Equipment for recovering precious metals from copper-containing sludge

A precious metal and copper sludge technology, applied in the direction of improving process efficiency, etc., can solve problems that affect the recovery effect of copper ions, filter blockage, and sludge that cannot be smoothly filtered during the filtration process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

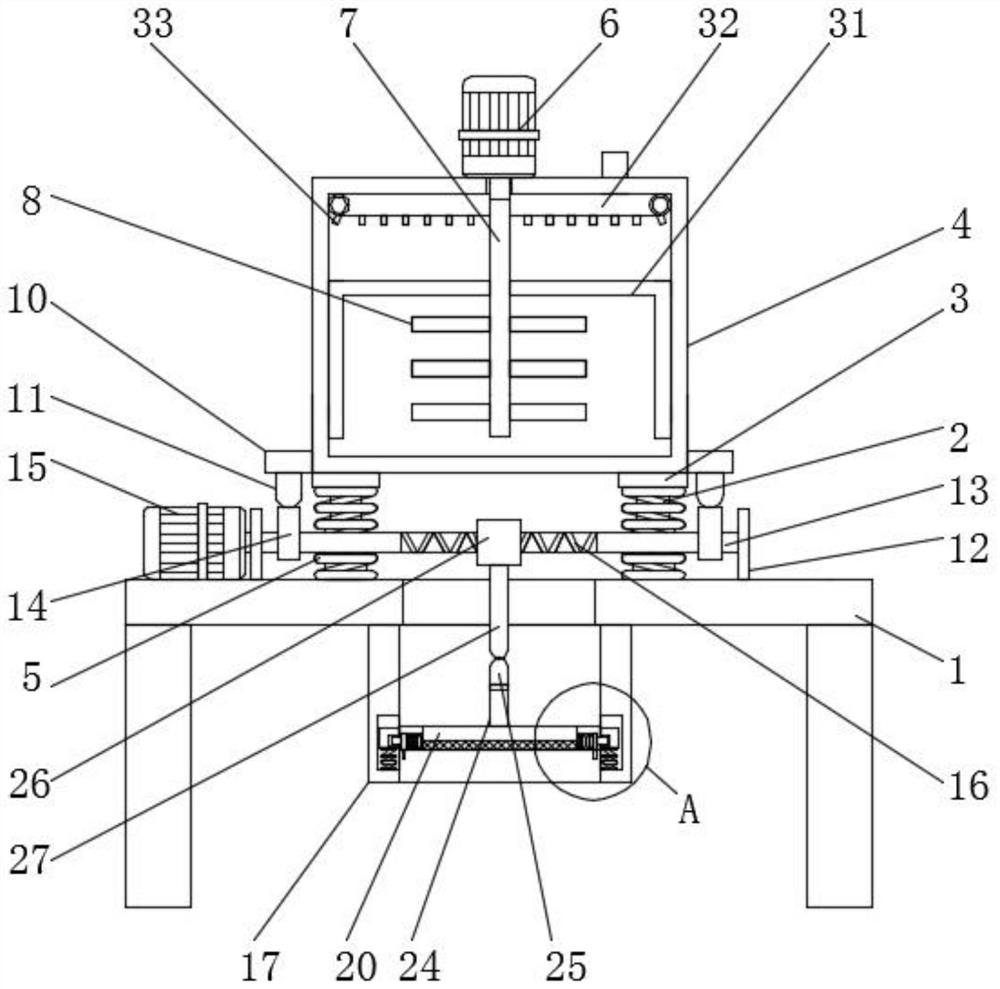

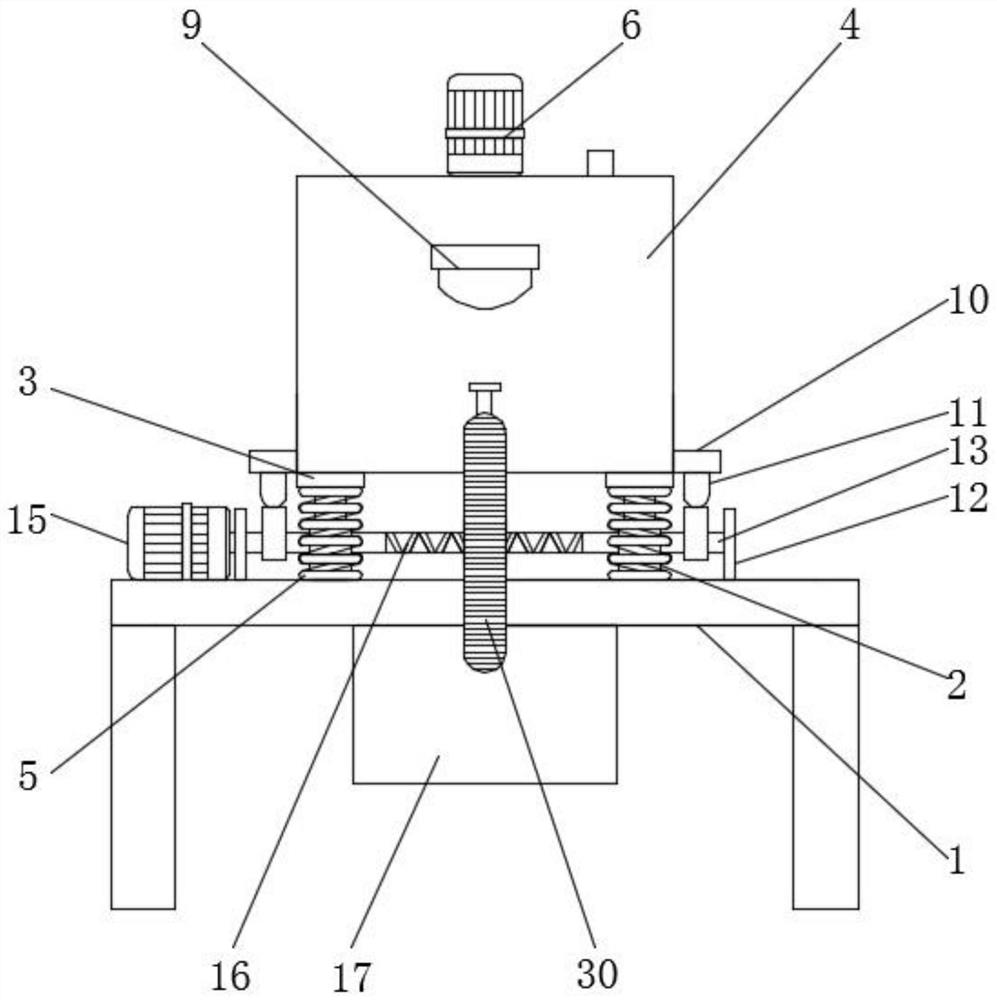

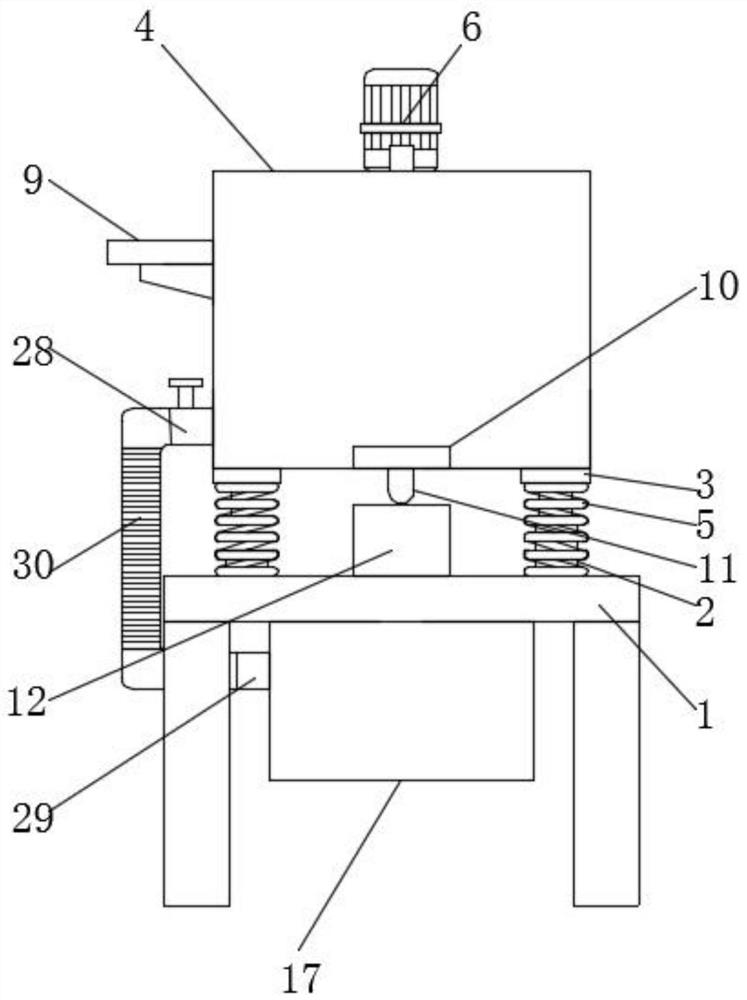

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0027] refer to Figure 1-7 A device for recovering precious metals from copper-containing sludge, comprising a bottom plate 1, the four corners of the bottom end of the bottom plate 1 are fixedly equipped with support legs, the top of the bottom plate 1 is provided with four telescopic rods 2, and the top of the telescopic rods 2 is fixedly installed with Backing plate 3, the tops of four backing plates 3 are jointly fixedly installed with reaction box 4, and four backing plates 3 are equidistantly distributed around the bottom of reaction box 4, and the outer casing of telescopic rod 2 is provided with first spring 5, and the first The two ends of the spring 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com