A Pre-warning Method for Judging Abnormal Blast Furnace Conditions Based on Static Pressure Difference

A static pressure difference, blast furnace furnace technology, applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as low pressure difference, lagging treatment methods, and inconspicuous total pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

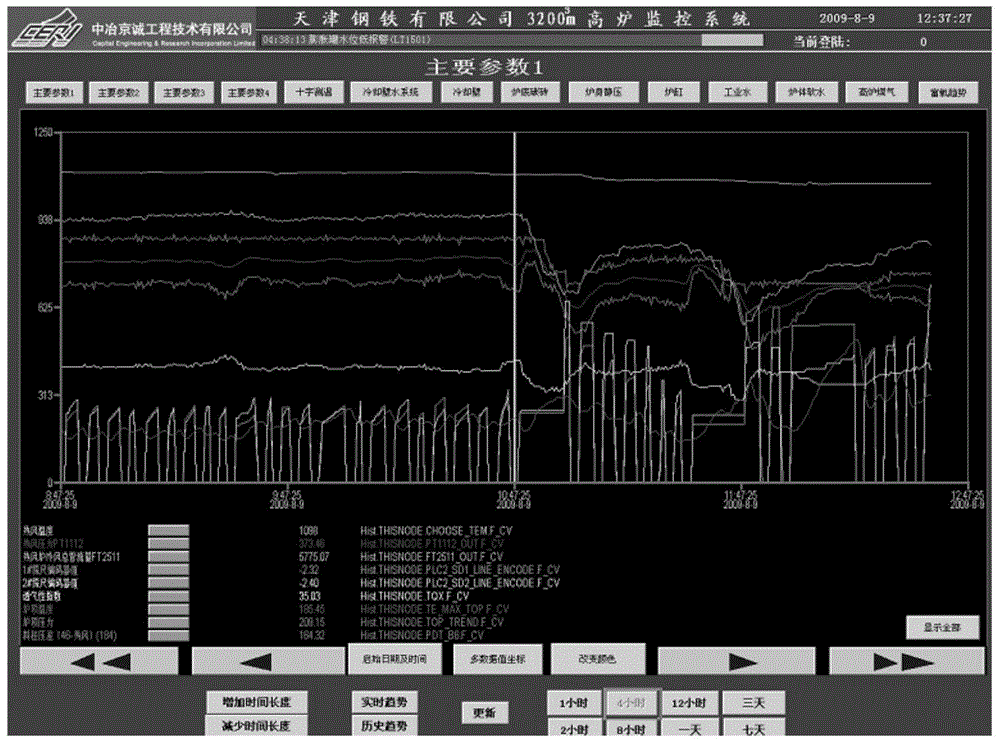

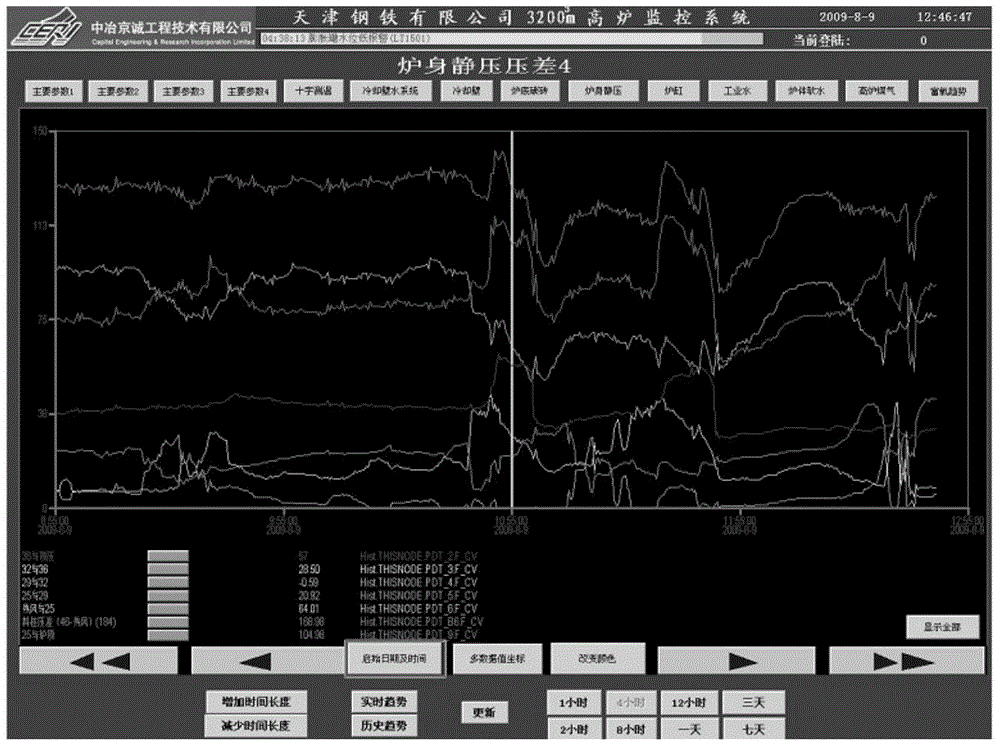

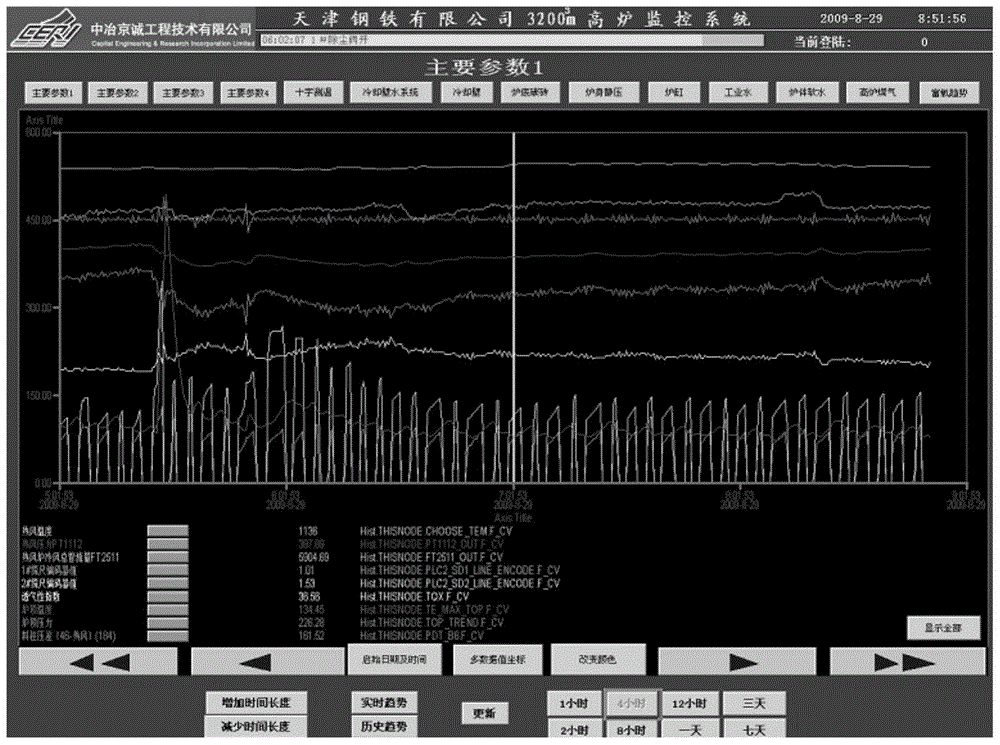

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0026] The present invention D judges the early warning method of blast furnace abnormal state according to static pressure difference, comprises the following steps:

[0027] Step 1: Divide the blast furnace into several partitions along the circumferential direction, and at the same time divide the blast furnace into five parts corresponding to the blast furnace along the height direction. Furnace lower part, furnace middle part, furnace upper part;

[0028] Step 2: Obtain the real-time data of the static pressure difference of each of the above partitions through the static pressure difference monitoring device of the blast furnace body;

[0029] Step 3: Construct the real-time data of the static pressure difference of the blast furnace in each of the above regions into samples, add the samples within 6 to 12 months to the general database o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com