Patents

Literature

44 results about "Zinc preparations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

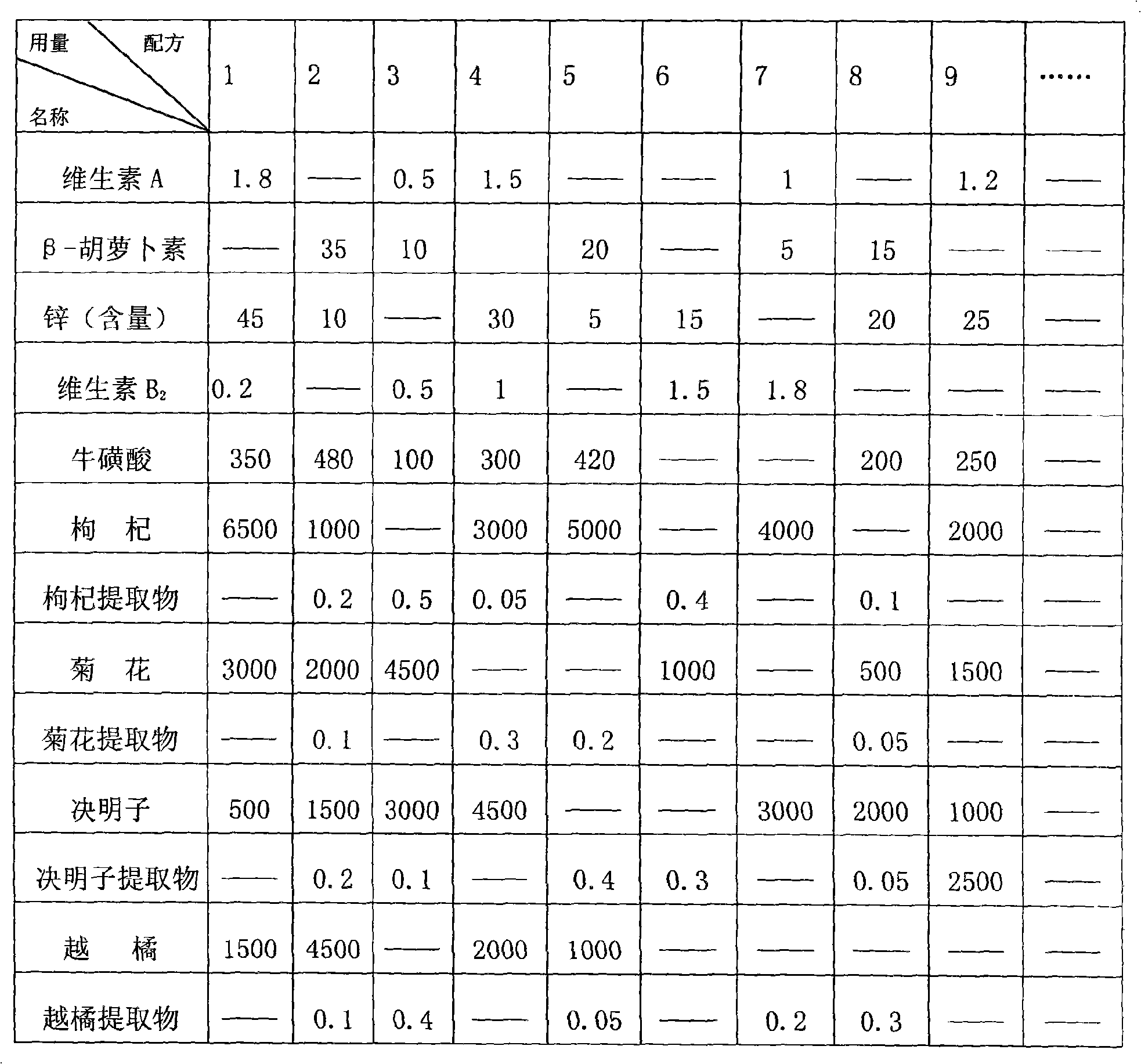

Health care drink for alleviating eyestrain

A health care drink for alleviating asthenopia is prepared by adding vegetable juice or animal and vegetable protein juice or a certain amount of ethanol to water, adding food raw materials and a food additive, and selectively adding vitamin A, beta-carotene, vitamin B2, a zinc preparation, taurine, Chinese wolfberry, chrysanthemum, cassia seed and cowberry and processing the materials. At present, 150 million of people have asthenopia in China; the health care drink of the invention can effectively alleviate the inconvenience of the asthenopia to people, and has broad market development space both at home and abroad.

Owner:曲建波

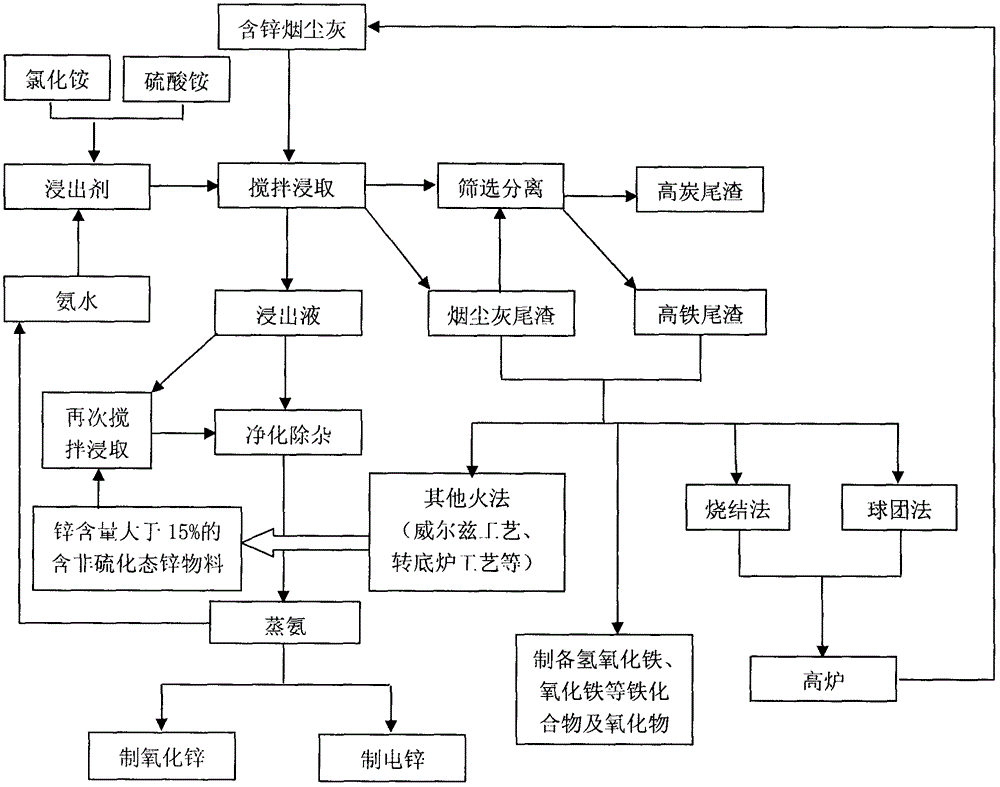

Utilizing method of zinc-containing dust ash of steel plant

InactiveCN106119556AIncrease concentrationSolve the problem of continuous enrichmentPhotography auxillary processesZinc oxides/hydroxidesEnvironmental resistanceAmmonia

The invention relates to a utilizing method for producing zinc oxide products by utilizing zinc-containing dust ash of a steel plant and recycling ferric carbon for returning to smelting. Zinc in the dust ash is leached by use of an ammonia method; materials which have the zinc content greater than 15% and contain non-vulcanized zinc are added for increasing the concentration of a zinc solution; leachate is purified, cleaned and subjected to ammonia distilling, and zinc oxide is prepared after electrolytic zinc preparation or zinc deposition; and original dust ash tailings or screened dust ash tailings are sent into a blast furnace for smelting, or a conventional pyrogenic process is adopted for recycling ferric carbon from the original dust ash tailings or the screened dust ash tailings, and collected secondary zinc oxide dust ash is used for the front end leaching, so that the zinc concentration of the leachate is increased. The utilizing method can be applicable to dust ash, with the zinc content as lower as 4% or even lower, of the steel plant; by use of a conventional method, the zinc extraction rate and the removing rate of harmful substances including alkali metal, fluorine and chlorine are both above 90%; the dust ash tailing recovery process is high in equipment adaptability, and appropriate treatment processes can be chosen according to existing equipment; and efficiency is high, the environment is protected, and comprehensive cyclic utilization of the zinc-containing dust ash is achieved.

Owner:李果

Zinc-contained preserved-egg pickling liquid and preparing method

ActiveCN101069565AIncrease contentReduce contentEggs preservationFood preparationEggshellHigh volume manufacturing

The present invention relates to a zinc-containing preserved egg pickling solution, its preparation method and method for pickling said preserved egg. Said pickling solution is made up by mixing the following raw materials: (by weight portion) 10-15 portions of quicklime, 5-8 portions of soda, 2-4 portions of edible salt, 0.1-0.4 portion of zinc sulfate, 80-120 portions of water and 0.8-1.5 portions of tea.

Owner:HUBEI SHENDAN HEALTHY FOOD

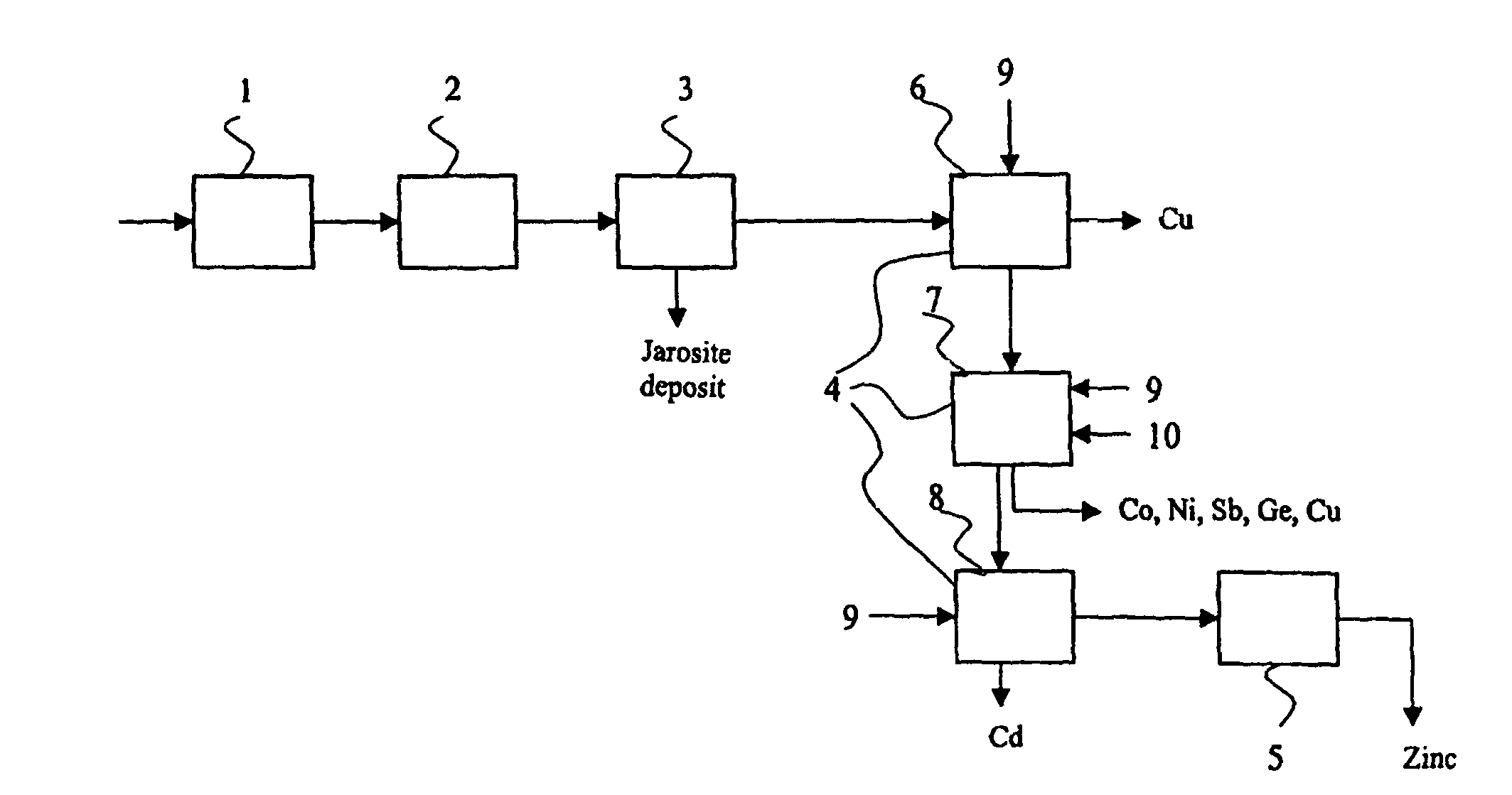

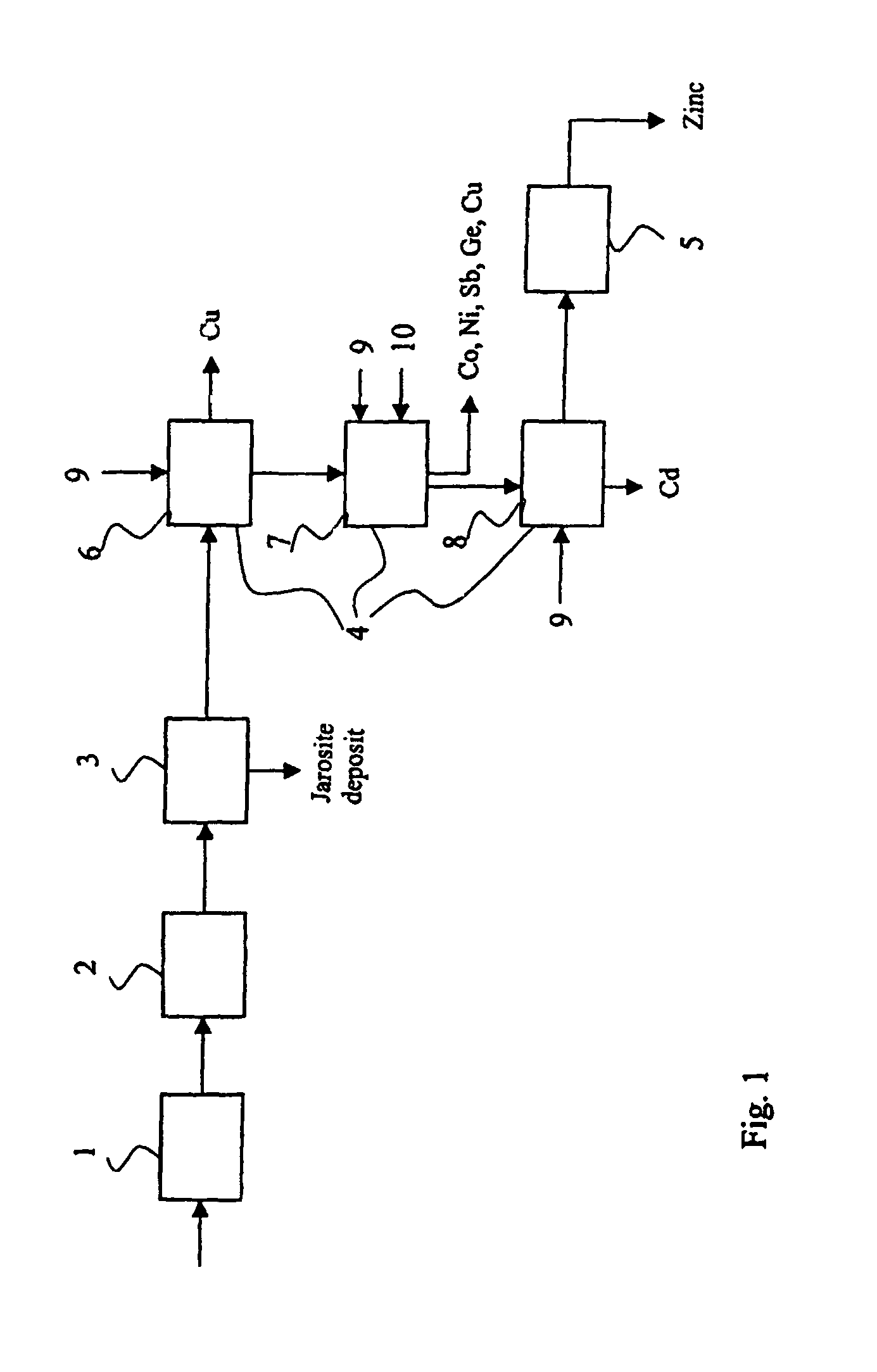

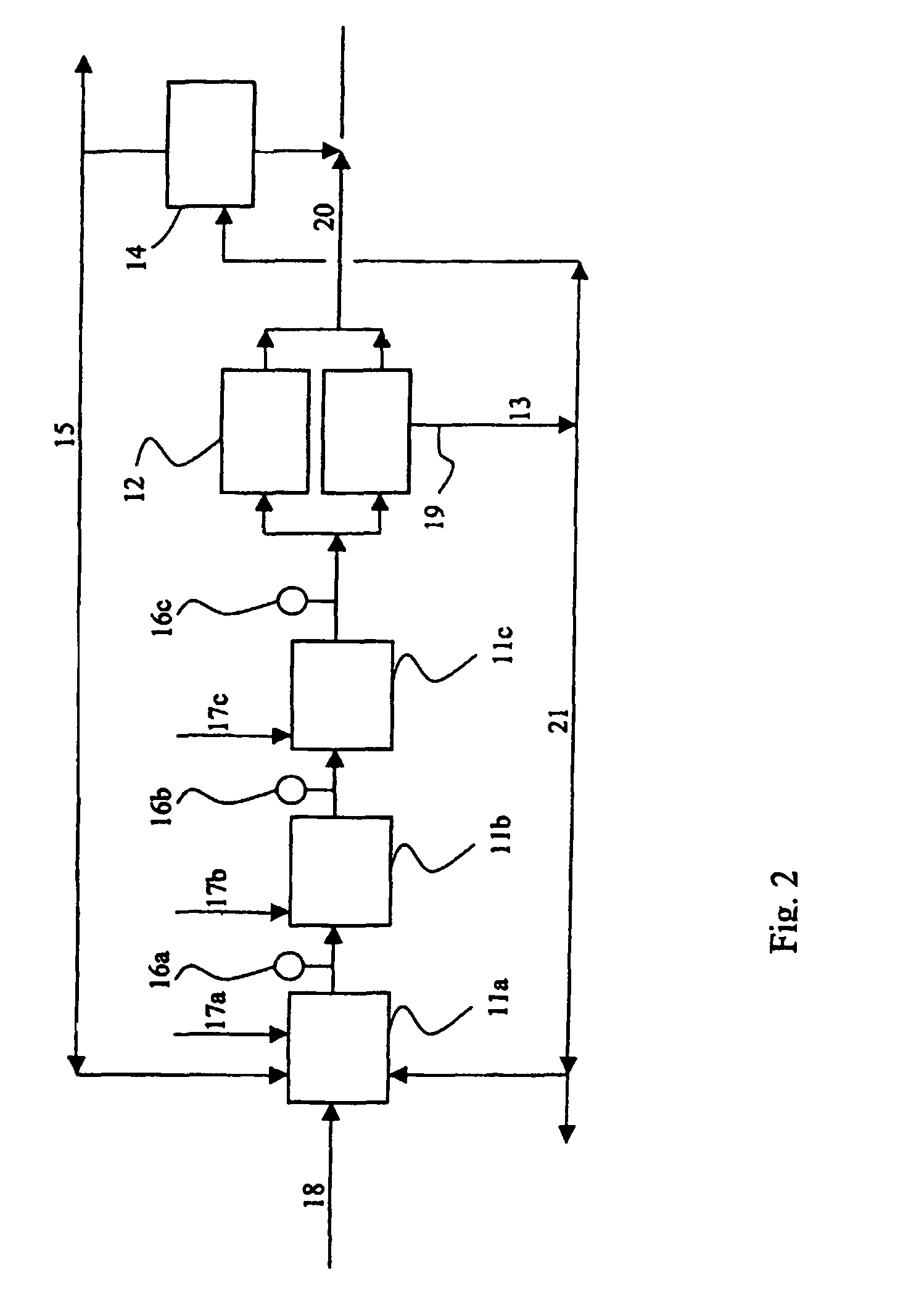

Method and apparatus for controlling metal separation

InactiveUS8021459B2Fouling of measuring is preventedMeasurement superfluousManufacturing convertersHeat treatment process controlPotential measurementMeasuring instrument

The invention relates to a method and apparatus for controlling a continuous metal removal in conjunction with a zinc preparation process, in which the metal removal is performed in one or more reactors (11a-c), in conjunction with the reactor, the redox potential (16a-c) and the acidity and / or basicity are measured, and based on the measurement results, the process variables (17a-c) of the metal removal are adjusted towards the desired direction. According to the invention, the redox potential measurements (16a-c) are performed from the sludge produced in the reactor in conjunction with the outlet pipe of the reactor outside the reactor, and the measuring instrument (16a-c) is purified at predetermined intervals.

Owner:OUTOTEC OYJ

Method for preventing and controlling bacterial wilt of vegetable crops

InactiveCN105941026AReduce lossesPlay a preventive effectBiocideDead animal preservationDiseaseCopper

The invention relates to a crop disease preventing and controlling method, in particular to a method for preventing and controlling bacterial wilt of vegetable crops. In one week after vegetable transplantation, or at a blossoming and fruit-bearing stage and an early stage of diseases, a composite reagent is adopted for root-irrigation treatment, and the composite reagent contains a copper-zinc preparation and a garlic extract; after half a month, beneficial bacteria are fertigated. The crop disease preventing and controlling method is simple, quick in effect and accurate in composition compatibility, does not affect farming seasons, ensures a prevention and control effect, timely supplements beneficial bacteria and prevents re-breeding of harmful bacteria so as to ensure the prevention and control effect.

Owner:万学闪

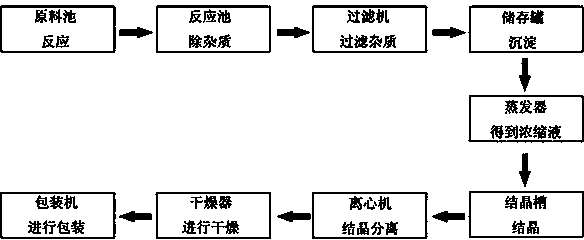

Process for preparing zinc sulfate

The invention provides a process for preparing zinc sulfate and the process is simple in step, low in energy consumption, high in production efficiency and high in product purity. The process comprises the following steps: putting secondary zinc oxide and zinc oxide in waste residues produced in zinc preparation in a raw material tank filled with dilute sulfuric acid, reacting to generate a zinc sulfate solution, guiding the zinc sulfate solution into a reaction tank, removing impurities such as iron, cobalt and copper in the reaction tank, filtering the impurities through a filtering machine, guiding the zinc sulfate solution into a storage tank for precipitation, evaporating the zinc sulfate solution in an evaporator to obtain a concentrated solution, crystallizing in a crystallizing tank, carrying out crystal separation in a centrifugal machine, cooling to obtain zinc sulfate containing crystal water and drying in a dryer to obtain the zinc sulfate. According to the process, the zinc sulfate solution is concentrated in the way of pouring hot oil and circularly heating, so that the heating temperature is higher, the heating material can be recycled, the energy consumption is little and the cost is reduced. The process for preparing the zinc sulfate is simple and clear in processing step, energy-saving, friendly to the environment and convenient to operate.

Owner:TIANJIN XINXIN CHEM FACTORY

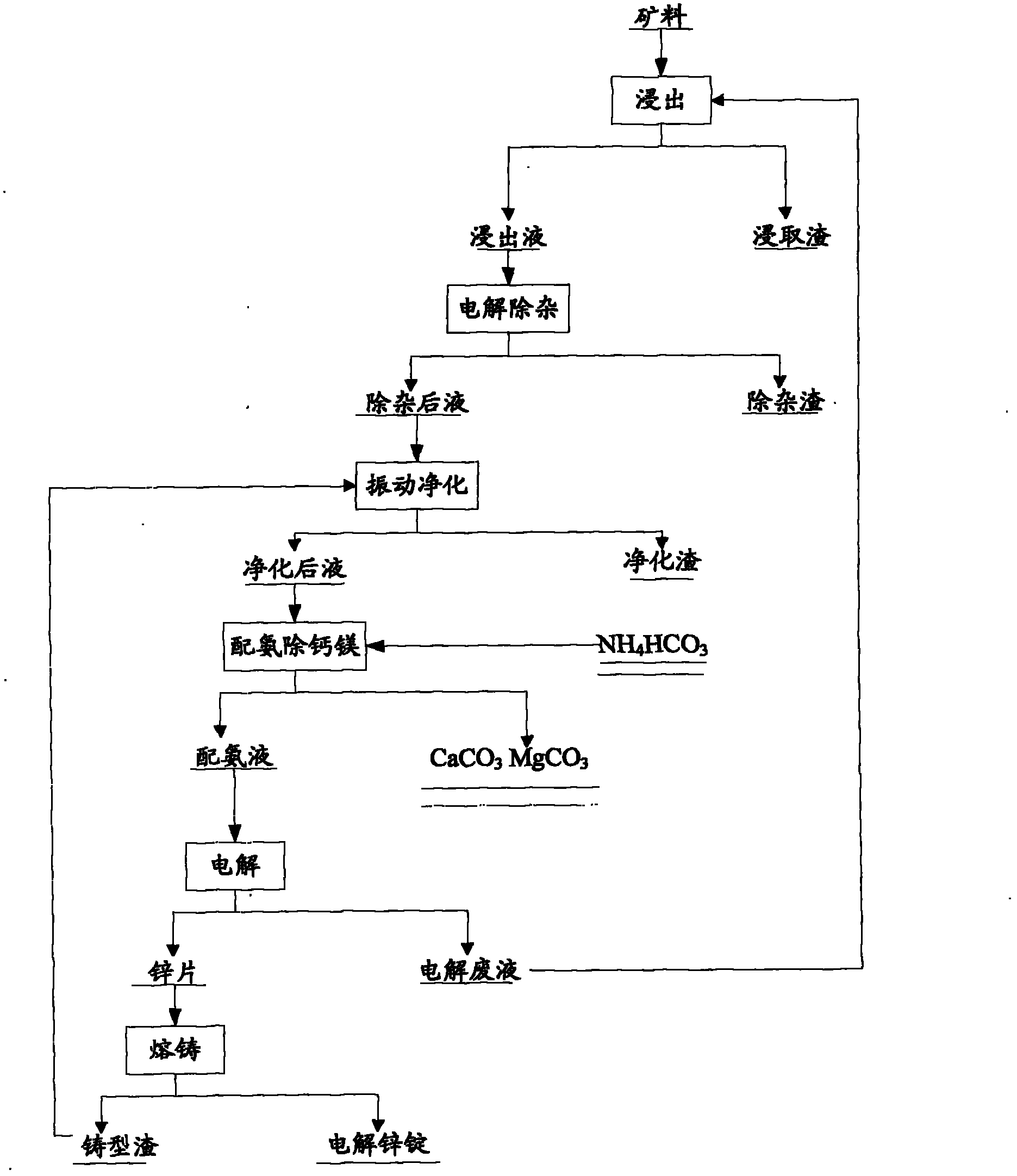

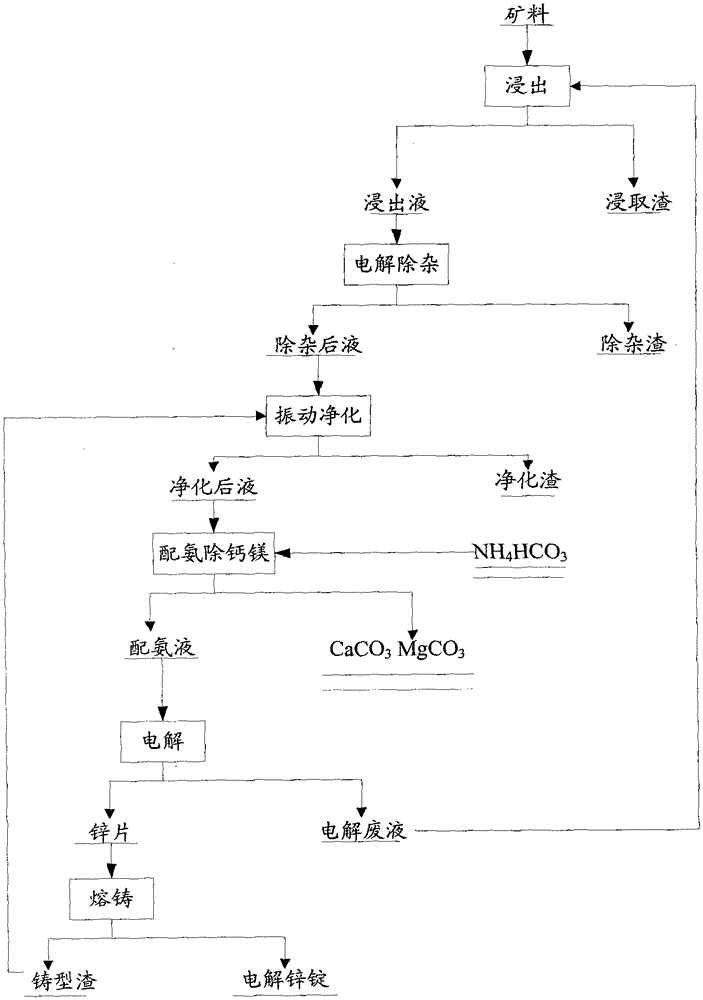

Method for preparing high-purity zinc by electrolysis

ActiveCN103184472AAvoid enrichmentAvoid the decontamination processPhotography auxillary processesProcess efficiency improvementElectrolysisImpurity ions

The invention provides a method for preparing high-purity zinc by electrolysis. The method comprises the following steps: leaching a zinc-containing material using an ammonium chloride solution to obtain a zinc-ammonia complex solution; performing impurity removal on the zinc-ammonia complex solution through constant-voltage electrolysis to remove most of impurity ions which are more electropositive than zinc from the solution; after impurity removal through constant-voltage electrolysis, allowing the zinc-ammonia complex solution to flow through a zinc particle vibration purifier to replace the residual impurity metal ions in the solution and thus to achieve the effect of deep purification of the solution; adding carbon-ammonium into the zinc-ammonia complex solution after deep purification to perform ammonia treatment and remove a part of calcium and magnesium ions from the solution; and performing electrolysis on the ammonia-treated solution to obtain high-purity metal zinc. Compared with the prior art of zinc preparation through electrolysis of a zinc-ammonia complex compound, the method provided by the invention adopts carbon-ammonium to replace liquid ammonia, so as to reduce the consumption cost of ammonia and avoid the enrichment of calcium and magnesium in the solution; and performs deep purification by impurity removal through constant-voltage electrolysis and treatment of the solution with the zinc particle vibration purifier after electrolysis impurity removal, so as to completely eliminate the use of zinc powder in the purification link, greatly reduce the purification cost and produce the purified solution which is higher in quality than purification with zinc powder. Therefore, the method stably produces No.0 metal zinc.

Owner:唐山瑞能再生资源有限公司

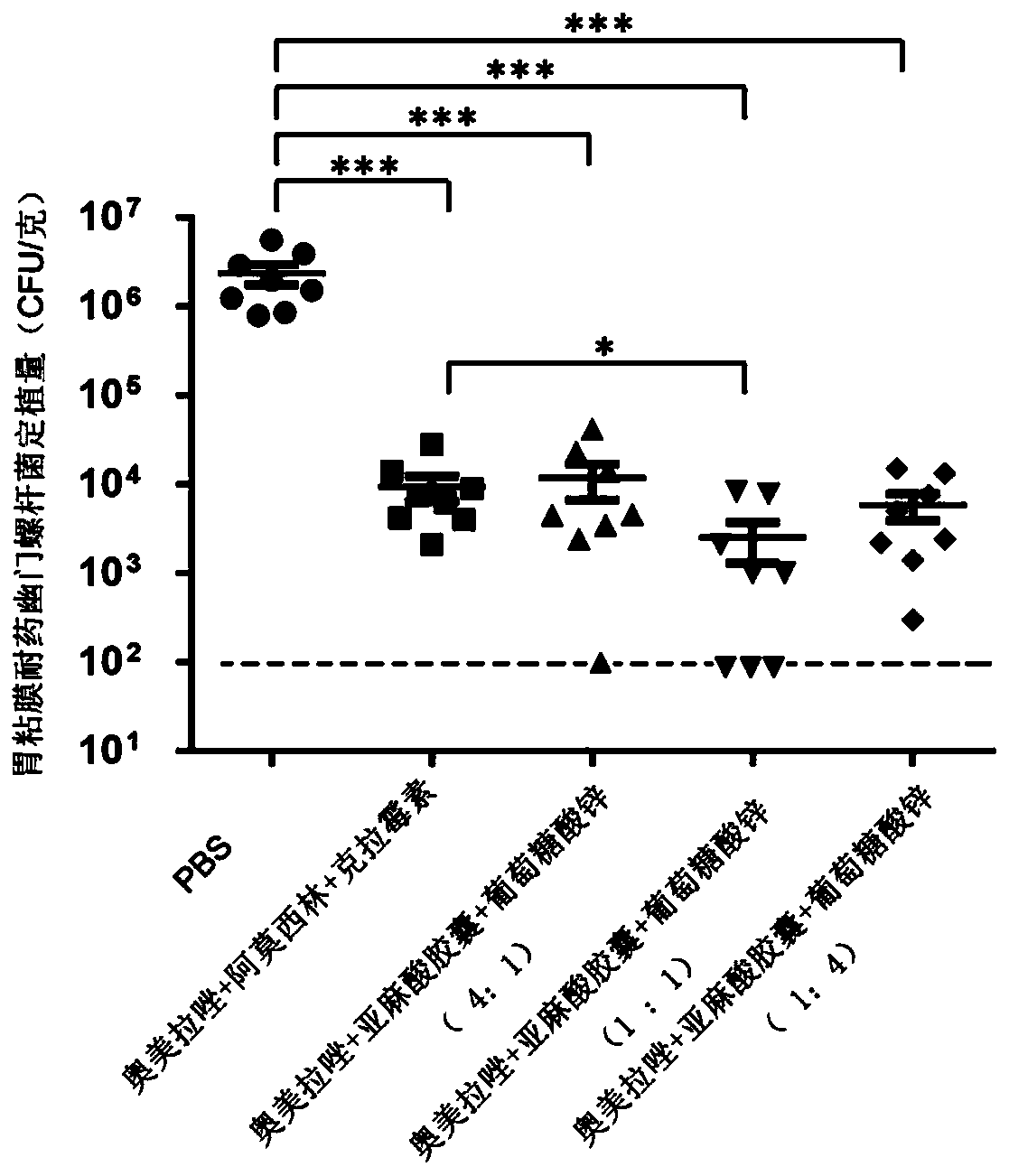

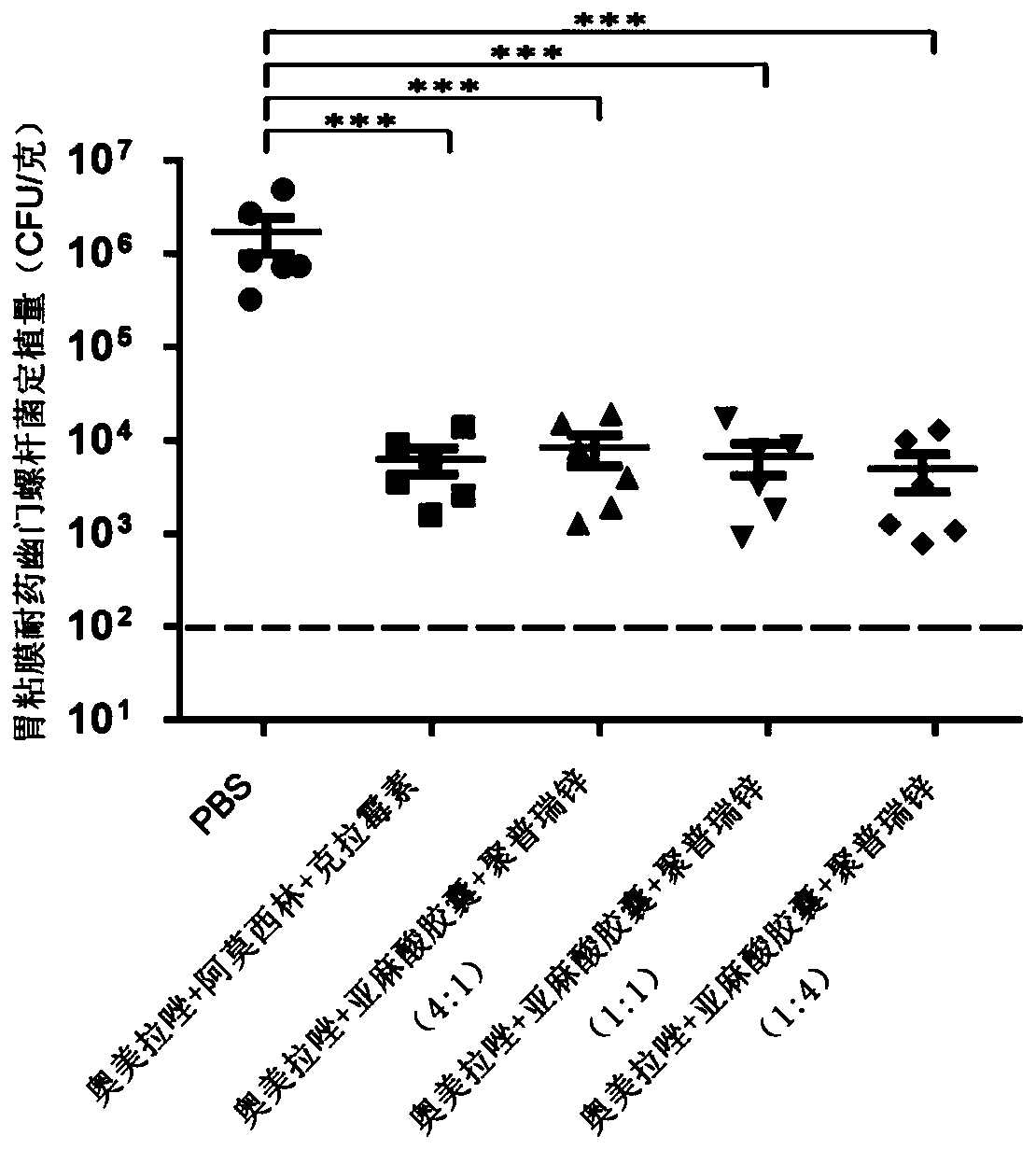

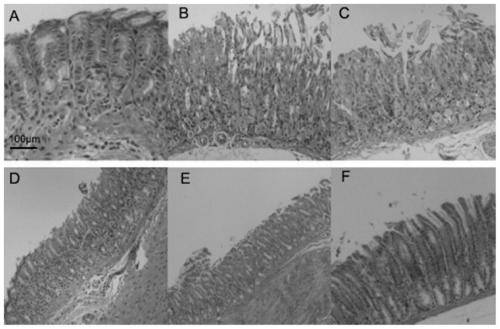

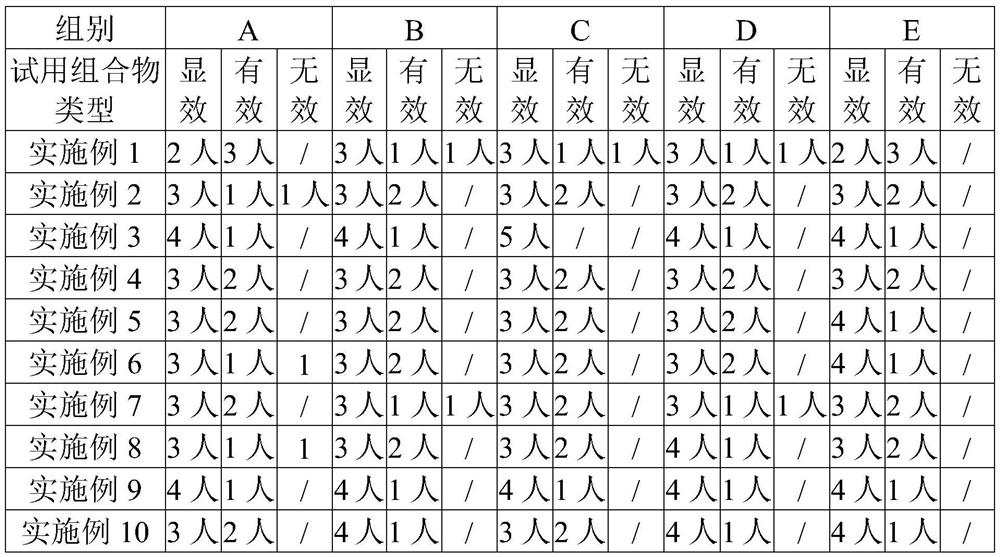

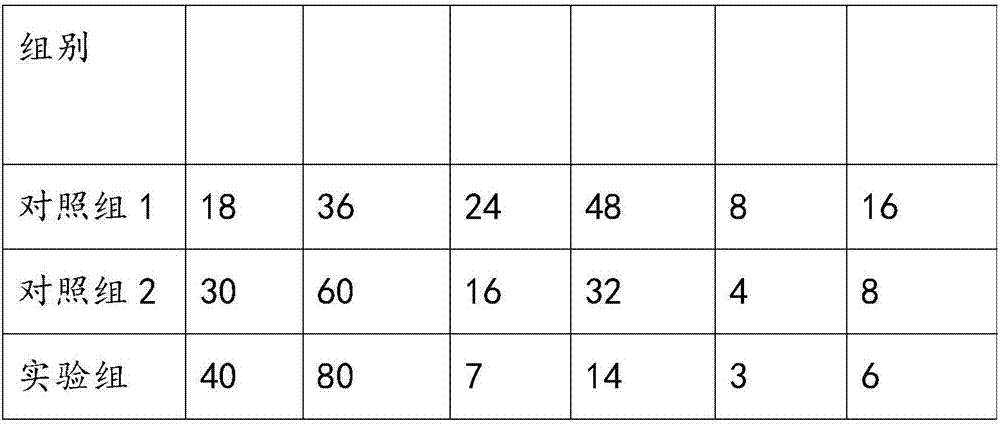

Composition for resisting helicobacter pylori and application thereof

InactiveCN111544451ADelay drug resistanceSmall side effectsAntibacterial agentsOrganic active ingredientsAntibiotic resistanceHelicobacter Infections

The invention discloses a composition for resisting helicobacter pylori and the application of the composition. The composition comprises linolenic acid capsules, a zinc preparation (zinc gluconate orpolaprezinc) and a proton pump inhibitor. The pharmaceutical composition can inhibit helicobacter pylori in vivo and in vitro by combined use, has a good effect on treatment of gastritis and other related diseases caused by helicobacter pylori infection, and especially has a good effect on refractory gastritis caused by drug-resistant helicobacter pylori infection. According to the composition, helicobacter pylori infection can be cured under the condition that antibiotics are not used, the cure rate is increased, and the occurrence rate of antibiotic resistance is reduced.

Owner:NANJING MEDICAL UNIV

Composition containing rehydration salt and probiotics

PendingCN112617207AIncreasing the thicknessPrevent intrusionOrganic active ingredientsSugar food ingredientsBiotechnologyLactose intolerance

The invention provides a composition containing rehydration salt and probiotics, and relates to the technical field of probiotics. The composition comprises a fluid supplementation probiotic composition and auxiliary materials; the auxiliary materials are auxiliary materials acceptable in foods, health care products, special medical foods or pharmaceutical processing; the fluid supplementation probiotic composition comprises the following raw materials: the probiotics and the rehydration salt; and the probiotics is 104 to 1,014CFU / g. The invention has the advantage that the composition is convenient to take and can adjust the intestinal function of a user, improve the immunity of the organism, inhibit proliferation of harmful bacteria in the intestinal tract, reduce toxin generation, relieve lactose intolerance, rapidly supplement water and electrolyte and relieve and treat diarrhea. The composition is beneficial for being taken and improving the treatment effect of diarrhea, and overcomes the defects that the probiotics, the rehydration salt, a zinc preparation and the like are complex to take, need to be taken for multiple times and are poor in taste when being combined for use in the actual operation process.

Owner:北京海思未来健康科技有限公司

Zinc replenisher with control released zinc and its preparing method and use

InactiveCN1857308AGood biocompatibilityGastrointestinal mucosaPowder deliveryPeptide/protein ingredientsControlled releaseBiocompatibility Testing

The present invention discloses zinc replenisher with control released zinc and its preparation process and use. The zinc replenisher is zeolite containing active zinc in 1.5-10 wt%. The preparation process includes the adsorption and ion exchange reaction between zinc salt and zeolite, filtering, drying and crushing to obtain zeolite containing active zinc. Supporting zinc onto zeolite, which possesses excellent biocompatibility, excellent gastrointestinal mucous membrane affinity, regular pore canal structures and cage spaces, high surface activity and great specific surface area, can obtain controlled releasing of zinc and raise utilization of zinc. The control released zinc preparation may be used as zinc replenisher for human body and animal.

Owner:ZHEJIANG UNIV

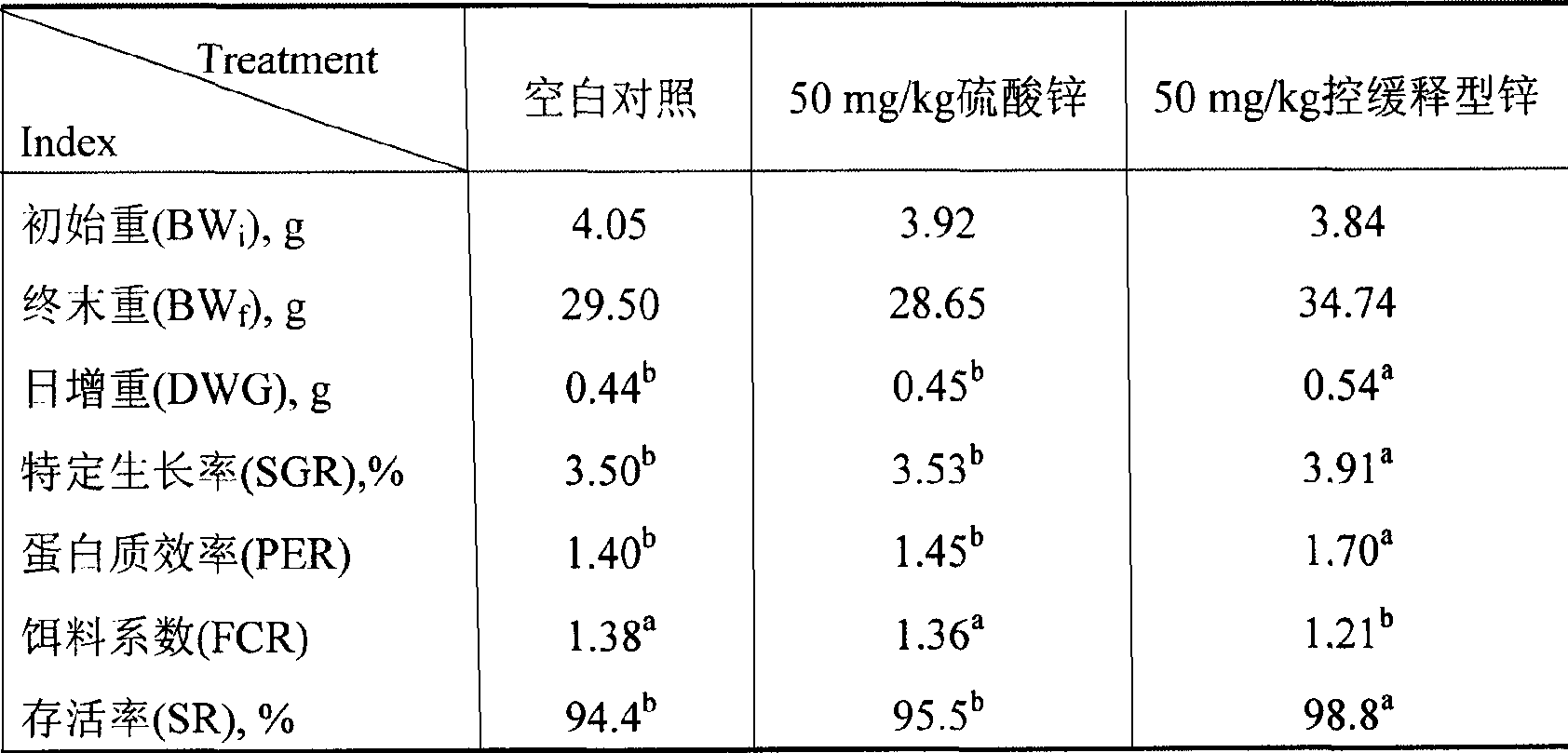

Biological zinc preparation and method for preparing same

ActiveCN102649969AIncrease profitPromote growthAnimal feeding stuffMicroorganism based processesFermentationPhotosynthetic bacteria

The invention discloses a biological zinc preparation and a method for preparing the same, specifically, a zinc-rich preparation which is produced by photosynthetic bacteria is utilized, the photosynthetic bacteria use sufficient zinc resources during the fermentation process to convert inorganic zinc into organic zinc as much as possible, so the content of the organic zinc in the photosynthetic bacteria is increased, and accordingly, the biological zinc preparation with higher zinc content is prepared. The biological zinc preparation has the advantages of simple production technology, less equipment investment and easily-obtained raw materials, the prepared biological zinc preparation can be widely applied in livestock and agricultural production, and has more market competitiveness compared with yeast zinc.

Owner:山东环亿生物科技有限公司

Sprouted brown rice flour capable of reducing weight and making method of sprouted brown rice flour

InactiveCN107997007AIncrease element contentElement content balanceNatural extract food ingredientsFood ingredient functionsCaladiumPolygonum fagopyrum

The invention discloses sprouted brown rice flour capable of reducing weight. The sprouted brown rice flour comprises main coarse food grain raw materials of sprouted brown rice, lotus seeds, red beans, soybeans, black beans, corn, oat and buckwheat, so that the content of starch in the sprouted brown rice flour can be increased, and digestive absorption is facilitated. Through combination of traditional Chinese medicine raw materials of haws, lotus seeds, lily bulbs, Chinese yams, poria cocos, honey, honeysuckle flowers, fresh ginger, lotus leaves, radix rehmanniae, immature orange fruits, prepared radix et rhizoma rhei, semen cassiae, rhizoma alismatis, rhizoma polygonati, coix seeds, fructus momordicae, semen pruni, linseeds and heartleaf houttuynia herbs, and the traditional Chinese medicine raw materials are mixed with the power prepared from the sprouted brown rice, the lotus seeds, the red beans, the soybeans, the black beans, the corn, the oat and the buckwheat, so that the effects of cooperation, mutual promotion and effective improvement of digestive ability can be achieved; and finally, through auxiliary materials of L-carnitine, beta-carotene, lycopene, a calcium preparation, chalybeate and a zinc preparation, the sprouted brown rice flour can supplement rich calcium elements, ferrum elements and zinc elements for eaters, promotes the element content in human bodiesto be balanced, and has the function of adjusting the health statuses of human bodies, including reducing blood sugar, reducing weight, easing constipation, improving sleep and the like.

Owner:浙江益万生物技术有限公司

Feeding composition and application thereof to animal feed additive preparation

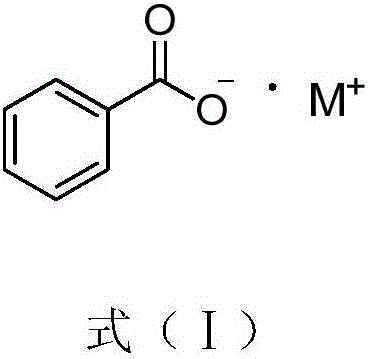

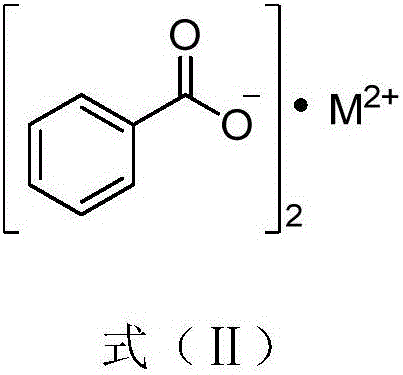

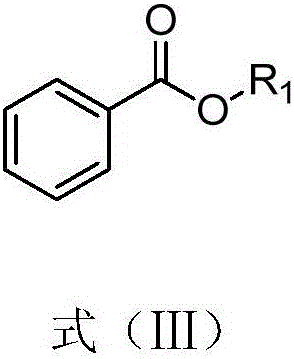

InactiveCN105815571ACan maintain healthIncrease production capacityAccessory food factorsBenzoic acidAntibiotic Y

The invention provides a feeding composition and application thereof to animal feed additive preparation. The feeding composition contains a benzoic acid derivative and a myristic acid derivative. The benzoic acid derivative is selected from benzoate or benzoate ester, the myristic acid derivative is selected from myristate or myristate ester, and the optimal mass ratio of the benzoic acid derivative to the myristic acid derivative in the feeding composition is 6:1-1:1. The feeding composition can serve as an animal growth promoter, and particularly substitute feeding antibiotics or high-dosage zinc preparations or copper preparations and other traditional animal growth promoters for the animal breeding industry. The feeding composition is a novel and safe animal feed additive and suitable for animals including livestock, poultry and aquaculture animals and has wide market prospects.

Owner:GUANGZHOU INSIGHER BIOTECHNOLOGY CO LTD

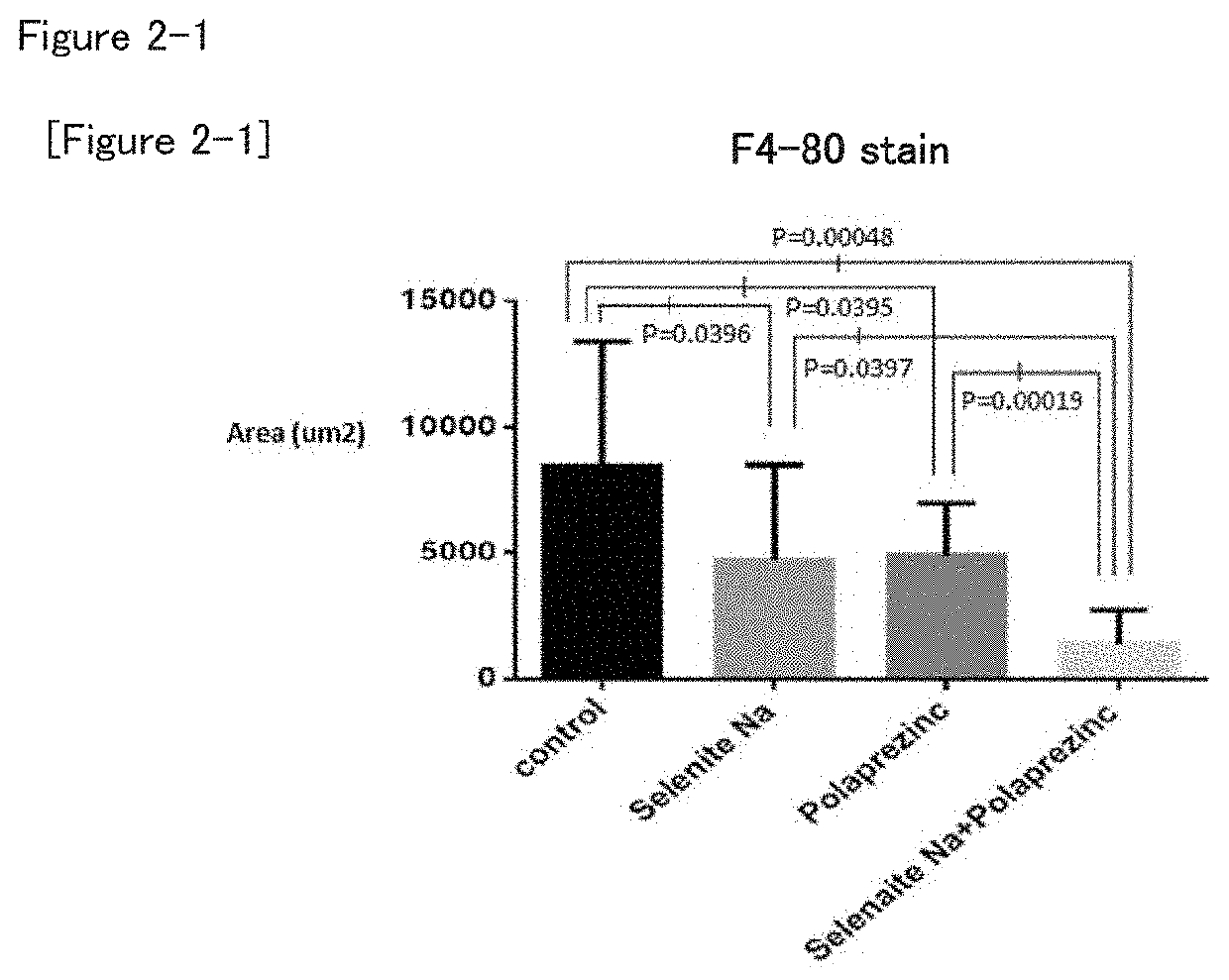

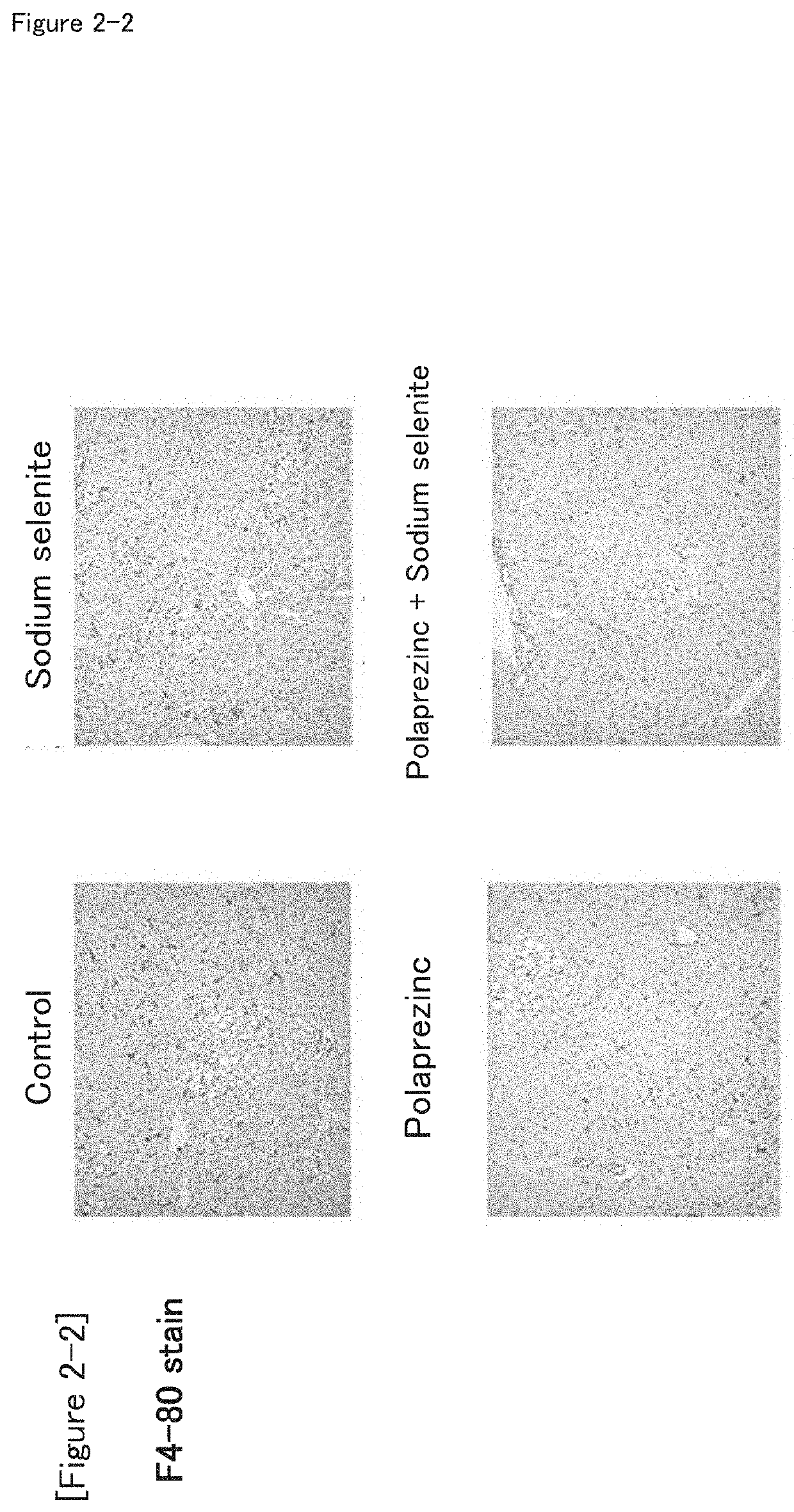

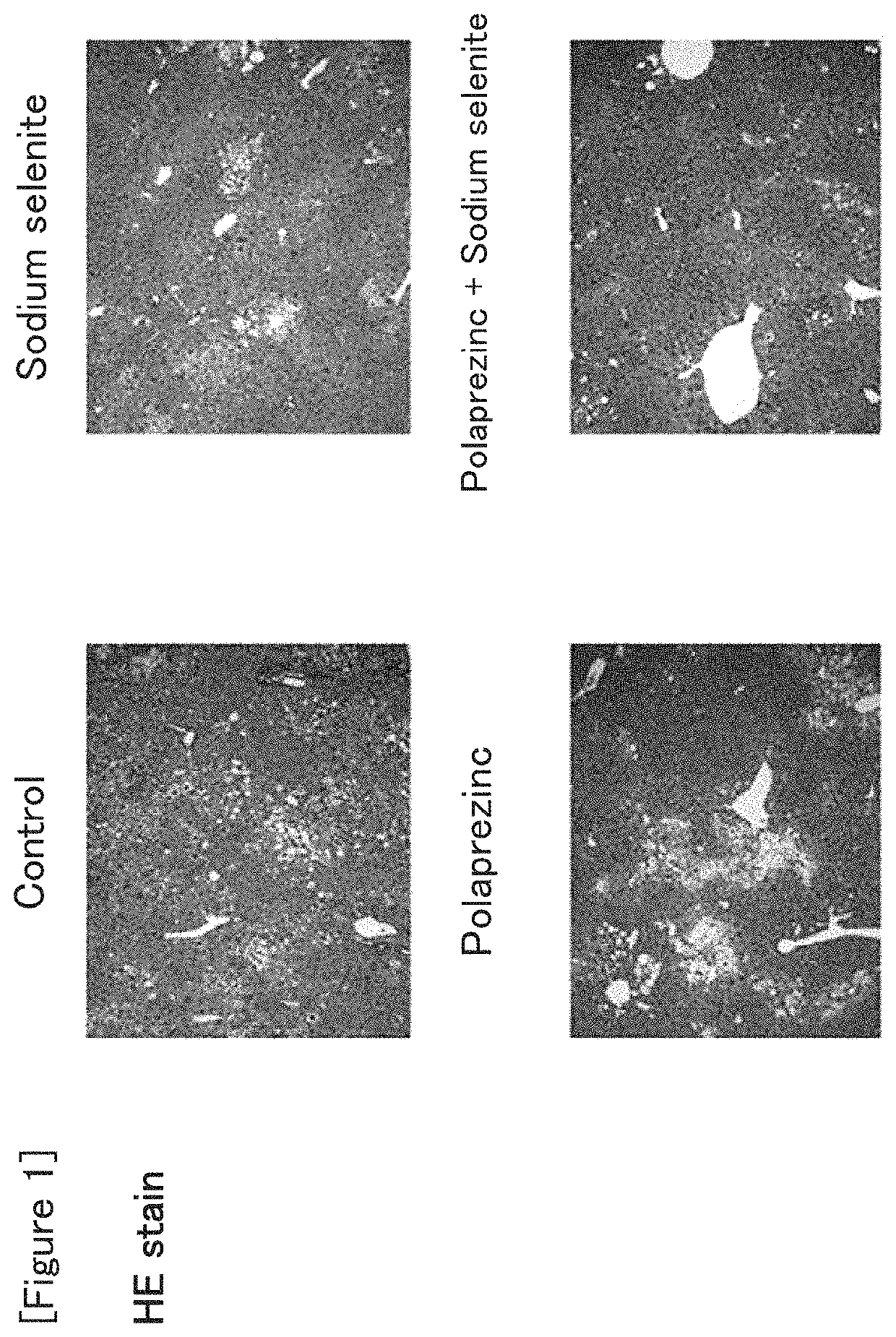

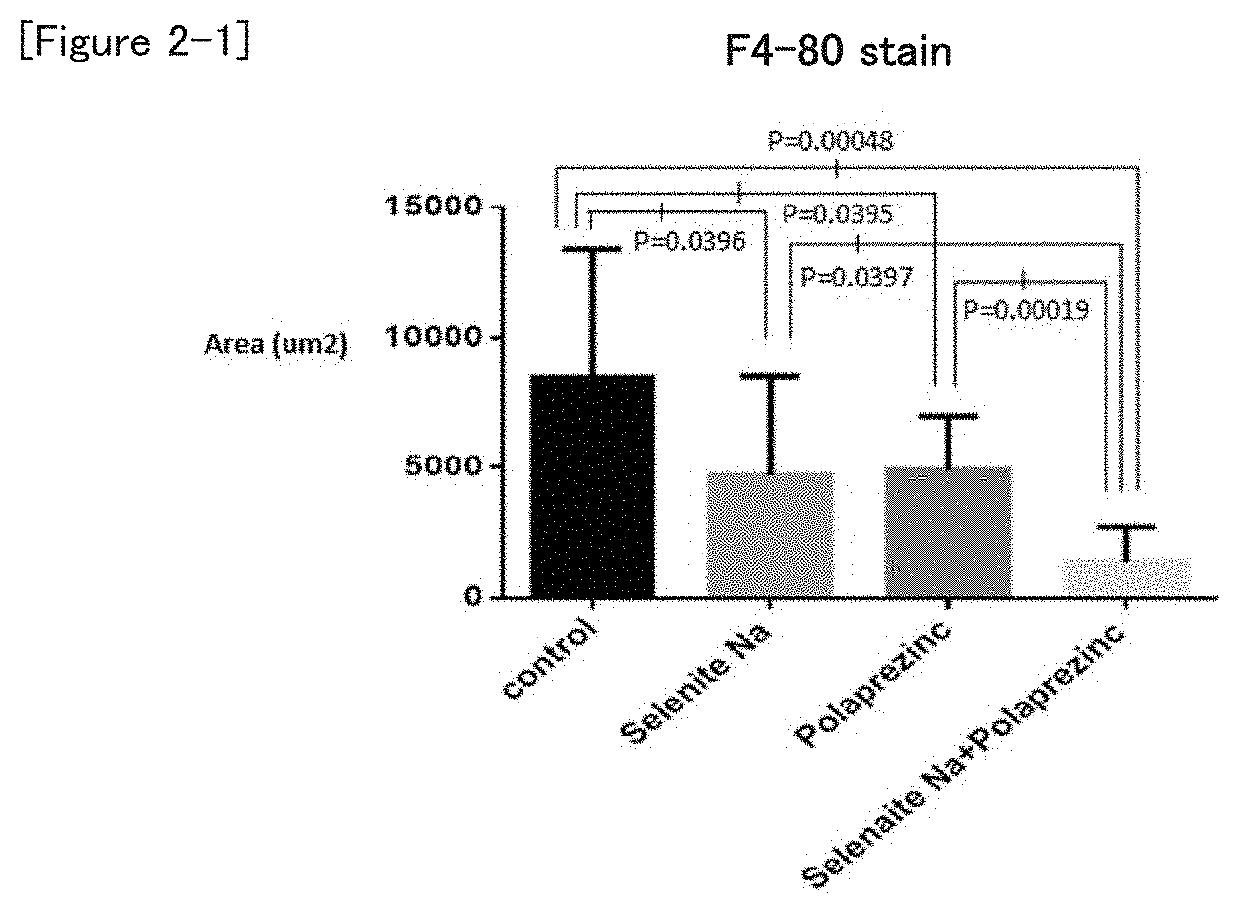

Combination drug suitable for treatment and prevention of non-alcoholic fatty liver disease (NAFLD) and/or non-alcoholic steatohepatitis (NASH), and/or hepatic fatty degeneration

InactiveUS20190336523A1Recover normal liverSuppress progressOrganic active ingredientsDigestive systemBULK ACTIVE INGREDIENTHealth food

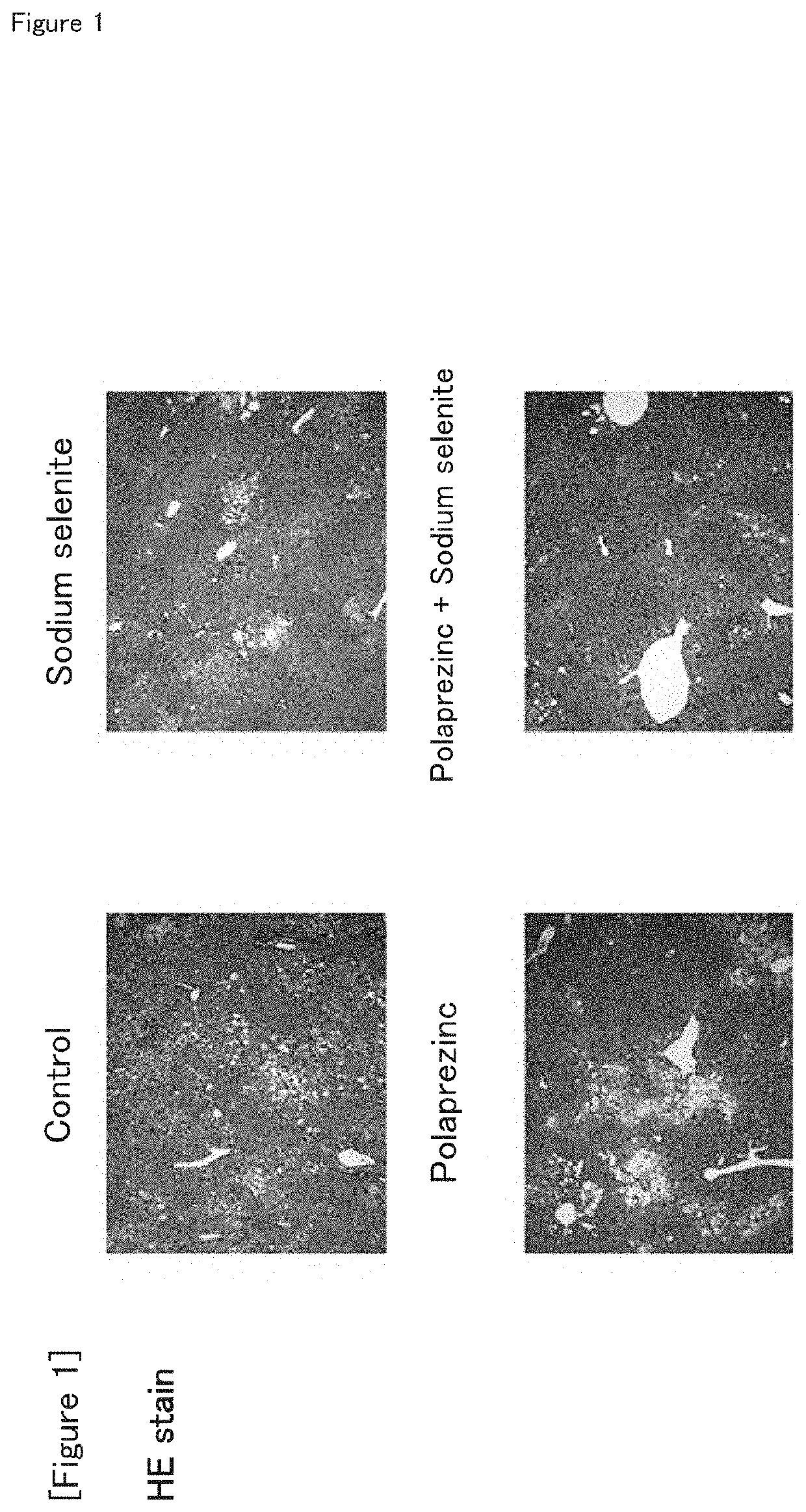

Problem to be SolvedTo provide medicine and health food suitable for treatment and prevention for non-alcoholic fatty liver disease (NAFLAD) and / or non-alcoholic steatohepatitis (NASH) which are not involved with hepatic virus, and / or hepatic fatty degeneration.Means for solving the problemA combination drug suitable for treatment of non-alcoholic fatty liver disease (NAFLAD) and / or non-alcoholic steatohepatitis (NASH), and / or hepatic fatty degeneration, wherein the active ingredients are zinc preparation and selenium preparation.

Owner:MEDICO CONSL CO LTD

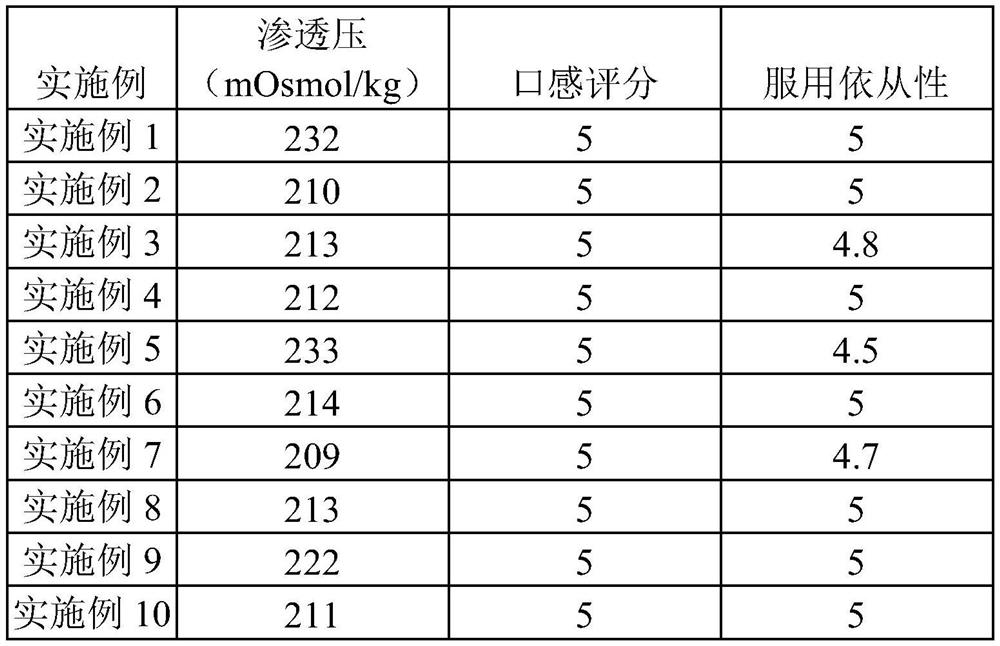

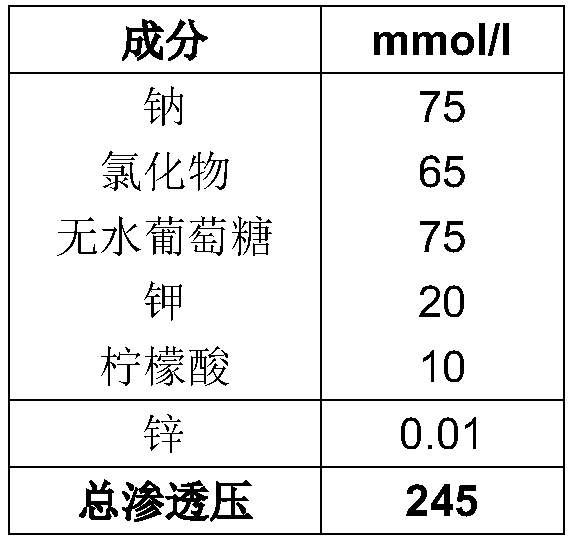

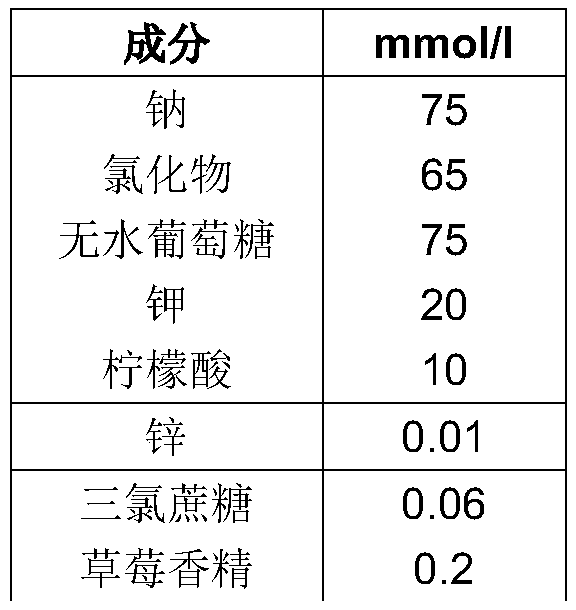

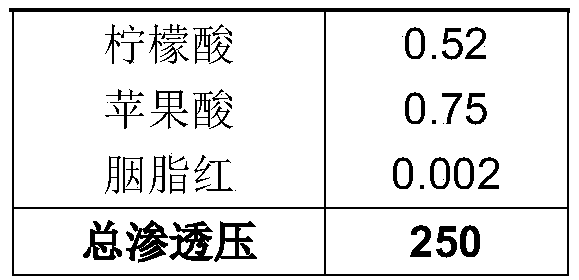

Hypotonic rehydration salt formula added with zinc preparation

The invention relates to a hypotonic rehydration salt formula added with a zinc preparation, which is formed by combining active ingredients, additives and an auxiliary material. Total substance concentration including glucose is within a range of 192 to 319mmol / l, wherein the active ingredients consist of: 60 to 90mmol / l of sodium: not smaller than concentration of sodium, but not greater than 111mmol / l of glucose: 14 to 26mmol / l of potassium; 8 to 12mmol / l of citric acid; 50 to 80mmol / l of chloride. Content of zinc contained in the zinc preparation does not exceed 0.154mmol / l. The additivesare an essence, a pigment, a sweetening agent and acidulant; and the auxiliary material is water. A food adopting the formula disclosed by the invention can be directly drunk by a user or be preparedinto corresponding concentration of solution for oral administration according to an indication on a package. According to the invention, the processes of oral rehydration and zinc supplementation canbe simultaneously completed by once drinking, and the hypotonic rehydration salt formula accords with related recommendations of authority organizations such as the world health organization, the Chinese medical association and the like for prevention and treatment on dehydration.

Owner:陆一江

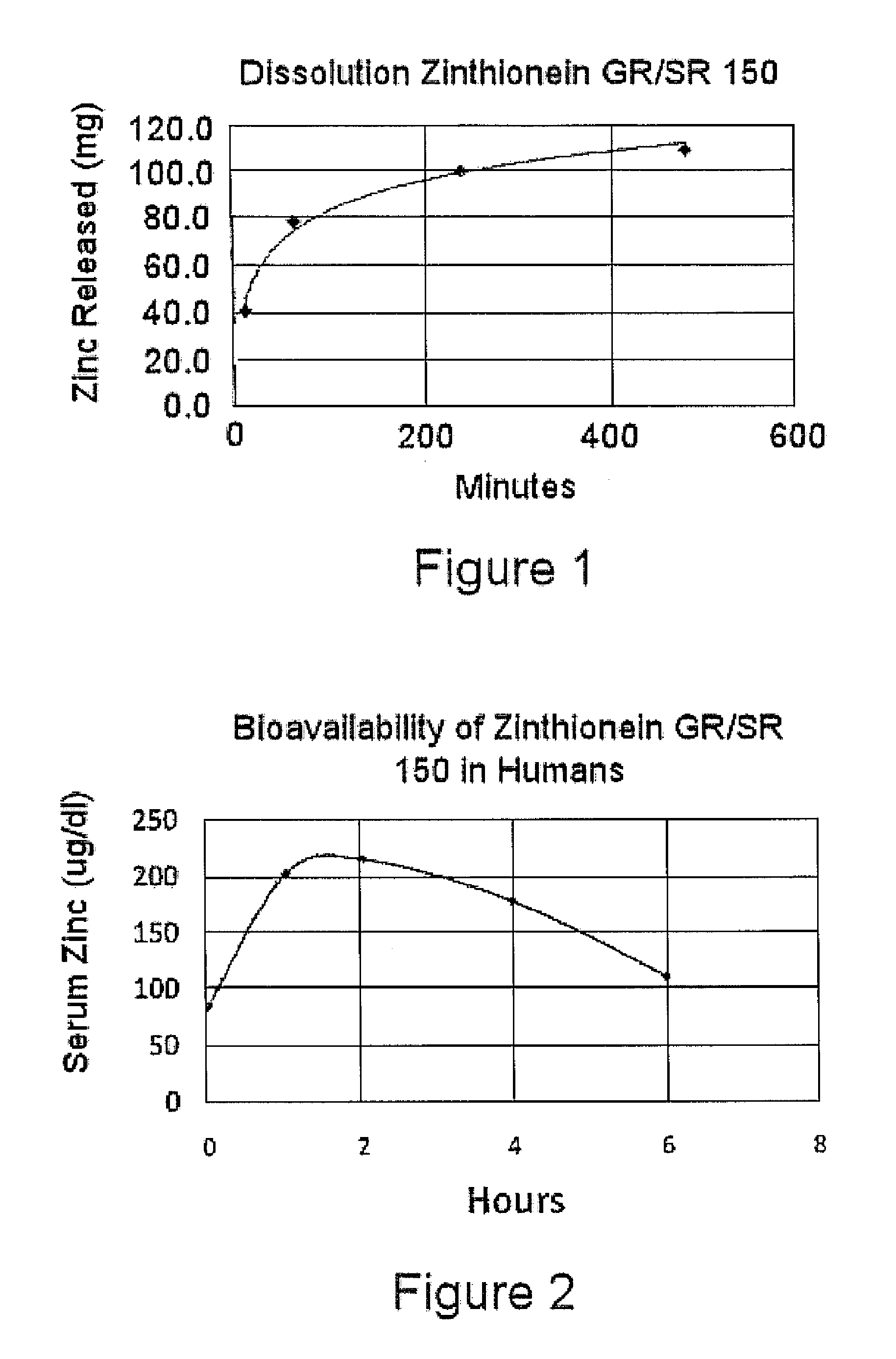

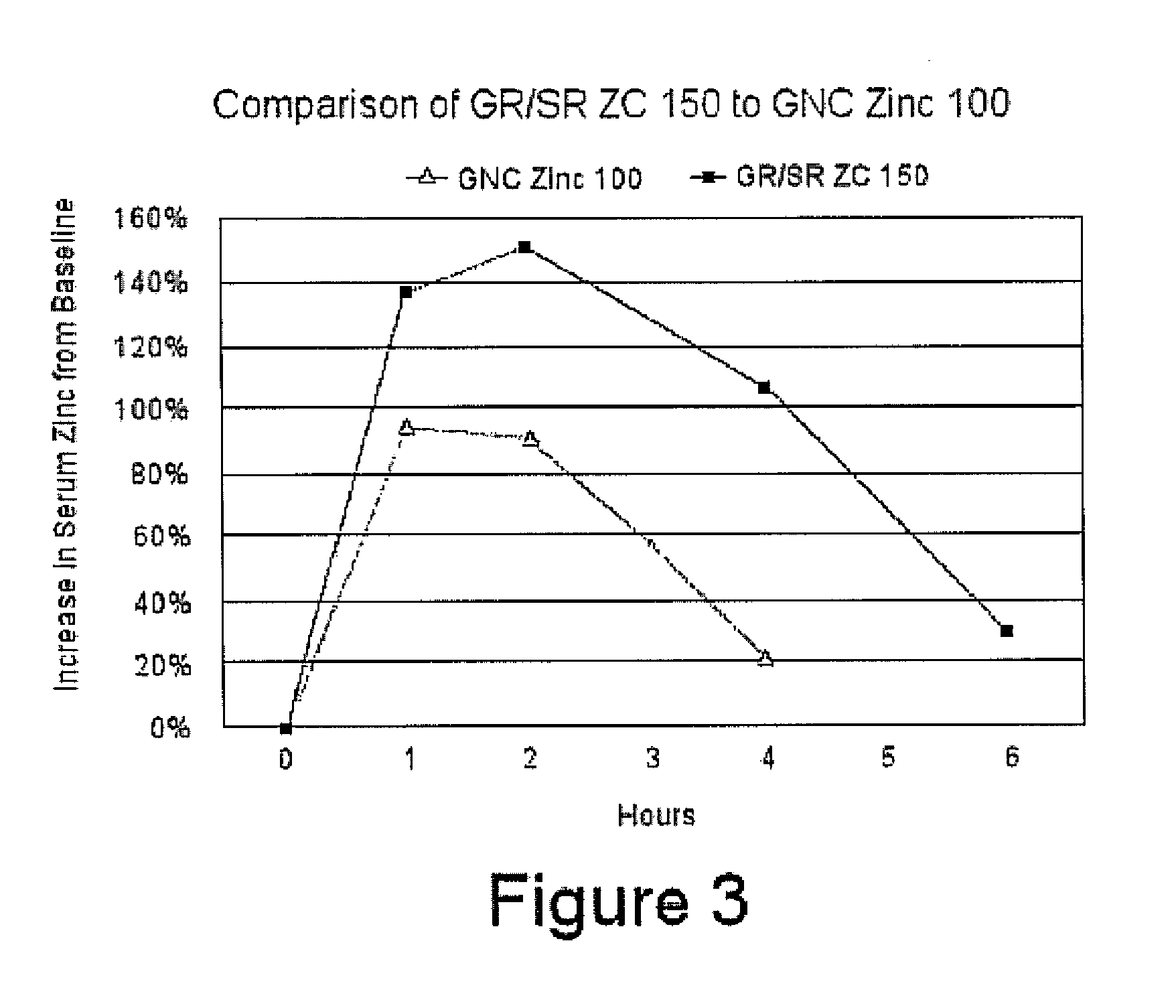

Gastrorententive oral high dose zinc preparations

InactiveUS20120058055A1Improve toleranceGreat oral unit dosBiocideSenses disorderHigh dosesPharmacology

Owner:CROUCH DENNIS BUEL

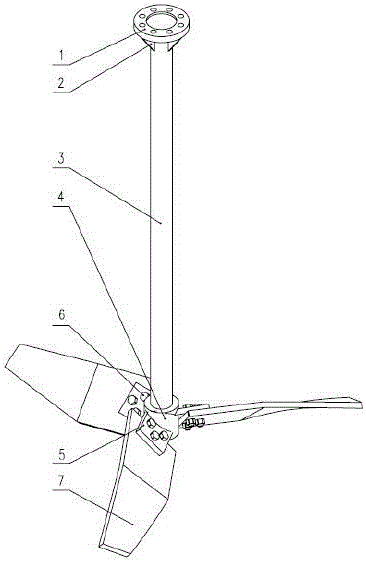

Highly-corrosion-resistant stirrer and making method thereof

ActiveCN107519781AHigh strengthHigh hardnessTransportation and packagingRotary stirring mixersMedium frequencyPulp and paper industry

The invention discloses a highly-corrosion-resistant stirrer and a making method. The highly-corrosion-resistant stirrer comprises a stirring shaft, a hub, blade fixing plates and blades, wherein one end of the stirring shaft is connected with a power device, and the other end of the stirring shaft is welded with the hub; one end of the blade fixing plate is welded with the hub, and the other end of the blade fixing plate is connected with the blade by fasteners; the blade fixing plates are flat plates and form angles of 30-50 degrees with the axis of the stirring shaft; and the surface hardness of the blades is 20-24HRC, the inclination angles and the widths of the blades change along with the length directions of the blades. The preparation method comprises the following steps: carrying out primary smelting in a medium-frequency induction furnace, carrying out refined smelting in an argon-oxygen decarburization furnace, adopting an electroslag remelting process to smelt a super duplex stainless-steel ingot, forging the super duplex stainless-steel ingot to be molded, and after solids are dissolved, assembling and molding. The highly-corrosion-resistant stirrer and the preparation method disclosed by the invention have the advantages that the production cost is reduced, and the service life of equipments prolonged and the use safety of equipment in the zinc preparation industry is improved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

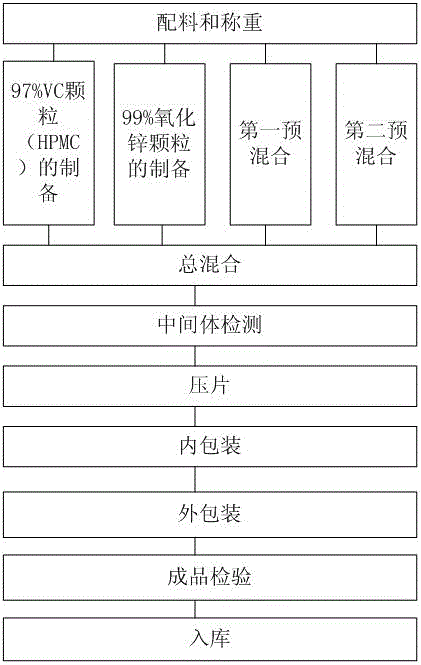

Fast-dissolvable vitamin C and zinc preparation and preparation method thereof

InactiveCN106491640AEasy to takeFit for consumptionOrganic active ingredientsMetabolism disorderVitamin CD-mannitol

The invention discloses a fast-dissolvable vitamin C and zinc preparation and a preparation method thereof. The fast-dissolvable vitamin C and zinc preparation is prepared from, by weight, 0.5%-2% of zinc oxide particles, 0.2%-0.6% of zinc gluconate, 3%-10% of vitamin C particles, 5%-10% of microcrystalline cellulose, 65%-85% of D-mannitol, 0.5%-1% of edible essence, 5%-8% of cross-linked polyvinylpyrrolidone, 0.05%-0.15% of sucralose and 0.5%-1% of magnesium stearate. The fast-dissolvable vitamin C and zinc preparation has advantages of reduction of irritation to digestive tract mucosa, convenience in administration, quickness in absorption, high bioavailability, reduction of risks in use and quickness in replenishment of essential vitamin C and zinc to human bodies.

Owner:JIANGSU ALAND NOURISHMENT

Animal local antimicrobial preparation and application thereof

InactiveCN108815184ALess irritatingImprove convenienceHydroxy compound active ingredientsAntipyreticIrritationPhenol

The invention relates to an animal local antimicrobial preparation and application thereof. The animal local antimicrobial preparation is prepared from the following components in percentage by weight: 0.001%-30% of a zinc preparation and 0.01%-80% of monoterpene phenol. Through synergistic effect of the zinc preparation and the monoterpene phenol, antibacterial effects are improved; the zinc preparation has effects of repairing and regenerating tissues for the wound, promotes the wound to repair while sterilizing, improves the antibacterial effects, is applied to the animal local anti-microbial and sterilization treatment, has very good effects of controlling and treating microbial infection such as animal toe dermatitis and cow nipple disinfection; and the zinc preparation and the monoterpene phenol are low in irritation, are environmentally friendly, are free of pollution, are conventional medical drugs; and materials are easily obtained, so that use convenience of the medicament isimproved.

Owner:FOSHAN NANHAI EASTERN ALONG PHARMA CO LTD

Nutrient enhanced pickled vegetables

InactiveCN108450851AGreat tasteHas nutritional valueFood ingredient functionsSonchus oleraceusNutrient

The invention relates to nutrient enhanced pickled vegetables. Wild vegetables, sonchus oleraceus or fiddlehead is selected as a raw material, and an iodine preparation and a zinc preparation are matched during pickling. The nutrient enhanced pickled vegetables have the characteristics of high nutrient value and good color, aroma and taste.

Owner:蒋寿悟

Walnut peptide stable to zinc ions as well as preparation method and application of walnut peptide

ActiveCN112841393AThe complexation reaction is sufficientConfectionerySweetmeatsPROTEIN S HEERLENZinc ion

The invention discloses a walnut peptide stable to zinc ions as well as a preparation method and application of the walnut peptide. By taking walnut protein powder as a raw material, walnut protein is decomposed into a short peptide mixture by virtue of an efficient biological enzymolysis technology, further a zinc preparation is added for complexing partial peptide fragment, target walnut peptide is obtained by virtue of a centrifugation and membrane filtration method, and finally a target product is obtained by virtue of concentration, sterilization and spray drying processes. The walnut peptide can be widely applied to the fields of products such as formula food for special medical purposes, oral liquid, dairy products and common beverages.

Owner:广州合诚实业有限公司

Leaching solution and leaching process of zinc

InactiveCN108842072AComplete leaching separationEfficient leaching and separationProcess efficiency improvementYttrium chlorideMaterials science

The invention relates to a leaching solution and a leaching process of zinc, and belongs to the technical field of zinc preparation methods. The leaching solution is characterized by comprising waterand the following raw materials by weight: 31.2-38.6 parts of ferric chloride, 49.8-58.7 parts of sodium chloride, 4.3-6.2 parts of yttrium chloride and 4.2-6.7 parts of hydrochloric acid. The leaching process comprises the following steps that zinc concentrate is crushed, then zinc leaching solution is added, and the solid-liquid ratio g : L of the zinc concentrate to the zinc leaching solution is 1~3 : 4~7; electrochemical reduction is carried out under the stirring condition, and meanwhile electrochemical reduction is carried out, the leaching temperature is 40 DEG C-50 DEG C, and the leaching time is 2.5 h-3 h; zinc powder accounting for 0.01% -1% of the mass of the zinc concentrate is added and filtered to obtain filtrate X1 and filter residue Y1; and the filtrate X1 is evaporated andcrystallized to obtain zinc chloride, and the evaporated steam is condensed and then returned to a zinc leaching solution for reuse. According to the leaching solution and the leaching process, the zinc in the ore can be fully leached. The used leaching solution can be recycled after the required zinc is separated.

Owner:淄博淦达环保科技有限公司

A kind of method for electrolytic preparation of high-purity zinc

ActiveCN103184472BAvoid enrichmentAvoid the decontamination processPhotography auxillary processesProcess efficiency improvementElectrolysisImpurity ions

The invention provides a method for preparing high-purity zinc by electrolysis. The method comprises the following steps: leaching a zinc-containing material using an ammonium chloride solution to obtain a zinc-ammonia complex solution; performing impurity removal on the zinc-ammonia complex solution through constant-voltage electrolysis to remove most of impurity ions which are more electropositive than zinc from the solution; after impurity removal through constant-voltage electrolysis, allowing the zinc-ammonia complex solution to flow through a zinc particle vibration purifier to replace the residual impurity metal ions in the solution and thus to achieve the effect of deep purification of the solution; adding carbon-ammonium into the zinc-ammonia complex solution after deep purification to perform ammonia treatment and remove a part of calcium and magnesium ions from the solution; and performing electrolysis on the ammonia-treated solution to obtain high-purity metal zinc. Compared with the prior art of zinc preparation through electrolysis of a zinc-ammonia complex compound, the method provided by the invention adopts carbon-ammonium to replace liquid ammonia, so as to reduce the consumption cost of ammonia and avoid the enrichment of calcium and magnesium in the solution; and performs deep purification by impurity removal through constant-voltage electrolysis and treatment of the solution with the zinc particle vibration purifier after electrolysis impurity removal, so as to completely eliminate the use of zinc powder in the purification link, greatly reduce the purification cost and produce the purified solution which is higher in quality than purification with zinc powder. Therefore, the method stably produces No.0 metal zinc.

Owner:唐山瑞能再生资源有限公司

Biological zinc preparation and method for preparing same

ActiveCN102649969BIncrease organic zinc contentHigh in zincMicroorganism based processesAnimal feeding stuffYeastFermentation

The invention discloses a biological zinc preparation and a method for preparing the same, specifically, a zinc-rich preparation which is produced by photosynthetic bacteria is utilized, the photosynthetic bacteria use sufficient zinc resources during the fermentation process to convert inorganic zinc into organic zinc as much as possible, so the content of the organic zinc in the photosynthetic bacteria is increased, and accordingly, the biological zinc preparation with higher zinc content is prepared. The biological zinc preparation has the advantages of simple production technology, less equipment investment and easily-obtained raw materials, the prepared biological zinc preparation can be widely applied in livestock and agricultural production, and has more market competitiveness compared with yeast zinc.

Owner:山东环亿生物科技有限公司

A kind of preparation technology of zinc acetylacetonate

ActiveCN108299175BImprove liquidityHigh purityPreparation of aldehyde/ketone chelatesPtru catalystPhysical chemistry

Owner:DONGGUAN CHNV TECH CO LTD

Zinc hydrogen citrate ascorbate and its preparation method and application

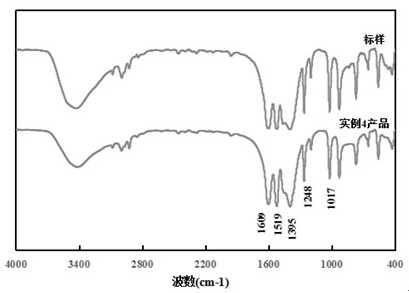

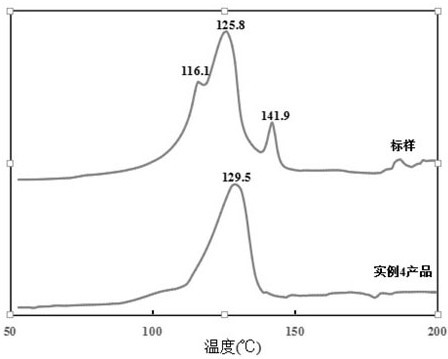

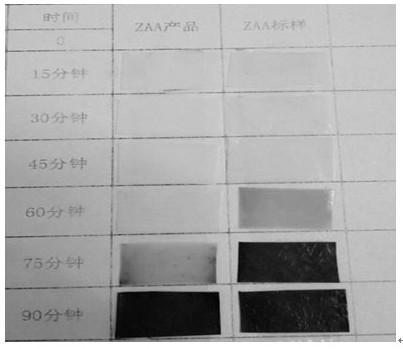

InactiveCN103739578BPromote absorptionMedicinalOrganic active ingredientsAntipyreticMineral ascorbatesFood additive

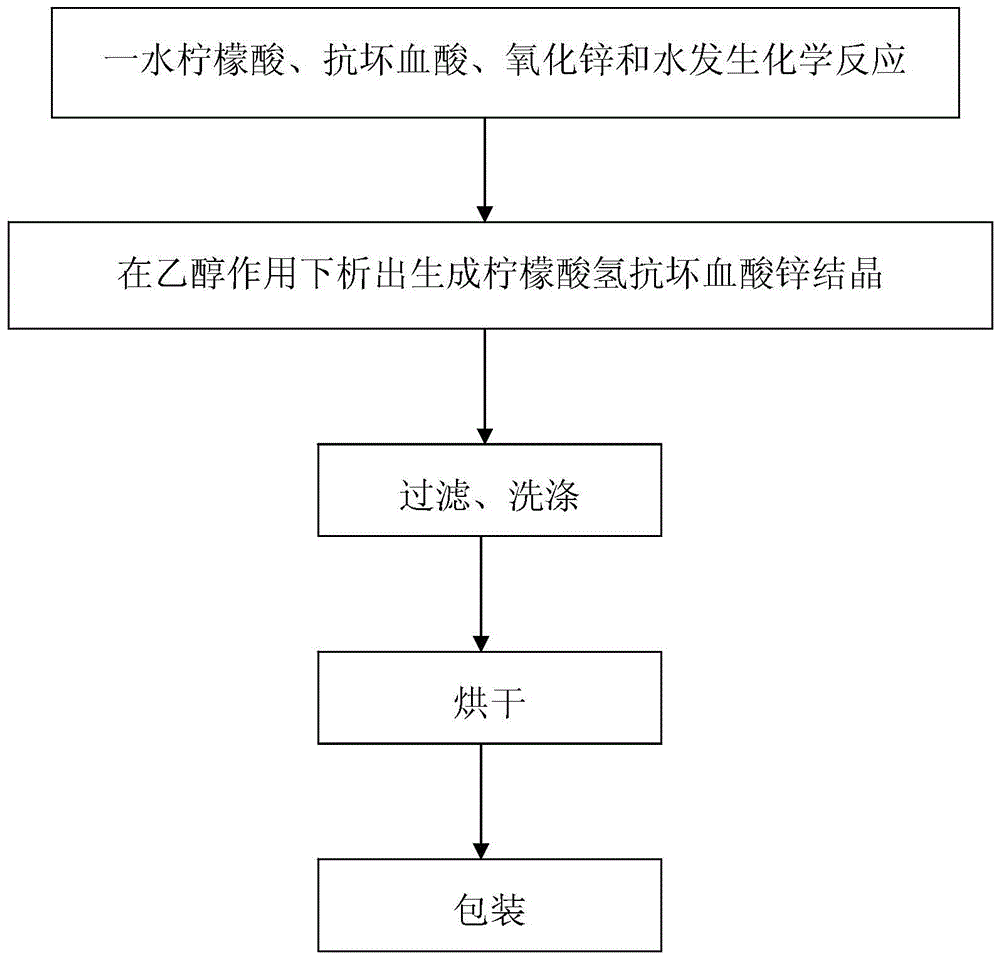

The invention relates to a new substance, namely zinc ascorbate hydrogen citrate, as well as a preparation method and an application thereof. The preparation method of the zinc ascorbate hydrogen citrate is characterized by comprising the following steps: (1) weighing raw materials, namely citric acid monohydrate, ascorbic acid, zinc oxide and water, and putting into a reaction kettle, wherein the weight ratio of the substances, namely the citric acid monohydrate, the ascorbic acid and the zinc oxide is 3: 1: 4; (2) starting a machine for performing chemical reaction for half an hour; (3) stopping the machine for half an hour, adding ethanol and enabling the chemical reaction to be mature; and (4) starting the machine for half an hour, and releasing the zinc ascorbate hydrogen citrate. The zinc ascorbate hydrogen citrate prepared by the preparation method provided by the invention can be dissolved in water, be conductive to absorption by people and animals, and be used as a zinc supplement Vc anti-oxidation preservative, a zinc supplement Vc food additive or medicines for treating bad appetite, dysplasia, stomach diseases, bronchitis, asthma, pneumonia, hepatitis, liver cancer and hypertension.

Owner:李玉成

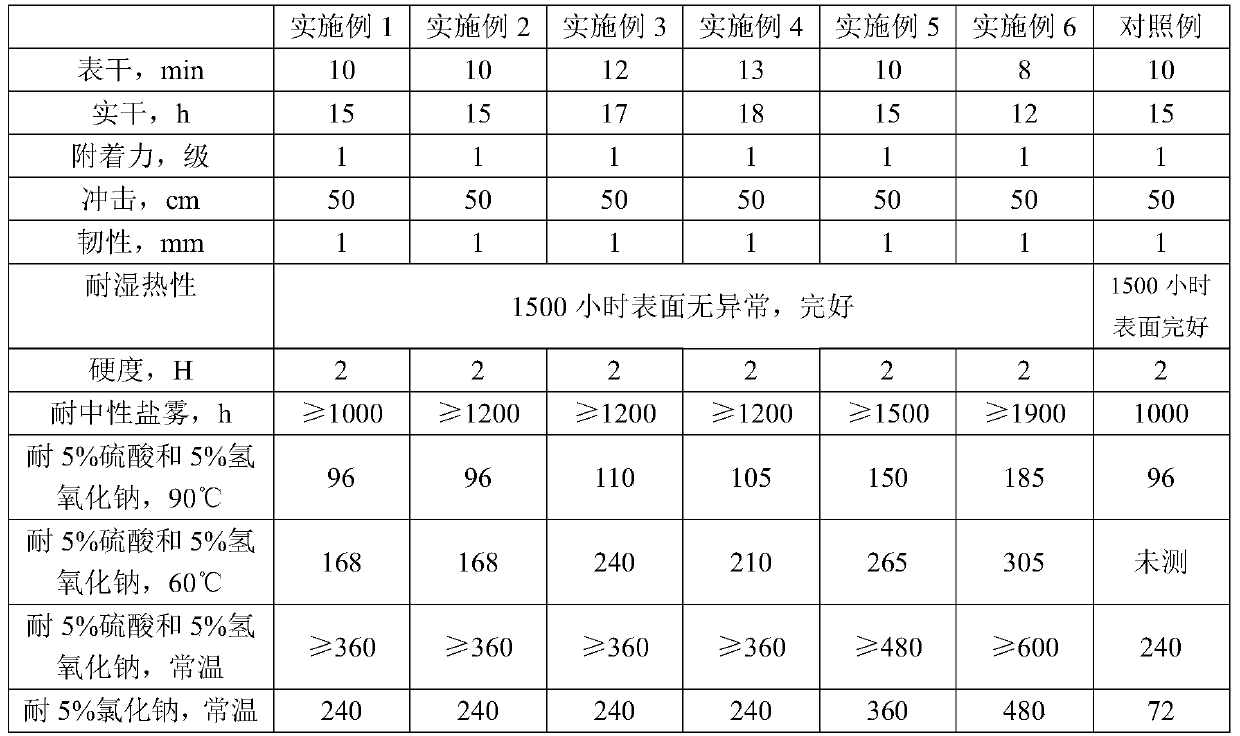

A kind of asphalt modified epoxy zinc phosphate heavy-duty anti-corrosion primer and preparation method thereof

Owner:JIANGSU HUAXIA PAINT MAKING

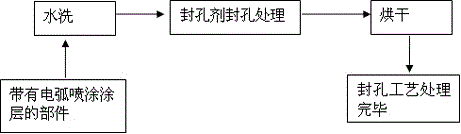

A high anti-corrosion electric arc spraying pure zinc coating sealing agent and its preparation process and application

InactiveCN104498856BImprove corrosion resistanceReduce porosityMolten spray coatingPorosityPhytic acid

Owner:HEBEI UNIV OF ENG

Method for treating non-alcoholic steatohepatitis (NASH) with the combination of polaprezinc and sodium selenite

ActiveUS11058718B2Recover liverSuppress progressDigestive systemSulfur/selenium/tellurium inorganic active ingredientsPolaprezincPharmaceutical drug

Owner:MEDICO CONSL CO LTD

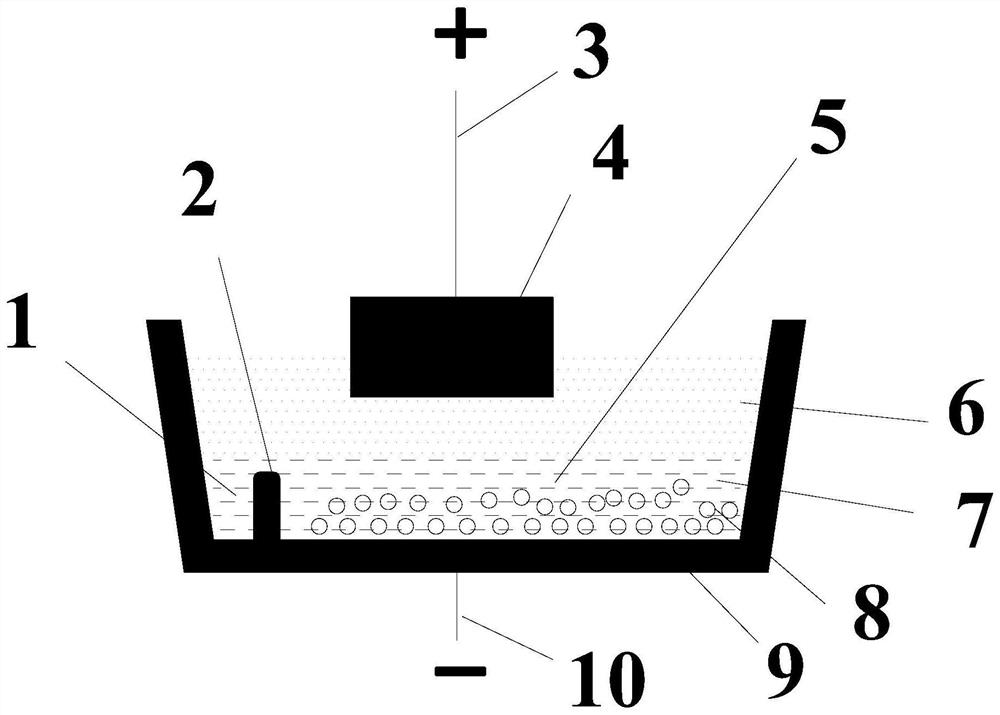

A kind of method for preparing metallic zinc by molten salt electrolysis

The invention belongs to the field of zinc preparation, and especially relates to a method for preparing zinc through molten salt electrolysis. According to the method, chloride melt is taken as the electrolyte, in an electrolysis device, spherical zinc sulfide concentrate particles are subjected to molten salt electrolysis; during the electrolysis process, liquid zinc generated by electrolysis issucked out intermittently from a liquid zinc layer, and spherical zinc sulfide concentrate particles are intermittently added into the liquid zinc layer to supplement reactants. The method takes chloride melt as the electrolyte, in the electrolysis device, the spherical zinc sulfide concentrate particles are subjected to molten salt electrolysis; the spherical zinc sulfide concentrate particles are added into the liquid zinc layer to participate the electrochemical reduction reactions directly to generate zinc, the step that zinc sulfide is oxidized to generate zinc is not needed, and thus the zinc preparation technology is simplified.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com