Highly-corrosion-resistant stirrer and making method thereof

A stirrer, high corrosion resistance technology, applied in chemical instruments and methods, mixer with rotating stirring device, improvement of process efficiency, etc., can solve problems such as high manufacturing cost, corrosion failure, complex coating process, etc., to achieve Reduce maintenance times and costs, ensure safety and reliability, and achieve obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

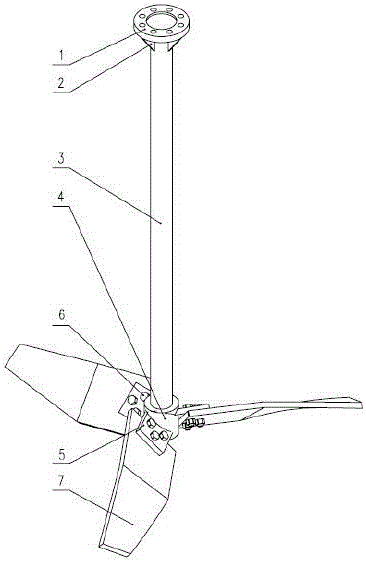

[0052] Example 1: 00Cr25Ni7Mo3.5WCuN super duplex stainless steel stirrer

[0053] (1) Stirrer structure design

[0054] a) According to the principle of fluid mechanics, calculate the critical speed N of the agitator according to the formula (5) c =74.8r / min, this speed meets the output speed requirement of the reducer.

[0055]

[0056] Among them, K is a constant, d is the blade diameter, d p is the solution particle diameter, C is the solid-liquid mass ratio, ν is the liquid kinematic viscosity, ρ is the liquid phase density, ρ s is the solid phase density, and g is the gravitational acceleration.

[0057] b) According to the principles of fluid mechanics, the power of the agitator is calculated according to formulas (6) to (11) P = 6.2KW, which is less than the power of the motor. Therefore, the selection of blade diameter and width is reasonable and meets the design requirements.

[0058] P=N pρ介质 N 3 d 5 (6)

[0059]

[0060]

[0061]

[0062]

...

Embodiment 2

[0093] Example 2: 00Cr25Ni7Mo4N super duplex stainless steel stirrer

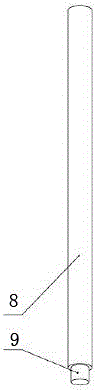

[0094] (1) Stirrer structure design

[0095] a) According to the principle of fluid mechanics, calculate the critical speed N of the agitator according to the formula (5) c =66r / min, this speed meets the requirements of the output speed of the reducer.

[0096] b) According to the principles of fluid mechanics, the power of the agitator is calculated according to formulas (6) to (11) P = 19.4KW, which is less than the power of the motor. Therefore, the selection of blade diameter and width is reasonable and meets the design requirements.

[0097] c) According to the principle of strength check, and considering the corrosion allowance of the material 6mm, calculate the shaft diameter d of the agitator according to the formula (12) ~ (19) 轴 It is 110mm, which meets the design requirements.

[0098] d) According to the size of the shaft diameter, the width of the blade fixing plate is designed to be 100mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com