Lead screw engaged elevator

A technology for lifting elevators and screw rods, applied to elevators, transportation and packaging in buildings, etc., can solve the problems of high elevator accident rate and high potential safety hazards of elevators, and achieve the effect of avoiding the falling of the car body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A detailed description will be given below with reference to the drawings and implementation examples.

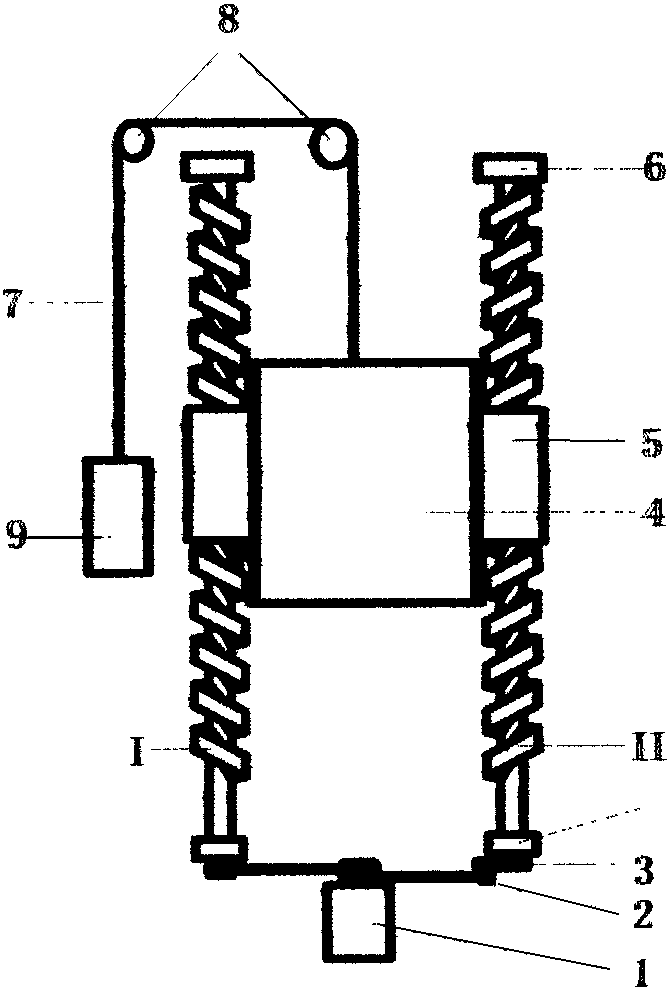

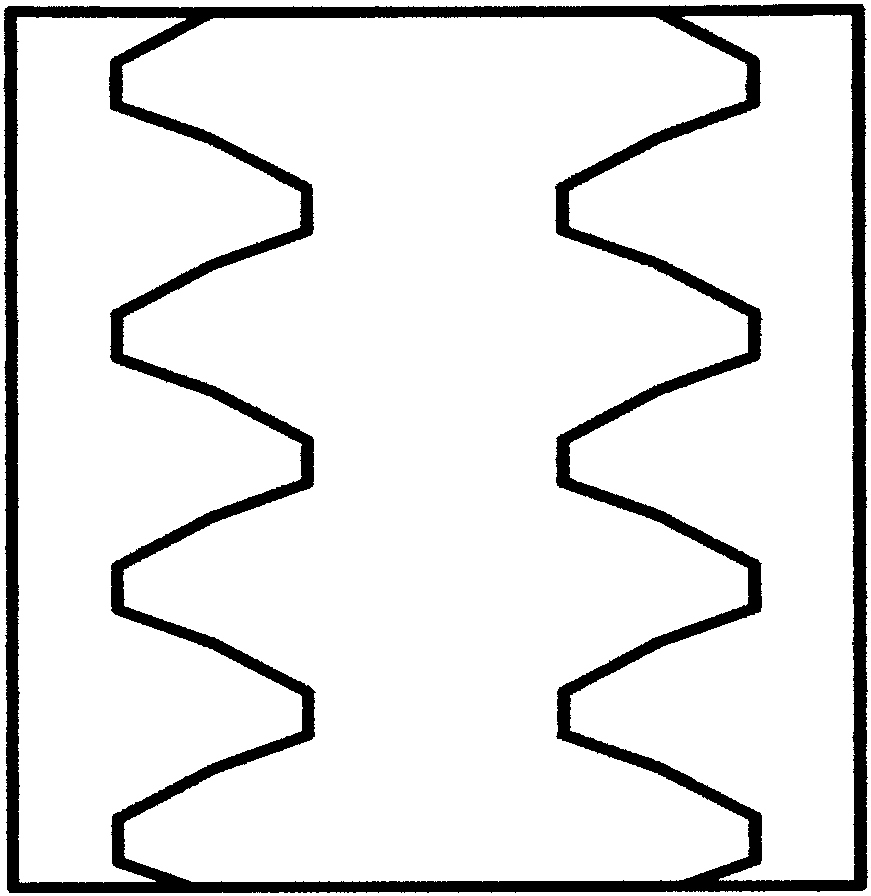

[0010] Such as figure 1 As shown, in the present invention, the motor drives the screw rod I to rotate through the belt, and drives the screw rod II to rotate by driving the reversing gear. The screw rod I and the screw rod II rotate and mesh with the wire sleeve on the car body to lift the car body. The screw rod is fixed up and down by bearings, the upper part of the car body is connected with the cable, and the cable is connected with the counterweight through the pulley. When the car body rises, the motor drives the screw rod to rotate in the direction of the car body. Under the condition that the screw rod and the screw sleeve are engaged, the car body climbs up along the screw rod. At the same time, the car body reduces the screw rod engagement under the traction of the counterweight. The lifting power can save power consumption. When the elevator breaks down, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com