Verification System and Verification Method of High Frequency Partial Discharge Detector

A partial discharge and detector technology, applied in the field of electric power engineering, can solve the problem that the test results cannot effectively and truly reflect the operation status of the transformer, the performance of the instrument and the test accuracy cannot be effectively guaranteed, and the performance of the high-frequency partial discharge detector cannot be regularly inspected and other problems to achieve accurate and reliable test results, solve performance verification problems, and be easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

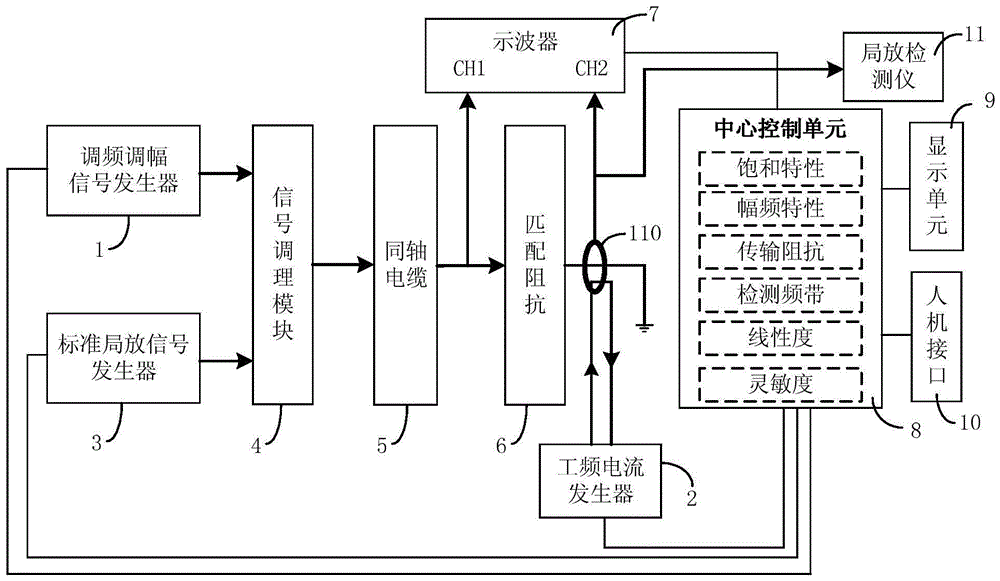

[0046] Such as figure 1 As shown, the verification system of the high-frequency partial discharge detector in this embodiment includes a frequency modulation and amplitude modulation signal generator 1, a power frequency current generator 2, a standard partial discharge signal generator 3, a signal conditioning module 4, a coaxial cable 5, and a matching impedance 6. The oscilloscope 7 and the central control unit 8, the output terminal of the FM and AM signal generator 1, and the output terminal of the standard partial discharge signal generator 3 are connected to the input terminal of the signal conditioning module 4 respectively, and the output terminal of the signal conditioning module 4 passes through the The coaxial cable 5 and the matching impedance 6 are grounded, and the high-frequency current sensor 110 of the verified high-frequency partial discharge detector 11 is set on the grounding cable of the matching impedance 6 and the output cable of the power frequency curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com