faucet structure

A faucet and structure technology, applied to valve details, multi-way valves, engine components, etc., can solve problems such as inaccurate alignment, bad, affecting assembly and subsequent use operation quality, etc., and achieve the effect of easy and fast disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

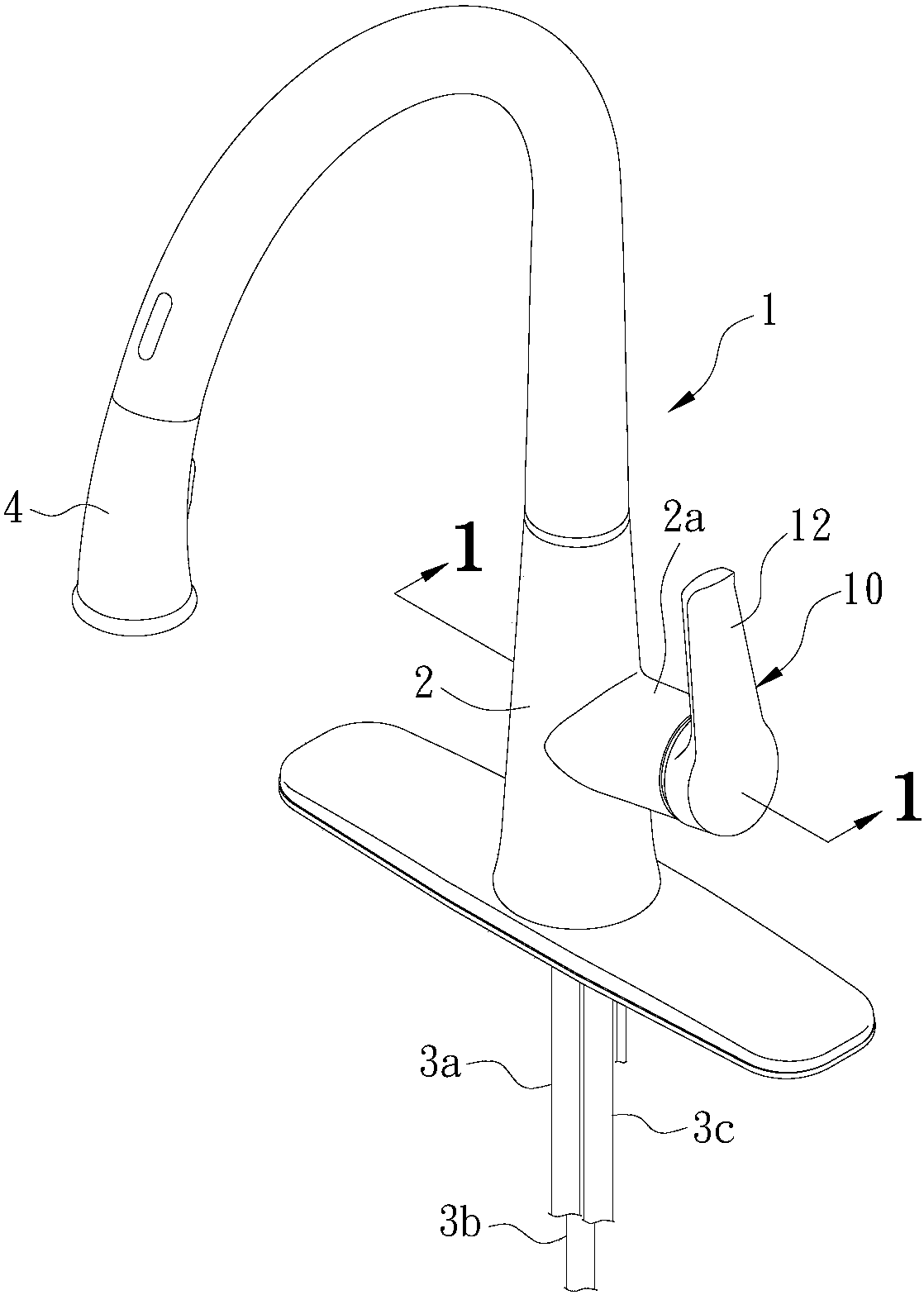

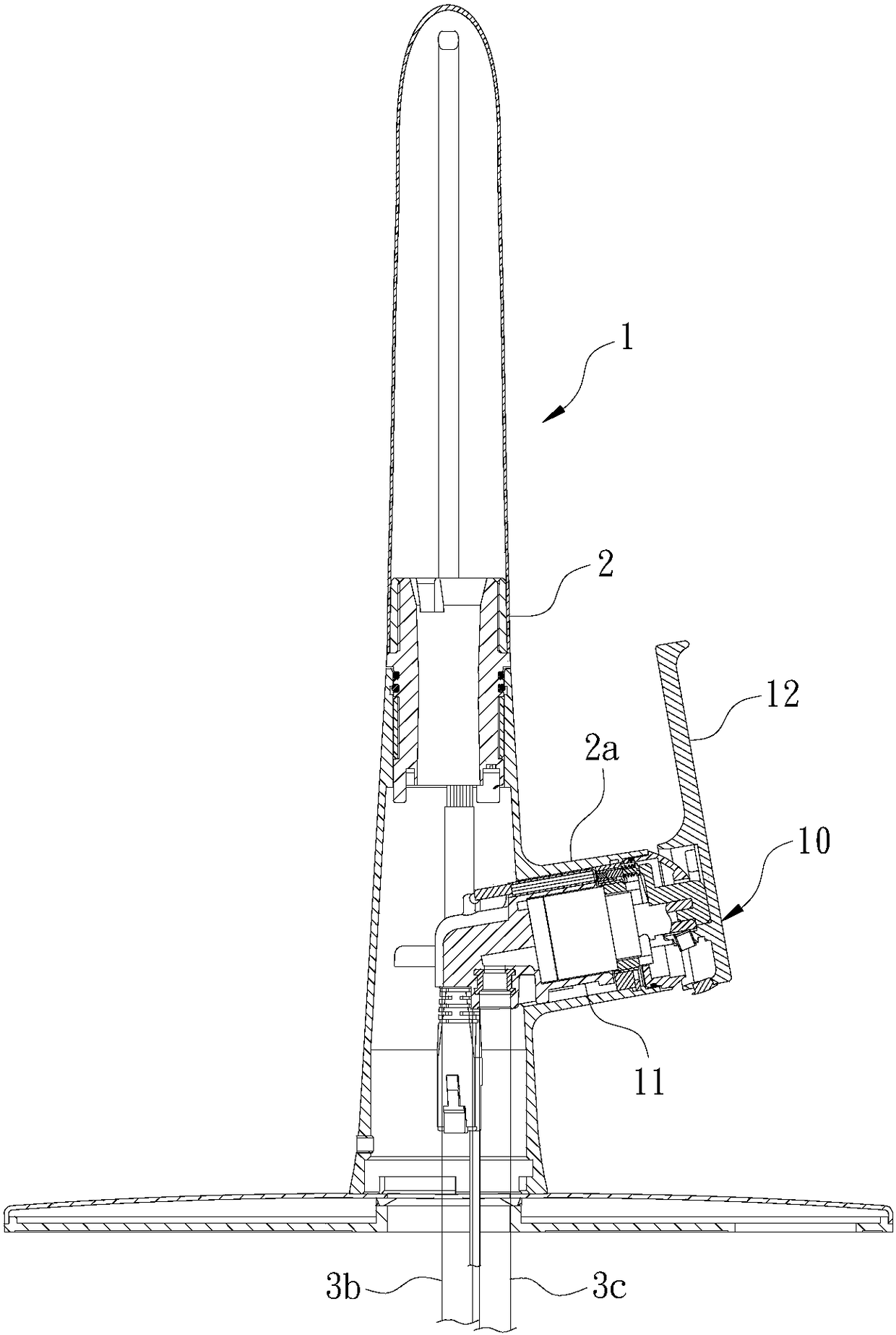

[0040] like Figures 1 to 6 As shown, the present invention provides a first embodiment of a faucet structure. The faucet can be an electronic faucet or a traditional manual switching faucet. This embodiment takes the electronic faucet 1 as an implementation form, and the electronic faucet 1 includes a control handle assembly 10. A switch device 20 and a touch element 30; wherein:

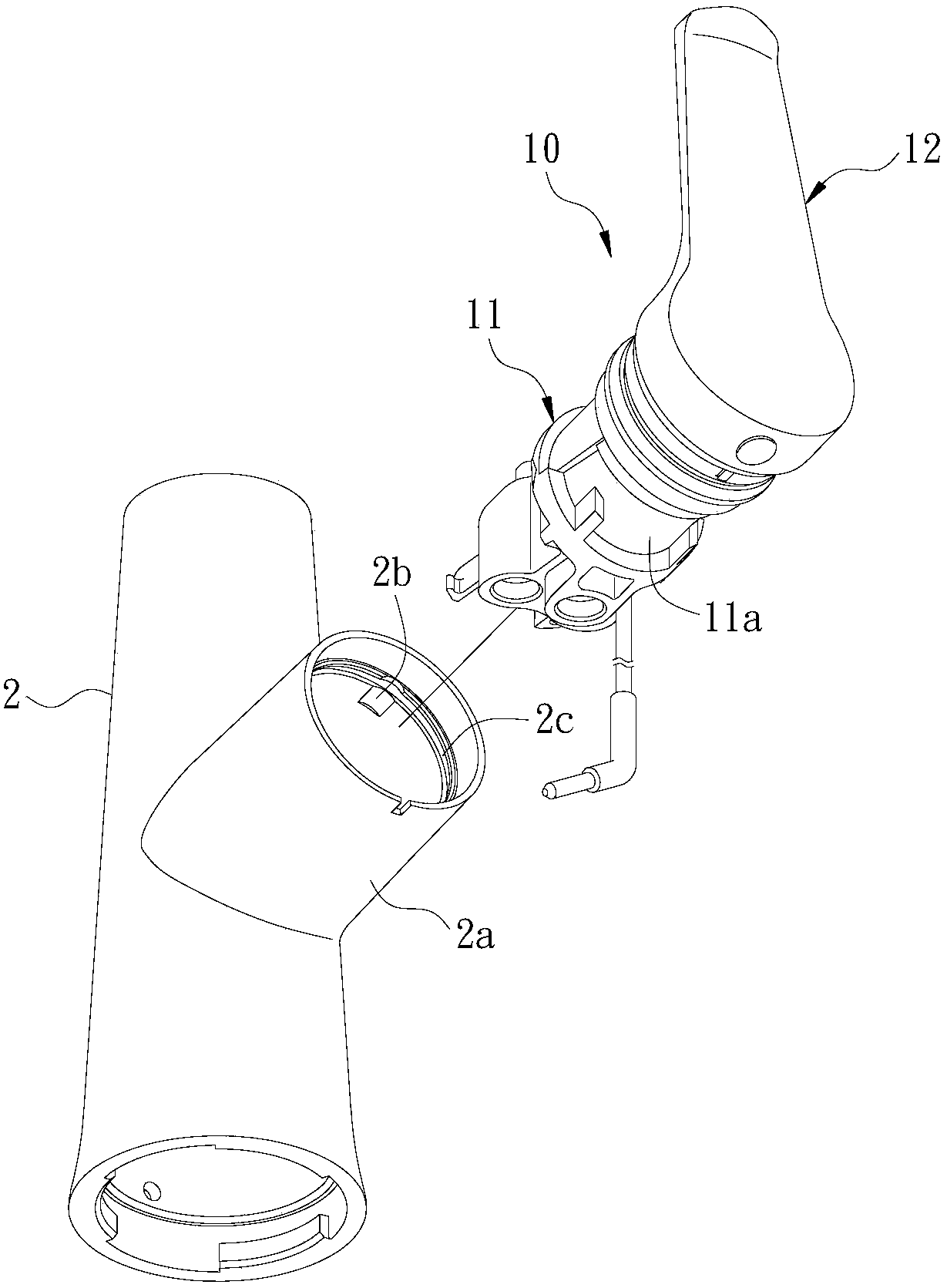

[0041] The control handle assembly 10 is installed on a faucet body 2 of the electronic faucet 1, and includes a valve assembly 11 and a handle 12. The valve assembly 11 can properly mix the inflowing cold and hot water to form mixed water and export it out. There is provided a first installation site 111 and a second installation site 112, such as Figure 7 As shown; the handle 12 is connected to the valve assembly 11, which can be pulled in and out between an open position and a closed position to switch and control the valve assembly 11, and be switched between a cold water position and a hot w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com