Measurement device for measuring temperature field of vehicle vent pipe

A measuring device and automobile exhaust technology, which is applied in the field of automobile manufacturing, can solve the problems of fixed measurement position, cumbersome layout, and inability to obtain measurement results, and achieve the effect of rapid layout and comprehensive and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The purpose of the present invention is to provide a measuring device for the temperature field of the exhaust pipe of an automobile, so that it can be quickly arranged during the measurement, and the number of sensors and the position of the sensors along the path and axial direction of the exhaust pipe can be adjusted to obtain a more comprehensive measurement results.

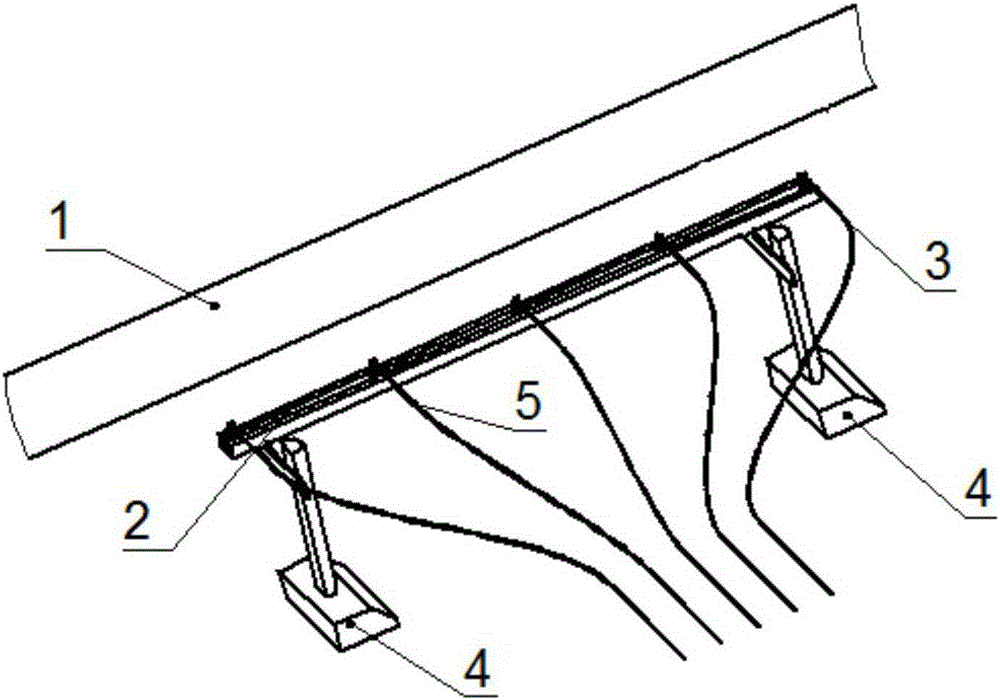

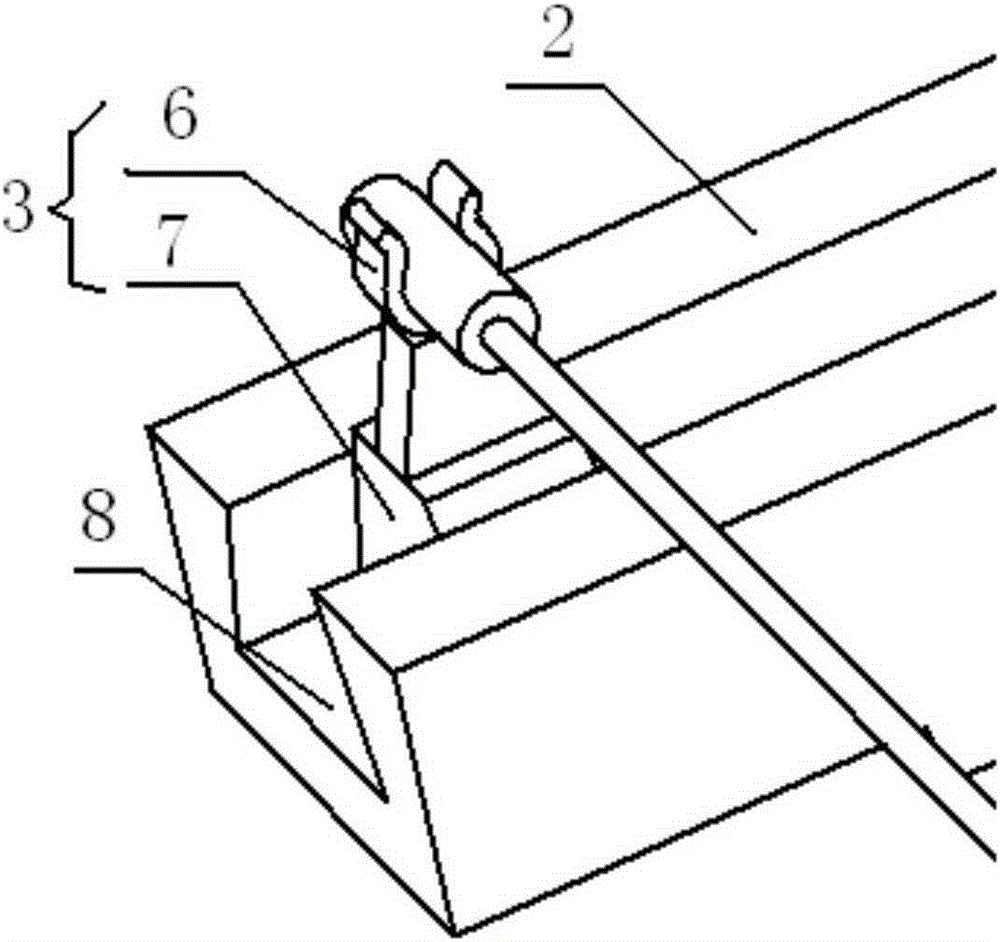

[0022] Please refer to figure 1 , figure 2 , in a specific embodiment, the measuring device for the temperature field of the automobile exhaust pipe provided by the present invention includes a base 4, a guide rail 2 fixed on the base 4 and parallel to the exhaust pipe 1 axis, arranged on the At least two sensor fixing seats 3 on the guide rail 2 and a sensor 5 arranged on the sensor fixing seats 3 , the sensors 5 are temperature sensors, and the sensor fixing seats 3 are slidably installed on the guide rail 2 . According to the requirements of the required measurement data, place the device at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com