Hand picking process with underground powered rubber belt for waste rocks

A technology of hand-picking and gangue, applied in sorting and other directions, can solve the problems of increasing the cost of gangue and sundries, jamming warehouses, etc., and achieve the effects of reducing manpower, high economic benefits, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0029] 1. Assisting the construction of the hand-selected gangue chamber in the strong tape lane.

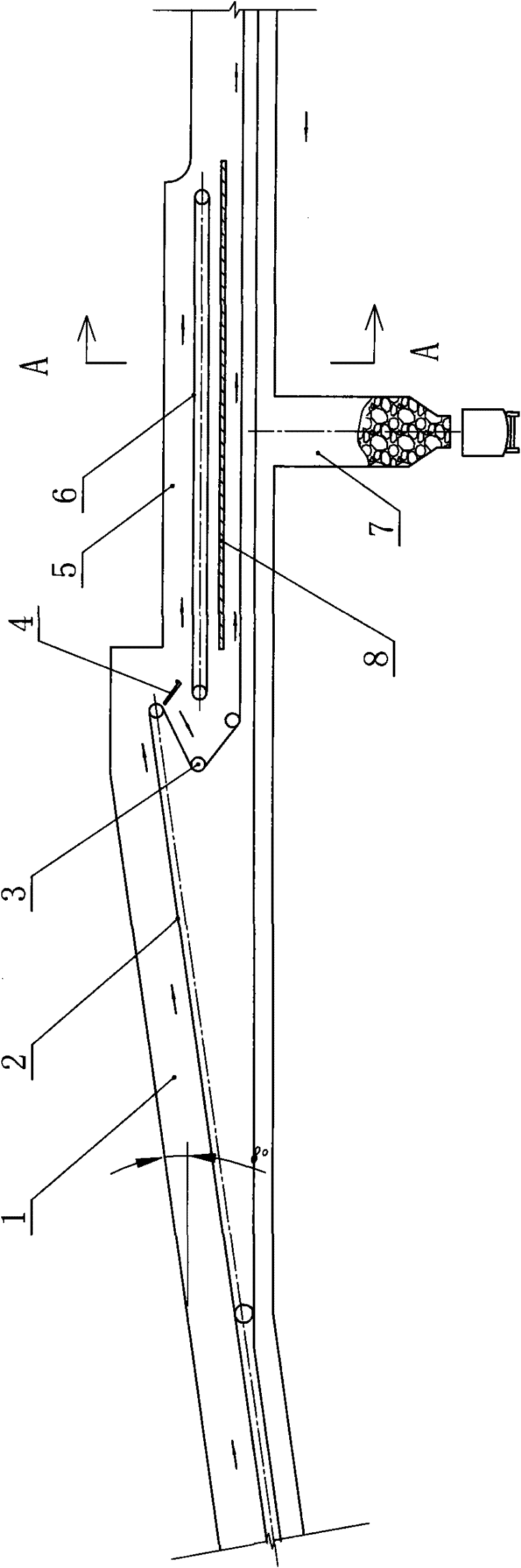

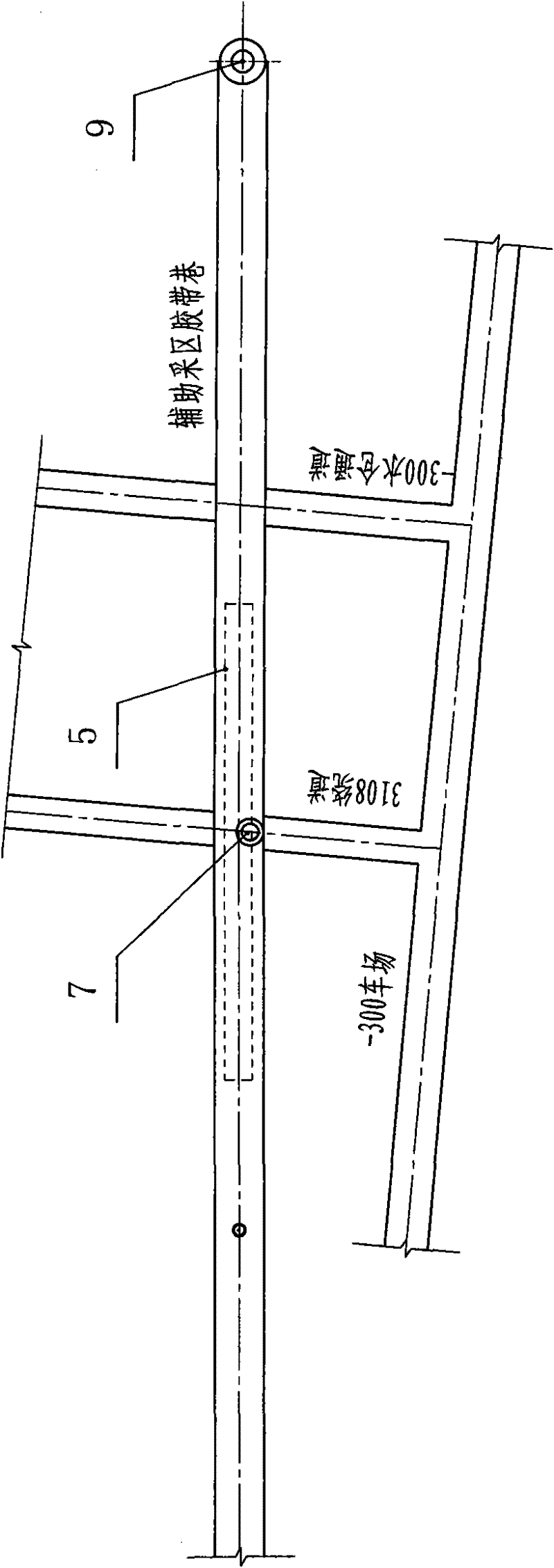

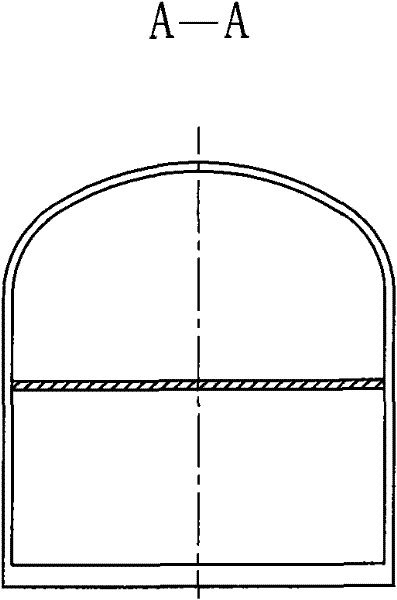

[0030] Such as figure 1 , figure 2 , image 3 As shown, the gangue chamber is selected manually for the construction of the roof.

[0031] 2. The auxiliary strong belt has been modified, and a belt turning (reversing) device has been installed, and a hand-selected belt has been installed. The model is L=20m, B=1.0m, v=0.3m / s, P= 15kw.

[0032] 3. A simple screening device is installed at the unloading point to screen the coal.

[0033] 4. After the coal flow is screened, the coal gangue with particles smaller than 50mm directly enters the belt under the strong belt, and the coal gangue with particles larger than 50mm passes through the screening device and enters the hand-selected belt.

[0034] 5. Set up 4 people in each shift to manually select the gangue at the position of the hand-selected belt, and the selected gangue will be transported to the hand-selected gangue bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com