Hydraulic gear grinding clamp and work method thereof

A working method and tooth grinding technology, which is applied in the field of tooth parts, can solve the problems of small expansion range of expansion sleeves, insufficient clamping force of large parts, and poor universality of fixtures, so as to improve production change efficiency, reduce application costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

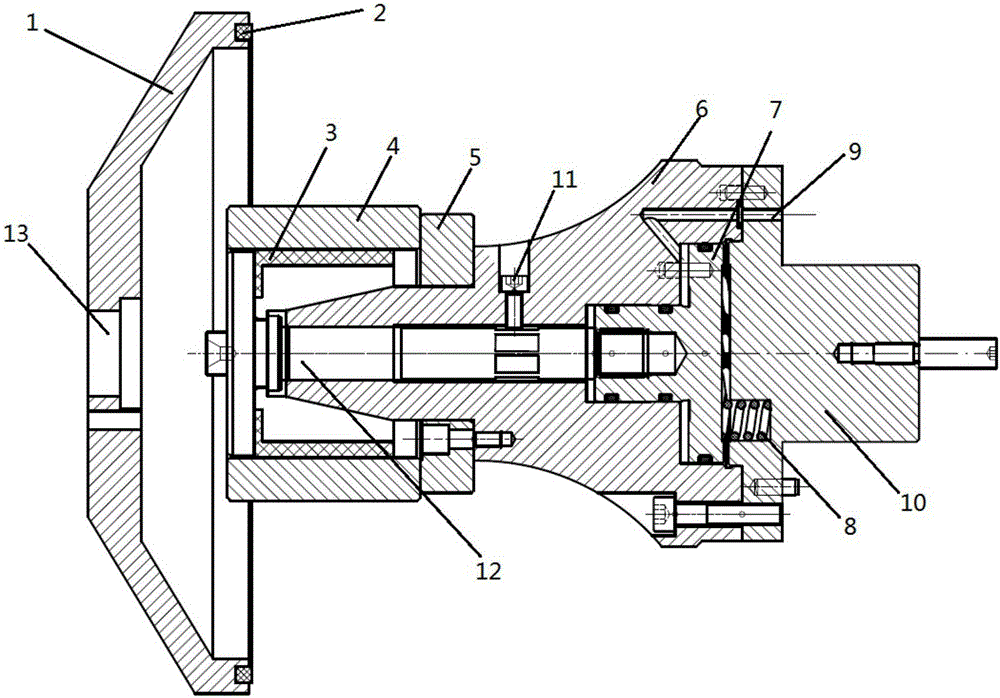

[0024] see figure 1 , a hydraulic gear grinding fixture, including a body 6 with a middle hole, a pull rod 12 is arranged in the middle hole of the body 6, both ends of the pull rod 12 protrude from the middle hole, a gland 1 is arranged on the top of the pull rod 12, and the body 6 The top is a frustum structure, the bottom of the frustum is fixed with a support seat 5, the support seat 5 is provided with an expansion sleeve 3, the bottom of the body 6 is provided with a sliding piston 7, the pull rod 12 is connected with the slide piston 7, and the expansion sleeve 3 is fixedly connected with the pull rod 12 , the expansion sleeve 3 is provided with an expansion sleeve standard part 4, the sliding piston 7 and the body 6 form a sealed oiling chamber, the bottom of the body 6 is also provided with a base 10, and the base 10 is provided with a number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com