Inductive transporting device and method for inductive detecting packaging equipment

A technology for handling devices and packaging equipment, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of complex methods, difficult to grip, time-consuming connection, etc., to achieve the effect of high switching speed, improving efficiency and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

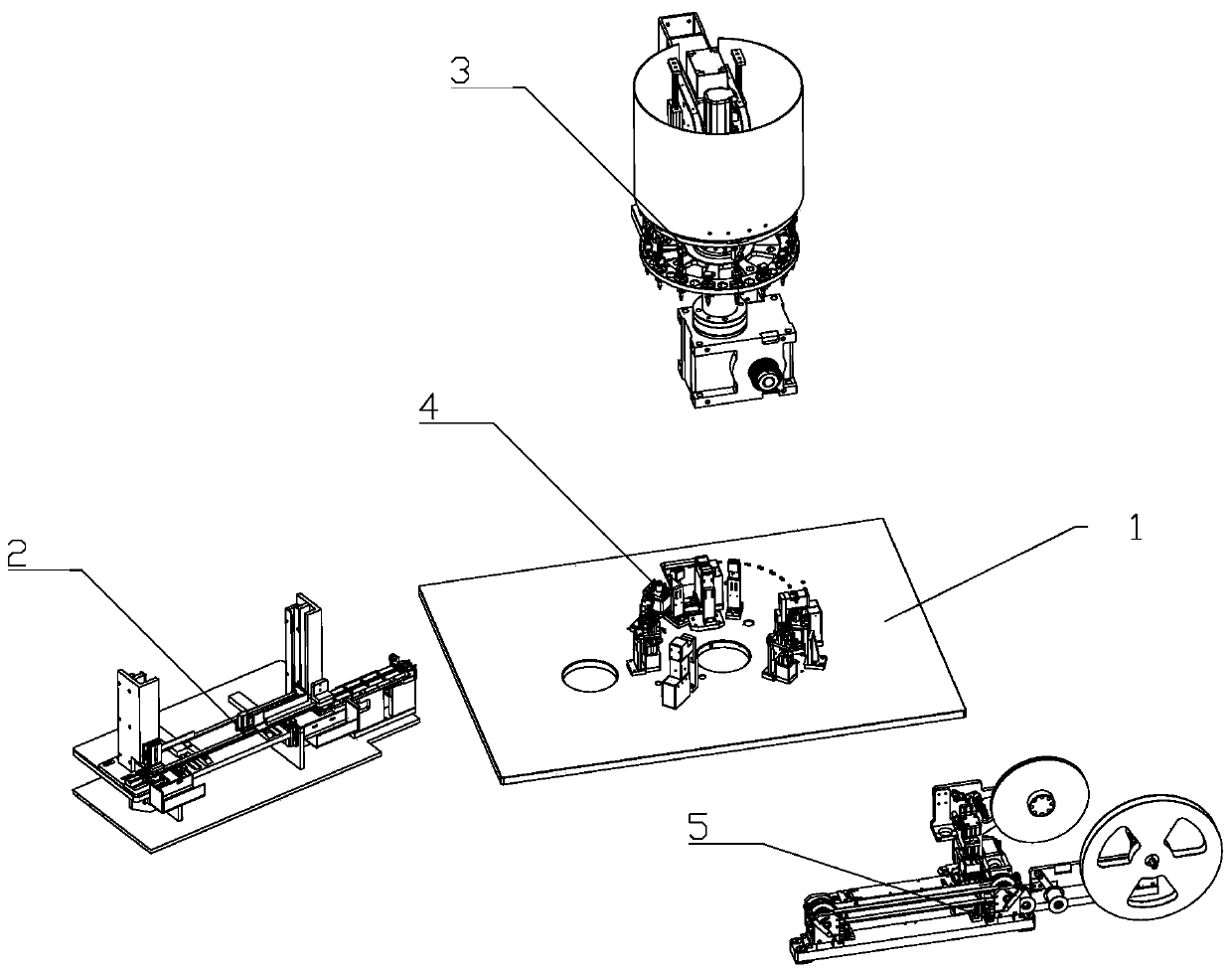

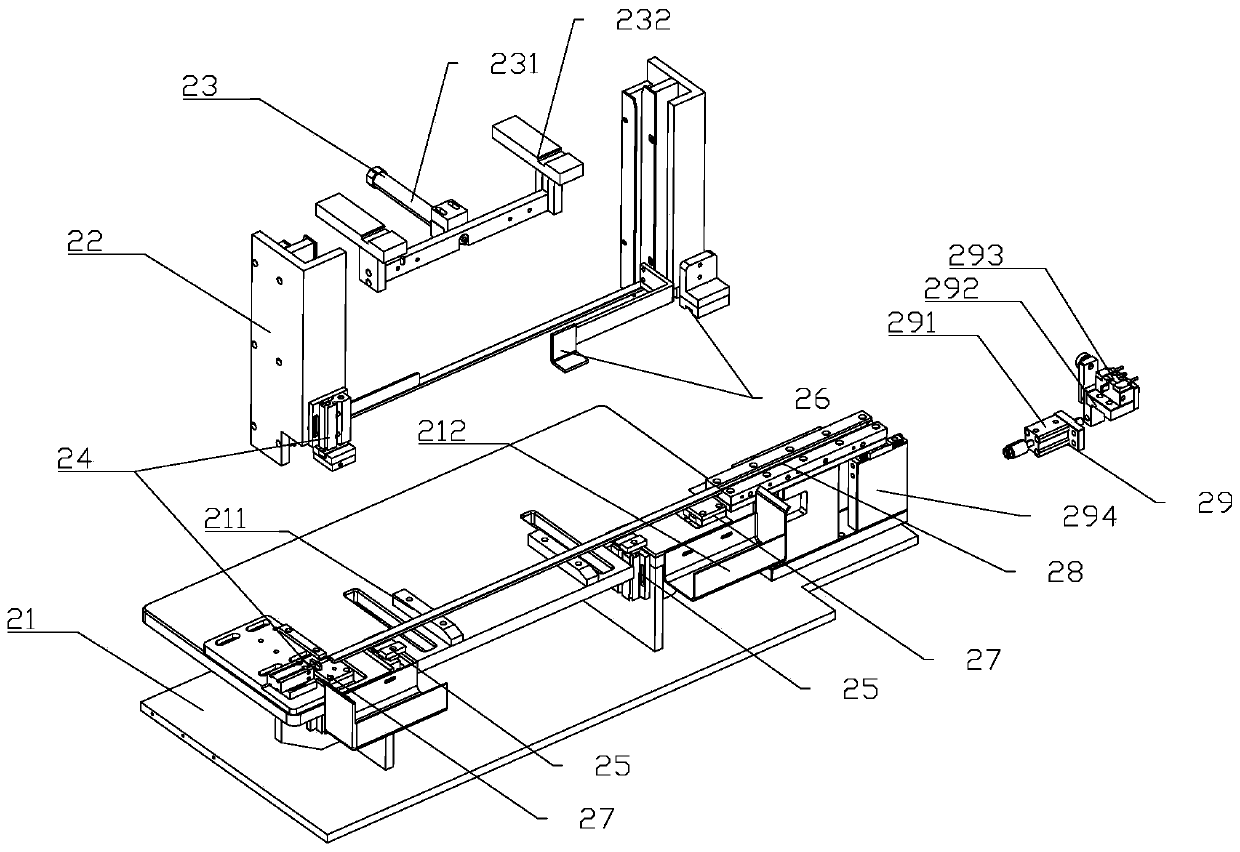

[0026] Such as figure 1 As shown, a detection and packaging equipment, including a frame 1 and an inductive feeding device 2 installed on the frame 1, an inductive handling device 3, a ring processing device 4 and an inductive tape braiding device 5; the inductive handling device 3 It is arranged in the middle of the frame 1, the ring processing device 4 is located below the induction conveying device 3, and the induction feeding device 2 and the induction tape braiding device 5 correspond to the sides of the induction conveying device 3.

[0027] The inductance feeding device 2 is used to realize the feeding of the inductance elements arranged in the magazine; the inductance handling device 3 is used to carry the inductance, and the ring processing device 4 is used to process the inductance accordingly. The inductance taping device 5 is used to realize blanking of the inductance after detection and sorting. The above-mentioned inductance conveying device 3 is an inductance c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com