Kitchen knife grinding machine

A technology for grinding machines and kitchen knives, which is applied in the direction of grinding workpiece supports, other manufacturing equipment/tools, manufacturing tools, etc. It can solve the problems of inconvenient kitchen knife movement, affecting vegetable cutting, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

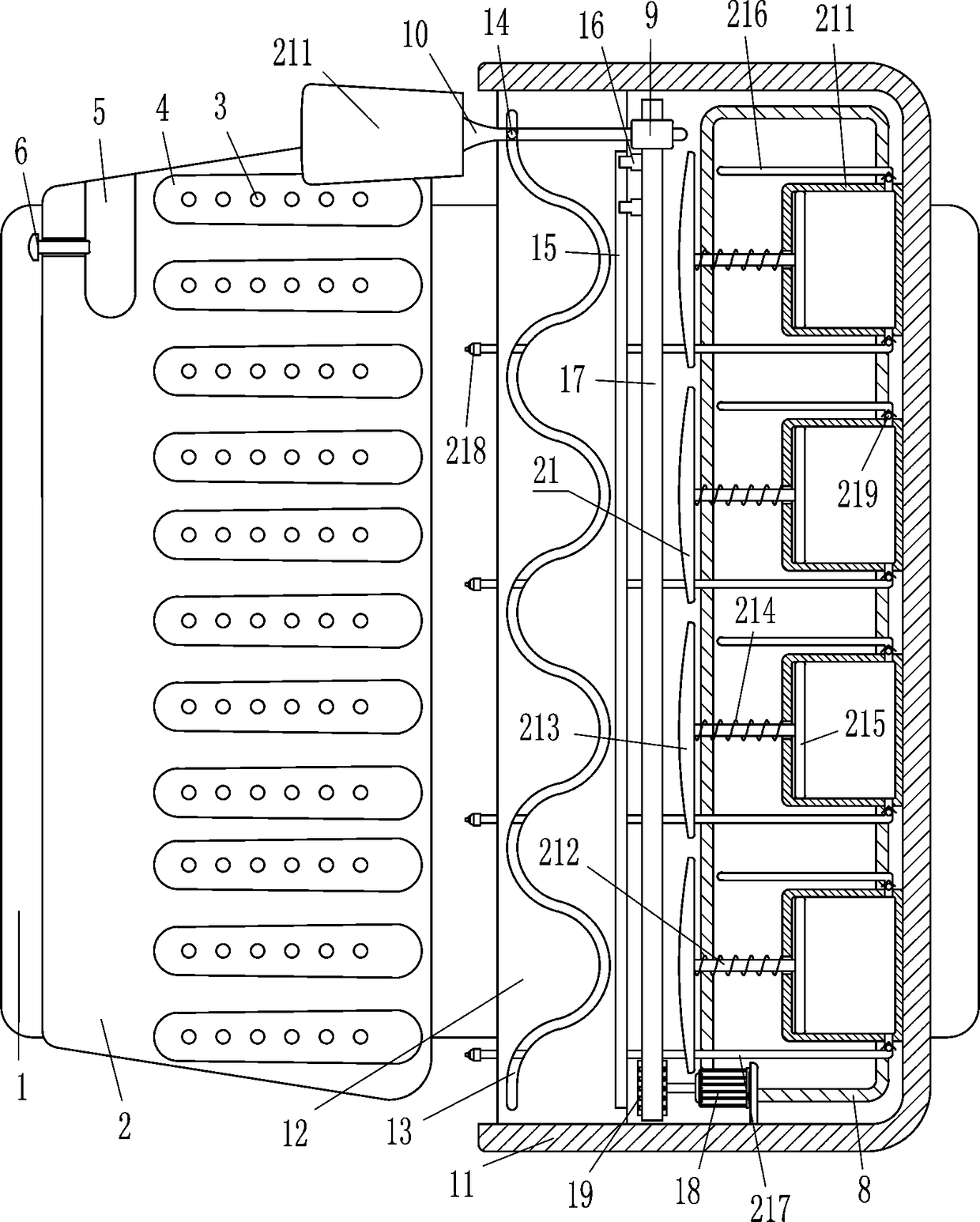

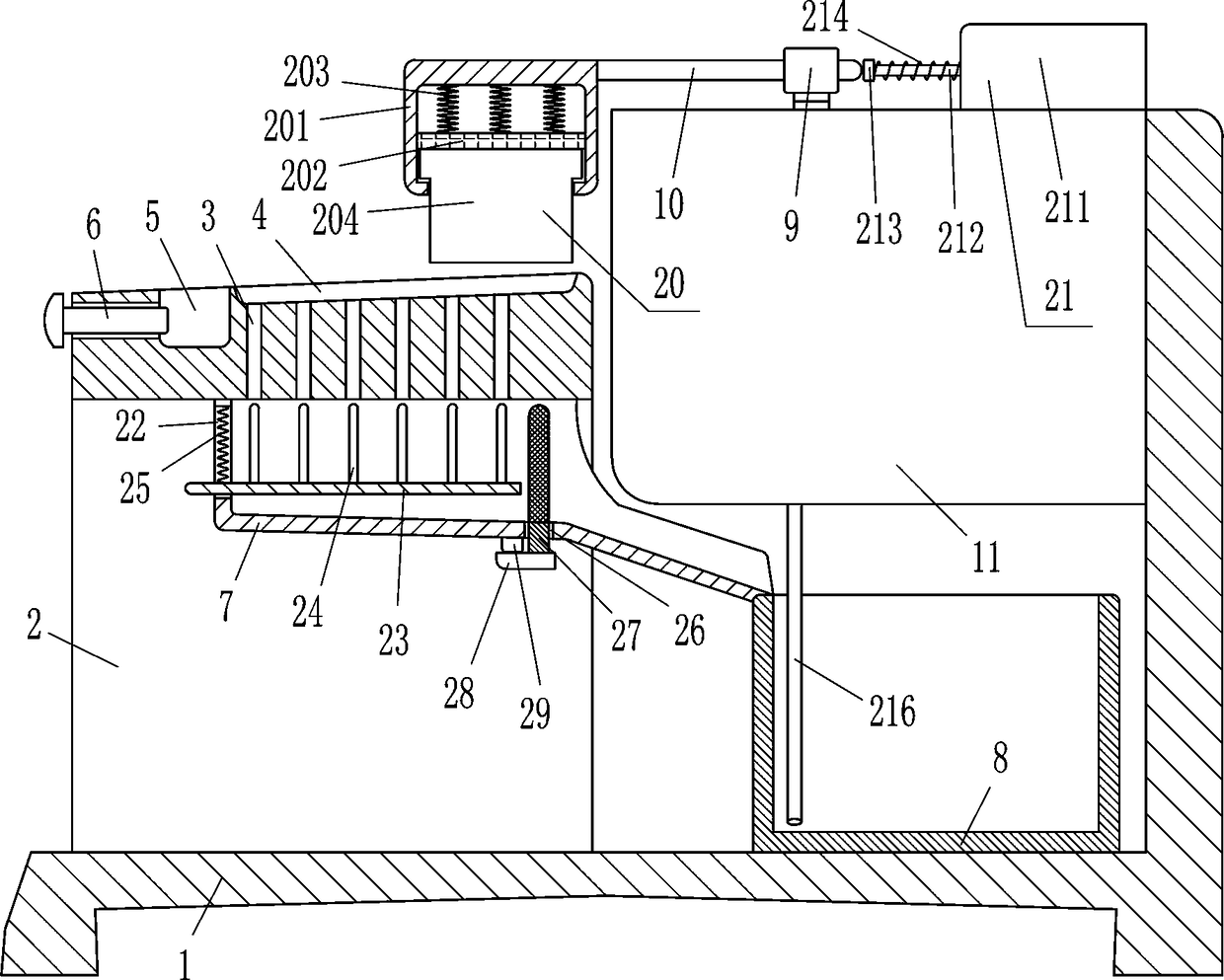

[0020] A kitchen knife grinder, such as Figure 1-2As shown, it includes L-shaped base 1, n-shaped plate 2, fastening bolt 6, lower hopper 7, collection frame 8, guide sleeve 9, cross bar 10, u-shaped plate 11, horizontal plate 12, roller 14, horizontal Slider 16, rack 17, driving motor 18, gear 19 and grinding device 20, the right side of the inner bottom of the L-shaped base 1 is provided with a collection frame 8 for collecting water, and the n-shaped plate 2 is installed on the left side of the inner bottom of the L-shaped base 1 On the side, the middle of the top of the n-type plate 2 is fixedly connected with a lower hopper 7 that can discharge water. The through hole 3 in the lower hopper 7 has a groove 4 on the right side of the outer top of the n-type plate 2, the groove 4 communicates with the inside of the through hole 3, and the left side of the outer top of the n-type plate 2 has a placement groove for placing a kitchen knife 5. The fastening bolt 6 that can fix ...

Embodiment 2

[0022] A kitchen knife sharpener such as Figure 1-2 As shown, it includes L-shaped base 1, n-shaped plate 2, fastening bolt 6, lower hopper 7, collection frame 8, guide sleeve 9, cross bar 10, u-shaped plate 11, horizontal plate 12, roller 14, horizontal Slider 16, rack 17, driving motor 18, gear 19 and grinding device 20, the right side of the inner bottom of the L-shaped base 1 is provided with a collection frame 8 for collecting water, and the n-shaped plate 2 is installed on the left side of the inner bottom of the L-shaped base 1 On the side, the middle of the top of the n-type plate 2 is fixedly connected with a lower hopper 7 that can discharge water. The through hole 3 in the lower hopper 7 has a groove 4 on the right side of the outer top of the n-type plate 2, the groove 4 communicates with the inside of the through hole 3, and the left side of the outer top of the n-type plate 2 has a placement groove for placing a kitchen knife 5. The fastening bolt 6 that can fi...

Embodiment 3

[0025] A kitchen knife sharpener such as Figure 1-2 As shown, it includes L-shaped base 1, n-shaped plate 2, fastening bolt 6, lower hopper 7, collection frame 8, guide sleeve 9, cross bar 10, u-shaped plate 11, horizontal plate 12, roller 14, horizontal Slider 16, rack 17, driving motor 18, gear 19 and grinding device 20, the right side of the inner bottom of the L-shaped base 1 is provided with a collection frame 8 for collecting water, and the n-shaped plate 2 is installed on the left side of the inner bottom of the L-shaped base 1 On the side, the middle of the top of the n-type plate 2 is fixedly connected with a lower hopper 7 that can discharge water. The through hole 3 in the lower hopper 7 has a groove 4 on the right side of the outer top of the n-type plate 2, the groove 4 communicates with the inside of the through hole 3, and the left side of the outer top of the n-type plate 2 has a placement groove for placing a kitchen knife 5. The fastening bolt 6 that can fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com