A kind of asphalt modified epoxy zinc phosphate heavy-duty anti-corrosion primer and preparation method thereof

A technology of epoxy zinc phosphate and heavy-duty anti-corrosion primer, which is applied in the field of coatings, can solve the problems that epoxy resin cannot meet the performance requirements, and achieve good drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

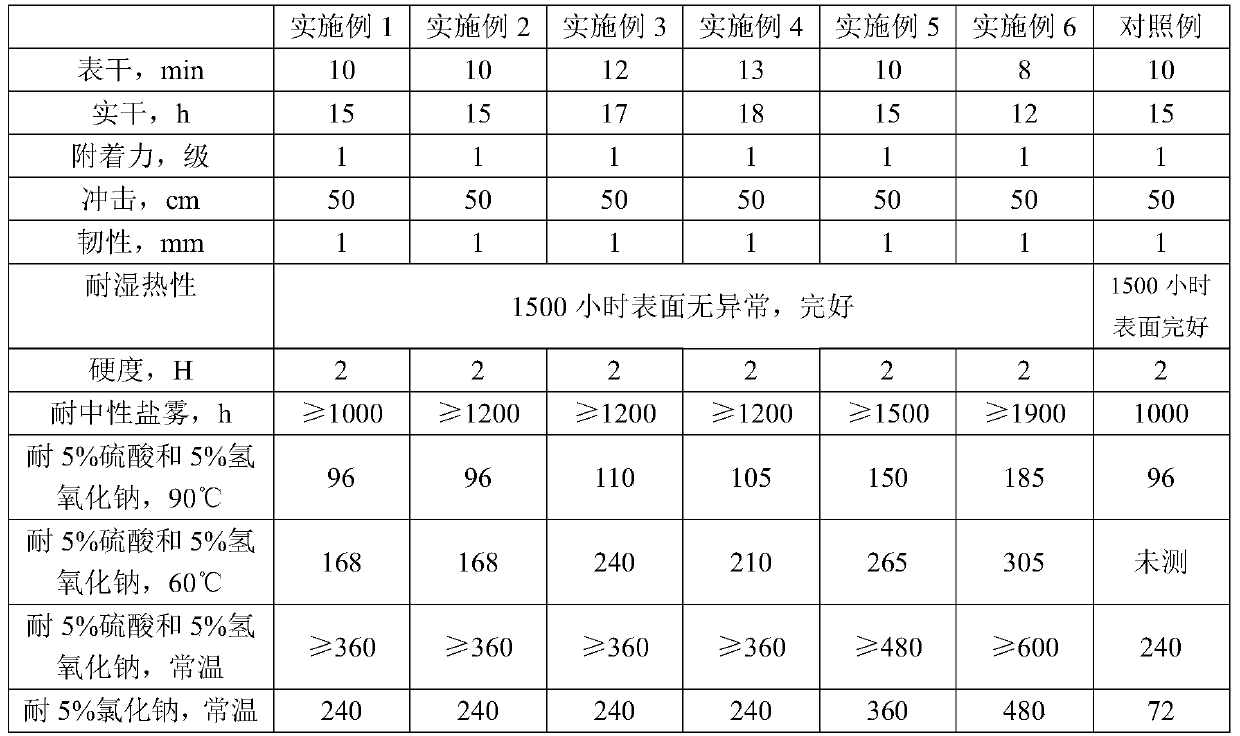

Examples

Embodiment 1

[0032] An asphalt modified epoxy zinc phosphate heavy-duty anti-corrosion primer, including the following components by weight: A component: 10 parts of epoxy resin A, 15 parts of epoxy resin B, 10 parts of zinc phosphate, coal tar 5 parts of asphalt, 2 parts of modified resin, 20 parts of iron oxide red, 18 parts of precipitated barium sulfate, 2 parts of sericite, 15 parts of composite phosphorus titanium powder, 0.6 parts of anti-sedimentation slurry, 0.2 parts of defoamer, 0.5 parts of dispersant , 6.7 parts of the first mixed solvent; component B: 50 parts of cardanol modified polyamide resin, 2 parts of salt spray resistance additive, and 38 parts of the second mixed solvent.

[0033] Preparation:

[0034] A component: step 1, dissolve the anti-settling slurry with a mixed solvent, then add epoxy resin A, epoxy resin B and coal tar pitch, add dispersant and defoamer while stirring at 400rpm, continue stirring at 600rpm for 10min , step 2, add iron oxide red, precipitate...

Embodiment 2

[0037] An asphalt modified epoxy zinc phosphate heavy-duty anti-corrosion primer, including the following components by weight: A component: 15 parts of epoxy resin A, 10 parts of epoxy resin B, 15 parts of zinc phosphate, coal tar 10 parts of asphalt, 2 parts of modified resin, 15 parts of red iron oxide, 20 parts of precipitated barium sulfate, 5 parts of sericite, 10 parts of composite phosphorus titanium powder, 0.5 parts of anti-sedimentation slurry, 0.3 parts of defoamer, 0.3 parts of dispersant , 6.9 parts of the first mixed solvent; component B: 55 parts of cardanol-modified polyamide resin, 2 parts of salt spray resistance additive, and 39 parts of the second mixed solvent.

[0038] Preparation:

[0039] A component: step 1, dissolve the anti-settling slurry with a mixed solvent, then add epoxy resin A, epoxy resin B and coal tar pitch, add dispersant and defoamer while stirring at 600rpm, and continue stirring at 400rpm for 15min , step 2, add iron oxide red, precip...

Embodiment 3

[0042] An asphalt modified epoxy zinc phosphate heavy-duty anti-corrosion primer, including the following components by weight: A component: 12 parts of epoxy resin A, 14 parts of epoxy resin B, 11 parts of zinc phosphate, coal tar 8 parts of asphalt, 4 parts of modified resin, 17 parts of red iron oxide, 19 parts of precipitated barium sulfate, 3 parts of sericite, 12 parts of composite phosphorus titanium powder, 0.5 parts of anti-sedimentation slurry, 0.3 parts of defoamer, 0.4 parts of dispersant , 9 parts of the first mixed solvent; component B: 54 parts of cardanol modified polyamide resin, 2 parts of salt spray resistance additive, and 39 parts of the second mixed solvent.

[0043] Preparation:

[0044] A component: step 1, dissolve the anti-settling slurry with a mixed solvent, then add epoxy resin A, epoxy resin B and coal tar pitch, add dispersant and defoamer while stirring at 500rpm, continue stirring at 500rpm for 13min , step 2, add iron oxide red, precipitated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com