An automatic press-fitting machine for a retaining ring for a shaft and a work detection method

A shaft retaining ring, press machine technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problem of high labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

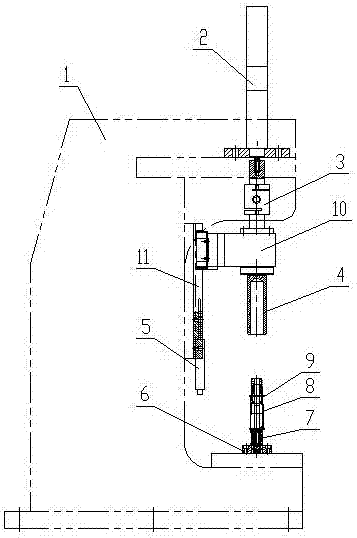

[0024] The shaft retaining ring automatic pressing machine is composed of a pressing bracket 1, an electric cylinder 2, a pressure sensor 3, a pressing head 4, a displacement sensor 5, a positioning seat 6 and a guide sleeve 8; the pressing bracket 1 is fixed on the work table. The upper end of the press-fit bracket 1 is equipped with an electric cylinder 2, the middle of the press-fit bracket 1 is equipped with a sliding arm 10 through the slideway 11, and the lower end of the slideway 11 is equipped with a displacement sensor 5; the upper end of the slide arm 10 is equipped with a pressure sensor 3. The pressure sensor 3 is connected to the lower part of the electric cylinder 2, and the lower end of the sliding arm 10 is equipped with a pressing head 4; the bottom of the pressing bracket 1 is equipped with a positioning seat 6 on the working table corresponding to the pressing head 4, and the workpiece is pressed The lower end of 7 is inserted into the central fixing hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com