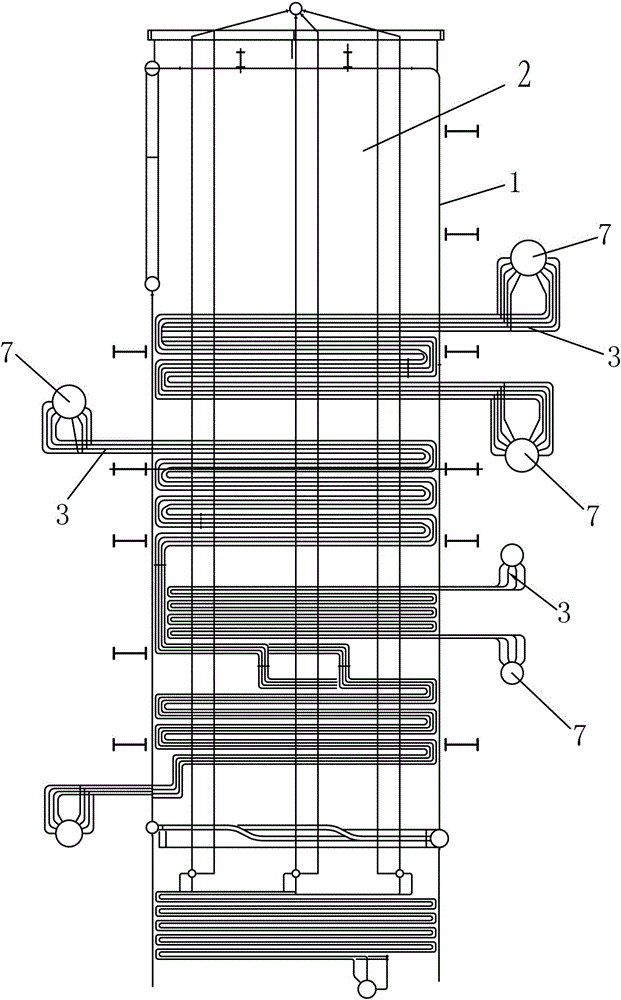

superheater for boiler

A superheater and boiler technology, which is applied in the field of boilers, can solve the problems of increased length, reduced service life, and increased cost of superheater tubes, and achieves the effects of saving product costs, prolonging service life, and eliminating expansion constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

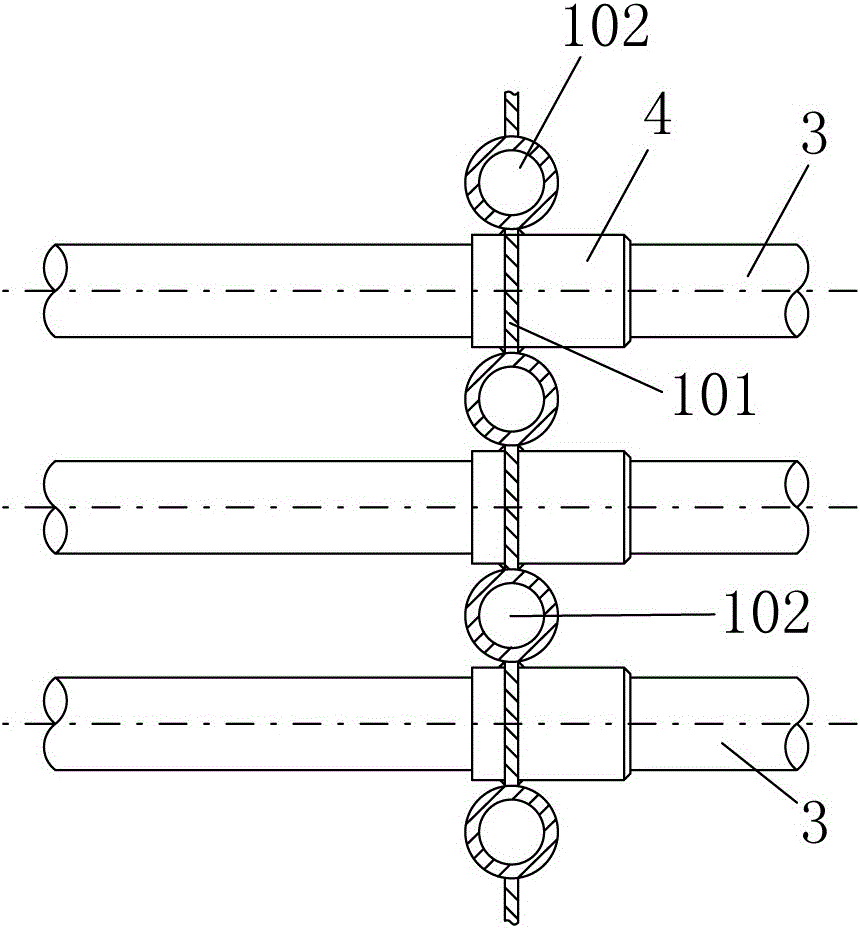

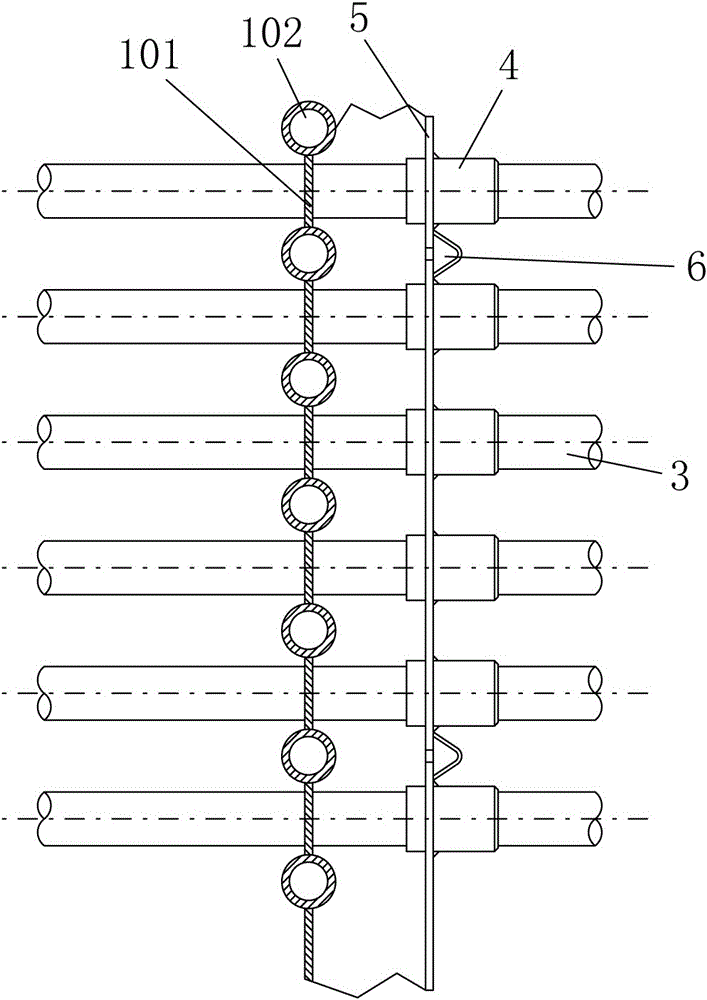

[0098] according to Figure 10~Figure 14 , the furnace wall 1 is a membrane wall, including furnace wall pipes 102 and fins 101 connected between the furnace wall pipes 102, and the wall penetration hole 10 includes several furnace wall pipes 102 directly adjacent to each other. Between the windows 1001, each window 1001 passes through several superheater tubes 3, in this embodiment, each window 1001 passes through three superheater tubes 3, the window The number of holes 1001 is determined by the number of superheater pipes 3, and one through-wall hole 10 is a unit. Between the window hole 1001 and the superheater pipe 3 is the expansion movement gap 11; the moving distance of the superheater pipe 3 during displacement is within the range of the expansion movement gap 11, that is to say, the superheater After the displacement, the pipe 3 is still located within the space accommodated by the expansion movement gap 11 without touching the hole wall of the window hole 1001 . T...

Embodiment 2

[0104] Different from Example 1, according to Figure 15 , the wall penetration hole 10 includes several window holes 1001, and the window holes 1001 are located on the fins 101; each window hole 1001 passes through one superheater tube 3, and the window holes 1001 and Between the superheater tubes 3 is the expansion movement gap 11 . The superheater pipe 3 is offset in the window 1001 to the opposite direction of the displacement path of the superheater pipe 3, such as Figure 15 , the displacement path of the superheater pipe 3 is to the right, then the superheater pipe 3 shifts to the left of the window hole 1001 in the cold state, and the displacement distance of the superheater pipe 3 is within the range of the expansion movement gap 11 Inside.

[0105] according to Figure 16 , the refractory component 12 includes several refractory units 1202, and the two side edges of the two adjacent refractory units 1202 are staggered back and forth to prevent the expansion differ...

Embodiment 3

[0108] Different from Example 1, according to Figure 17 , Figure 18 , Figure 19, the wall penetration hole 10 includes several windows 1001 between two furnace wall pipes 102, and the two furnace wall pipes 102 on both sides of the window hole 1001 can be non-adjacent furnace wall pipes. When another 1 or 2 furnace wall pipes, that is, the middle furnace wall pipe 103 are arranged between the 2 furnace wall pipes 102 on both sides of 1001, when the middle furnace wall pipe 103 passes through the window hole 1001 of the through-wall hole 10 , through partly bending in the direction of avoiding space collision with the displacement path of the superheater pipe 3 to form a curved section 1031, so as to reserve the window hole 1001 of the through-wall hole 10, so that the superheater pipe 3 can pass through the through-wall hole At 10 o'clock, there is no obstacle on the displacement path of the superheater pipe 3 . In this embodiment, each window hole 1001 traverses through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com