A device for realizing continuous punching and cutting of double-skeleton products through cylinder movement

A double skeleton and cylinder technology, applied in metal processing and other directions, can solve the problems of increasing production safety accidents, low degree of automation, and complicated installation, and achieve the effect of reducing production safety accidents, sensitive action response, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

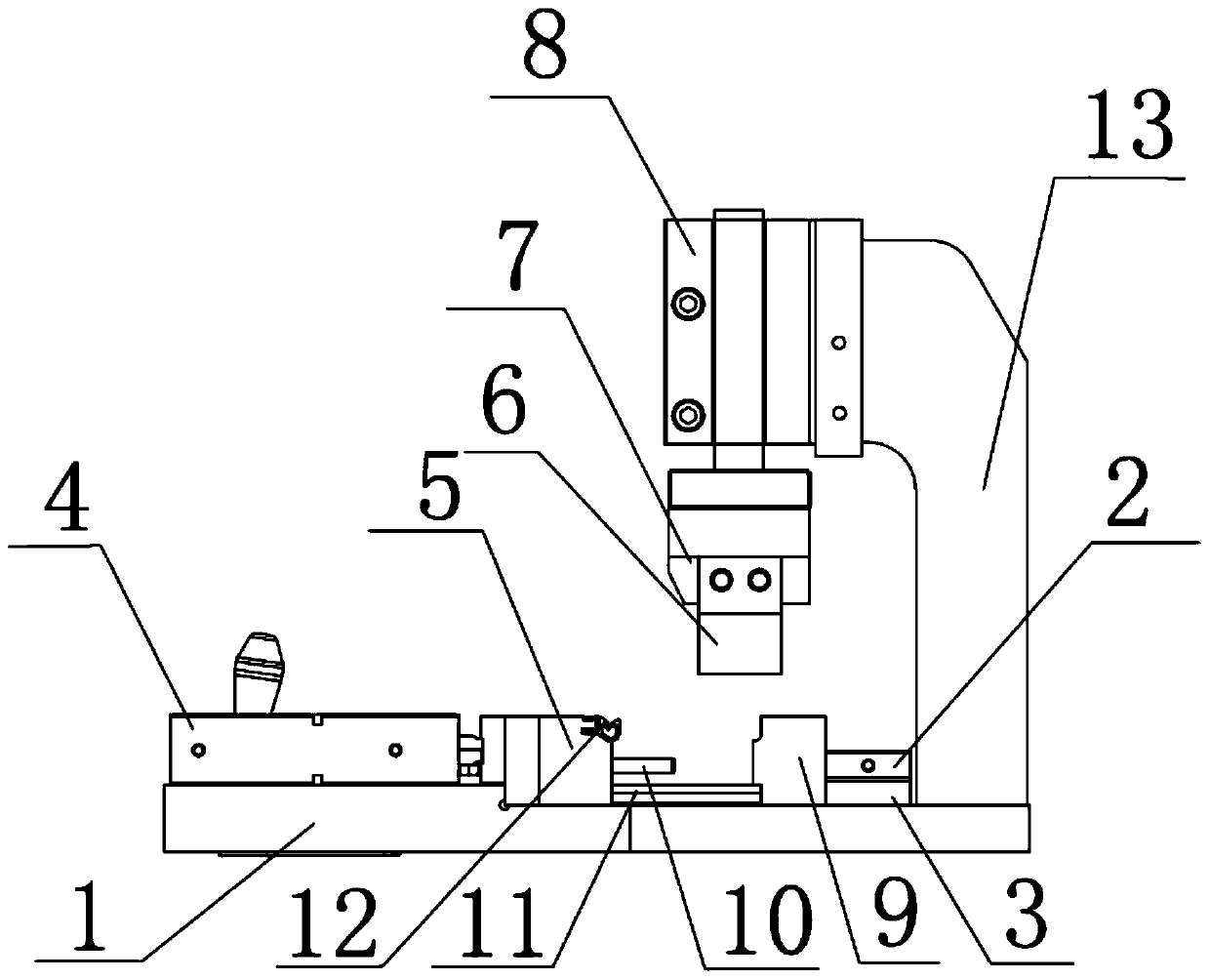

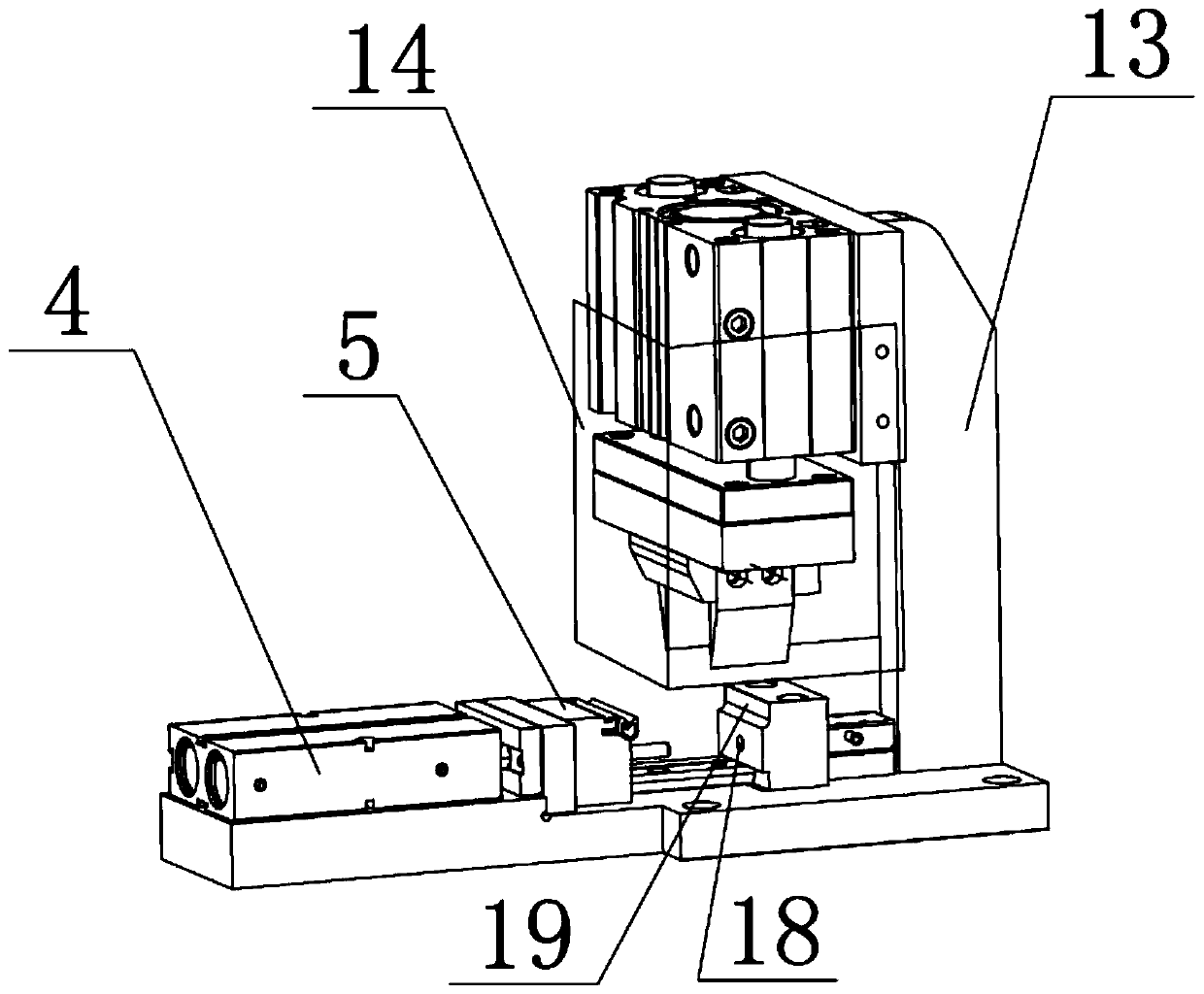

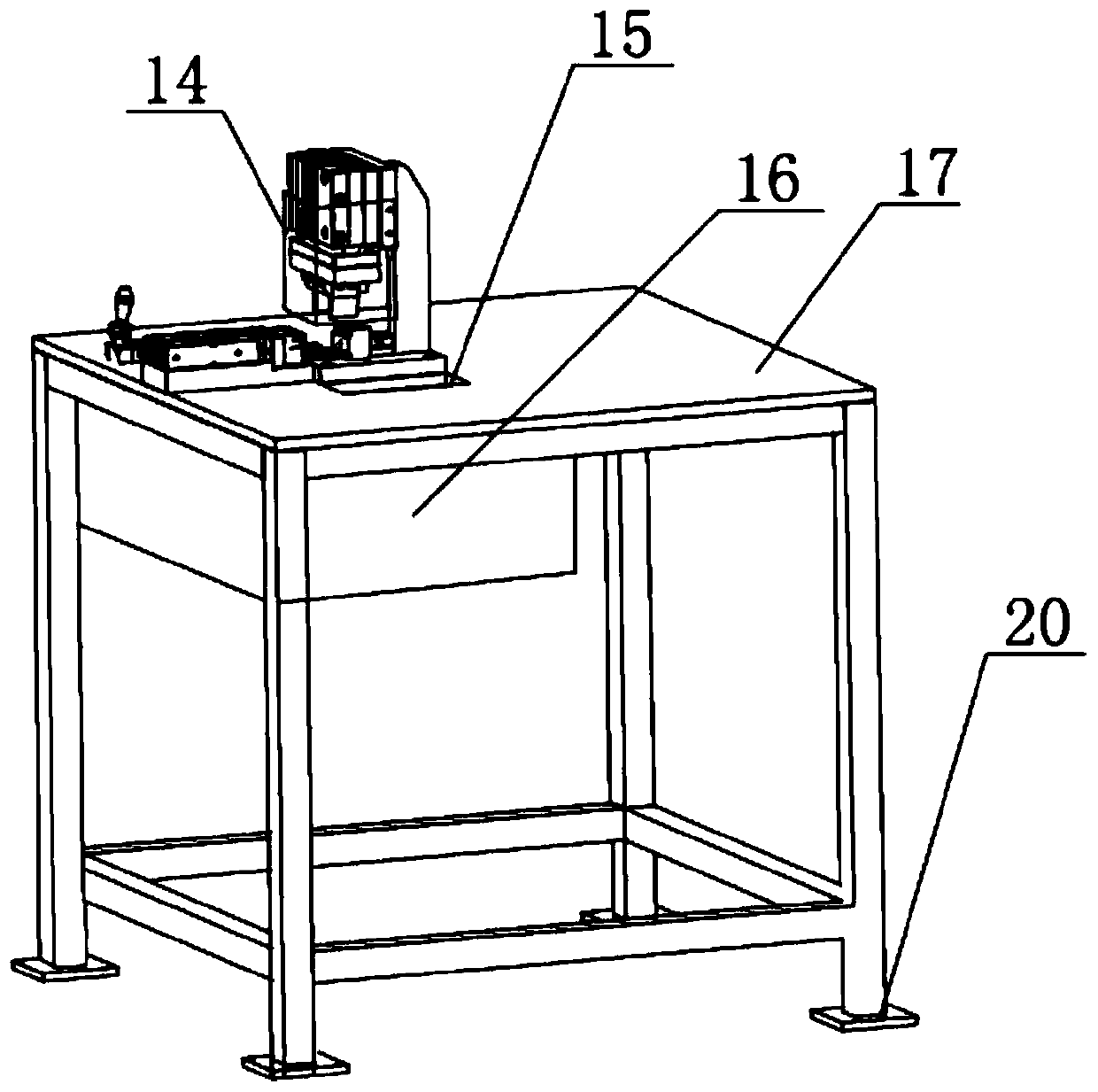

[0024] When using the punching device to punch the product, first put the punched product into the groove 12 of the slider 5 and fix it, reserve the punching material at both ends, and start to push the cylinder 4 to quickly push the slider 5 moves toward the die 9 and cooperates with the die 9 to clamp the product. At the same time, the switch pin 10 on the slider 5 passes through the through hole 18 of the die 9 and touches the mechanical valve 2, so that the switch of the mechanical valve 2 opens to The punching cylinder 8 is inflated, quickly drives the cutter fixing plate 7 and the cutter 6 to move downward to complete the punching of the product, and the waste enters the waste box 16 from the waste hole 15, and then controls and pushes the cylinder 4 to keep the slider 5 away from the die 9 Movement, the switch pin 10 is separated from the mechanical valve 2, the cutter fixed plate 7 and the cutter 6 return to their original positions, and the product is taken out from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com