Electromagnetic parameter optimization design-based scaled composite material preparation method

A technology of electromagnetic parameters and composite materials, applied in the fields of electrical digital data processing, calculation, special data processing applications, etc., can solve problems such as increasing the difficulty of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Take carbonyl iron powder mixed with epoxy resin as an example.

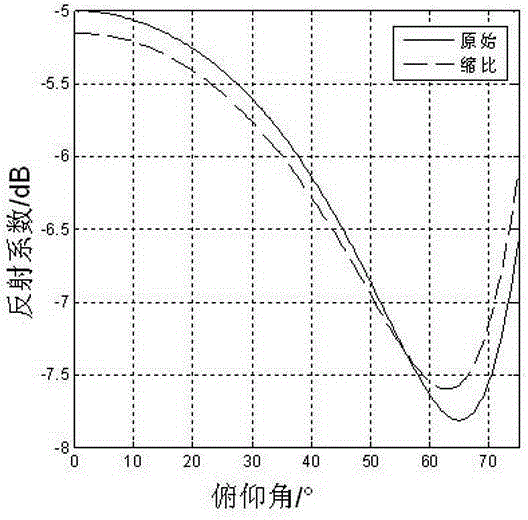

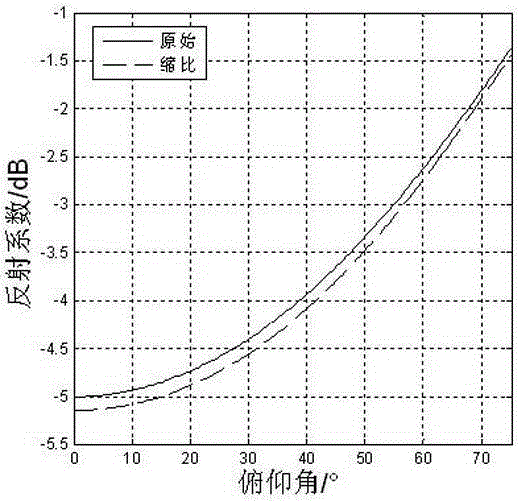

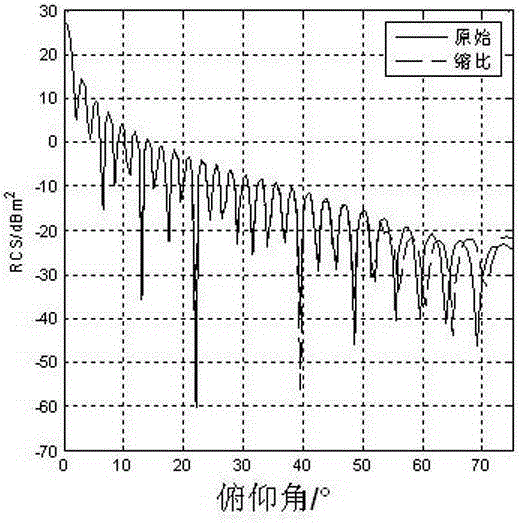

[0038] Firstly, the reflection coefficients of horizontal polarization and vertical polarization are calculated according to the electromagnetic parameters of the composite material in the original frequency band, see figure 1 and figure 2 shown by the solid line.

[0039] figure 1 It is a metal substrate with a dielectric thickness of 1mm. The solid line is the dielectric constant of 22.04+1.32i and the magnetic permeability of 3.76+2.52i at the original 4GHz frequency; the dotted line is the dielectric constant of 11.6+0.69i at the reduced frequency of 8GHz. The vertical polarization reflection coefficient of the magnetic permeability 1.8+1.21i varies with the pitch angle. figure 2 With figure 1 Variation curves of horizontal polarization reflection coefficient with elevation angle under the same conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Media thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com