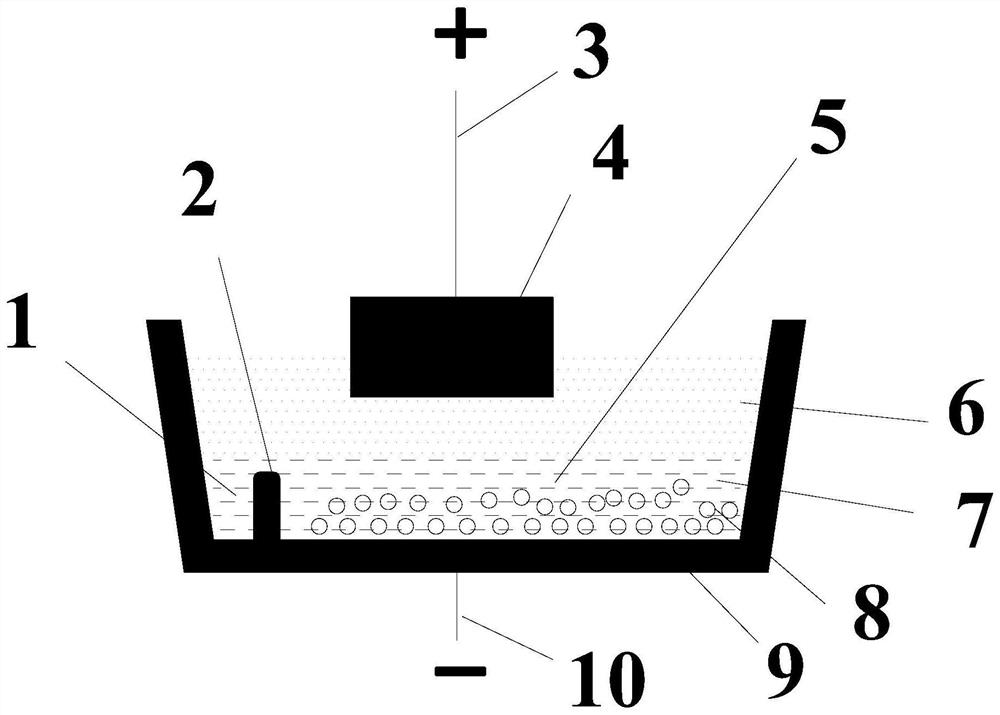

A kind of method for preparing metallic zinc by molten salt electrolysis

A technology of molten salt electrolysis and metal zinc, which is applied in the field of molten salt electrolysis to prepare metal zinc, which can solve the problems of long process and complicated process, and achieve the effects of reducing electrolysis temperature, simplifying the process, and preventing volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add a certain amount of polyvinyl alcohol binder with a concentration of 0.03g / ml to the zinc sulfide concentrate powder below 200 mesh. The specific amount of binder is: add 5ml of polyvinyl alcohol per 100g zinc sulfide concentrate powder material solution. Making zinc sulfide concentrate pellets with a particle size of 2-5 mm by using a disc granulator, drying the zinc sulfide concentrate pellets at 90° C. for 5 hours to obtain pelletized zinc sulfide concentrate particles. NaCl-CaCl in a molar ratio of 1:1 2 The molten salt is used as the electrolyte for electrolysis, the electrolysis temperature is 800°C, and the voltage is 3.4V. The purity of the prepared zinc is over 99%, and the refined zinc with a purity of over 99.9% is obtained after vacuum distillation of the prepared zinc.

Embodiment 2

[0038]Add a certain amount of polyvinyl alcohol binder with a concentration of 0.03g / ml to the zinc sulfide concentrate powder below 200 mesh. The specific amount of binder is: add 10ml of polyvinyl alcohol per 100g zinc sulfide concentrate powder material solution. Making zinc sulfide concentrate pellets with a particle size of 5-10 mm by using a disc granulator, drying the zinc sulfide concentrate pellets at 100° C. for 6 hours to obtain pelletized zinc sulfide concentrate particles. The electrolysis was carried out using NaCl-KCl molten salt with a molar ratio of 1:2 as the electrolyte, the electrolysis temperature was 850°C, and the voltage was 3.5V. The purity of the prepared zinc is more than 97%, and the refined zinc with a purity of more than 99.9% is obtained after vacuum distillation of the prepared zinc.

Embodiment 3

[0040] Add a certain amount of dextrin binder to the zinc sulfide concentrate powder below 200 mesh, the specific amount of binder is: add 0.5g of dextrin and 10ml of water per 100g of zinc sulfide concentrate powder material. Making zinc sulfide concentrate pellets with a particle size of 2-5 mm by using a disc granulator, drying the zinc sulfide concentrate pellets at 90° C. for 5 hours to obtain pelletized zinc sulfide concentrate particles. NaCl-CaCl in a molar ratio of 1:1:0.5 2 -KCl molten salt is used as the electrolyte for electrolysis, the electrolysis temperature is 820°C, and the voltage is 3.2V. The purity of the prepared zinc is over 99%, and the refined zinc with a purity of over 99.9% is obtained after vacuum distillation of the prepared zinc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com