Controlled surface modification method for carbon material

A technology of carbon materials and derivatives, which is applied in the field of controllable modification of the surface of carbon materials, can solve the problems of low degree of functionalization and narrow application range, and achieve expansion of application area, improvement of functional modification degree, aryl diazonium salt couple Efficient effect of combined reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

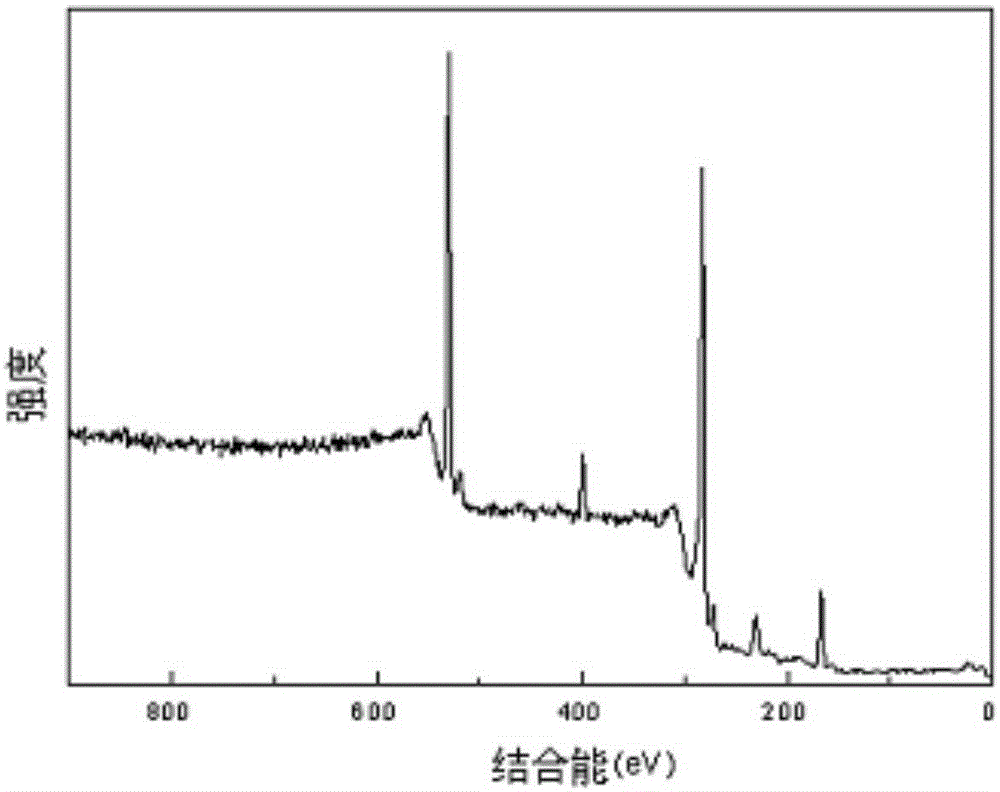

Image

Examples

specific Embodiment approach 1

[0022] Specific implementation mode 1: The method for the controllable modification of the carbon material surface in this implementation mode is realized according to the following steps:

[0023] Step 1, the preparation of benzophenone hydrazone derivatives:

[0024] Add 2g to 20g of benzophenone derivatives into a 0.1 to 2L round bottom flask, add 50mL to 1000mL of absolute ethanol and 1g to 50g of hydrazine hydrate with a mass fraction of 85% in sequence, and carry out a reflux reaction under stirring for 24h to 120h, After the reaction is completed, 25mL-600mL of ethanol in the reaction solution is distilled off under reduced pressure, and the remaining reaction solution is cooled and crystallized in an ice-water bath for 10min-60min, and the crystallized product is obtained by vacuum filtration with a sand core funnel, and the crystallized product is washed with distilled water for 3-60 minutes. 5 times, after the final vacuum drying, the preparation of the benzophenone ...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the temperature for the reflux reaction described in Step 1 is 80°C. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the vacuum drying described in Step 1 is vacuum drying at 20° C. to 60° C. for 12 hours to 36 hours. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com