A waste rubber regeneration device

A recycling device and waste rubber technology, applied in the field of recycled rubber, can solve the problems of affecting the concentration of the slurry pool, affecting the surrounding environment, and exhaust gas not up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

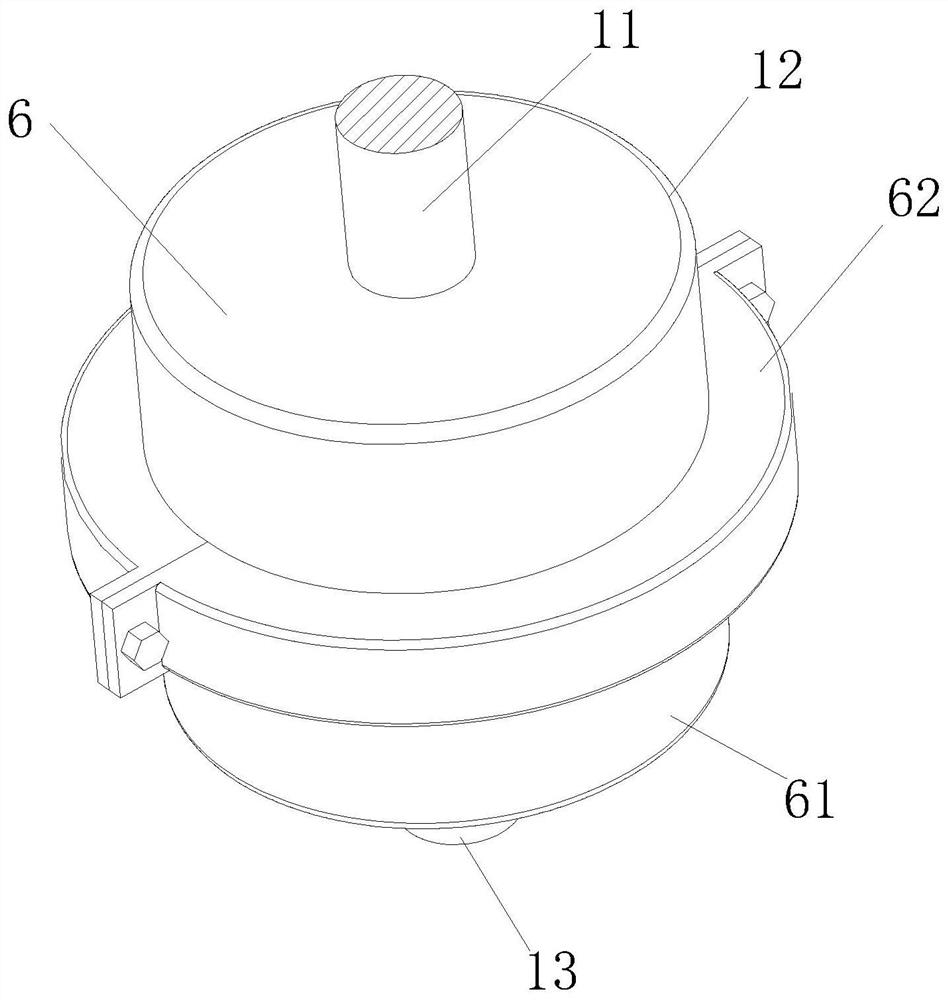

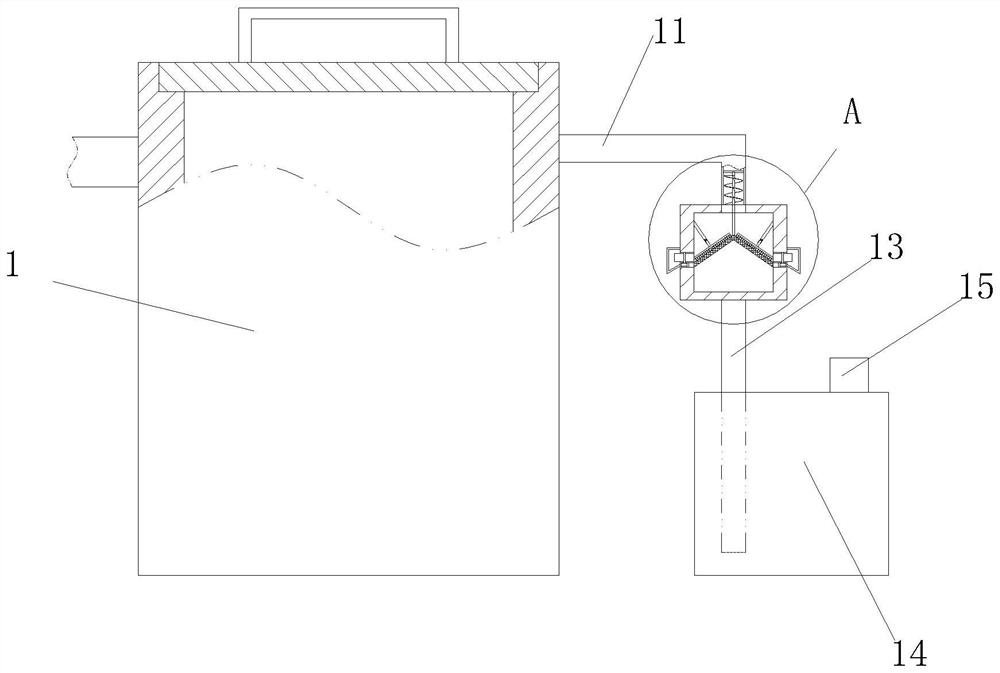

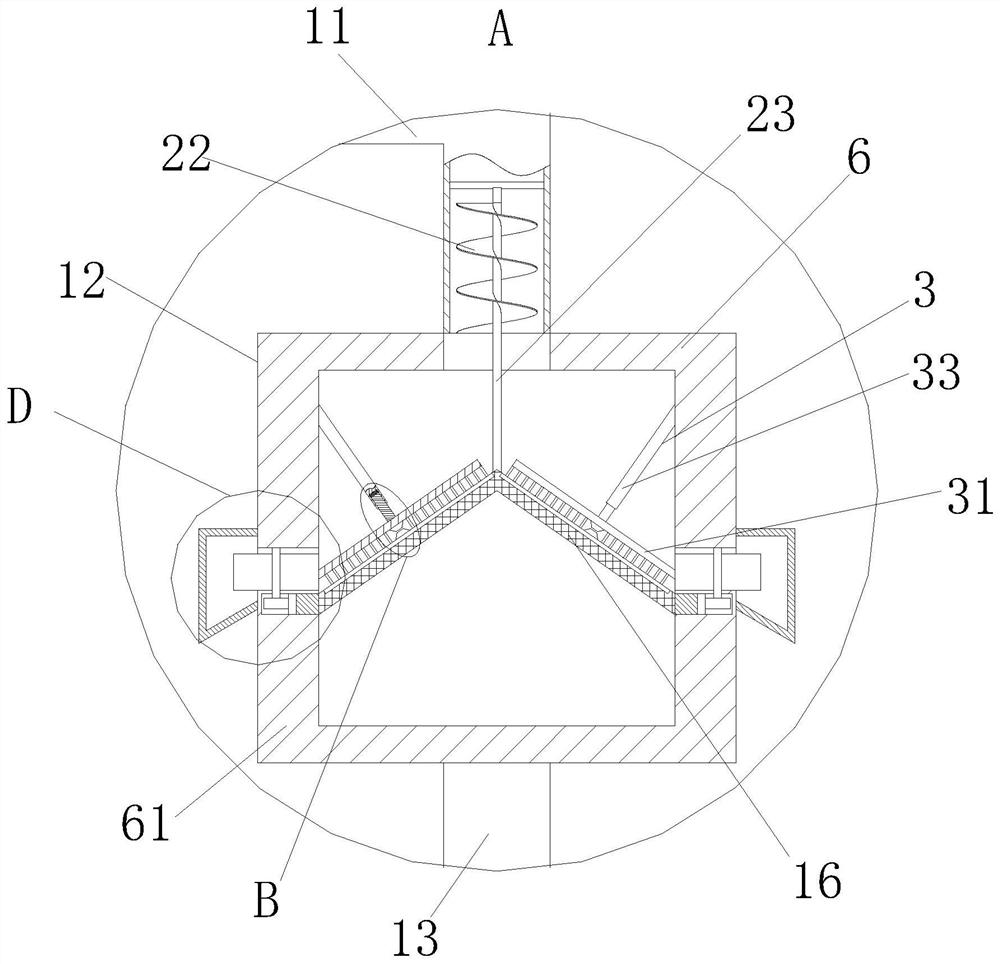

[0032] like Figure 1 to Figure 7 As shown, a waste rubber recycling device according to the present invention includes a desulfurization tank 1; a waste gas pipe 11 is provided on the side wall of the desulfurization tank 1; the waste gas pipe 11 is L-shaped, and the bottom end of the waste gas pipe 11 is fixed Connected with a filter box 12; the bottom end of the filter box 12 is connected with a slurry tank 14 through a connecting pipe 13; the inside of the slurry tank 14 is limestone slurry, and the connecting tube 13 extends into the slurry; the slurry tank 14 is provided with Exhaust pipe 15; the filter box 12 is provided with a conical filter screen 16, and the tip of the cone is upward; in the prior art, when using the desulfurization tank 1 to regenerate the waste rubber, a large amount of waste gas will be generated, and the waste gas contains rubber Colloidal particles and organic pollutants, etc., people will use water and limestone slurry to remove impurities from...

Embodiment 2

[0042] see Figure 8As shown in Comparative Example 1, as another embodiment of the present invention, a layer of rubber layer 67 is affixed to the inner wall of the semicircular collection box 62; Connect and wrap the impurity removal tank 68, and then collect the rubber powder particles filtered by the conical filter screen 16. In order to prevent the waste gas from escaping from the contact between the semicircular collection box 62 and the upper box body 6 and the lower box body 61, the semicircle A rubber layer 67 is fixedly attached to the side wall of the circular collection box 62, which can increase the sealing effect and prevent exhaust gas from escaping.

[0043] Working principle: The waste gas produced by the desulfurization tank 1 enters the filter box 12 through the waste gas pipe 11, and the rubber powder particles are filtered out through the conical filter screen 16, and then the filter gas is passed into the slurry pool through the connecting pipe 13 to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com