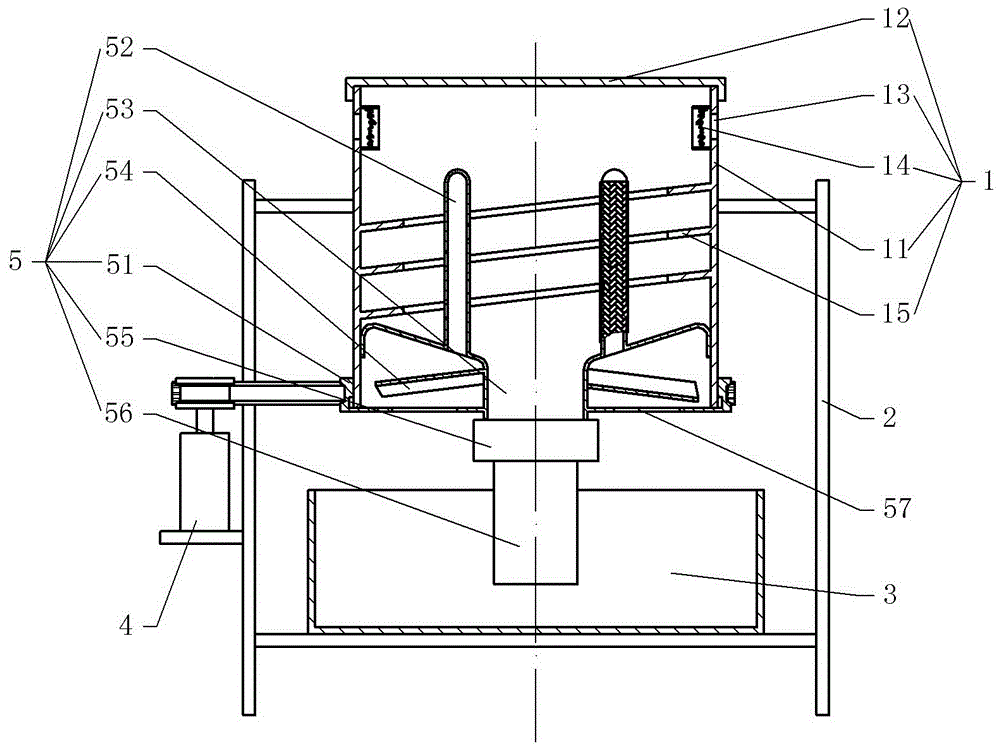

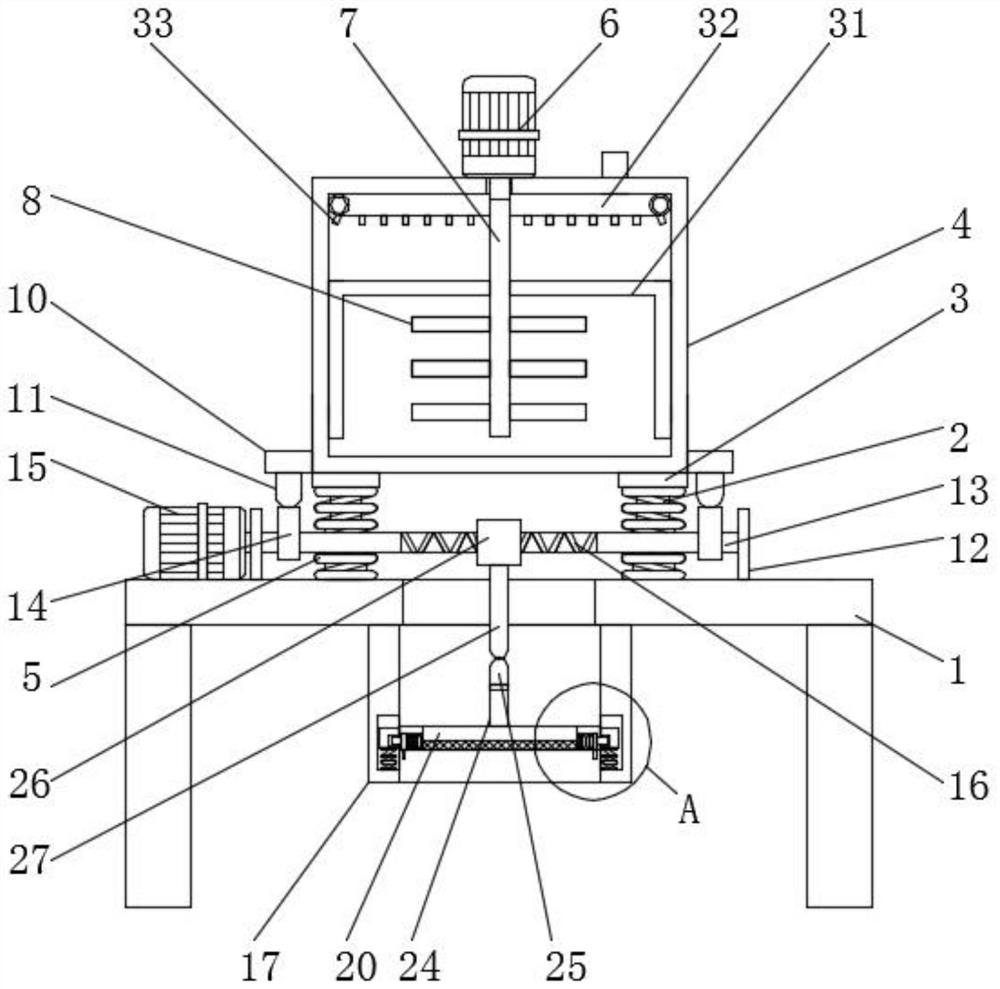

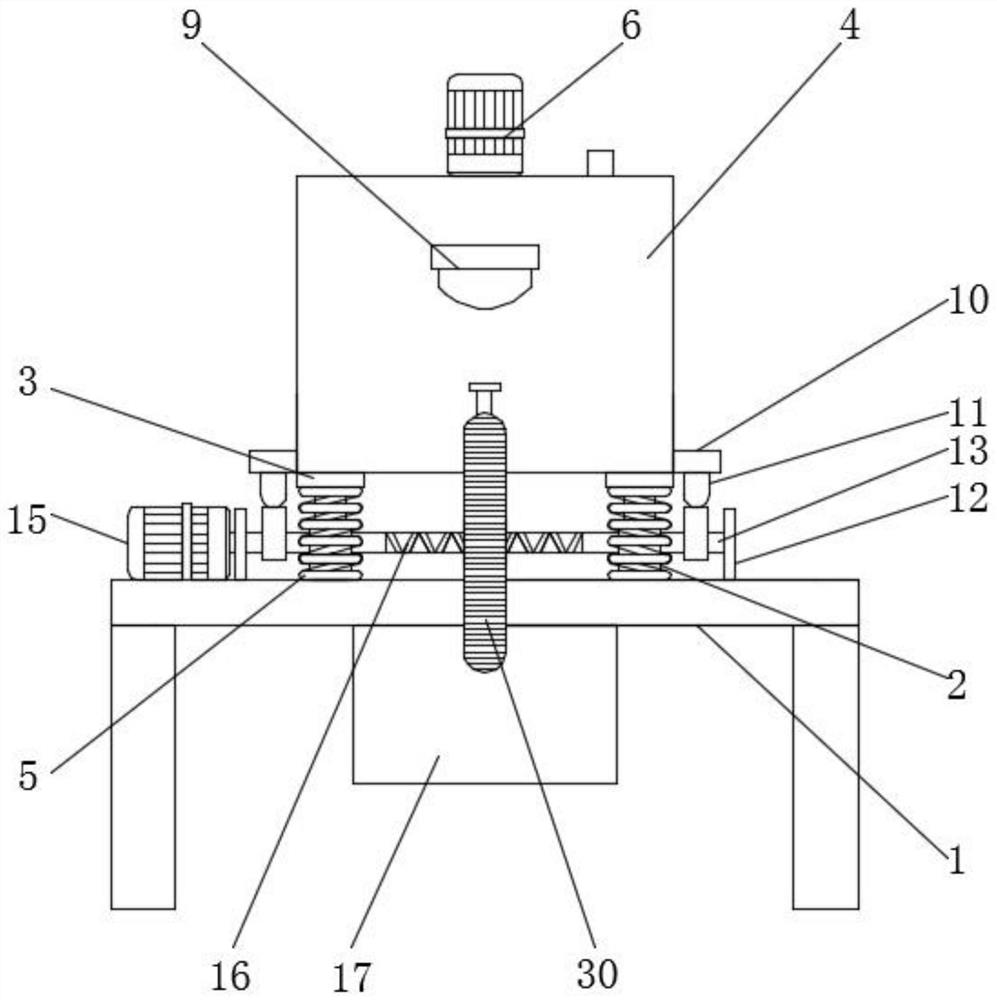

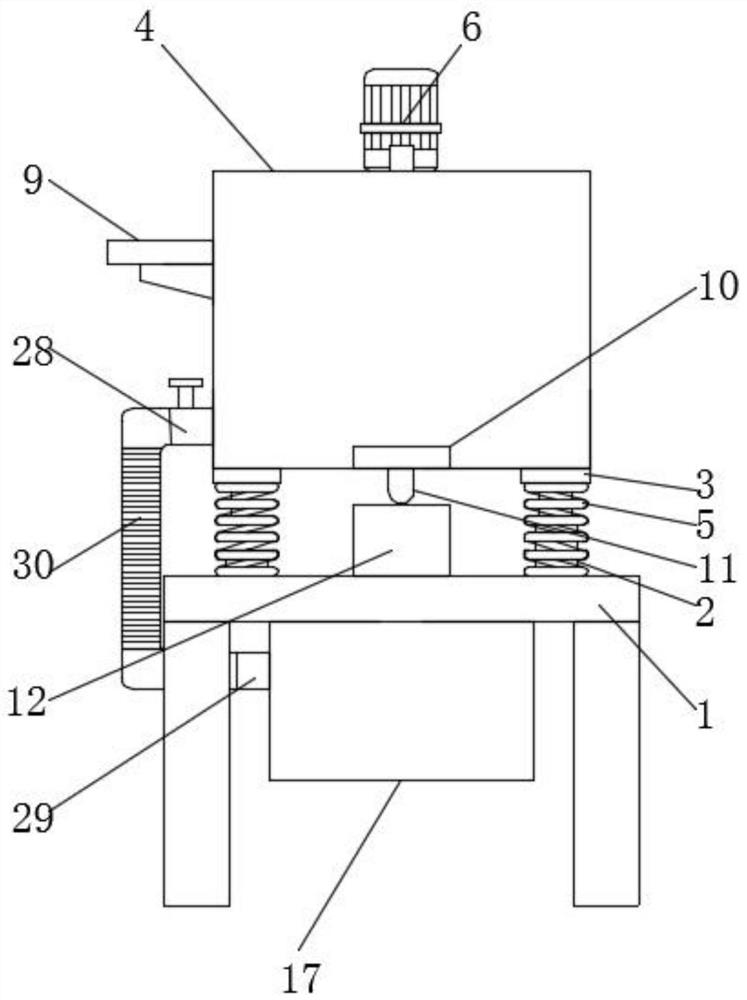

Novel material powder uniform mixing device

PendingCN113230966AImprove work efficiencyWell mixedRotating receptacle mixersRotary stirring mixersEngineeringSupport plane

Owner:黄淑群

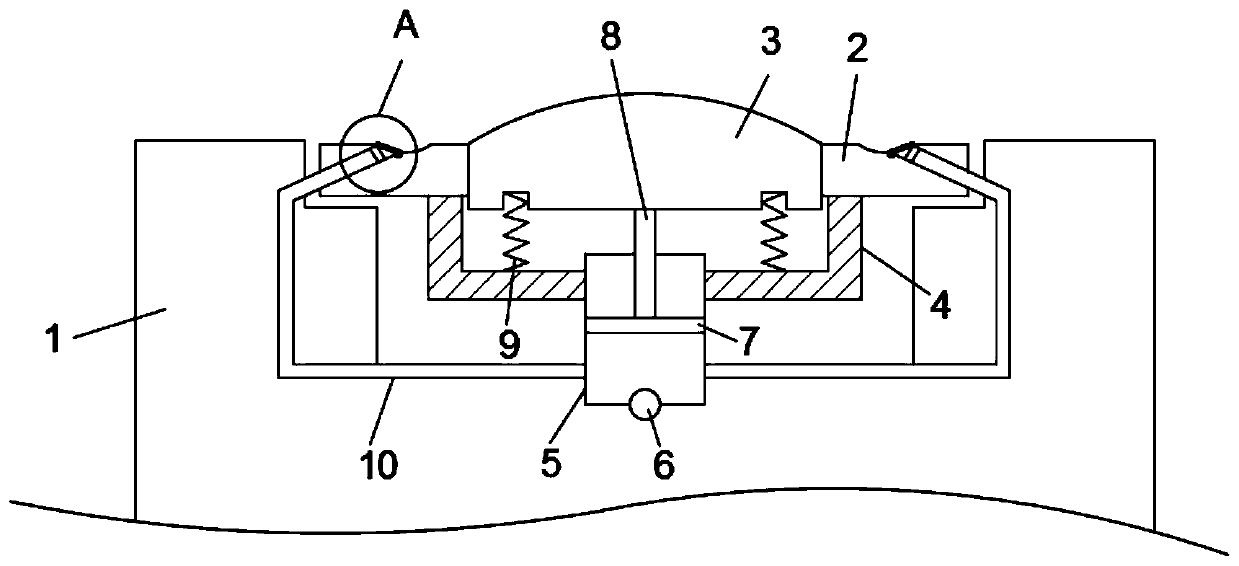

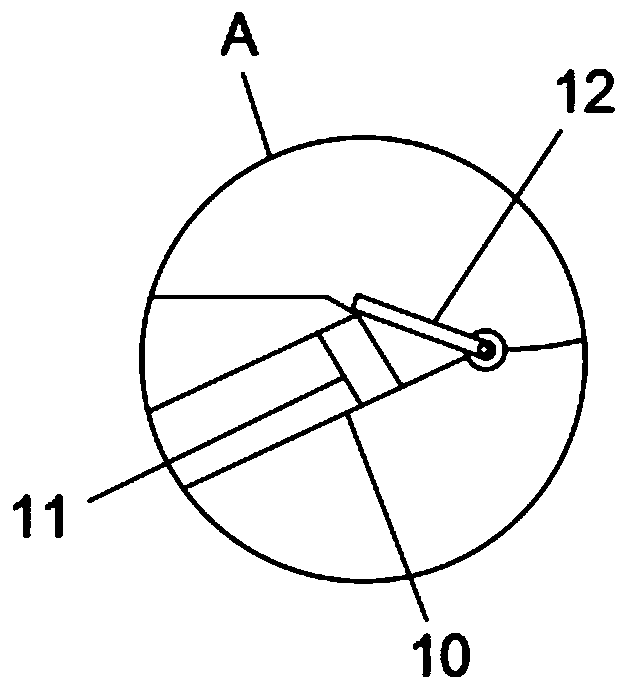

Sewage well cover

InactiveCN111206621AAvoid cloggingSmooth drainageArtificial islandsUnderwater structuresPistonSewage

The invention discloses a sewage well cover. The sewage well cover comprises a well cover body mounted on a sewage well. A mounting port is formed in the middle of the well cover body. A sliding plateis arranged in the mounting port in a sliding mode. The upper side wall of the sliding plate is in an arc shape. The lower side wall of the well cover body is fixedly connected with two connecting rods which are symmetrically arranged. The two connecting rods are arranged in the shape of an L. Telescopic springs are fixedly connected between the sliding plate and the connecting rods correspondingly. A piston pipe is fixed between the ends of the two connecting rods. A piston is arranged in the piston pipe in a sliding mode. A connecting rod is fixed to the upper side wall of the piston. The upper end of the connecting rod penetrates through the upper side wall of the piston pipe and is fixedly connected with the lower side wall of the sliding plate. The sewage well cover has the advantages that by arranging the sliding plate on the well cover body, when a vehicle runs over the well cover, gas in the piston pipe is extruded out by extruding the sliding plate to move downwards, impurities in notches rush out, the notches are prevented from being blocked, and water drainage is guaranteed to be smooth.

Owner:王浩怡

Waste rubber regeneration device

The invention belongs to the technical field of regenerated rubber, and particularly relates to a waste rubber regeneration device which comprises a desulfurization tank, wherein a waste gas pipe is arranged on the side wall of the desulfurization tank; the waste gas pipe is L-shaped, and the bottom end of the waste gas pipe is fixedly connected with a filter box; the bottom end of the filter box is connected with a slurry box through a communicating pipe; limestone slurry is filled in the slurry tank, and the communicating pipe extends into the slurry; and a conical filter screen is arranged in the filter box, and the conical tip of the conical filter screen faces upwards. The invention provides a waste rubber regeneration device, aiming at solving the problems that when waste rubber is regenerated by utilizing a desulfurization tank, a large amount of waste gas is generated, the waste gas contains rubber powder particles, organic pollutants and the like, and people can remove impurities from colloidal particles and the organic pollutants by utilizing clear water and limestone slurry, but after the colloidal particles are removed by utilizing the clear water, waste gas carries a large amount of water to enter a slurry pond, the concentration in the slurry pond is influenced, impurity removal of organic pollutants is influenced, the discharged waste gas does not reach the standard, and the surrounding environment.

Owner:徐州托普新材料有限公司

Plastic particle drying machine

InactiveCN105965722AAvoid cloggingEvenly distributedGranular material dryingDrying gas arrangementsDrive motorDry box

This patent discloses a plastic particle dryer, which relates to the technical field of plastic machinery; the plastic particle dryer includes a drying box, a support frame, a material receiving box and an air induction device; the drying box includes a box body and a top cover matched with the upper end of the box body , the upper end of the side wall of the box is provided with an air inlet one, and one place of the air inlet is provided with a heating wire; the air induction device includes a shell, an exhaust fan and a plurality of air induction pipes, the shell is rotatably connected to the lower end of the drying box, and the exhaust fan is fixed on Inside the casing, the lower end of the casing is provided with an air outlet, the air induction pipe is fixed on the upper end of the casing and communicates with the interior of the casing, a number of air inlets are opened on the side wall of the air induction pipe, and the outer circumference of the air induction pipe is wrapped with barbed wire , The center of the shell is provided with a discharge port, and a discharge valve is installed at the discharge port; the material receiving box is provided under the drying box; and a driving motor is provided to drive the air induction device to rotate. When the device dries the plastic particles, the plastic particles are heated more uniformly and have higher efficiency.

Owner:重庆敏驰塑胶有限公司

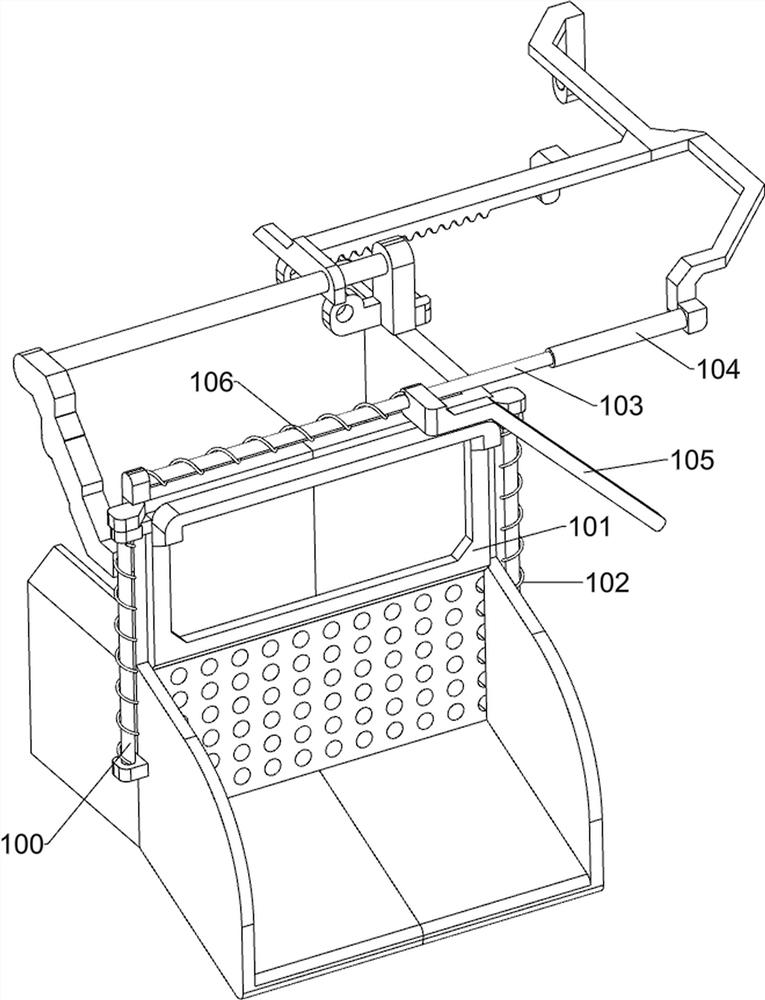

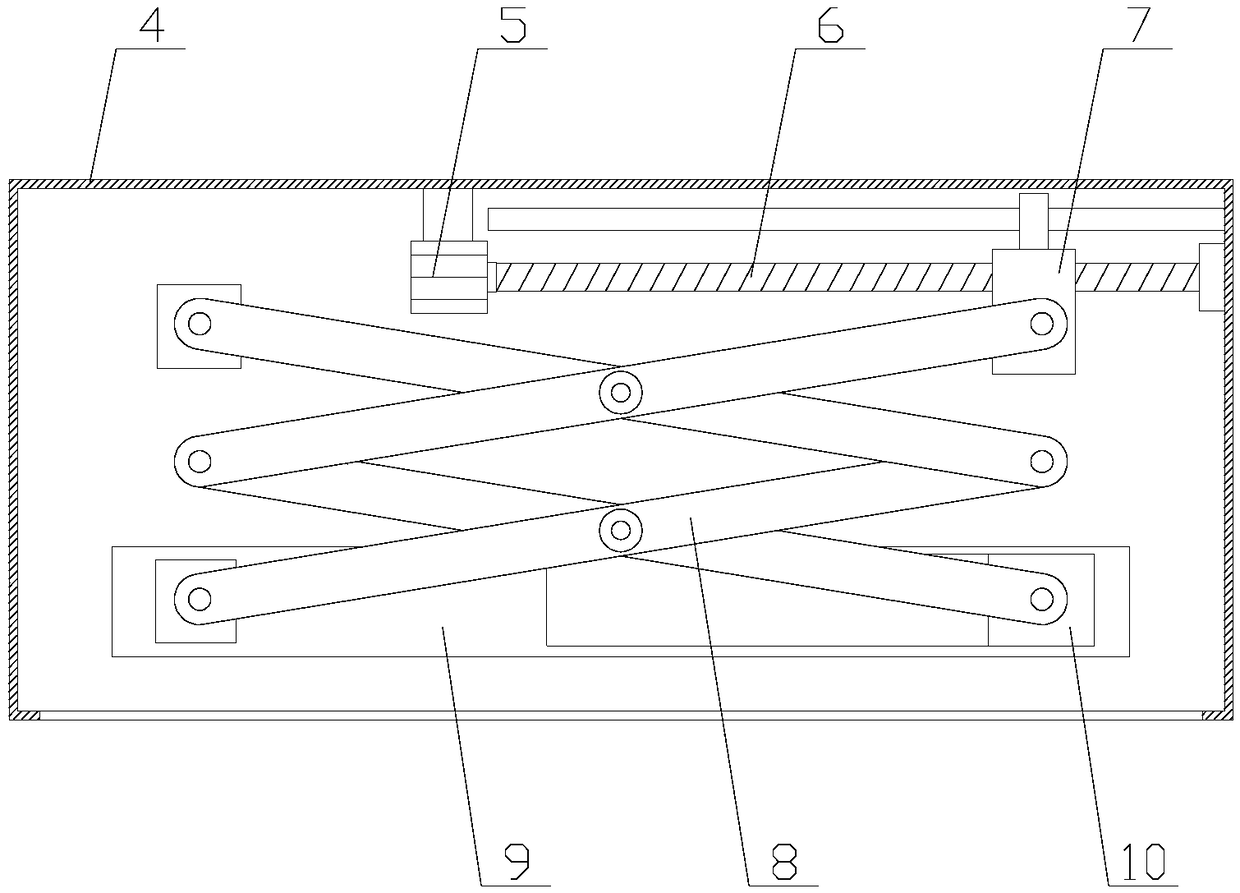

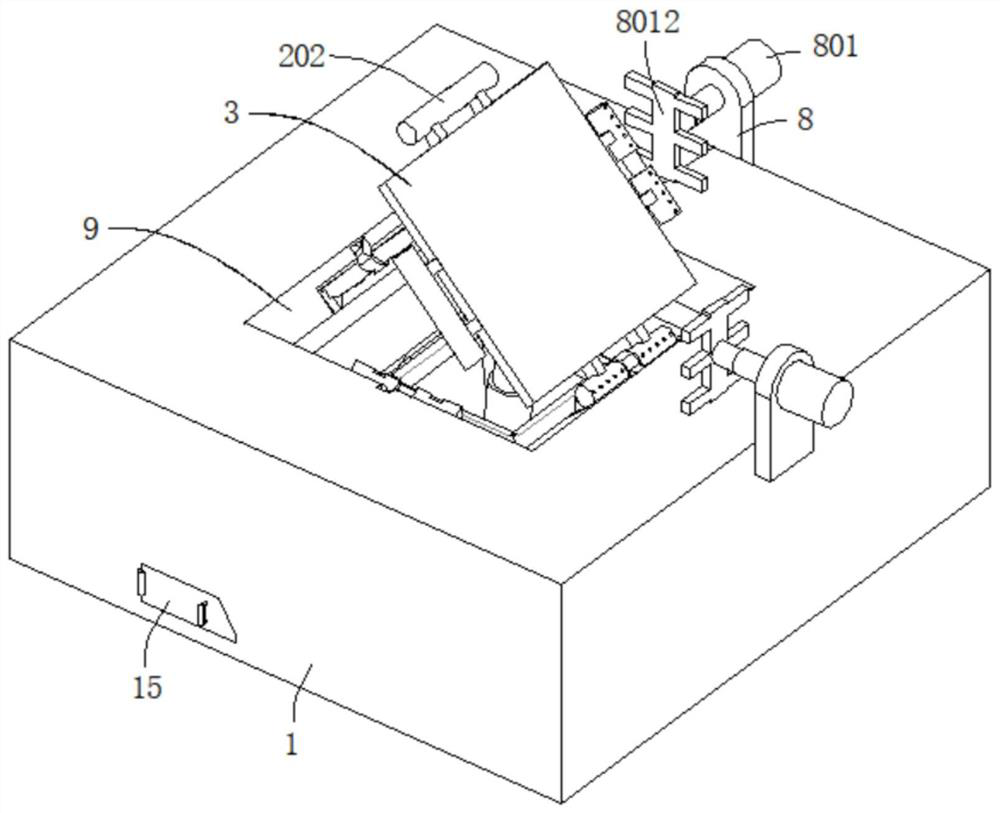

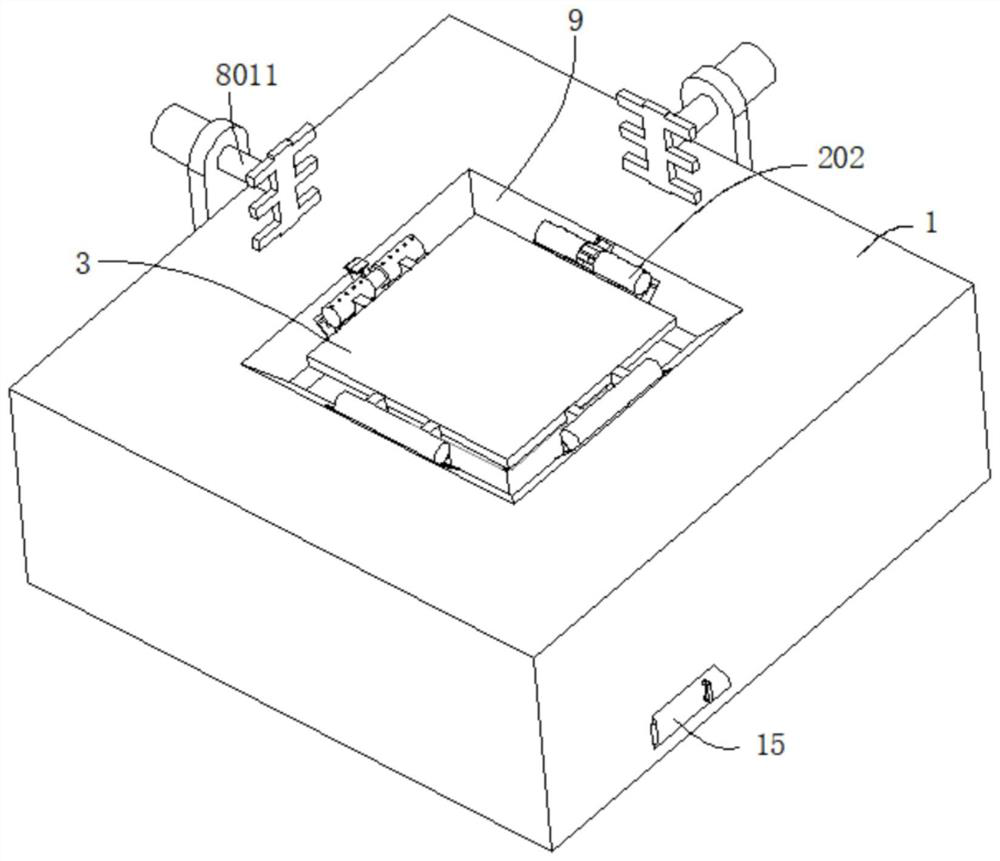

Energy-saving and environment-friendly industrial sewage treatment equipment

InactiveCN113413654AAvoid influenceEasy to collectSewerage structuresStationary filtering element filtersWater storageFiltration

The invention relates to energy-saving and environment-friendly industrial sewage treatment equipment which comprises a support, a water storage frame, a flow channel, a filter plate, a lifting mechanism and a power mechanism; the water storage frame is fixedly connected to one side outside the support, and the filter plate is fixedly connected to one side of the water storage frame in a penetrating mode. Sewage is discharged into the water storage frame, the filter plate filters impurities in the sewage, the sewage after impurity filtration is discharged through the flow channel, the power mechanism is started to drive the lifting mechanism to operate, and the lifting mechanism operates to drive the impurities to move upwards to a proper position, so that the impurities can be pushed down; therefore, the influence of the impurities in the sewage on the environment can be avoided.

Owner:魏连花

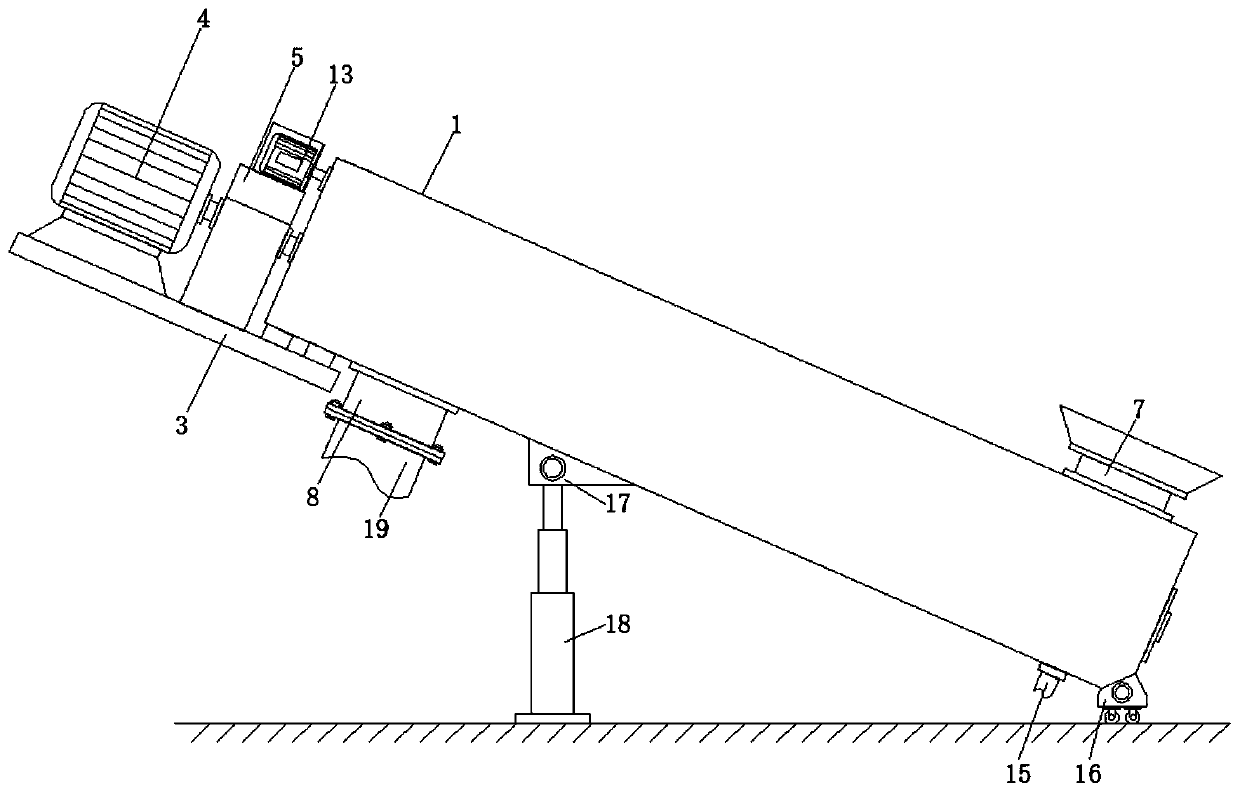

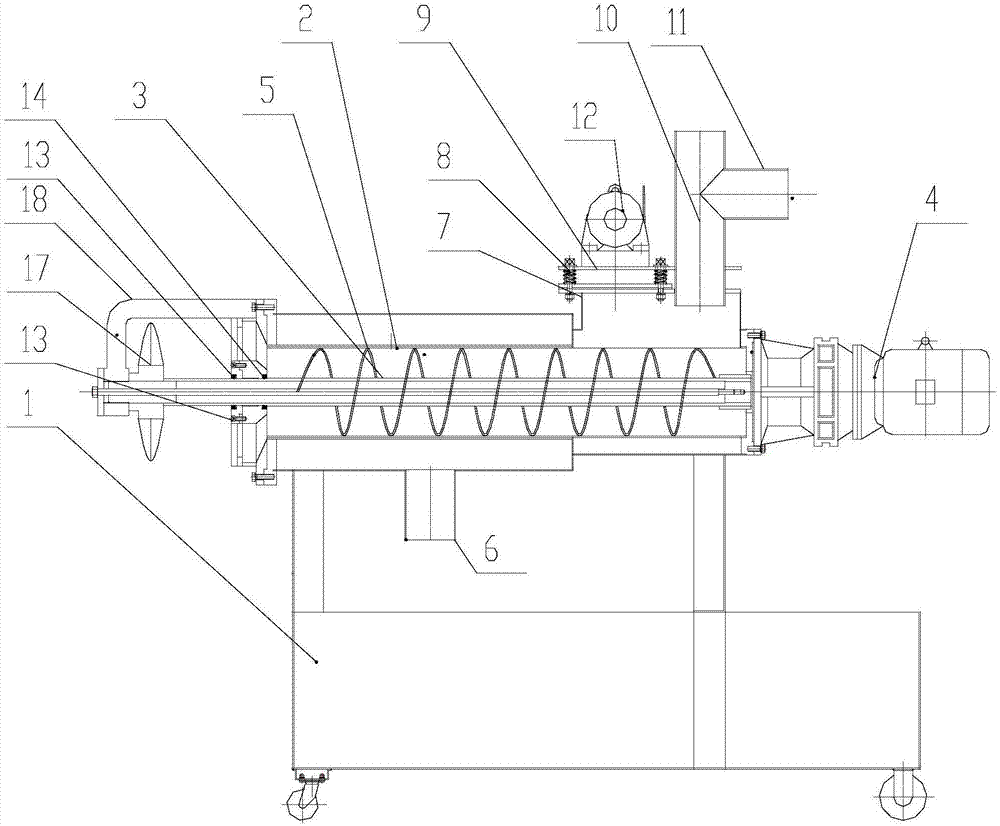

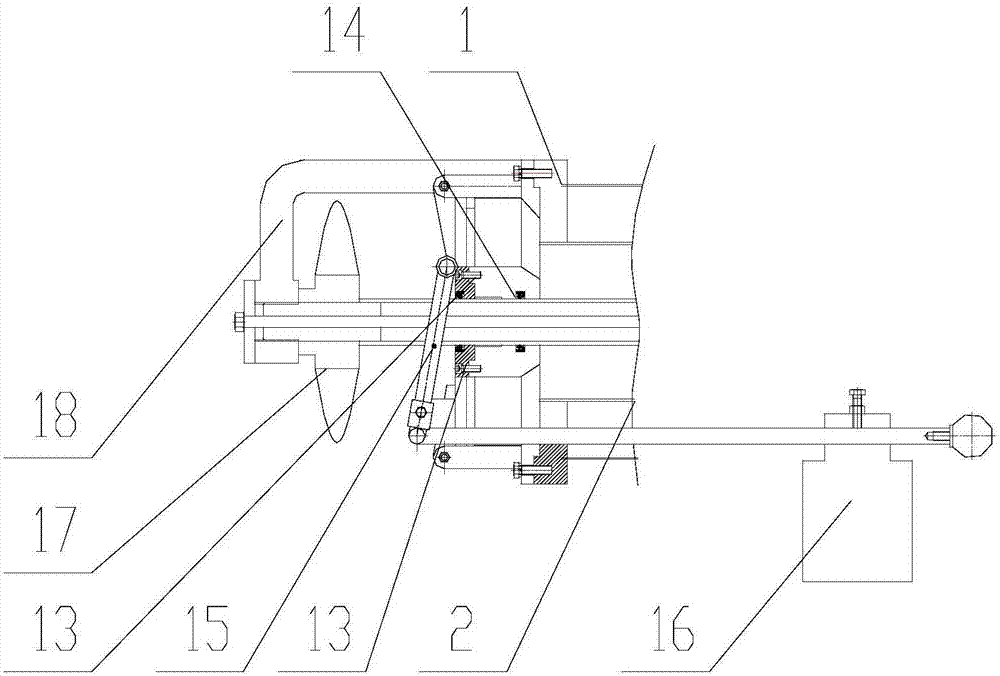

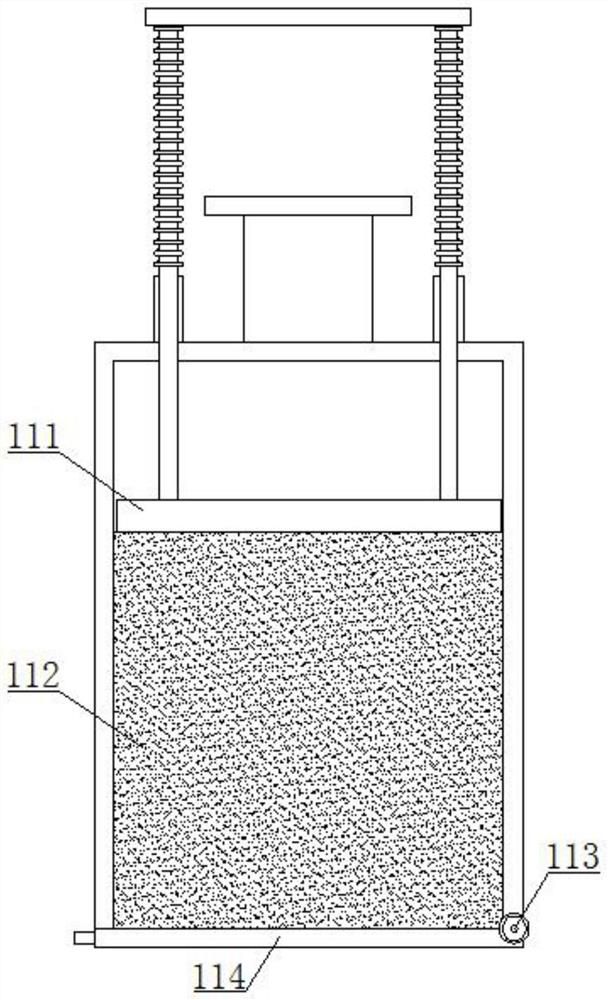

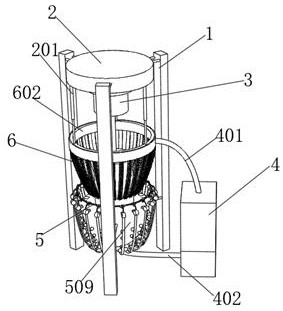

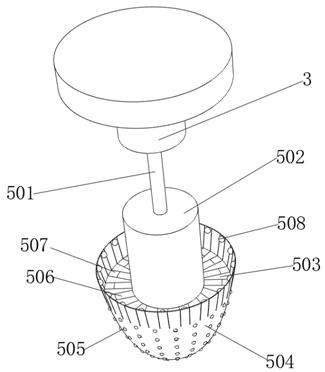

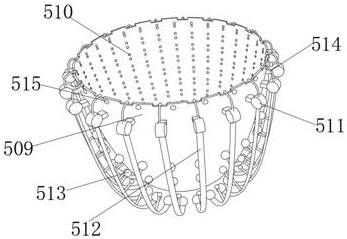

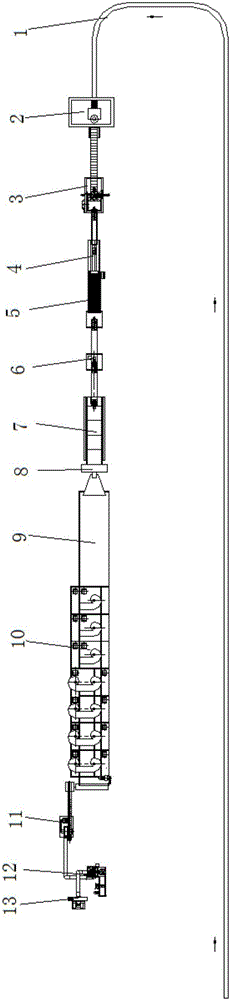

Spiral extrusion type solid-liquid separator

The invention discloses a spiral extrusion type solid-liquid separator. The spiral extrusion type solid-liquid separator can better separate moisture in materials. The spiral extrusion type solid-liquid separator comprises a rack. An extrusion cylinder is arranged on the rack. An extrusion screw is arranged in the extrusion cylinder in a penetrating manner. A main power device driving the extrusion screw is arranged on the rack. A filtering net is arranged on the inner wall of the extrusion cylinder. The extrusion cylinder is provided with a material inlet and a liquid outlet. An installation seat is arranged at the position, at the material inlet, on the extrusion cylinder. The installation seat is provided with a vibration seat through four springs, and a feeding pipe penetrating in the material inlet is arranged on the vibration seat. A vibration motor is arranged on the vibration seat. A material slag outlet is arranged at the end, away from the main power device, of the extrusion cylinder. An upper discharging baffle and a lower discharging baffle are hinged to the position, at the material slag outlet, on the extrusion cylinder. The discharging baffles are connected with a connecting rod mechanism, and the connecting rod mechanism is provided with a hammer making the discharging baffle pressing positions of the connecting rod mechanism adjustable. A bulk material wheel is arranged at the end, stretching out of the extrusion cylinder, of the extrusion screw, and the extrusion cylinder is provided with a positioning frame which supports the extrusion screw and makes the extrusion screw away from the main power device.

Owner:ZHANGJIAGANG ZHONGNAN CHEM MACHINERY

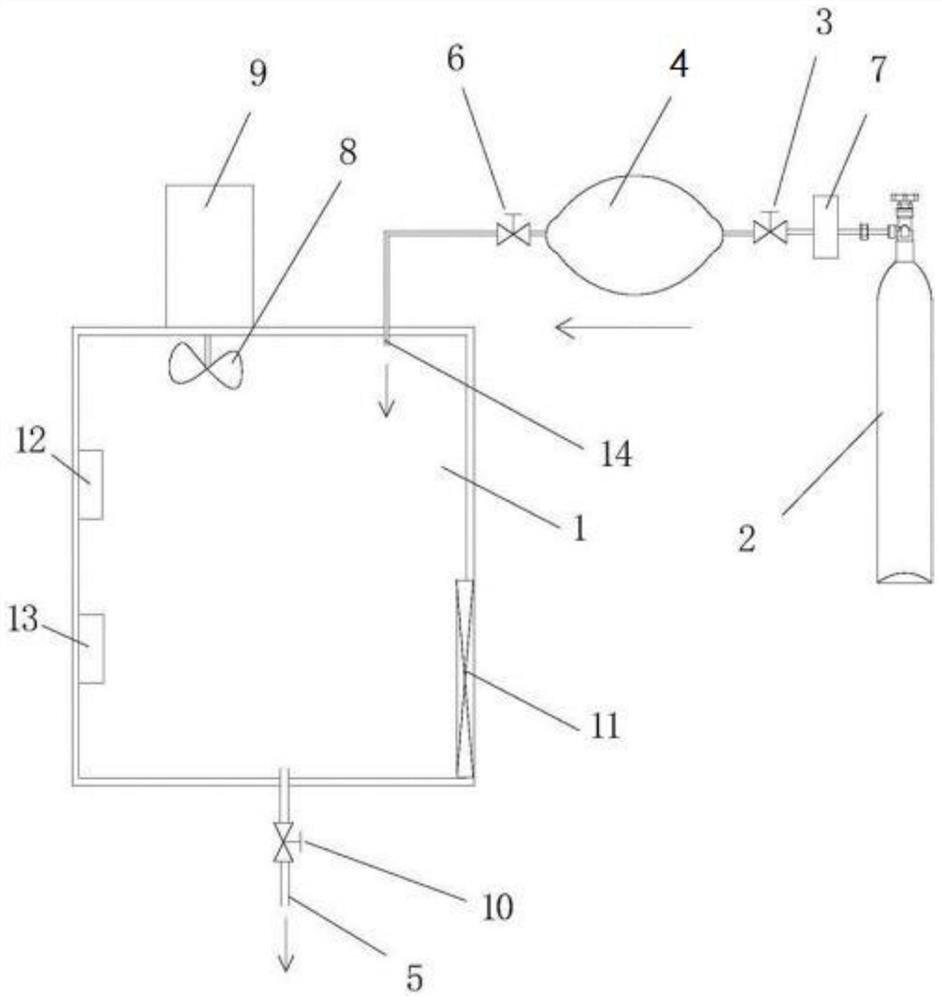

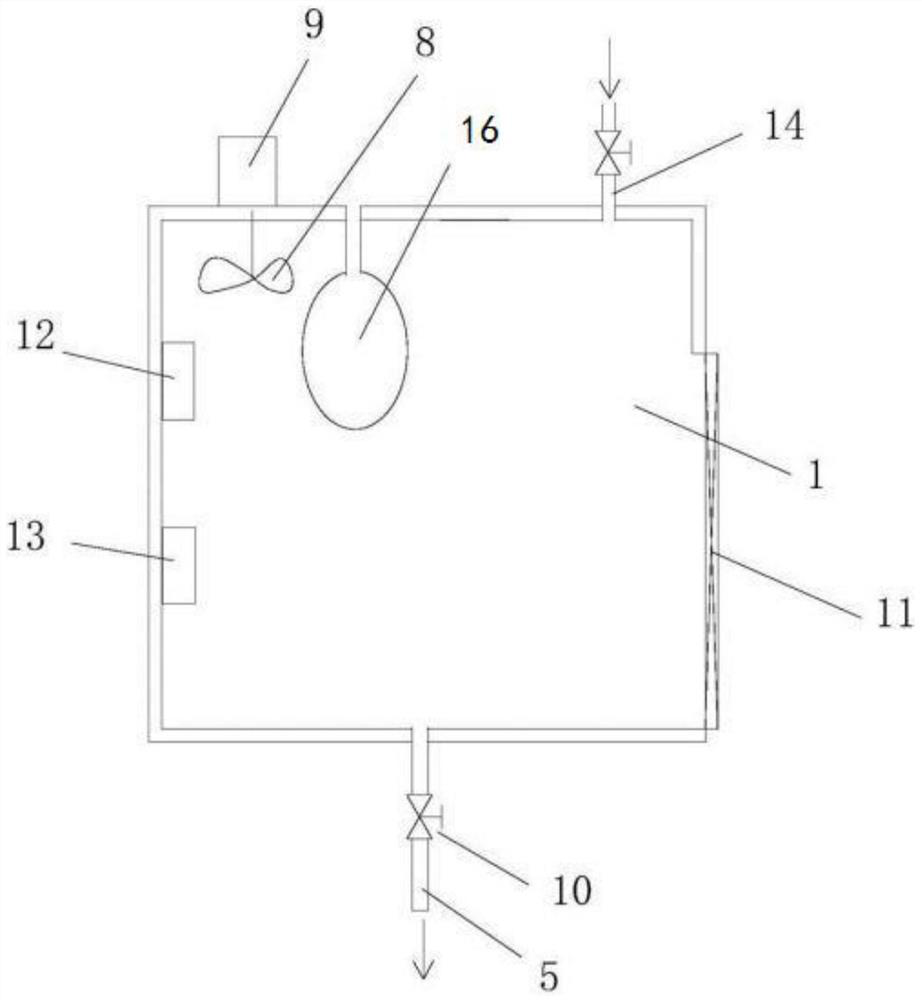

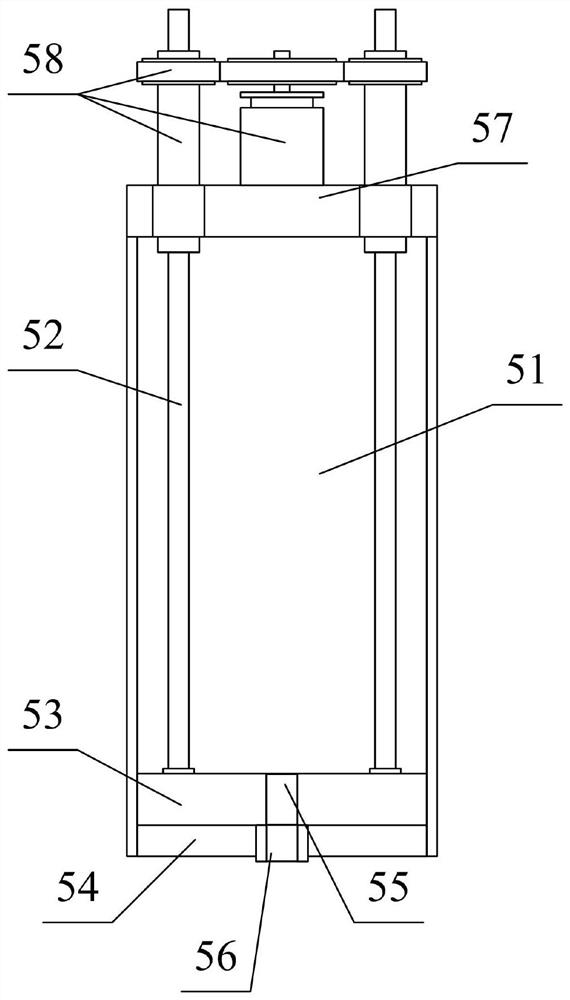

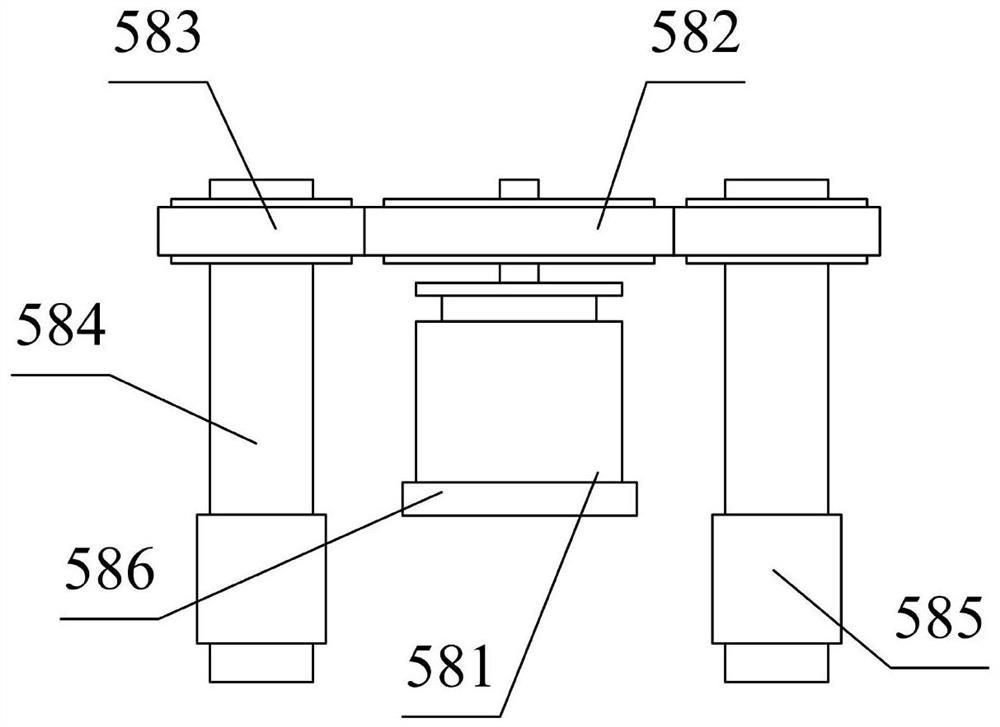

Sealed cabin sampling system

InactiveCN112903374AAvoid disturbing effectAvoid enteringWithdrawing sample devicesGas analyser construction detailsAtmospheric sciencesMechanical engineering

The invention provides a sealed cabin sampling system, which comprises a clean cabin body which is used for storing a to-be-detected object, keeping constant temperature and / or constant humidity and is in a closed state, and a compensation bag which can be expanded and is used for compensating the volume of gas in the clean cabin body, the clean cabin body is provided with an exhaust sampling port used for exhausting to-be-detected gas in the clean cabin body and a gas supplementing port used for circulating external gas, the compensation bag goes deep into the clean cabin body, the compensation bag is communicated with the gas supplementing port through a gas supplementing pipeline, and the compensation bag can perform volume compensation on the interior of the cabin body in the gas sampling and extracting process, so that pollution gas outside the cabin body can be prevented from entering the cabin body due to air pressure difference, the influence of environmental factors or other uncertain factors on a test result is avoided, the compensation bag goes deep into the clean cabin body, in the gas sampling, extracting and expanding process, the gas in the clean cabin body can be disturbed in a large range, the volatile organic compounds in the clean cabin body are distributed more uniformly, and the precision of a measurement result is ensured.

Owner:DONGGUAN CITY SIMPLEWELL TECH

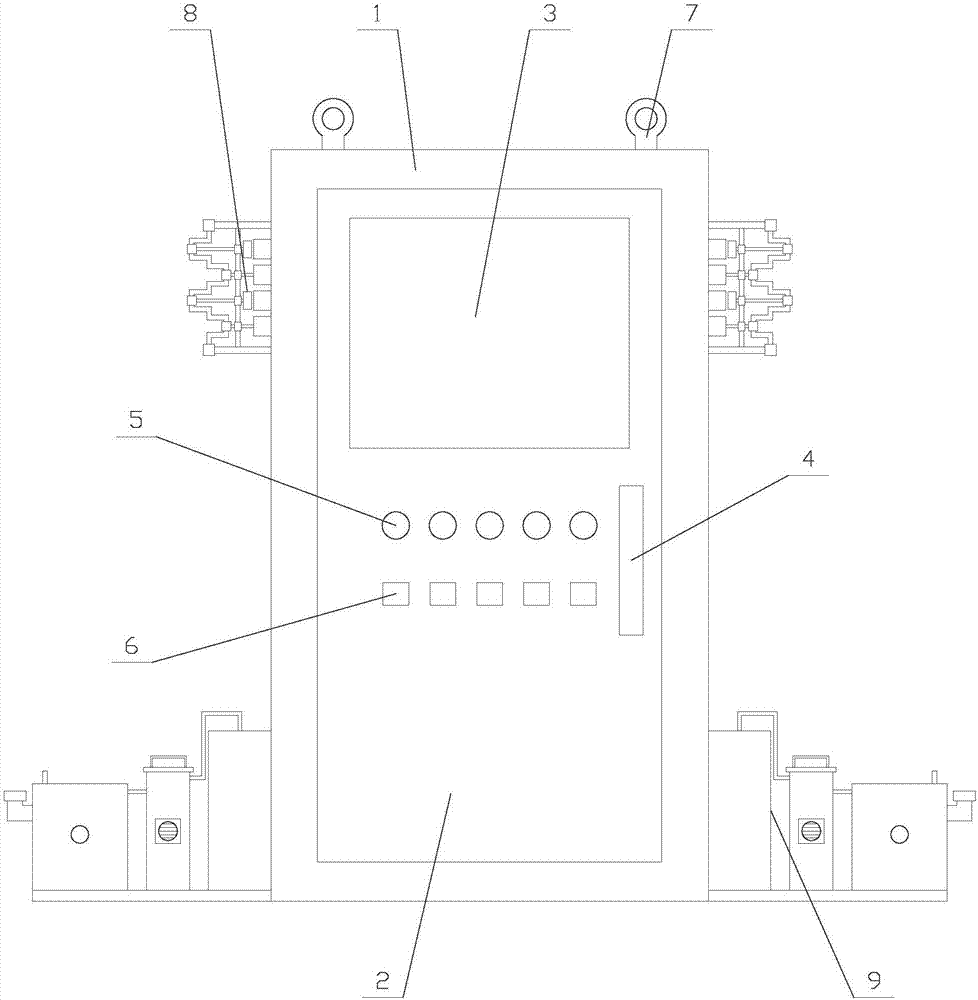

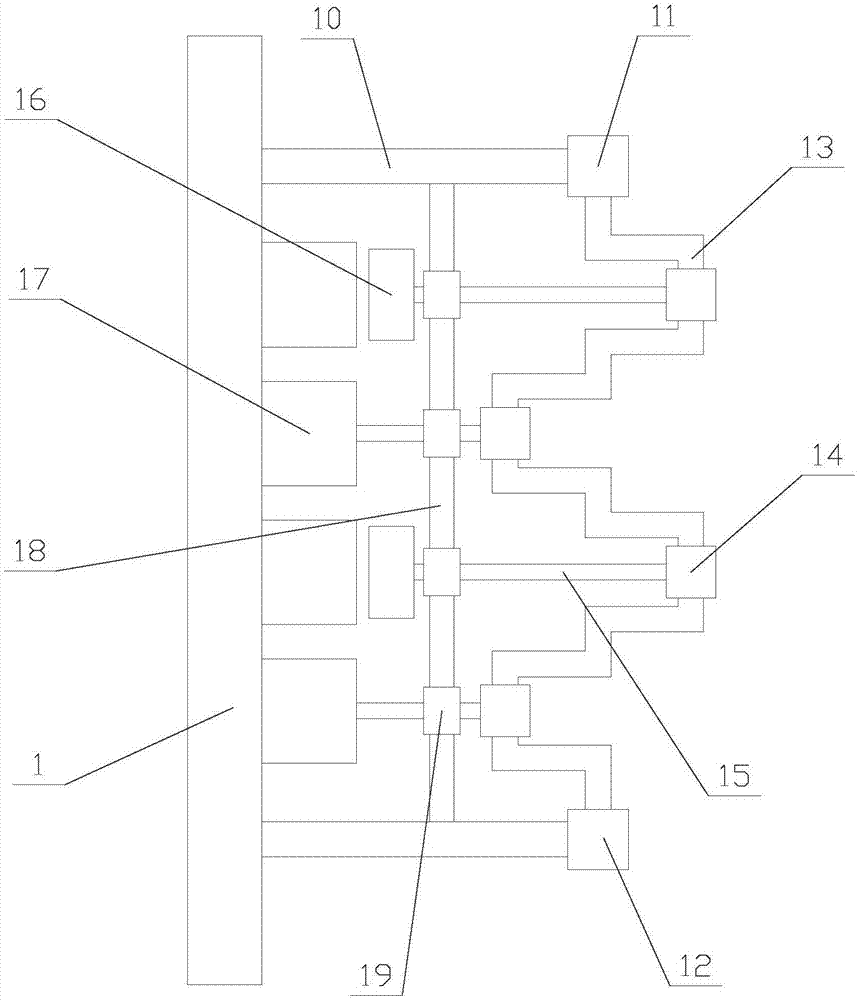

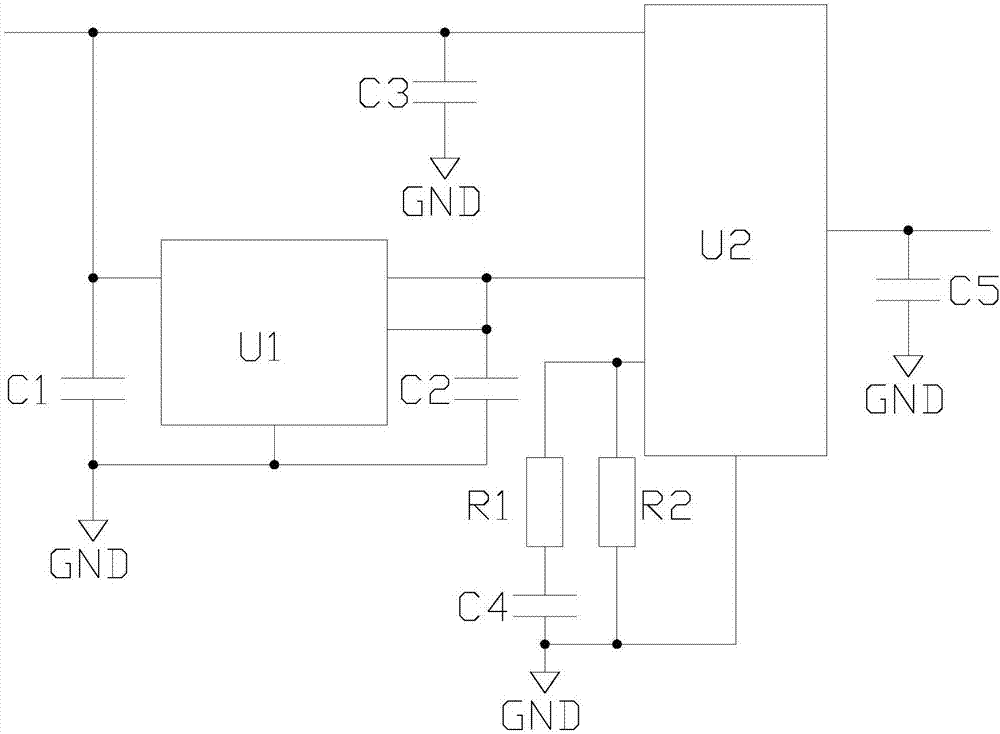

Intelligent power distribution cabinet with efficient heat dissipation

InactiveCN107492795AAvoid short circuit failureImprove cooling effectSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsLow noiseCurrent limiting

The invention relates to an intelligent power distribution cabinet with high-efficiency heat dissipation, which includes a main body, a switch door, two dust suction mechanisms and two air transmission mechanisms, and a handle, a display screen, several indicator lights and several control buttons are arranged on the switch door , the dust suction mechanism includes a first motor, a buffer block, two poles and several dust suction units, the dust suction unit includes a frame, a collar, a connecting rod, a dust suction block and a heat dissipation pipe, and the air transmission mechanism includes a bottom plate, a water tank, a drying Box, air guide box, first air pipe, cover plate, second air pipe and third air pipe, this intelligent power distribution cabinet with efficient heat dissipation absorbs the dust on the inner wall of the heat dissipation pipe through the dust suction mechanism to prevent blockage and affect the hot air discharge, so as to ensure efficient heat dissipation performance, not only that, in the voltage stabilizing circuit, the current limiting terminal of the second integrated circuit U2 is connected to the ground terminal through the second resistor R2, which limits the size of the current and ensures the stability of the output terminal Since the model of the second integrated circuit U2 is LT3086, the output voltage stability of the circuit is good, the pressure difference is small and the working noise is small, which further improves the practicability and market competitiveness of the device, and greatly improves the equipment. practicality.

Owner:时枫娇

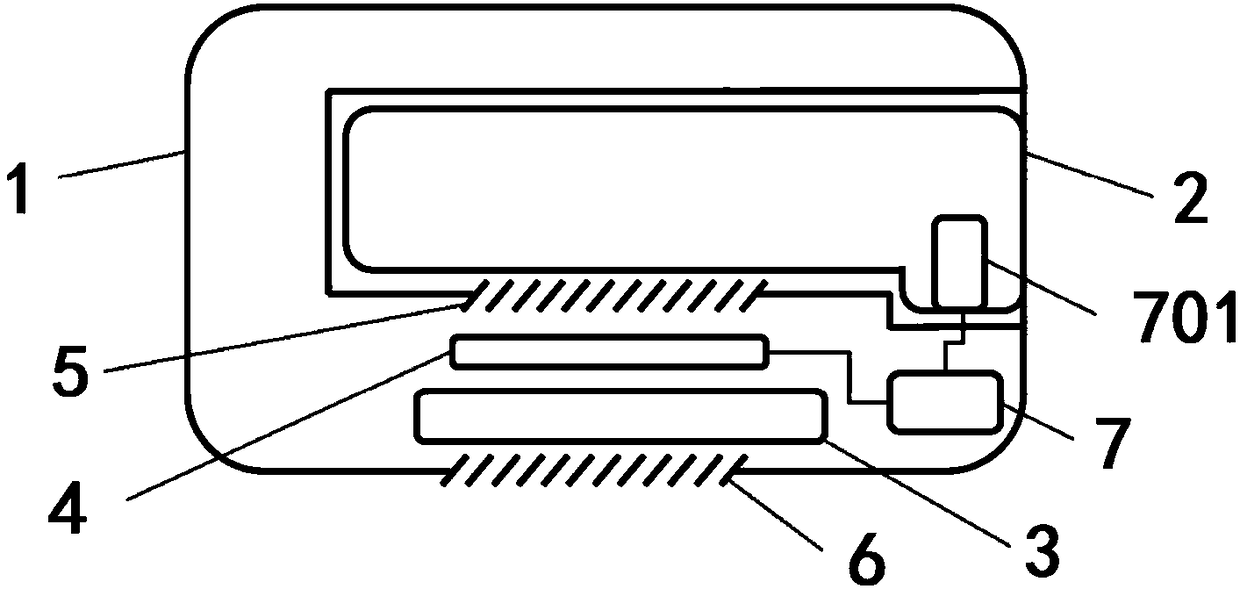

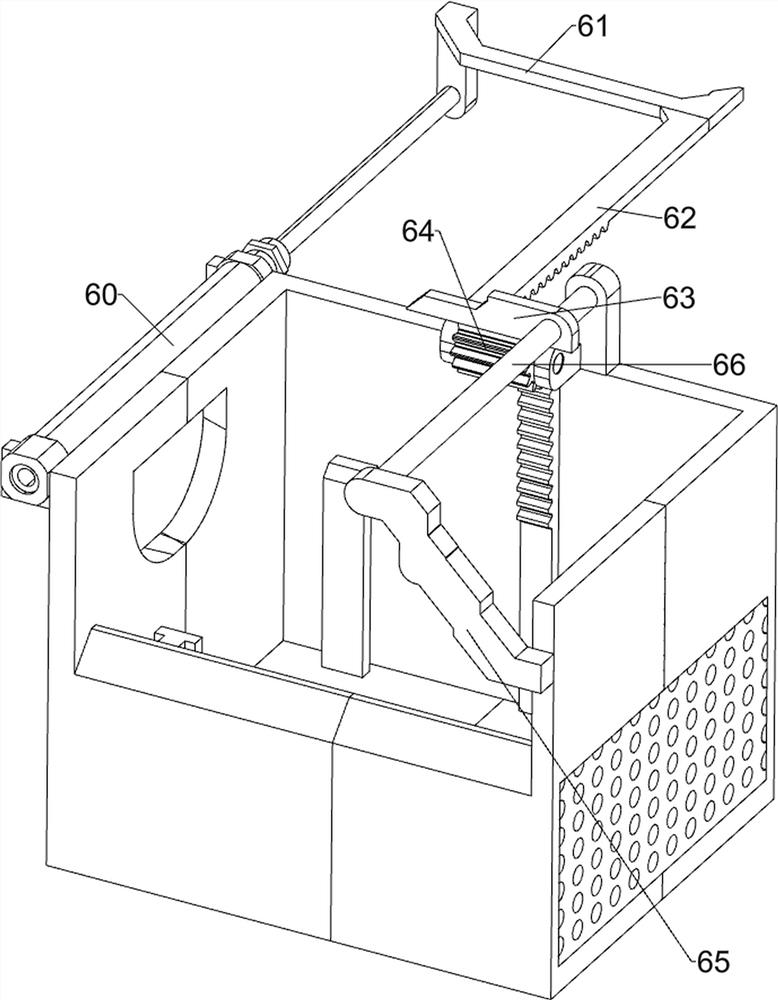

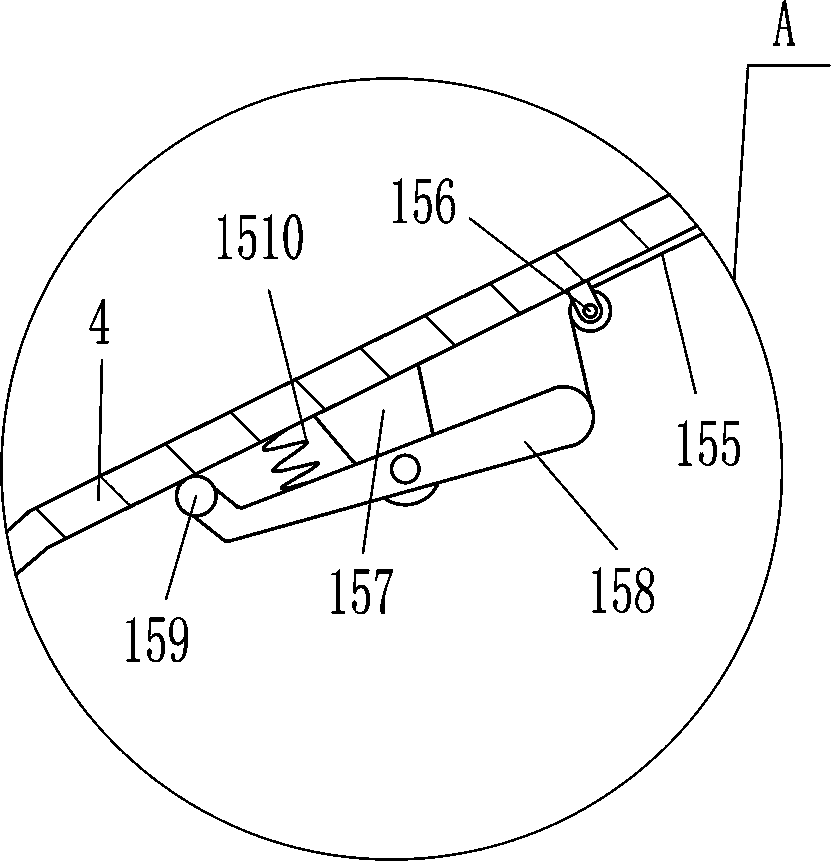

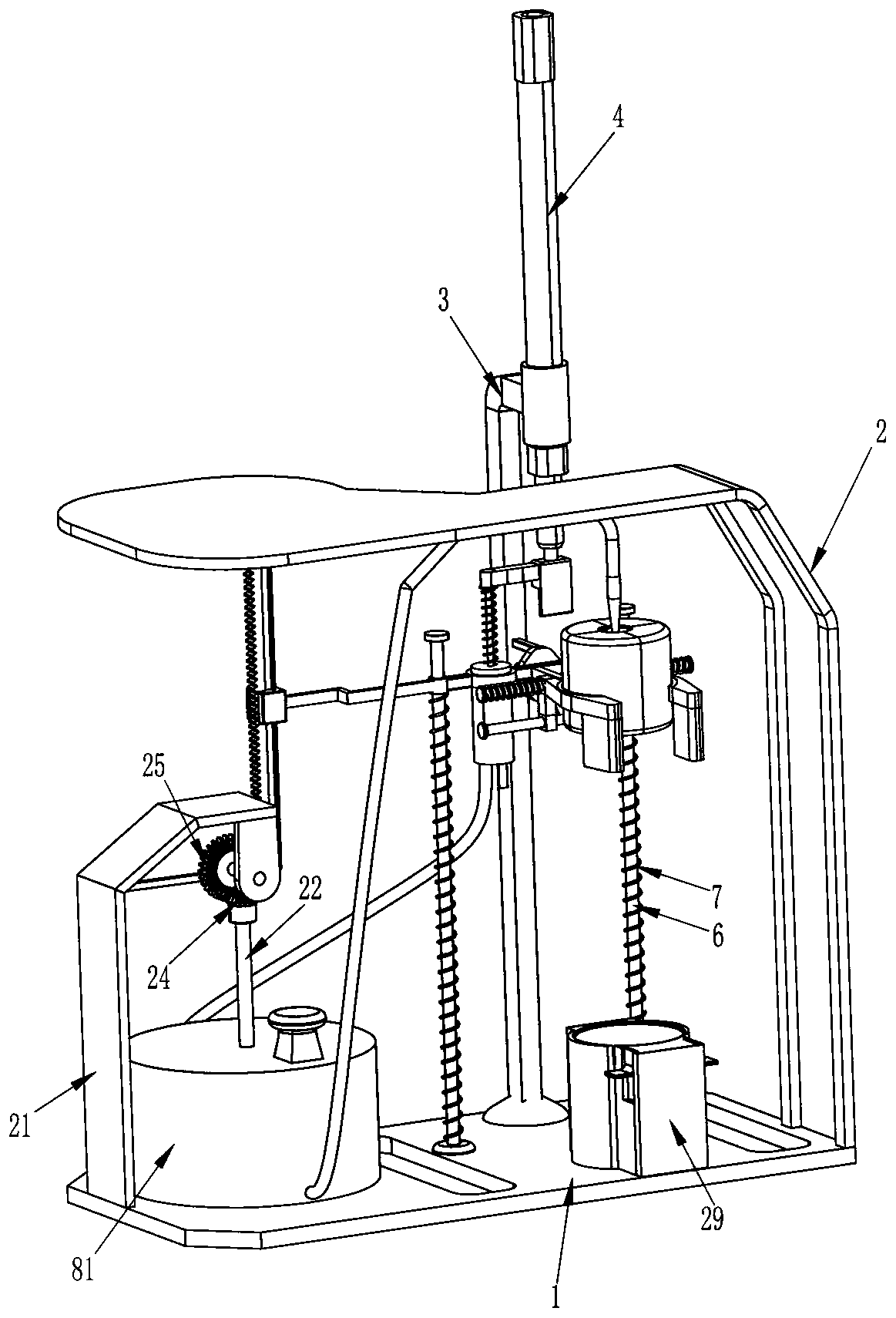

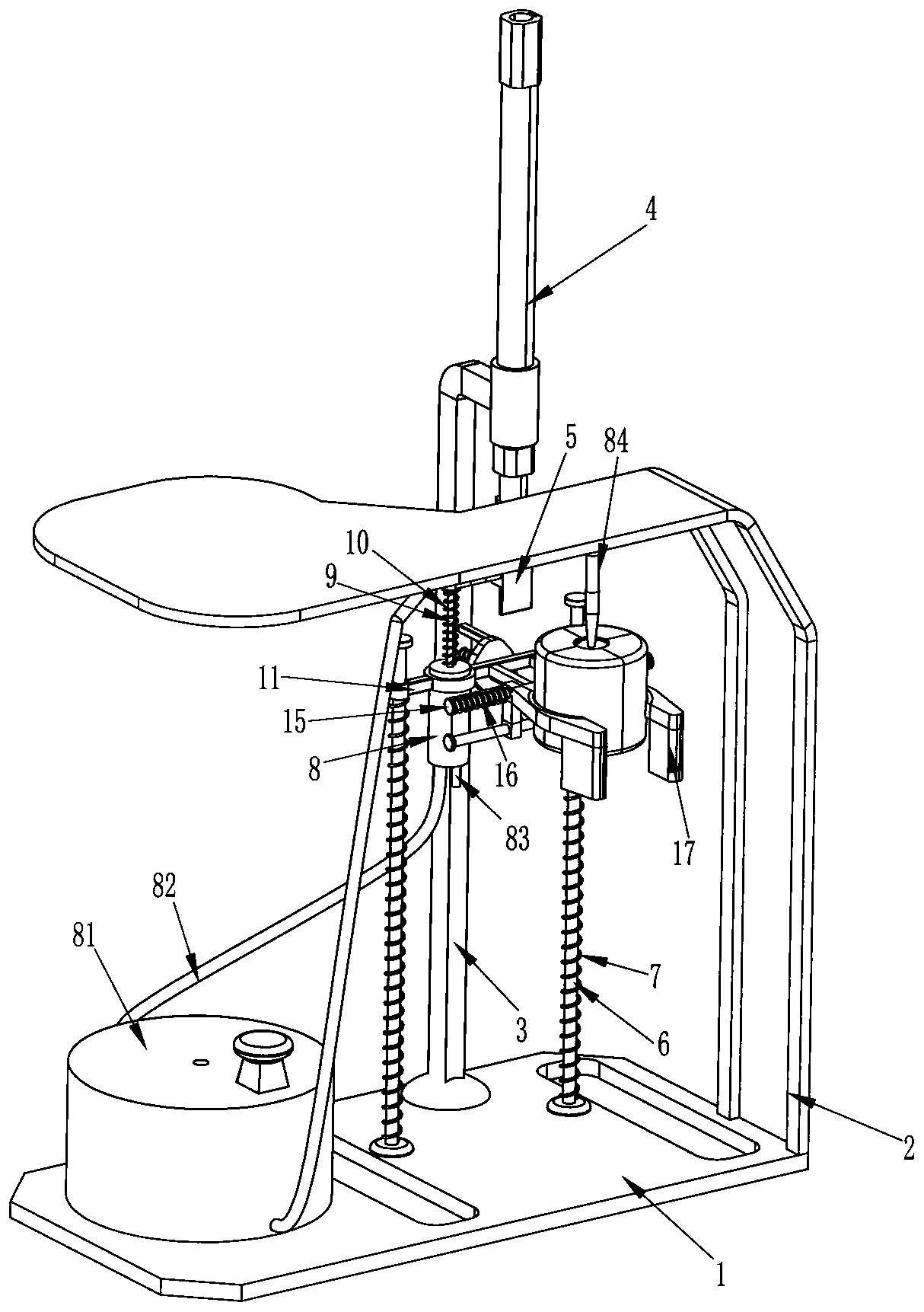

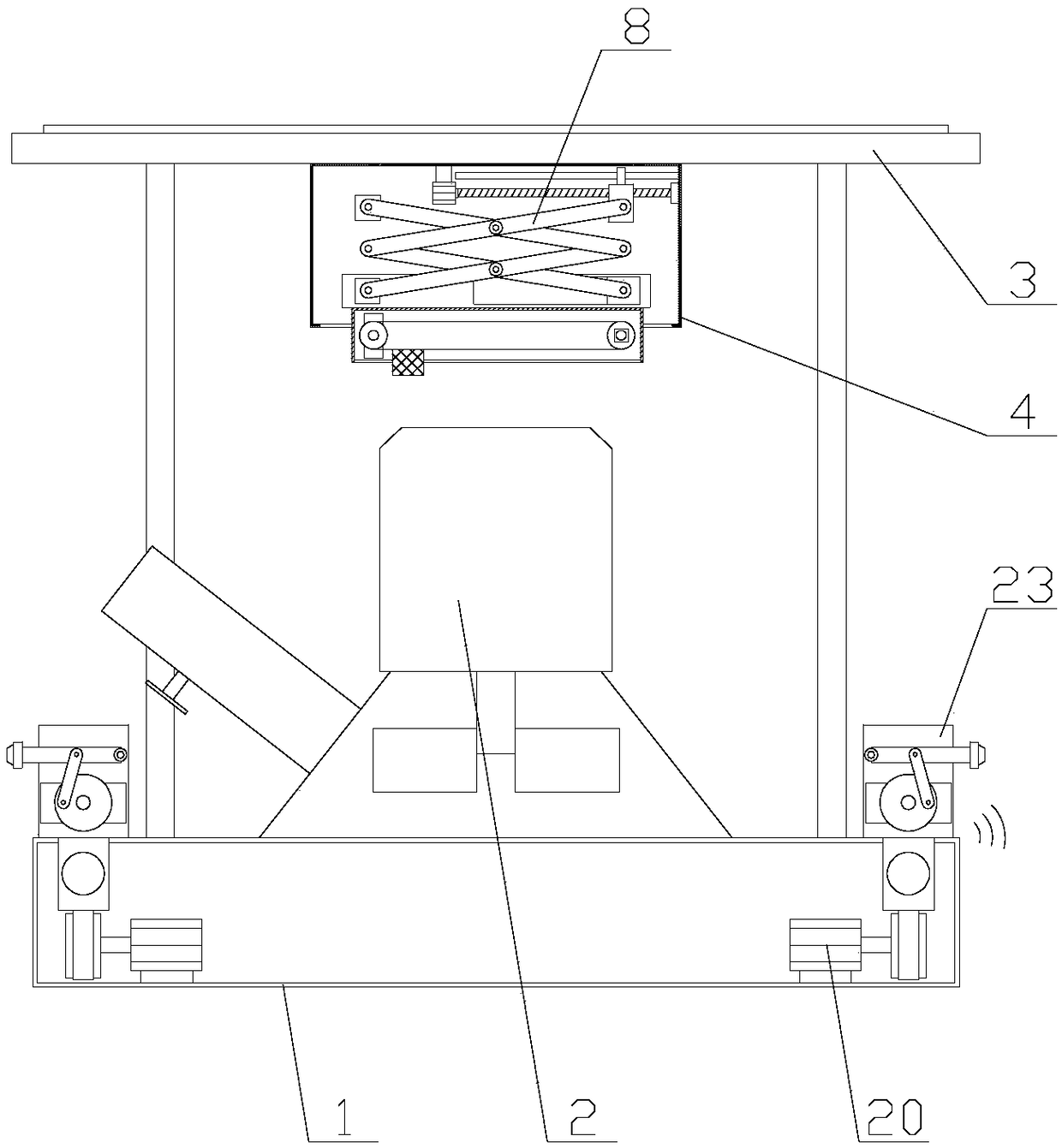

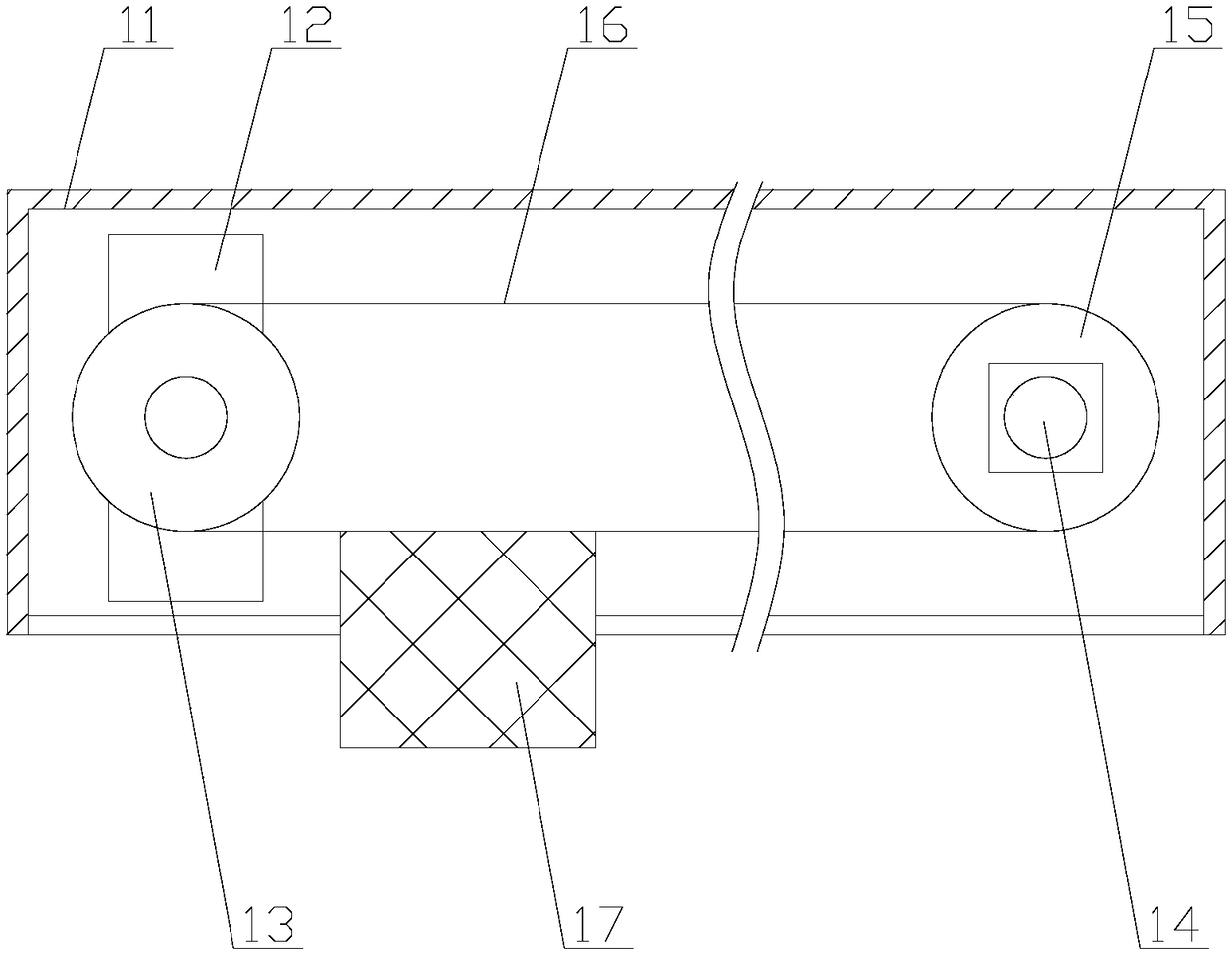

Kitchen knife grinding machine

ActiveCN109227239AAffect dischargeEasy to polishOther manufacturing equipments/toolsGrinding work supportsDrive motorIncised wound

The invention relates to a grinding machine, in particular to a kitchen knife grinding machine. The to-be-solved technical problem is to provide a more convenient kitchen knife grinding machine capable of replacing manual grinding of a kitchen knife, avoiding incised wound and spraying water onto the kitchen knife while the kitchen knife is grinded. The kitchen knife grinding machine comprises anL-shaped base, an n-shaped plate, a fastening bolt, a discharging hopper, a collecting frame, a guide sleeve, a transverse bar, a u-shaped plate, a transverse plate, a roller, a horizontal sliding block, a rack, a driving motor and the like; the right side of the inner bottom of the L-shaped base is provided with the collecting frame used for collecting water, the n-shaped plate is arranged at theleft side of the inner bottom of the L-shaped base, and the discharging hopper capable of discharging the water is fixedly connected to the middle of the inner top of the n-shaped plate. The kitchenknife grinding machine has the advantages that the kitchen knife is placed on the n-shaped plate to be in contact with grinding stone, and the driving motor is started, so that the grinding stone canmove left and right and move back and forth to grind the kitchen knife, and a person does not need to hold and continually move the kitchen knife for grinding, thereby avoiding the situation that grinding is affected due to the fact that the hand is cut.

Owner:嘉兴市迅程信息技术有限公司

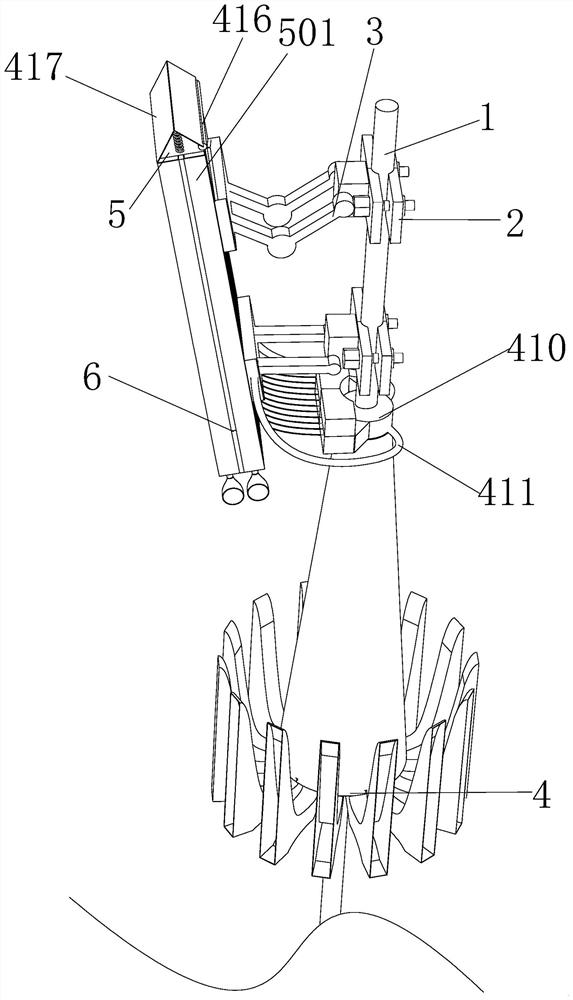

Rotary excavating drilling bucket pushing type deslagging noise reduction construction method

PendingCN114151034AAvoid strong collisionImprove slag removal effectEarth drilling toolsBorehole/well accessoriesNoise controlEnvironmental noise

The invention discloses a rotary excavating drilling bucket pushing type deslagging noise reduction construction method, belongs to the technical field of rotary excavating drilling buckets, and aims to solve the problems that when a rotary excavating drill encounters the condition that deslagging is difficult, a rotary excavating machinist usually operates a drilling bucket to rotate forwards and backwards alternately to impact and throw soil, or drilling slag in the drilling bucket is shaken out through an emergency brake measure in the rotating process, the whole deslagging process generates large noise, and the deslagging effect is poor. The noise of the surrounding environment severely exceeds the standard. The pressure-bearing disc on the upper portion of the drilling bucket is pushed downwards through the drilling machine power head, the pressure-bearing disc pushes the slag discharging plate arranged in the drilling bucket to move downwards through the dowel bar, and therefore slag adhering to the inner wall of the drilling bucket is completely pushed out; the pushing type drilling bucket is adopted for deslagging, deslagging can be completed only by lifting the drilling bucket to make contact with a power pressure plate of the rotary drilling machine to generate continuous pushing force, noise pollution in the deslagging process is greatly reduced, and the noise pollution is greatly reduced especially in a site with strict noise control. And the construction period delay loss caused by shutdown due to complaint caused by overlarge noise is effectively avoided.

Owner:SHENZHEN GONGKAN GEOTECHN GRP +1

Equipment for recovering precious metals from copper-containing sludge

The invention relates to the technical field of copper-containing sludge treatment, in particular to equipment for recovering precious metals from copper-containing sludge. The equipment comprises a bottom plate, wherein supporting legs are fixedly arranged at the four corners of the bottom end of the bottom plate; four telescopic rods are arranged at the top end of the bottom plate; base plates are fixedly arranged at the top ends of the telescopic rods; a reaction box is fixedly arranged at the top ends of the four base plates jointly; the four base plates are distributed on the periphery ofthe bottom end of the reaction box at equal intervals; and first springs sleeve the telescopic rods. Through continuous ascending and descending of the reaction box, internal sludge water and a sodium sulfide solvent react sufficiently, the sodium sulfide and the sludge water react more sufficiently in cooperation with stirring of stirring blades, so that copper ions are recycled more thoroughly,generated copper sulfide can be filtered, meanwhile, a filter screen is prevented from being blocked, filtering is prevented from being affected, a filter screen frame is convenient to mount and dismount, the interior of the reaction box is convenient to clean, and the equipment is worthy of application and popularization.

Owner:湘潭云萃环保技术有限公司

Metal powder treatment device for electronic product processing

The invention provides a metal powder treatment device for electronic product processing, and relates to the technical field of metal powder treatment. The metal powder treatment device for electronic product machining comprises a support, a telescopic base, a rotating device, an air supply device, a grinding mechanism and a cleaning mechanism, wherein the telescopic base is fixedly connected to the top end of the support, the rotating device is fixedly connected to the bottom end of the telescopic base, the air supply device is arranged at the bottom end of the right side of the support, the grinding mechanism is fixedly connected to the bottom end of the rotating device, the cleaning mechanism is arranged on the inner side of the middle of the support, and the top end of the cleaning mechanism is fixedly connected with the telescopic base. Metal powder blocks which are not completely smashed between a squeezing cylinder and a grinding groove can move through the grinding mechanism to accelerate the smashing effect on the metal powder blocks. The metal powder treatment device for electronic product machining solves the problem that since after metal powder blocks are squeezed and smashed, the metal powder is attached to the inner wall of a grinding groove and a squeezing smashing block, the metal powder is wasted.

Owner:荷兴电子科技(南通)有限公司

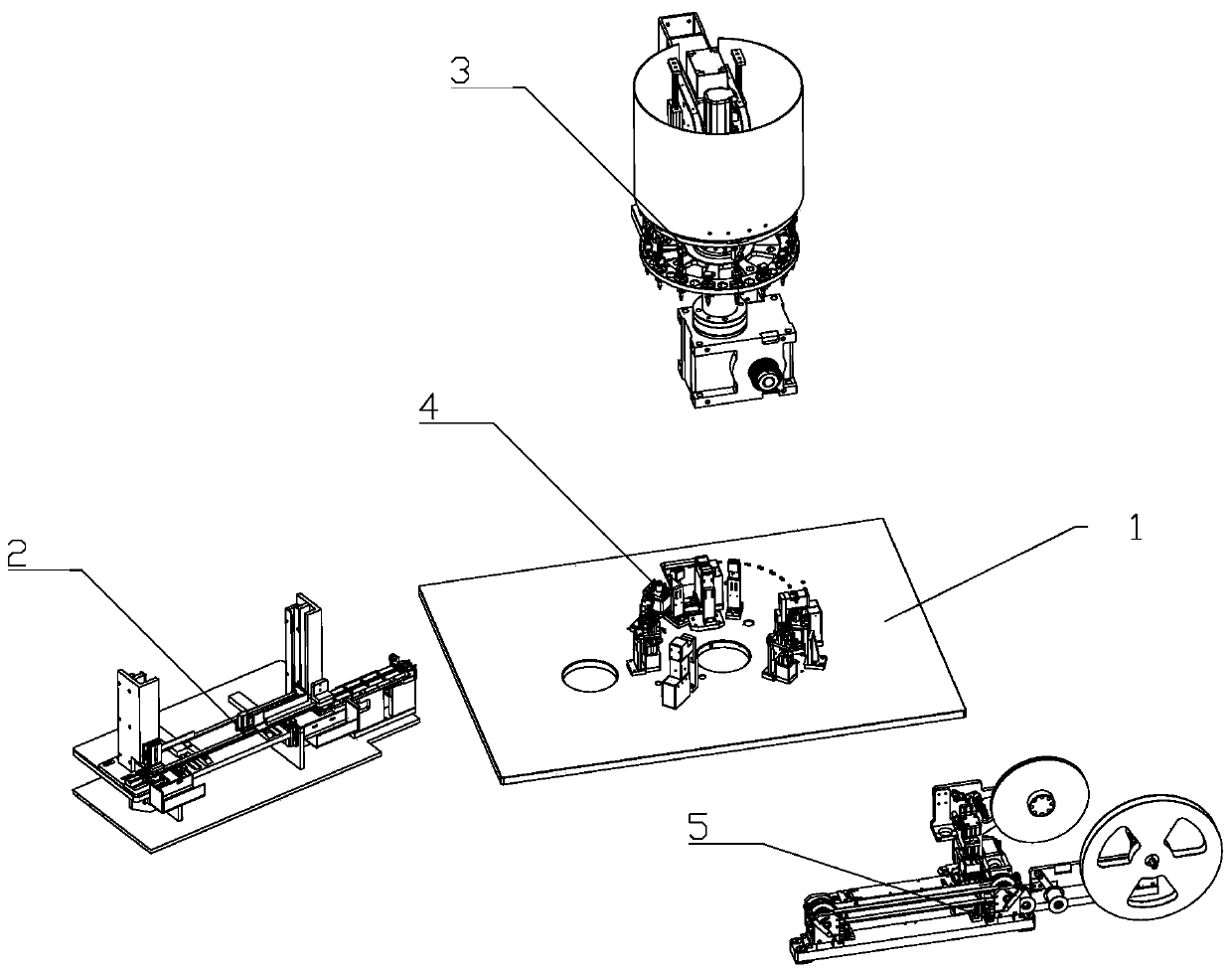

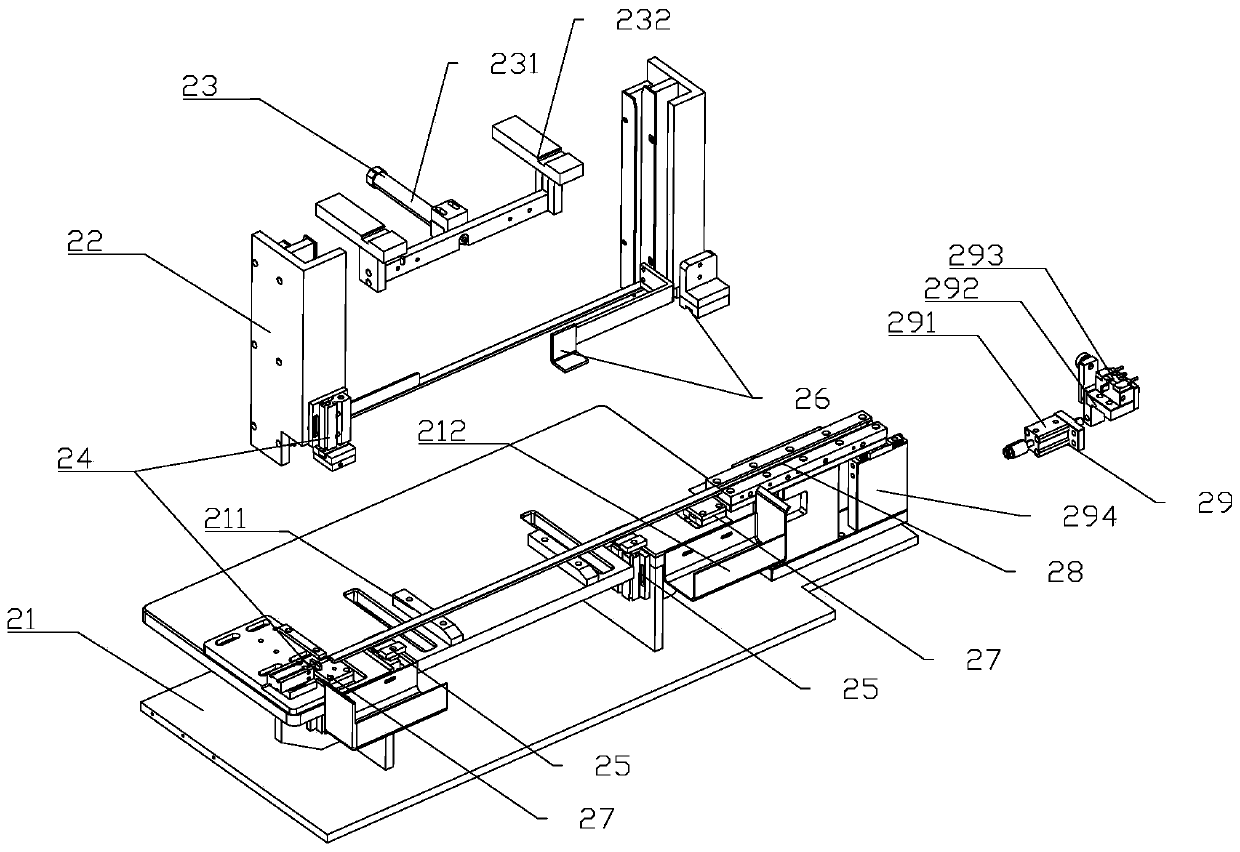

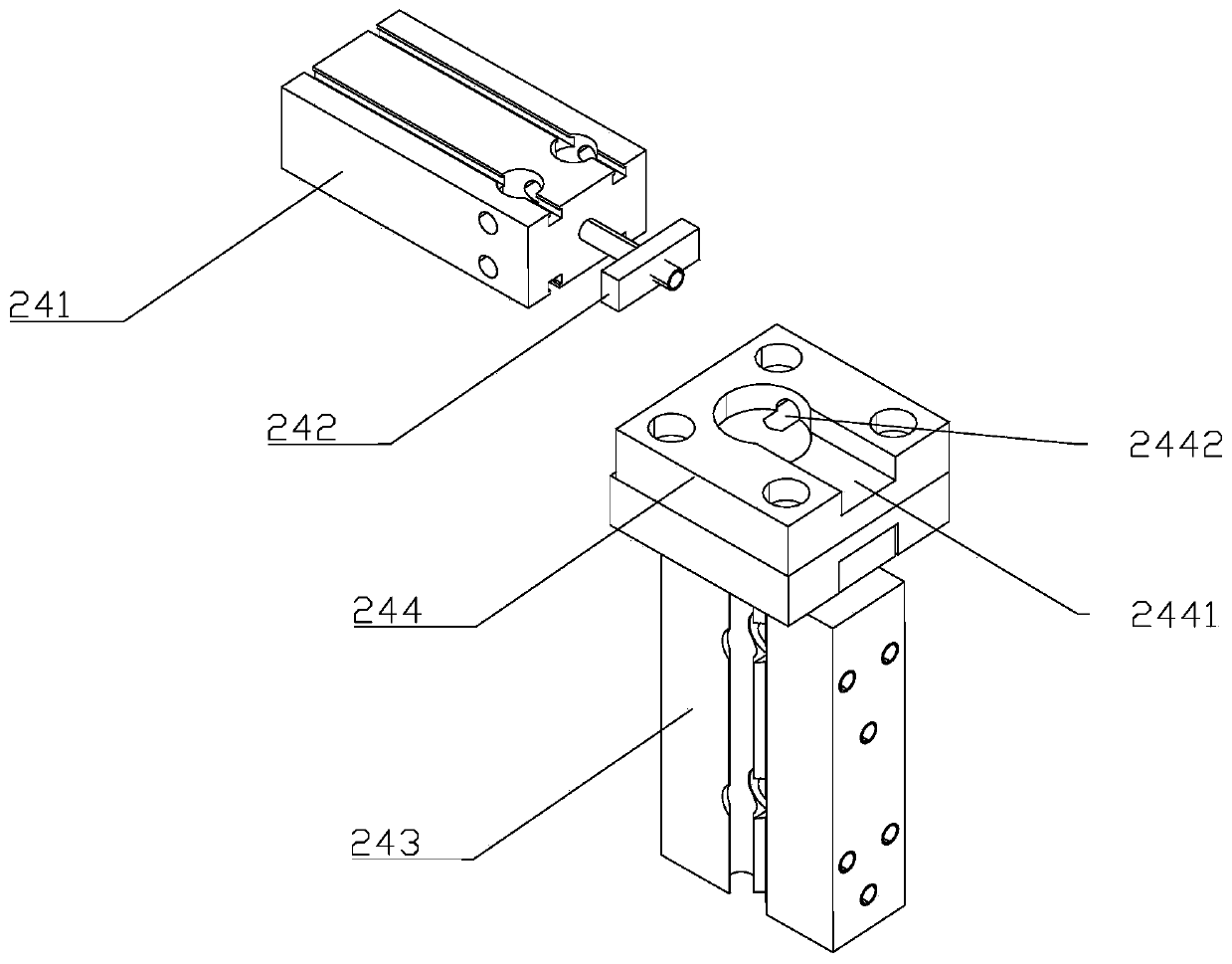

Inductive transporting device and method for inductive detecting packaging equipment

InactiveCN111348238AImprove handling efficiencyFast processingPackaging automatic controlElectric machineryEngineering

The invention relates to the technical field of inductive production. An inductive transporting device for inductive detecting packaging equipment comprises a cutter, a rotary disc, a sucking assembly, a bracket, a reduction motor, a lead screw assembly, a lifting ring, a pressing assembly, a light shield and a lifting gas cylinder. The inductive transporting device has the advantages of efficientinductive transporting, and matched and sequenced processing and transferring.

Owner:周俊英

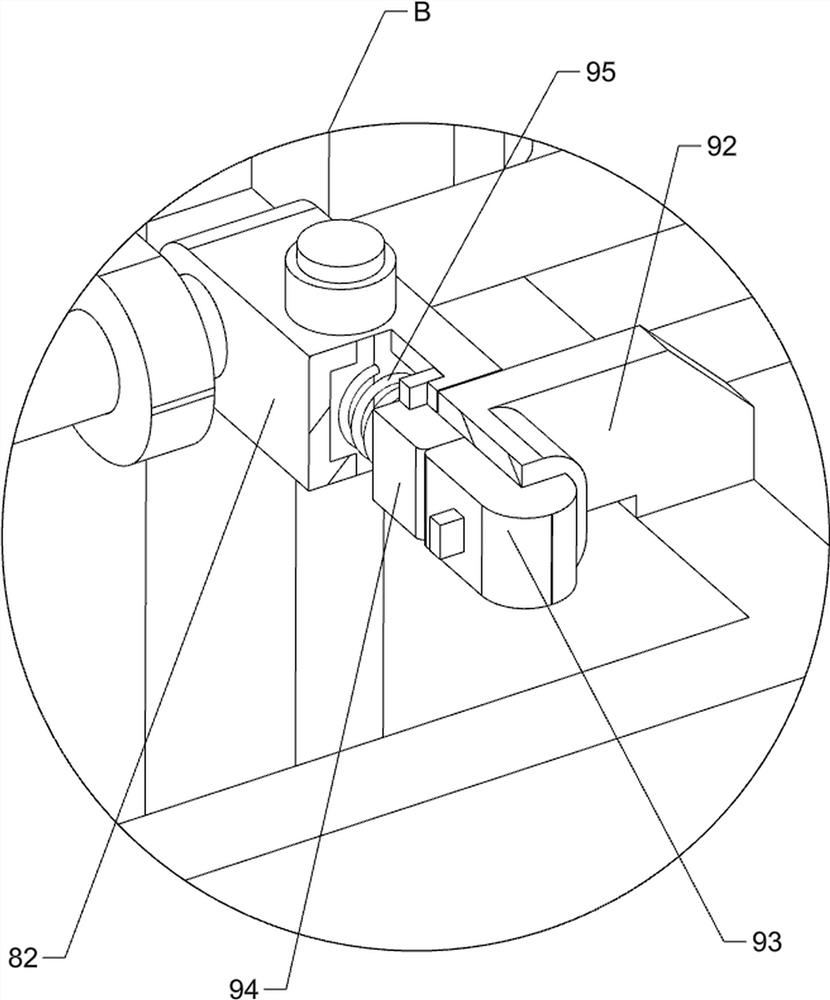

Interesting fish feeder for gardens

ActiveCN108967292AAvoid cloggingAffect dischargeClimate change adaptationPisciculture and aquariaEngineeringHandrail

The invention relates to a fish feeder, in particular to an interesting fish feeder for gardens and provides an interesting fish feeder for gardens to accurately feed fish at appointed positions. Theinteresting fish feeder comprises a container, a handle, a feeding pipe, a discharging pipe, a moving rod, a bearing seat, an arc plate and the like. The feeding pipe is connected to the right side ofthe top of the container and communicated with the interior of the container. The handle is mounted on the right outer lower portion of the container, the bottom middle of the container is connectedwith a hollow barrel which is communicated with the interior of the container, the right lower portion of the hollow barrel is provided with a through hole, and a retaining plate is arranged in the through hole. By placement of an arc plate on a handrail, the discharging pipe can be rotated to realize feeding at the appointed positions through the bearing seat, and the discharging pipe is long enough to feed fish far away. By a knocking device, the discharging pipe can be knocked to prevent fish feed blockage, interestingness can be improved, and tourists can enjoy feeding.

Owner:临沂高新城乡发展有限公司

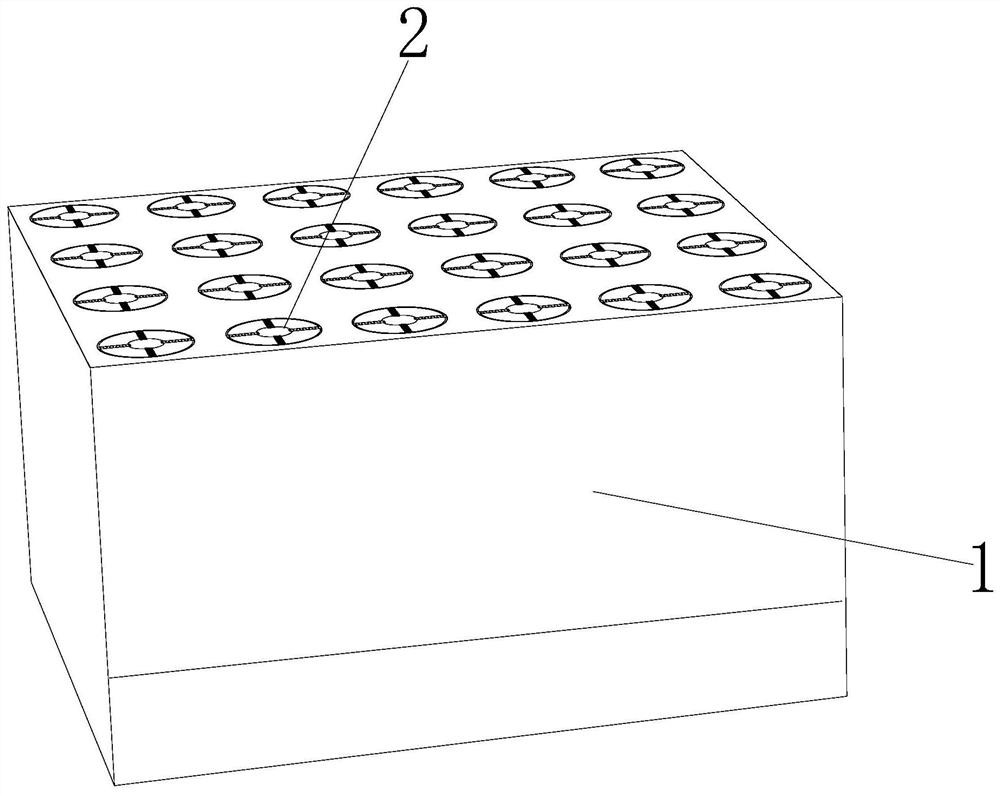

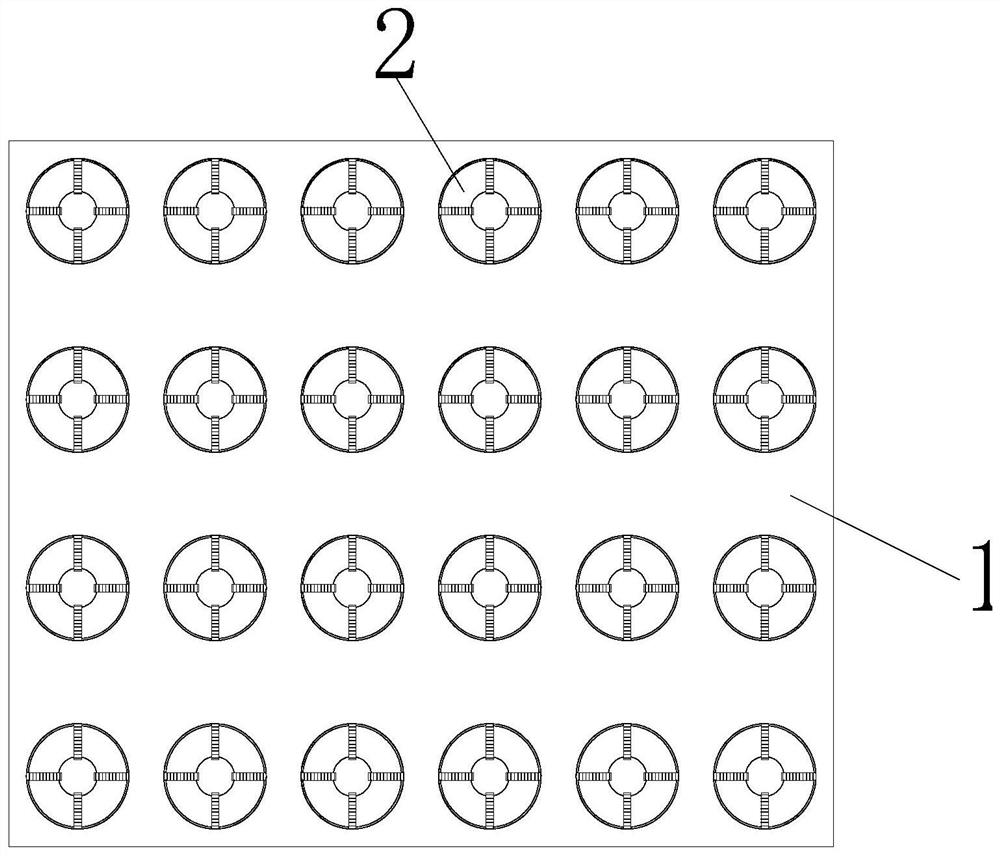

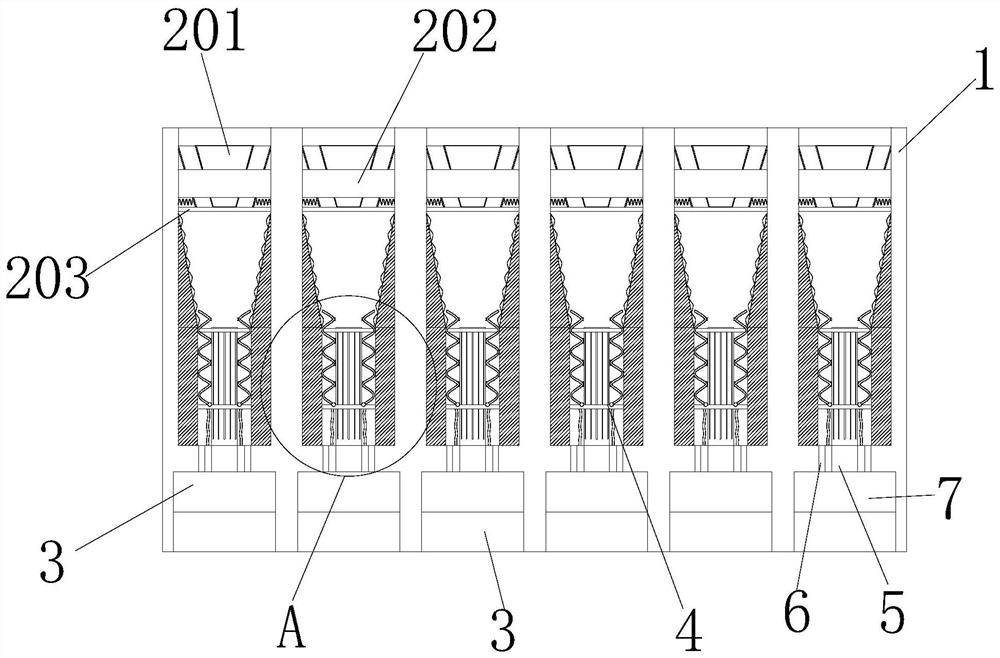

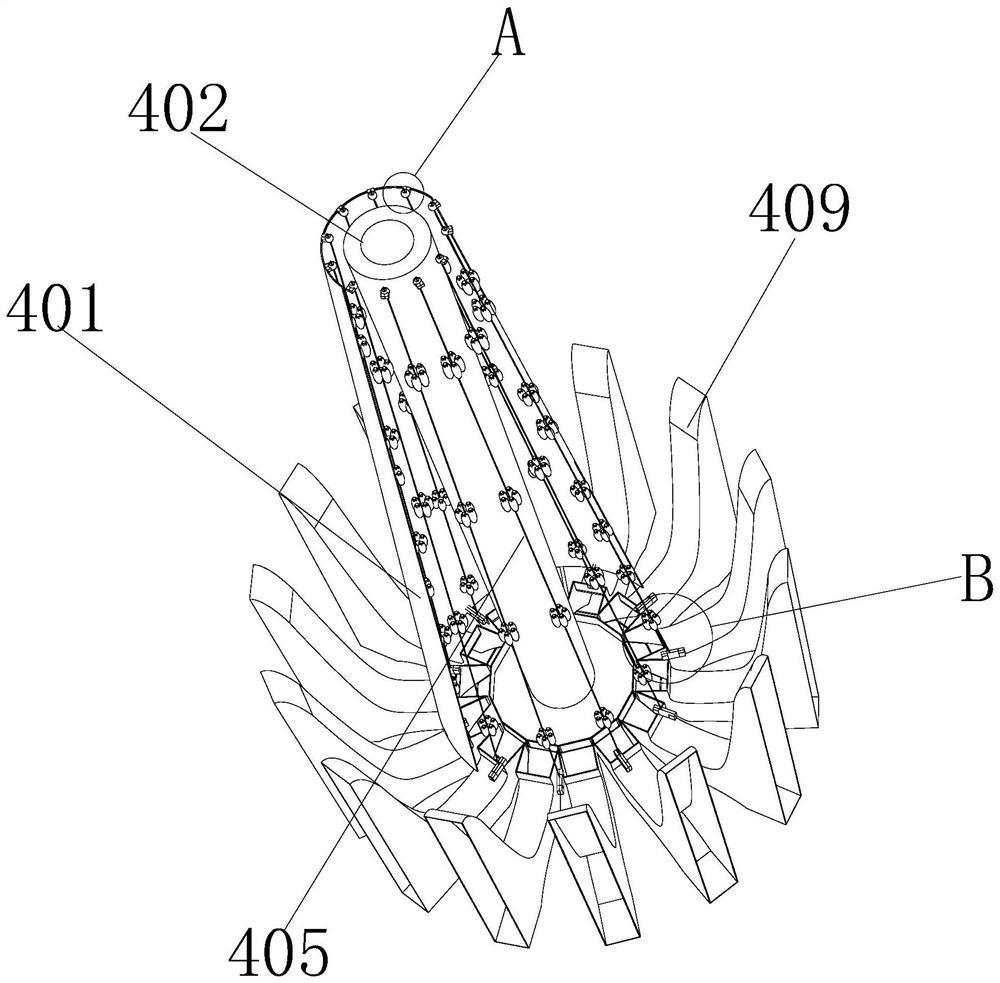

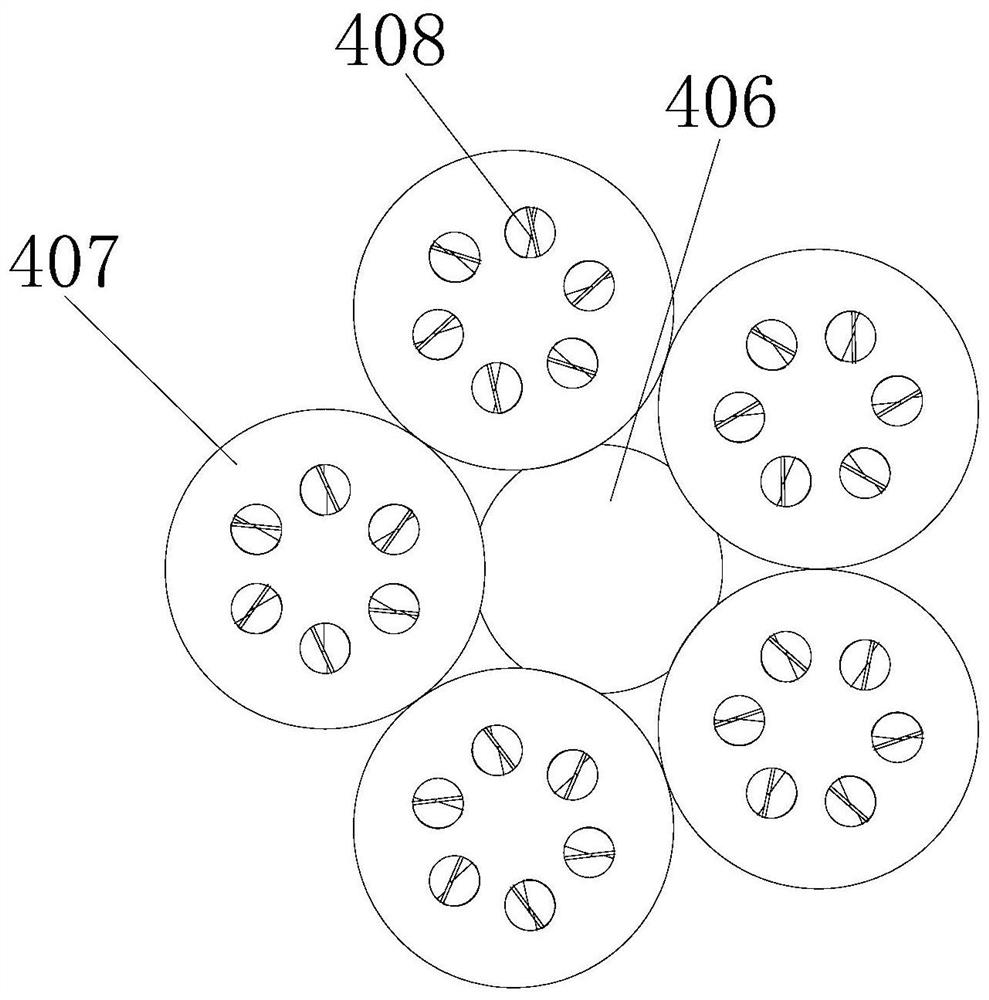

Corn stigma separating device for corn with husks

InactiveCN112970421AAffects the peeling effectAffect the separation effectHarvestersThreshersAgricultural scienceAgricultural engineering

The invention provides a corn stigma separating device for corn with husks, and relates to the technical field of corn processing. The corn stigma separating device for the corn with husks comprises a shell, fixing mechanisms, air supply devices, stigma removing mechanisms, exhaust pipes, air supply pipes and collecting boxes, wherein the fixing mechanisms are evenly arranged in the top end of the shell; the air supply devices are arranged at the bottom ends of the fixing mechanisms in the shell; the bottom ends of the air supply devices are fixedly connected with the bottom end of the shell; and the stigma removing mechanisms are arranged in the bottom ends of the fixing mechanisms. The stigma of the corn with husks is removed through the stigma removing mechanisms, the bottom ends of the fixing mechanisms are fixedly connected with the exhaust pipes and the air supply pipes, the bottom ends of the exhaust pipes and the bottom ends of the air supply pipes are fixedly connected with the top ends of the air supply devices, the collecting boxes are arranged at the top ends of the air supply devices, and the air supply pipes penetrate through the collecting boxes and are fixedly connected with the collecting boxes. The invention provides the corn stigma separating device for the corn with husks, and solves the problem that the efficiency is low when corn stigma separation is carried out on the corn with husks.

Owner:张彬

New energy household garbage odor treatment device

PendingCN112249554AAvoid breedingReduce lossRefuse receptaclesRefuse cleaningActivated carbonNew energy

The invention discloses a new energy household garbage odor treatment device. The new energy household garbage odor treatment device comprises a cavity formed in the ground, wherein a fixing plate isfixedly connected to the inner wall of the cavity; a barrel body is placed on the fixing plate; an inner barrel is placed in the barrel body; a pedal plate is slidably embedded in the fixing plate; aconnecting plate is fixedly connected to the lower side wall of the pedal plate; a limiting plate arranged on the outer wall of the connecting plate in a sleeving mode is fixedly connected to the lower side wall of the fixing plate; a telescopic spring is fixedly connected between the limiting plate and the pedal plate; an air suction pipe is fixed in the cavity; a piston plate is slidably arranged in the air suction pipe; and an air outlet pipe is connected between the upper end of the air suction pipe and the barrel body. According to the new energy household garbage odor treatment device, suction type movement is realized through walking of pedestrians and vehicles, odor in the barrel body is sucked out and adsorbed through an activated carbon bag, so that the surrounding environment isprotected, energy generated when the pedestrians and the vehicles walk is converted into electric energy to be stored and utilized, and the loss of energy is reduced.

Owner:李玉成

Waste plastic recycling, screening and pelleting device

InactiveCN111844551AHigh tensile heightAffect dischargePlastic recyclingWeighing apparatus for materials with special property/formWinding machineElectric machinery

The invention discloses a waste plastic recycling, screening and pelleting device, and belongs to the technical field of reprocessed plastics. The waste plastic recycling, screening and pelleting device comprises a separating device, a conveying device and a reaction still. The reaction still comprises a still body, a heating pipe, a feeding bin, a top cover, a stirrer, a metal net, a first metalpull rope, a second metal pull rope, a first winding machine, a second winding machine, a valve, a metal material outlet, a still body support, a stirring motor and two weight measuring scales. Due tothe fact that certain metal objects exist in waste plastics possibly, the overall weight of the reaction still is monitored in real time through the two weight measuring scales; when the weight is too high, the first winding machine and the second winding machine work, the metal net is raised through the first metal pull rope and the second metal pull rope, the stretching height of the first metal pull rope is larger than that of the second metal pull rope, and at this moment, an inclined face is formed by the metal net; and the metal objects are discharged out of a metal discharging port, and the technical problem that when the waste plastics are subjected to a pelleting procedure in the prior art, the metal objects are doped is avoided.

Owner:航仟源科技(杭州)有限公司

Ceramic mold uniform grouting frame

The invention relates to a grouting frame, in particular to a ceramic mold uniform grouting frame. The technical problem is how to design the ceramic mold uniform grouting frame which can replace manpower to fill a mold with slurry and is convenient to operate and high in working efficiency. The ceramic mold uniform grouting frame comprises a base, wherein a rack is fixedly connected to the edge of one side of the base, the rack is in an L shape, a supporting rod is mounted on one side of the base and is close to the rack, and an air cylinder is vertically mounted at the tail end of the supporting rod. According to the grouting frame, the slurry is poured into a charging box, then the mold is moved to the potion between clamping blocks on two sides to be clamped and fixed, a telescopic rodof the starting air cylinder is stretched, and a proper amount of slurry is sprayed into the mold through a slurry spraying pipe. Meanwhile, the clamping blocks drive the mold loaded with the slurryto move downwards, and the slurry does not need to be poured into the mold manually, so that operation is convenient, and the working efficiency is high.

Owner:DEHUA COUNTY LIDE HOUSEHOLD ARTICLE CO LTD

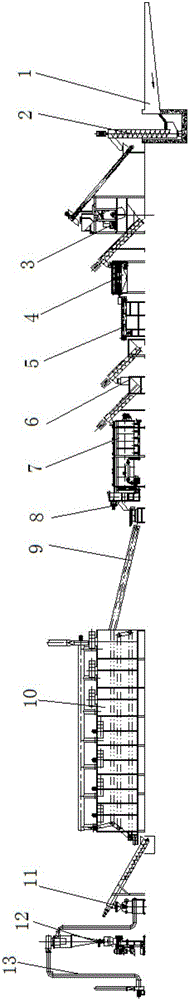

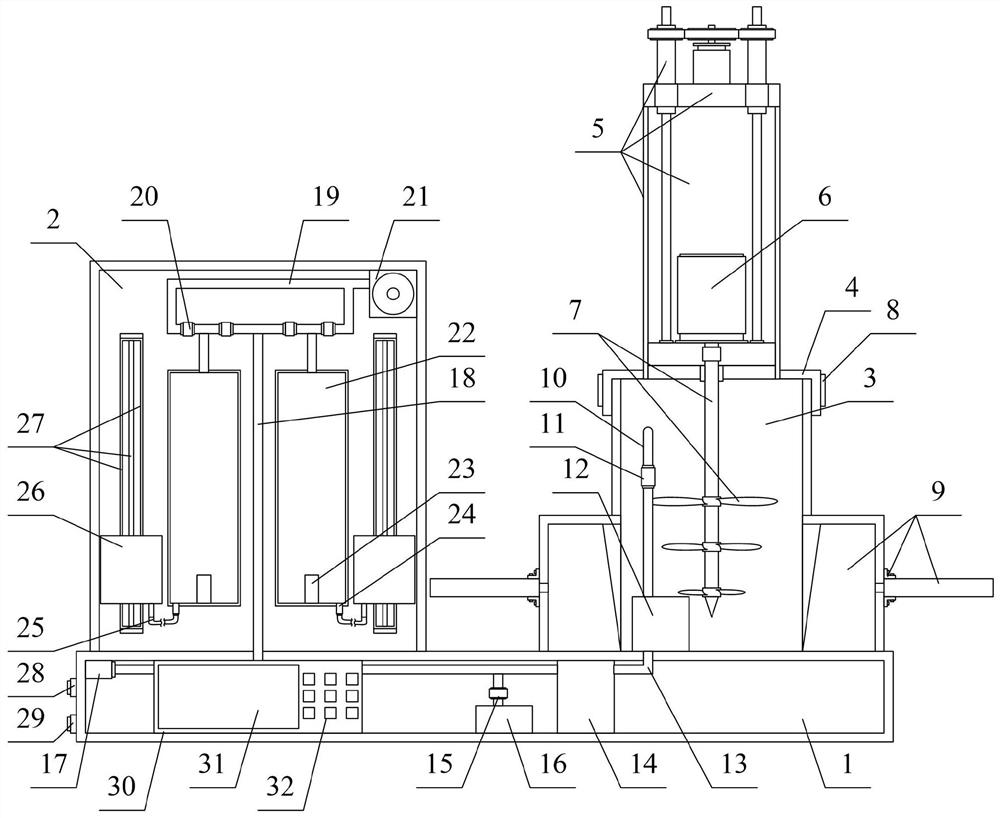

Complete production equipment for whole potato flour

PendingCN105831654AWithout destroying nutritional flavorAvoid sticking to each otherFood scienceProcess engineeringFood science

The invention discloses complete production equipment for whole potato flour. The complete production equipment sequentially comprises a potato raw material cleaning system, steam peeling equipment, trimming equipment, a dicer, a bleacher, draining equipment, low-temperature drying equipment, flour milling equipment and a packaging machine, wherein the equipment is connected through elevating conveying equipment; the produced whole potato flour is conveyed to the weighing packaging machine for product packaging after being screened by the flour milling equipment through an air conveying system. According to the complete production equipment, high-temperature bursting treatment is performed on peel of potatoes in a steam peeling manner, so that the potatoes can be rapidly peeled; potato dices are bleached by the bleacher, so that oxidase on the surfaces of the potato dices can be inactivated, the phenomenon that the surfaces of the potato dices are browned to influence the color and cluster of the produced flour can be prevented, and a whole potato flour product is kept white-yellow; the low-temperature drying equipment is adopted, so that low-cost drying can be implemented, and peculiar nutrient substances of potatoes are preserved in the produced whole flour.

Owner:CHINA NAT PACKAGING & FOOD MACHINERY

Waste paper pulp manufacturing device

InactiveCN113215845AAffects the crushing effectAffect dischargePaper recyclingRaw material divisionCartonPapermaking

The invention provides a waste paper pulp manufacturing device, belonging to the technical field of papermaking. The waste paper pulp manufacturing device comprises a stirring box, a base, a driving motor, an air extractor, a connecting box, a first filtering mechanism, a second filtering mechanism, a discharging opening and an air supply pump, wherein the base is fixedly connected to the bottom end of the stirring box; the driving motor is arranged at the bottom end of the stirring box; the air extractor is fixedly connected to the top end of the driving motor; the connecting box is fixedly connected to the top end of the air extractor; the top end of the connecting box is fixedly connected with the first filtering mechanism; the first filtering mechanism is rotationally connected with the bottom end of the stirring box; the bottom end of the first filtering mechanism is fixedly connected with the second filtering mechanism and used for filtering out staples doped in paper pulp; and the left side of the bottom end of the connecting box is fixedly connected with the discharging opening. The waste paper pulp manufacturing device provided by the invention overcomes the problem that too many staples are doped in paper pulp formed by smashing a book carton.

Owner:王子祥

Hydroelectric generation apparatus with cleaning function

InactiveCN108979935AWith cleaning functionExtended service lifeHydro energy generationMachines/enginesEngineeringImpurity

The invention relates to a hydroelectric generation apparatus with a cleaning function, comprising a base, a power generator and a top plate, as well as a cleaning mechanism and expelling mechanisms.The cleaning mechanism includes a lifting component and a cleaning component; the lifting component includes a housing and a telescopic unit; the cleaning component includes a driving chamber and a cleaning unit. Each expelling mechanism includes a moving component and a spraying component. The cleaning mechanism herein can clean impurities on air holes, thereby preventing influence upon interiorheat dissipation due to air hole blocking; damage of a hydroelectric generator due to high temperature is avoided, the service life of the hydroelectric generator is extended. The expelling mechanismsallow nozzles to spray water columns to animals for expelling, damage to the hydroelectric generation apparatus due to the approaching animals is prevented, normal delivery of power is guaranteed, and the hydroelectric generation apparatus is more practical and functional.

Owner:SHENZHEN BEIYOUTONG NEW ENERGY TECH DEV CO LTD

Steel ingot forging and compacting device and using method thereof

ActiveCN113070430AImplement flipping movementIncrease the level of automationUpsetting pressesSwagging pressesHydraulic cylinderEngineering

The invention discloses a steel ingot forging and compacting device and a using method thereof, and belongs to the technical field of steel ingot forging. The steel ingot forging and compacting device comprises a forging table, a movable groove is formed in the outer wall of the forging table, a square frame is connected to the inner wall of the movable groove, four brackets are connected to the top of the square frame, arc-shaped grooves are formed in the outer walls of the four brackets, fixing rods are movably connected to the inner walls of the arc-shaped grooves, and connecting rods are connected to the outer walls of the fixing rods. The end, away from each fixing rod, of the corresponding connecting rod is connected with an objective table, a shell is connected between the square frame and the bottom wall of the movable groove, a jacking mechanism is arranged in the shell and connected with the bottom wall of the objective table, annular grooves are formed in the outer walls of every two adjacent brackets, and a first groove is formed in the forging table. Through cooperation of the objective table and a hydraulic cylinder, overturning and moving of the steel ingot are achieved, the automation level of steel ingot forging is improved, the complexity of the forging device is reduced, and therefore the forging cost is saved.

Owner:HANGZHOU STEAM TURBINE CASTING & FORGING

A waste rubber regeneration device

The invention belongs to the technical field of regenerated rubber, and specifically relates to a waste rubber regeneration device, which includes a desulfurization tank; a waste gas pipe is provided on the side wall of the desulfurization tank; the waste gas pipe is L-shaped, and the bottom end of the waste gas pipe is fixed There is a filter box; the bottom end of the filter box is connected to a slurry tank through a connecting pipe; the inside of the slurry box is limestone slurry, and the connecting pipe extends into the slurry; a conical filter is provided in the filter box, and the tip of the cone faces Above; the present invention provides a waste rubber regeneration device to solve the problem that a large amount of waste gas will be generated when using a desulfurization tank to regenerate waste rubber. The waste gas contains rubber powder particles and organic pollutants. Particles and organic pollutants are removed, but after the colloidal particles are removed with clean water, the exhaust gas will carry a large amount of water into the slurry tank, which will affect the concentration in the slurry tank, affect the removal of organic pollutants, and cause the exhaust gas to fail to meet the standard. The problem of the surrounding environment.

Owner:徐州托普新材料有限公司

Coal mine underground coal seam gas content automatic measuring device

ActiveCN113008729AEasy to placeEasy to installPreparing sample for investigationFuel testingGraduated cylinderHolding tank

The invention provides a coal mine underground coal seam gas content automatic measuring device which comprises a first mounting shell, a second mounting shell, a coal sample tank, a tank cover, a supportable lifting seat structure, an anti-explosion high-speed motor, a rotary crushing frame structure, an anti-skid pad, an auxiliary gathering crushing seat structure, a first conveying pipe, a first electromagnetic valve, a gas-solid separator and a second conveying pipe. The device comprises a methane concentration sensor, a second electromagnetic valve, an intelligent flowmeter, a first gas pressure sensor, a third conveying pipe, a fourth conveying pipe, a third electromagnetic valve, an anti-explosion vacuum pump, a measuring cylinder, a liquid pressure sensor, a fourth electromagnetic valve, a rubber hose, a storage tank, a rodless cylinder, a second gas pressure sensor, a temperature sensor, a PLC, a control panel and an operation switch. The device has the beneficial effects that through the arrangement of the supportable lifting seat structure, the rotary crushing frame structure can conveniently ascend from the interior of the coal sample tank, and large samples can be conveniently placed and measured.

Owner:TAIAN SUCCEED ELECTRONICS SCI & TECH

Airflow self-guiding communication base station

InactiveCN113596608ATimely maintenanceAffect cleaning effectSelection arrangementsSnow removalSnowpack

The invention provides an airflow self-guiding communication base station, and relates to the technical field of communication. The airflow self-guiding communication base station comprises a supporting rod, a fixing frame, a hinge, a snow removing mechanism, a communication device and anti-freezing mechanisms, wherein the fixing frame is fixedly connected to the position, close to the bottom end, of the supporting rod; the hinge is fixedly connected to the left side of the fixing frame; the snow removing mechanism is arranged below the fixing frame on the supporting rod; the communication device is arranged above the left side of the snow removing mechanism; the communication device is fixedly connected with the hinge; and the anti-freezing mechanisms are fixedly connected to the two sides of the communication device. The snow removing mechanism prevents snow from being accumulated at the top end of the communication device to cause the snow to be melted to freeze the outer side of the communication device, and the anti-freezing mechanisms prevent the side face of the communication device from being frozen. The invention provides an airflow self-guiding communication base station, and solves the problem that a thick ice layer on the outer side of a communication device affects timely maintenance of the communication device in winter.

Owner:陈杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com