A seven-way valve

A seven-way valve and valve block technology, applied in the field of seven-way valves, can solve problems affecting vehicle safety, affecting gear shift accuracy, affecting braking effects, etc., to extend the gas transmission distance, simple and practical structure, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

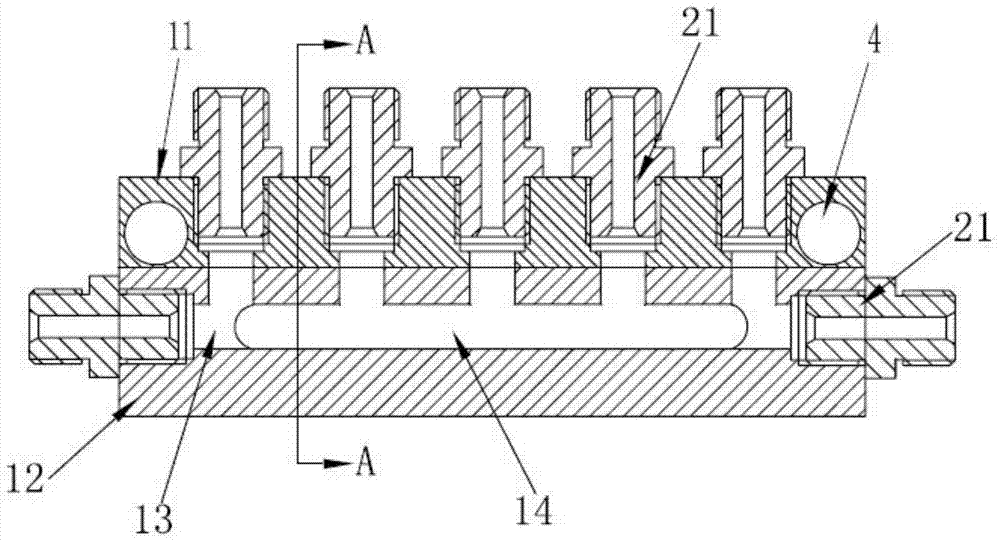

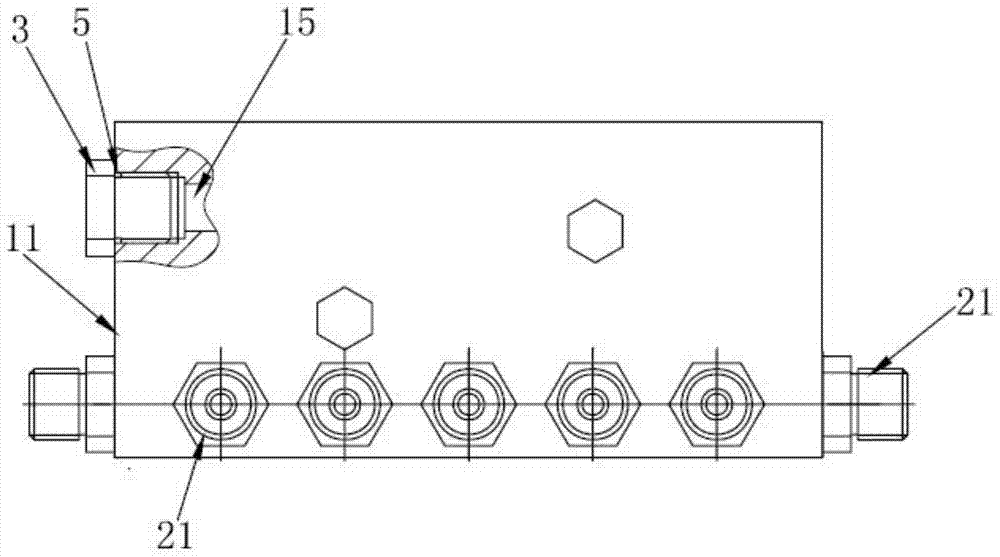

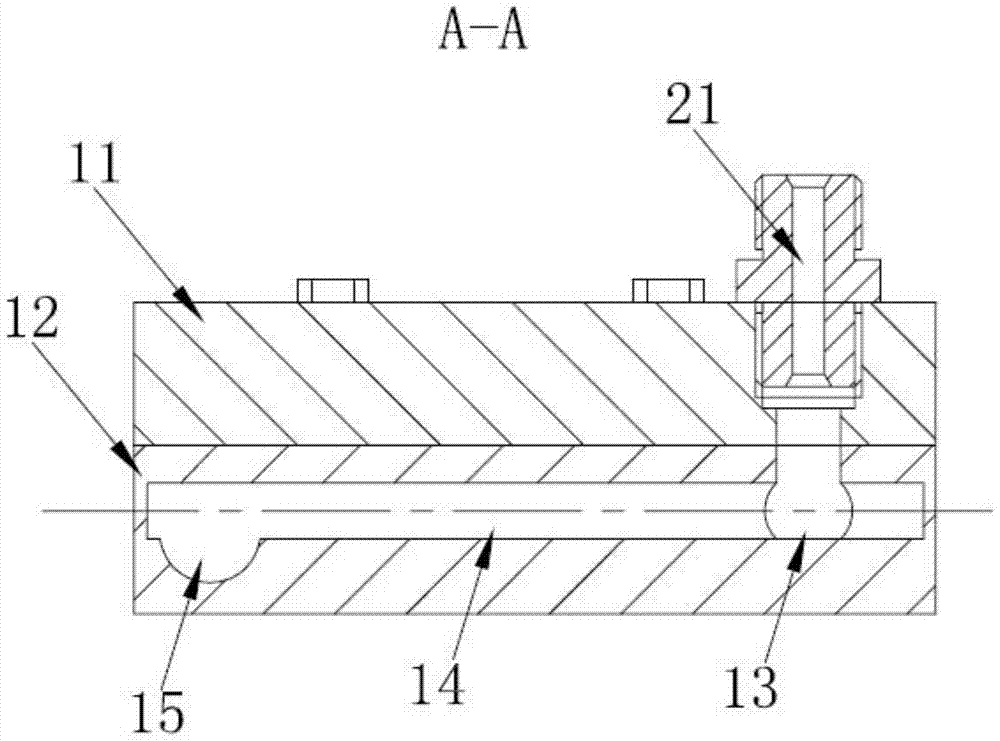

[0016] Such as figure 1 and figure 2 As shown, the present invention is made up of valve body and seven interfaces etc., and described valve body comprises upper valve block 11 and lower valve block 12, and described upper valve block 11 and lower valve block 12 are screwed and fixed up and down, in described The two included angles of the upper end of the upper valve block 11 are provided with fixed through holes 4, and five interfaces are fixed on the upper end surface of the upper valve block 11, and the left and right ends of the lower valve block 12 are respectively provided with There is an interface, and each of the seven interfaces is provided with a one-way valve 21, and the middle part of the lower valve block 12 is provided with a ventilation groove 13, and the ventilation groove 13 is connected to the seven interfaces, so the ventilation groove 13 One side is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com