Quarter-mode substrate integrated waveguide frequency selective surface with high parasitic passband suppression

A frequency selective surface and substrate integrated waveguide technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problem of low parasitic passband suppression, improve grating lobe suppression, improve passband characteristics, and realize The effect of bandwidth control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

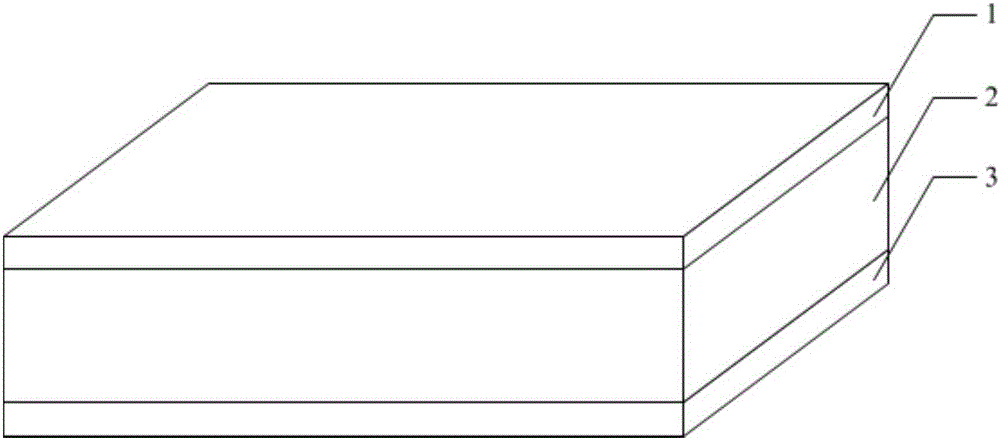

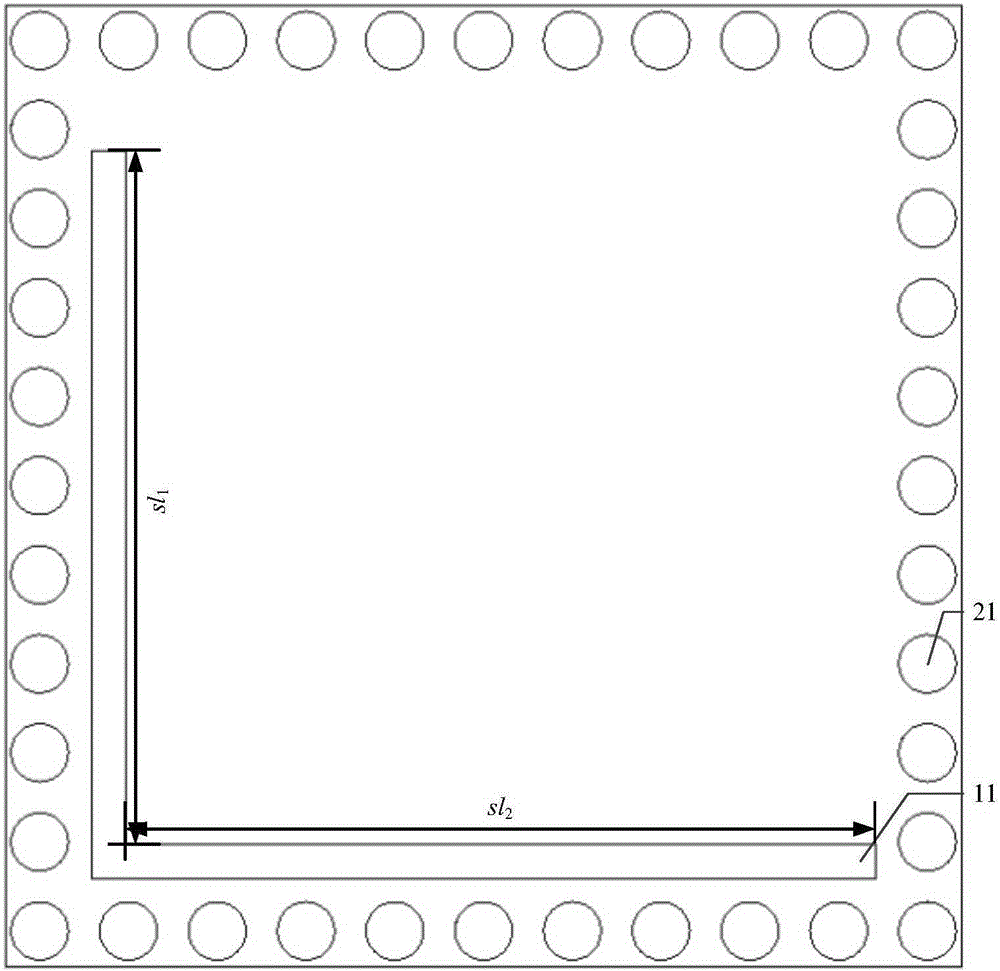

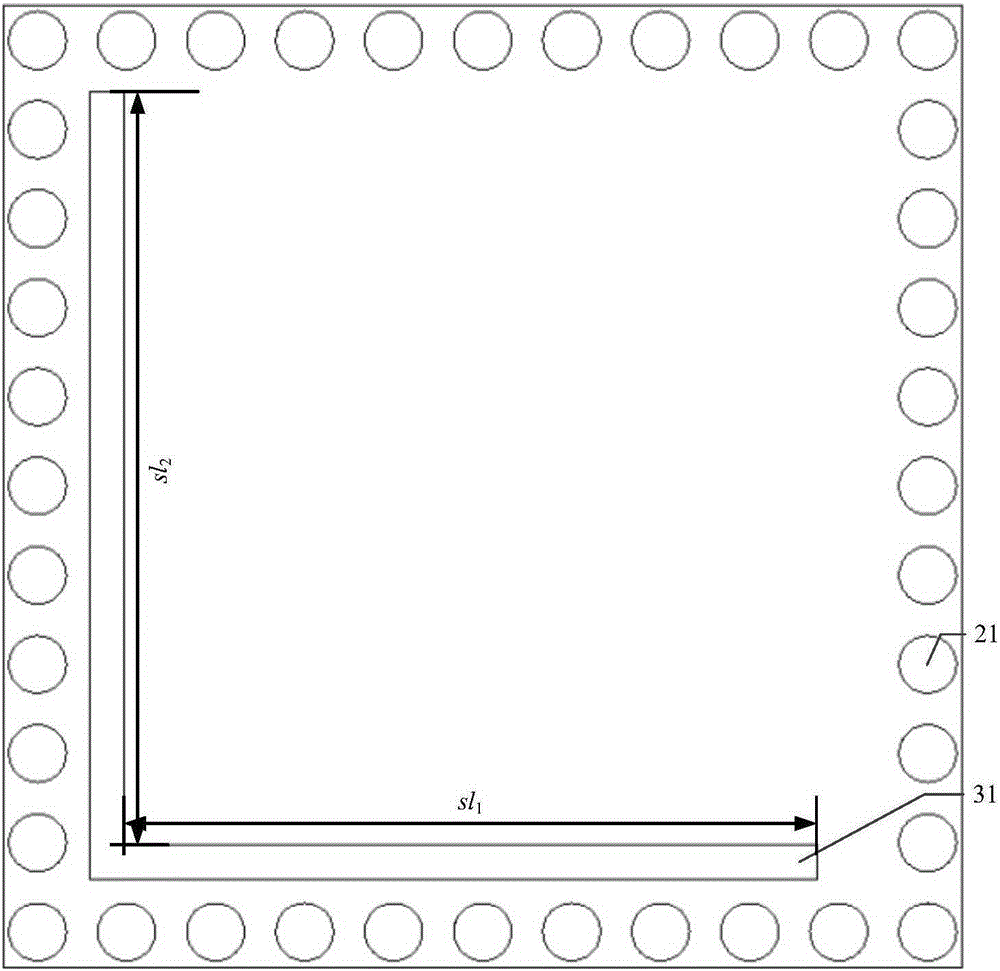

[0027] In this embodiment, a high spurious passband suppression quarter-mode substrate integrated waveguide frequency selective surface is provided, and its structure is as follows figure 1 As shown, its upper layer and lower layer structure are as follows figure 2 , image 3 As shown, the substrate integrated waveguide frequency selective surface includes stacking the first metal copper clad layer 1, the dielectric layer 2, and the second metal copper clad layer 3 sequentially from top to bottom; the first metal copper clad layer 1 is engraved along the edge An "L"-shaped slit 11 is etched to form a frequency-selective surface unit; an "L"-shaped slit 31 is etched along the edge of the second metal copper clad layer 3, which is vertically corresponding to the "L"-shaped slit 11; the "L"-shaped Slit 11 is identical with " L " type slit 31 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com