A high anti-corrosion electric arc spraying pure zinc coating sealing agent and its preparation process and application

An arc spraying and sealing agent technology, applied in metal material coating process, coating, melting spraying and other directions, can solve the shrinkage of inorganic sealing agent during solidification, poor sealing effect of coating, and inability to achieve sealing. pore depth and other issues, to achieve good sealing effect, improve corrosion resistance, and reduce porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

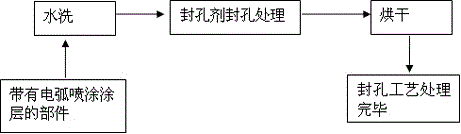

Image

Examples

Embodiment 1

[0040] A high anti-corrosion arc spraying pure zinc coating sealing agent, based on 1 liter of the sealing agent, including the following components, phytic acid 3 g / L, sodium molybdate 5 g / L, sodium silicate 55 g / liter, benzimidazole 2 g / liter, the balance is water.

[0041] The sealant is formulated as follows:

[0042] 1) Add benzimidazole to 100ml of water and mix well;

[0043] 2) Slowly add sodium silicate and mix well;

[0044] 3) Then add sodium molybdate and mix well;

[0045] 4) Add phytic acid and mix well;

[0046] 5) Finally, slowly add water to reach the reference volume, and mix well to complete the preparation of the sealing agent.

[0047] The application of high anti-corrosion arc spraying pure zinc coating sealing agent,

[0048] Wash the parts with arc-sprayed pure zinc coating with water at a temperature of 30 °C, and then remove the moisture on the surface of the parts;

[0049] Then, by immersion, the parts with the arc sprayed pure zinc coatin...

Embodiment 2

[0052] A high anti-corrosion arc spraying pure zinc coating sealing agent, based on 1 liter of the sealing agent, including the following components, phytic acid 2 g / L, sodium molybdate 3 g / L, sodium silicate 45 g / liter, benzimidazole 2 g / liter, the balance is water.

[0053] The sealant is formulated as follows:

[0054] 1) Add benzimidazole to 100ml of water and mix well;

[0055] 2) Slowly add sodium silicate and mix well;

[0056] 3) Then add sodium molybdate and mix well;

[0057] 4) Add phytic acid and mix well;

[0058] 5) Finally, slowly add water to reach the reference volume, and mix well to complete the preparation of the sealing agent.

[0059] The application of high anti-corrosion arc spraying pure zinc coating sealing agent,

[0060] Wash the parts with the pure zinc coating by arc spraying, choose the temperature of the water to be 40℃, and then remove the moisture on the surface of the parts;

[0061] Then, by immersion, the parts with the arc spraye...

Embodiment 3

[0064] A high anti-corrosion arc spraying pure zinc coating sealing agent, based on 1 liter of the sealing agent, including the following components, phytic acid 4 g / L, sodium molybdate 6 g / L, sodium silicate 55 g / liter, benzimidazole 4 g / liter, the balance is water.

[0065] The sealant is formulated as follows:

[0066] 1) Add benzimidazole to 100ml of water and mix well;

[0067] 2) Slowly add sodium silicate and mix well;

[0068] 3) Then add sodium molybdate and mix well;

[0069] 4) Add phytic acid and mix well;

[0070] 5) Finally, slowly add water to reach the reference volume, and mix well to complete the preparation of the sealing agent.

[0071] The application of high anti-corrosion arc spraying pure zinc coating sealing agent,

[0072] Wash the parts with arc-sprayed pure zinc coating with water at a temperature of 45°C, and then remove the moisture on the surface of the parts;

[0073] Then, by immersion, the parts with the arc sprayed pure zinc coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com