A pressing device

A technology of gluing and platen, which is applied to workpiece clamping devices, material gluing, connecting components, etc., can solve the problems of inability to guarantee the quality requirements of pasting flatness, complex structure of gluing device, inconvenient installation and maintenance, etc. Simple, low cost, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

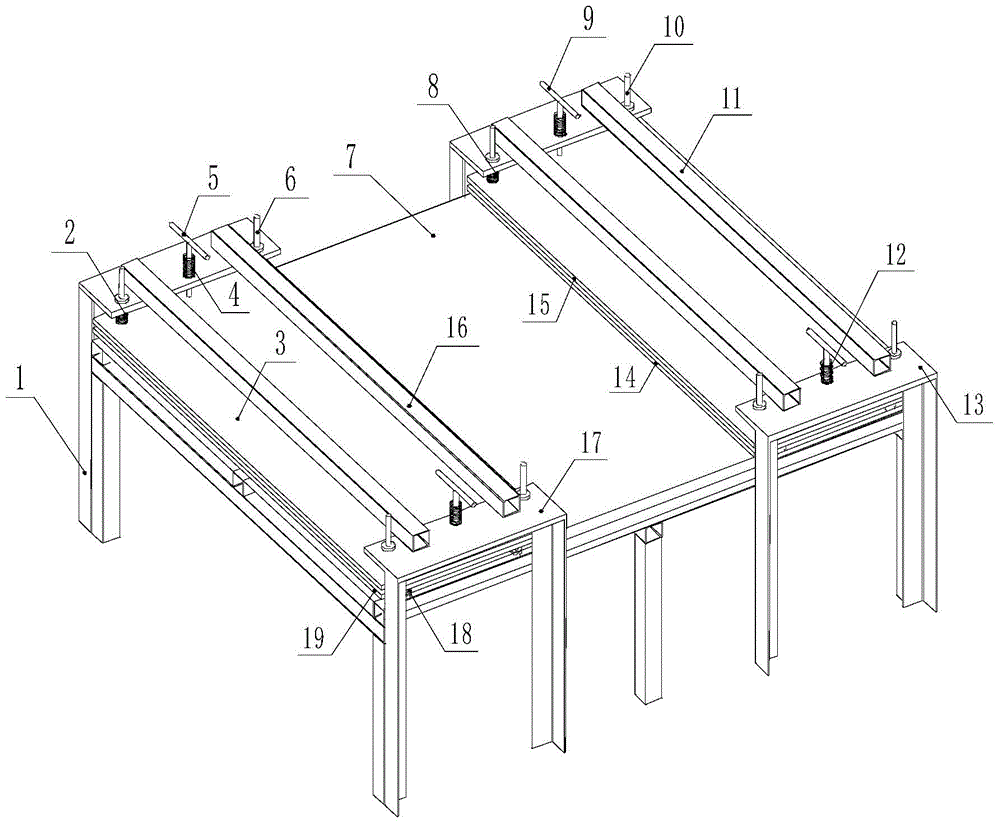

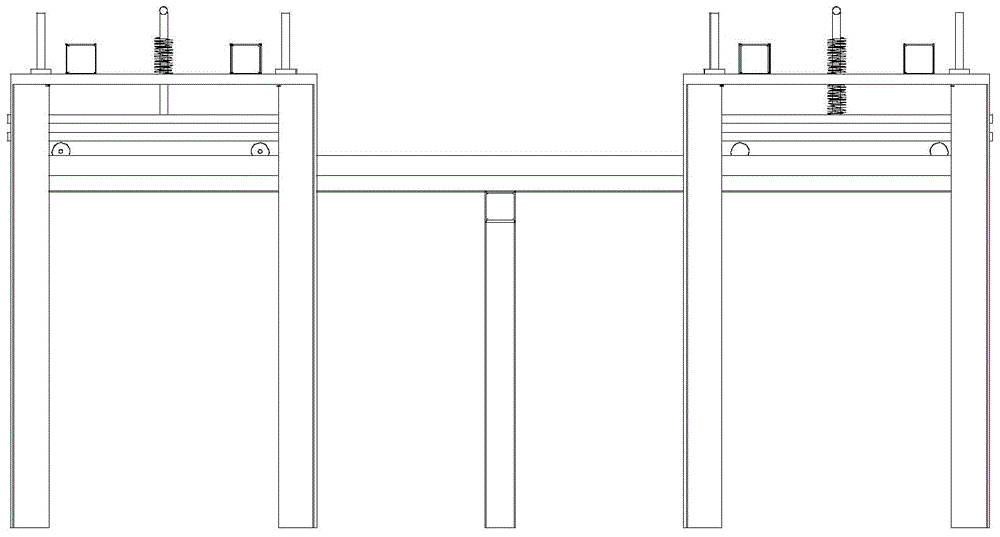

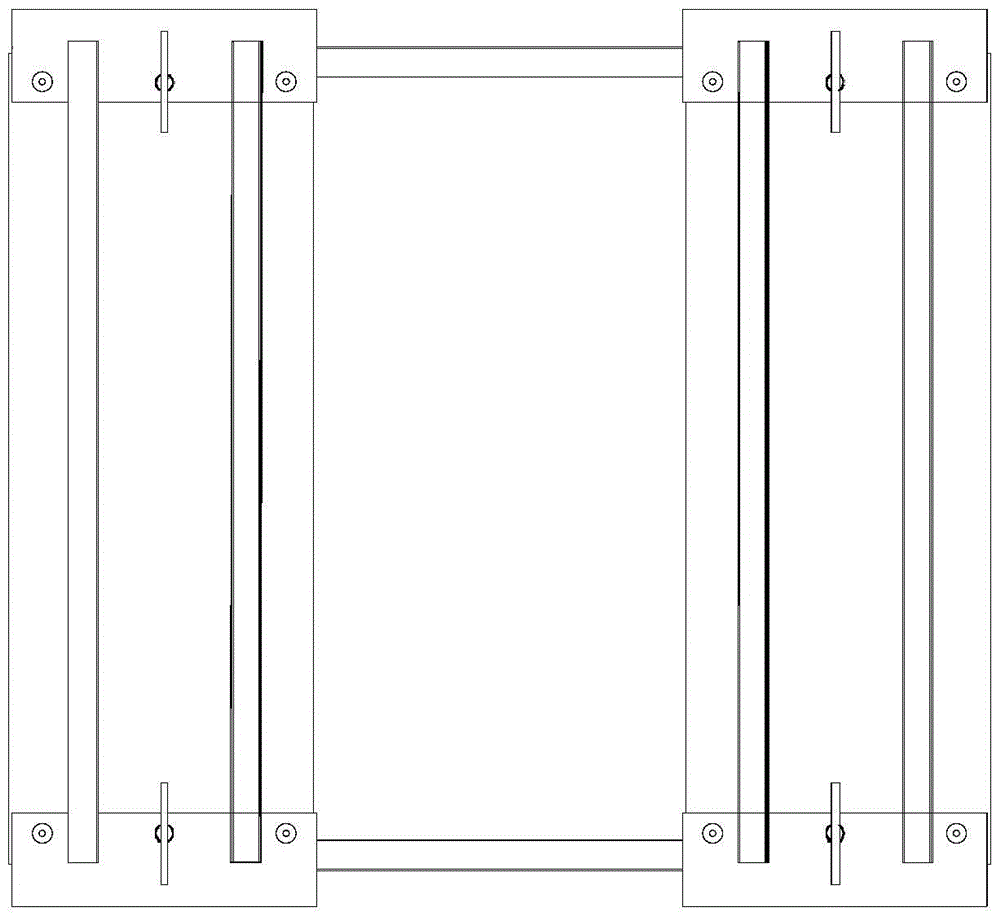

[0017] Examples such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a pressing device includes a supporting base 1, a lower left spring 2, a left pressing plate 3, an upper left spring 4, a left pressing rod 5, a left lifting screw 6, a bottom plate 7, a right lower spring 8, and a right pressing rod 9 , right lifting screw 10, right connecting bar 11, right upper spring 12, right mounting plate 13, right supporting base plate 14, right pressing plate 15, left connecting bar 16, left mounting plate 17, roller 18, left supporting base plate 19 and slide rail 20. The support base 1 is welded by angle steel, the left mounting plate 17 is fixedly installed on the top surface of the support base 1 and close to the left side, the left lifting screw 6 is installed in the mounting hole of the left mounting plate 17 and its The bottom end is fixedly installed on the left pressing plate 3, the left lower spring 2 is sleeved on the left lifting screw 6 and its bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com