Coal mine underground coal seam gas content automatic measuring device

A coal seam gas and measuring device technology, applied in the direction of measuring devices, fuel oil testing, test sample preparation, etc., can solve the problems of poor crushing effect, inconvenient placement of samples, and easy residue of large samples, etc., to achieve easy disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

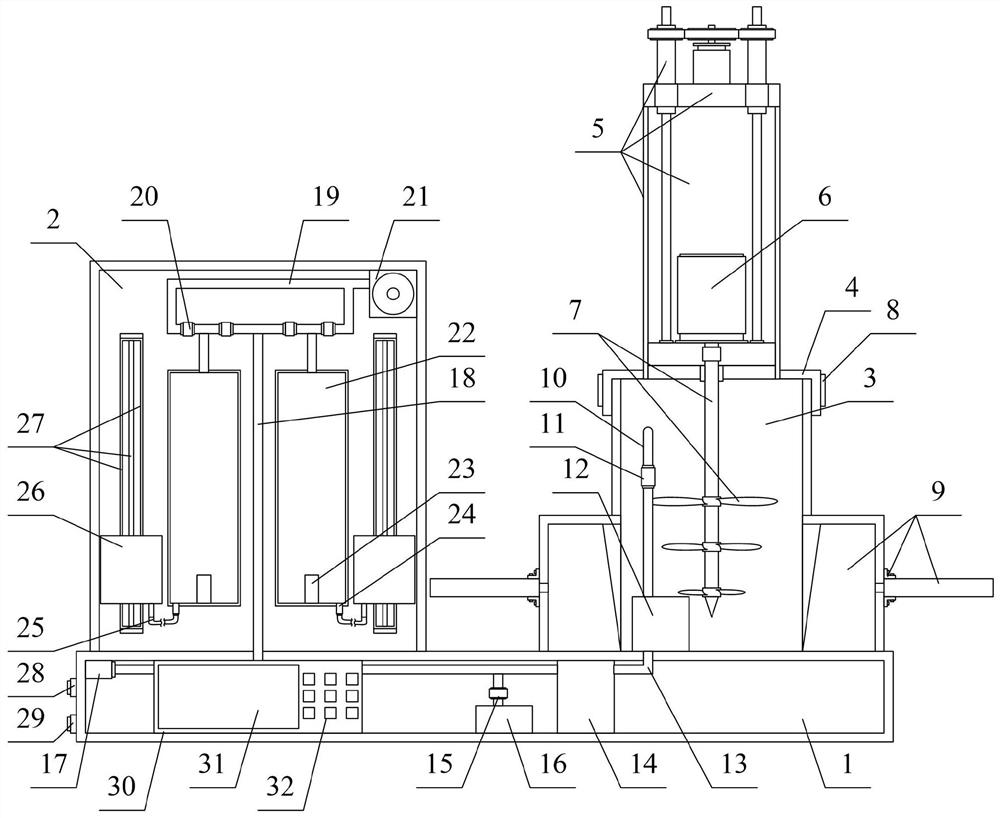

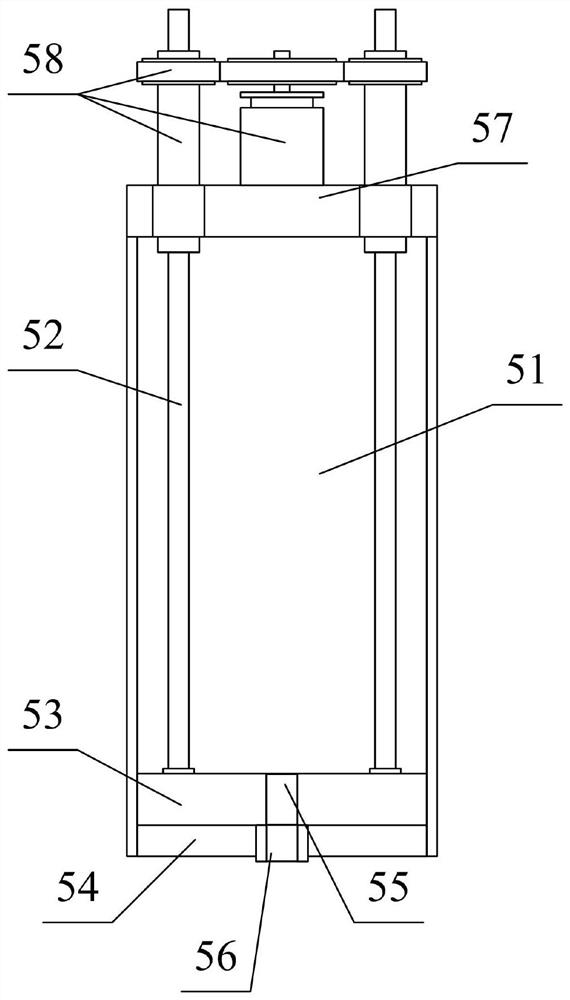

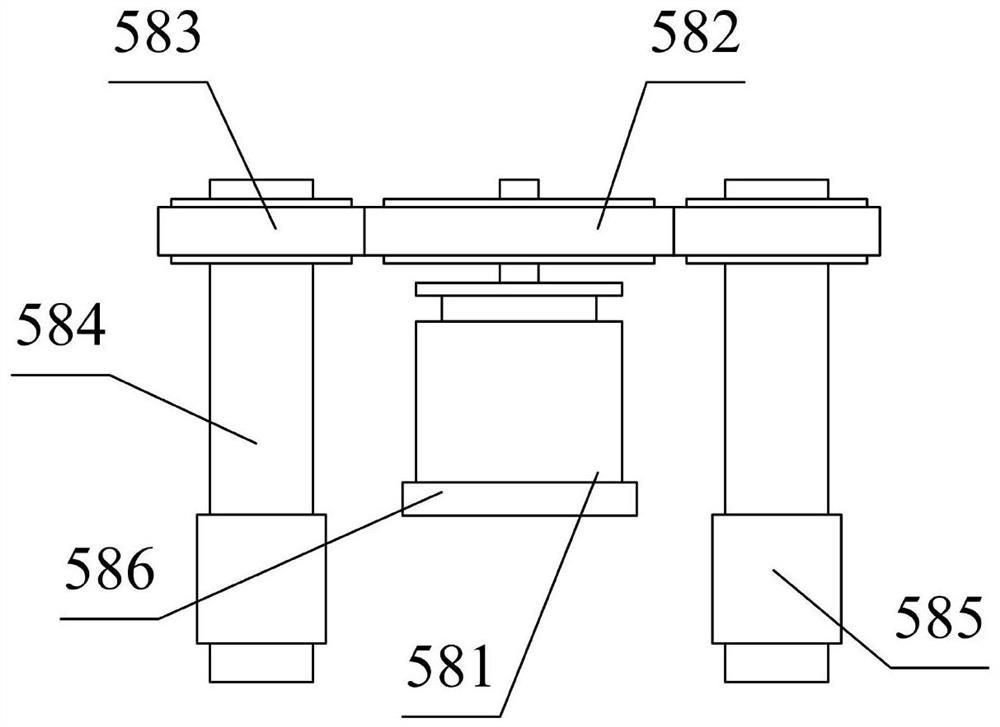

[0038] as attached figure 1 To attach figure 2 As shown, an automatic measurement device for gas content in coal seams in underground coal mines, including a first installation shell 1, a second installation shell 2, a coal sample tank 3, a tank cover 4, a supportable lifting seat structure 5, an explosion-proof high-speed motor 6, and a rotary crushing Frame structure 7, anti-slip mat 8, auxiliary aggregate crushing seat structure 9, first delivery pipe 10, first solenoid valve 11, gas-solid separator 12, second delivery pipe 13, methane concentration sensor 14, second solenoid valve 15, Intelligent flow meter 16, first gas pressure sensor 17, third delivery pipe 18, fourth delivery pipe 19, third electromagnetic valve 20, explosion-proof vacuum pump 21, measuring cylinder 22, liquid pressure sensor 23, fourth electromagnetic valve 24, soft rubber Pipe 25, storage tank 26, rodless cylinder 27, second gas pressure sensor 28, temperature sensor 29, PLC 30, control panel 31 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com