Festoon cable with rapid conical roll replacement device

A tapered roller and cable technology, applied in the field of cable trolling, can solve the problems of inconvenient disassembly, maintenance and adjustment, and achieve the effect of simple structure, quick installation and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

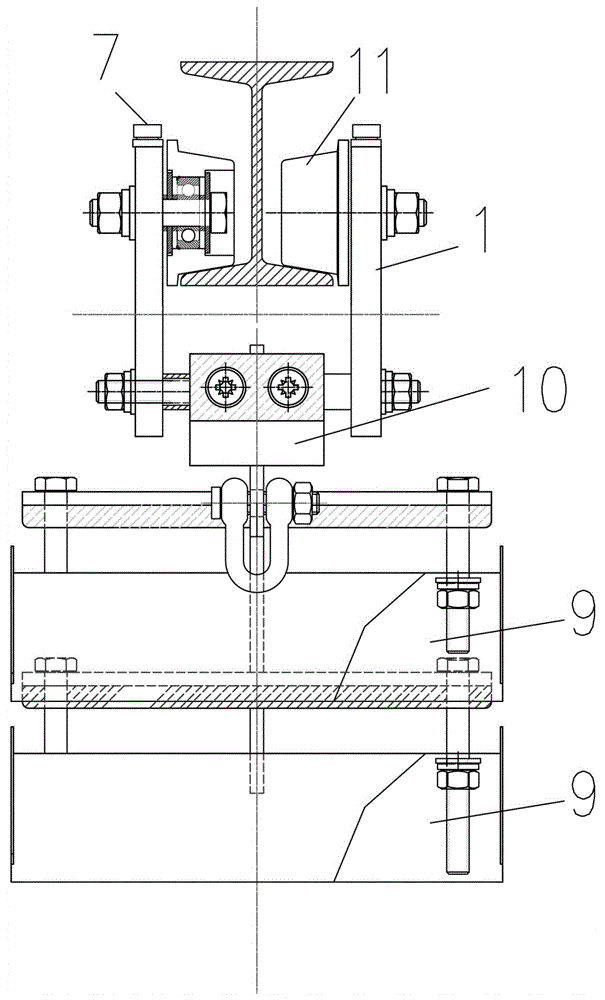

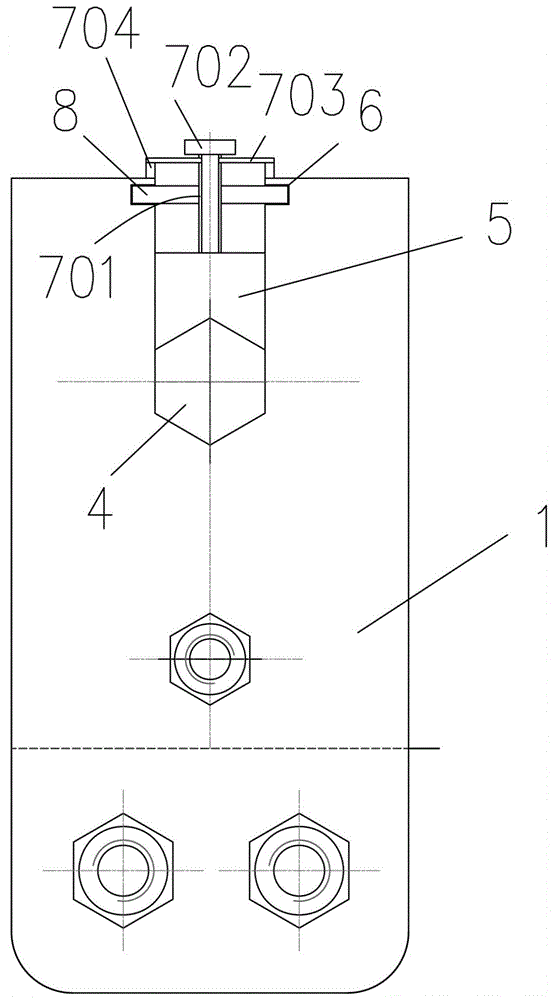

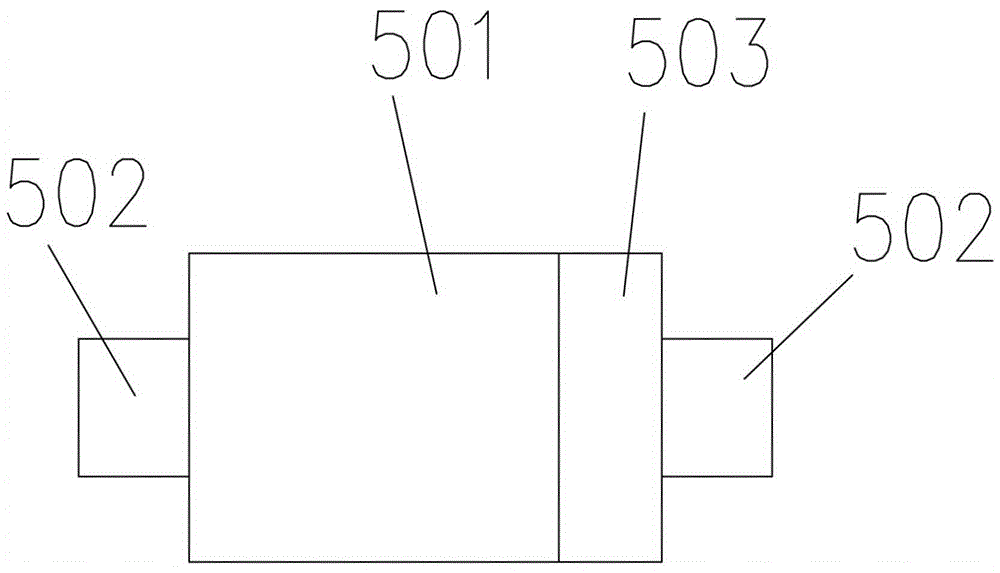

[0022] Embodiment 1: as figure 1 , 2 , 3 and 4, including two pallets 9, a bracket 10 connected to the pallet 9 and a tapered roller 11 mounted on the bracket through a tapered roller quick change device, the tapered roller quick change device It includes a support plate 1 and an installation screw 2 for installing the tapered roller, the installation screw 2 is provided with a hexagonal column section 3, and the support plate 1 is provided with an installation opening 4 matching the hexagonal column section 3 And the insertion slot 6 communicating with the installation opening 4, the installation opening 4 is provided with a clamping slider 5, the insertion slot 6 is provided with a sliding insertion plate 8, and the sliding insertion plate 8 A vertical drive mechanism 7 for driving the clamping slider 5 to clamp the hexagonal prism section 3 is provided on the top; the vertical driving mechanism 7 drives the clamping slider 5 to lock the hexagonal prism section 3 .

[0023...

Embodiment 2

[0026] Embodiment 2, see attached Figure 5 The difference from Example 1 is that six sliding pin holes 705 are evenly distributed on the inner hole of the pressing ring 703, and a sliding pin 706 and a compression spring 707 are arranged in the sliding pin hole 705, and one end of the compression spring acts on On the bottom surface of the sliding pin hole, the other end acts on the sliding pin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com