Manual preservative-film sealing device

The invention relates to a technology of a fresh-keeping film and a film sealer, which is applied in the field of tools for the use of fresh-keeping film and sealing film, and can solve the problems of affecting work efficiency and economic benefits, trouble, slow speed, etc., and achieve the effect of improving work efficiency and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

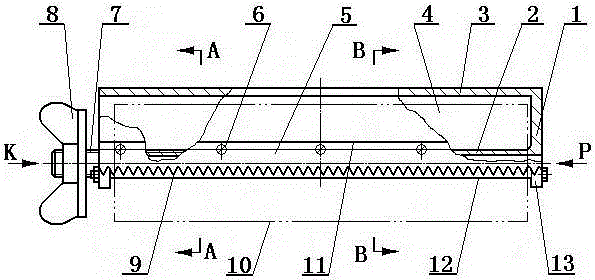

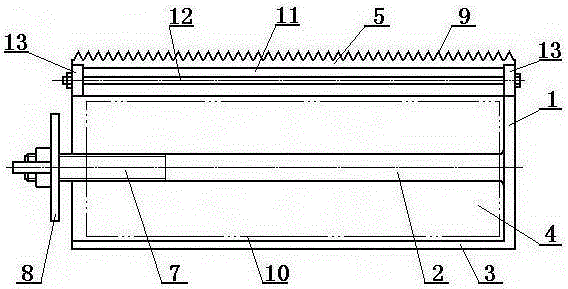

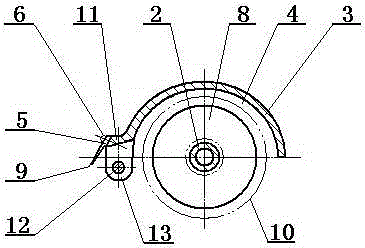

[0024] Embodiment: As shown in the figure, a manual sealer for plastic wrap consisting of a handle (3), a cutter (5), a screw (6), a wing nut (8) and a pull rod (12), the handle ( 3) The right end is provided with a fan-shaped shaft seat plate (1), and the inner end surface of the fan-shaped shaft seat plate (1) is provided with a hollow shaft (2) for inserting the inner hole of the paper tube of the plastic wrap (10).

[0025] The axis of the hollow shaft (2) overlaps with the left and right horizontal center axes of the semicircular inner hole (4) of the handle (3), and the left end of the hollow shaft (2) is provided with an external thread connected with the wing nut (8) (7), the length of the hollow shaft (2) is 15mm greater than the length of the handle (3).

[0026] The front end of the handle (3) is provided with a forward-protruding horizontal boss (11) along the left and right directions, and the left and right ends of the horizontal boss (11) are respectively provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com