Variable-compression-ratio mechanism for engines, variable-compression-ratio engine and automobile

A compression ratio and engine technology, applied in engine components, engine control, machine/engine, etc., can solve the problems of difficult operation and complex structure of variable compression ratio mechanism, and achieve the effect of avoiding knocking, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

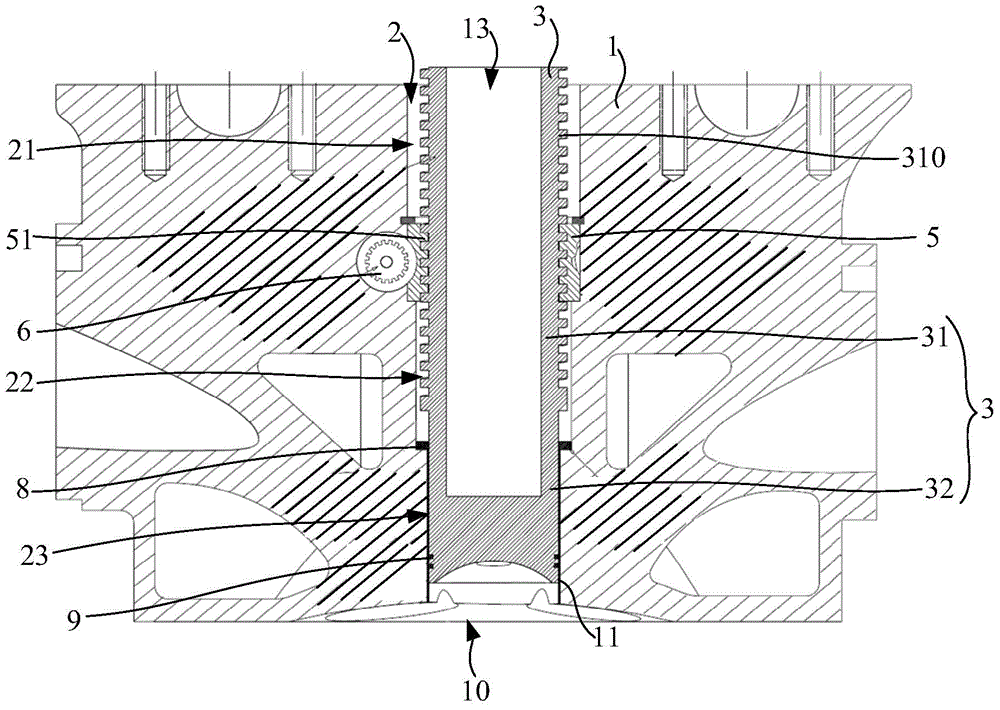

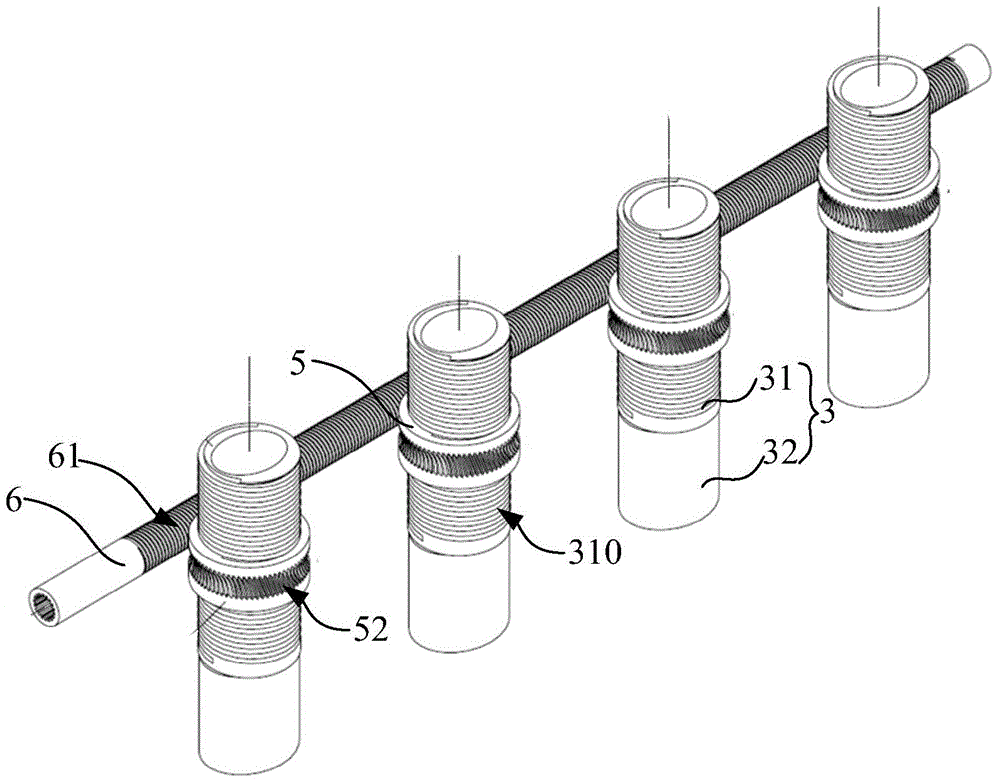

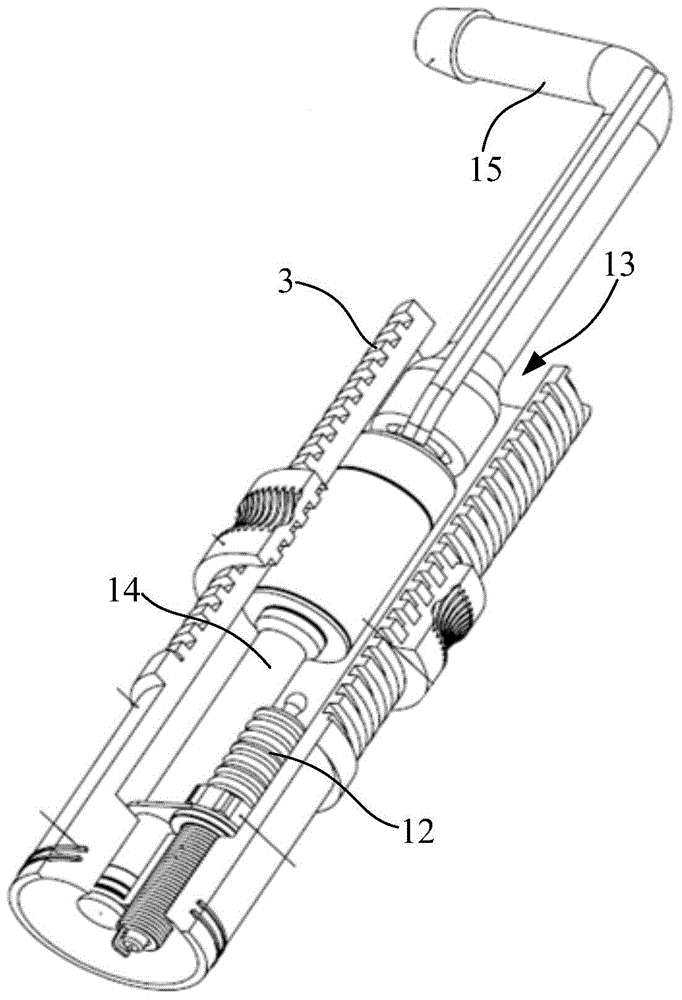

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] The engine is a complete set of power output equipment. The existing engine includes a cylinder, and the cylinder includes a cylinder head and a cylinder block. The part of the cylinder block near the cylinder head is the cylinder combustion chamber. The engine work mainly includes four strokes. During the ignition stroke, the piston in the cylinder moves toward the cylinder head to the top dead center of the piston, and squeezes the mixture of air and fuel into the combustion chamber of the cylinder, and at the same time, the spark plug discharges to ignite the fuel.

[0039] This embodiment proposes a variable compression ratio mechanism on the basis of the cylinder head, and the compression ratio and cylinder pressure of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com