Elevator traction machine

A technology for traction machines and elevators, which is applied in the field of traction machines for elevators, and can solve problems such as the complex structure of the whole machine, the complicated shape and structure of the sheave, and the increase in the volume and weight of the sheave, so as to keep the structure of the whole machine simple Simplification, layout and operation are convenient, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

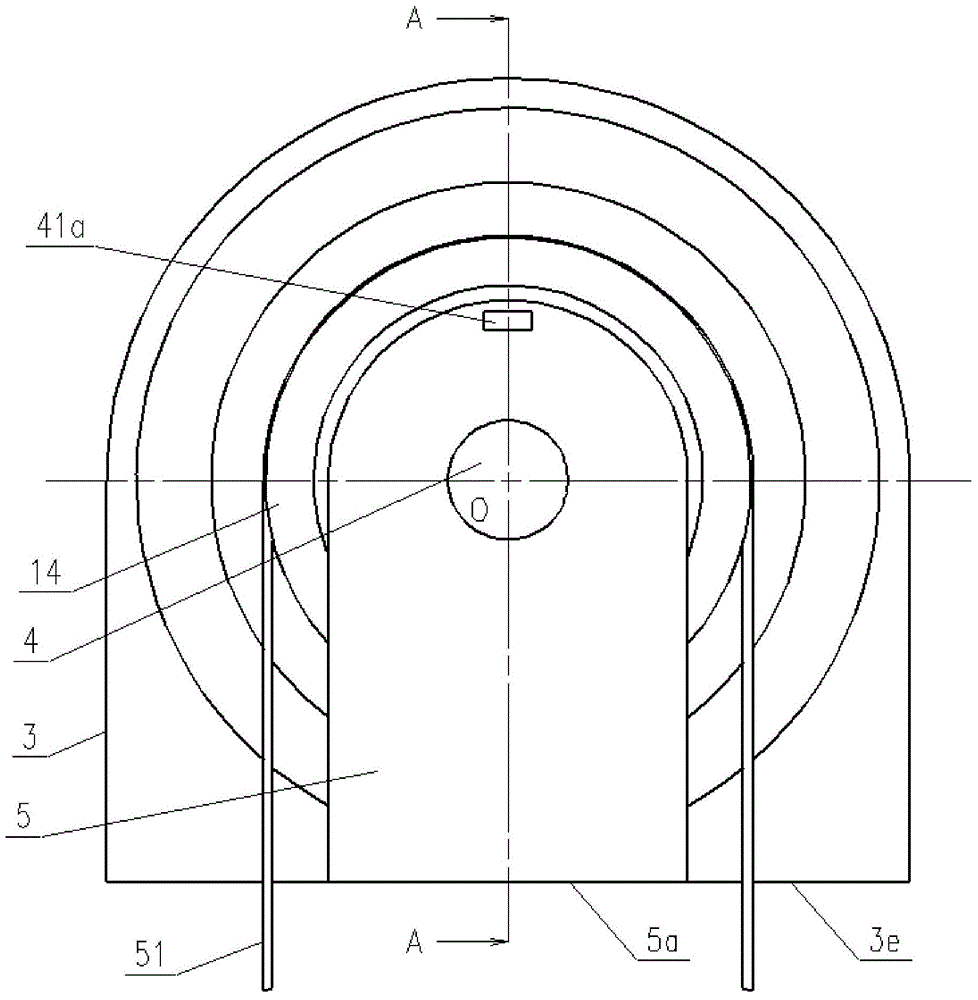

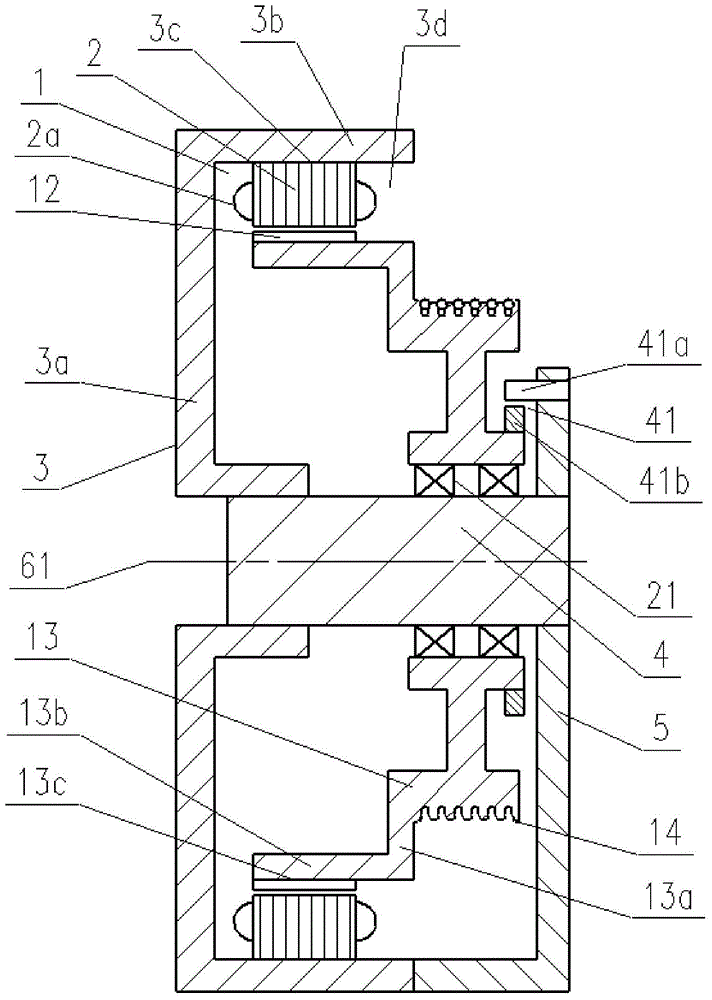

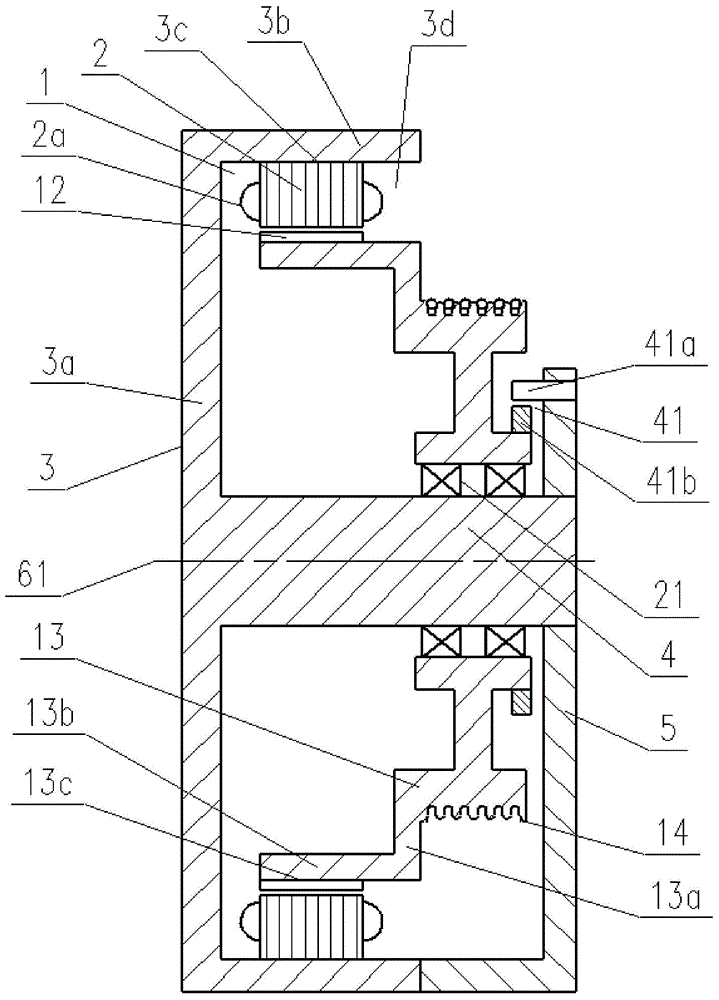

[0037] Such as figure 1 and figure 2 Shown is the first embodiment of the elevator traction machine of the present invention, comprising a motor 1, a fixed frame 3, a fixed main shaft 4, a rotor case 13, a sheave 14 for driving the elevator rope 51, a bearing 21, and a supporting frame 5;

[0038] The motor 1 comprises a stator 2 and a rotor 12 provided with a stator coil 2a, and the stator 2 and the rotor 12 are relatively arranged; the motor 1 is a cylindrical motor, which provides rotational power for the sheave 14 driving the elevator rope 51;

[0039] The fixed base 3 has a hollow disc-shaped extension 3a extending radially outward, a cylindrical portion 3b bent from the extension 3a to the vertical direction and extending axially, and a stator mounting portion 3c provided on the cylindrical portion 3b; The stator 2 is fixedly arranged at the stator installation part 3c;

[0040] The fixed main shaft 4 is arranged near the rotation center 61, and the fixed main shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com