Solar battery panel bearing mechanism based on crank rocking bar expansion structure

A solar panel and crank rocker technology, which is applied in the field of solar power generation, can solve problems such as the difficulty in effectively utilizing solar energy and panels, the limited number, and the single installation form of solar panels, so as to achieve convenient direction change, rapid deployment and retraction. The effect of meeting the power supply demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

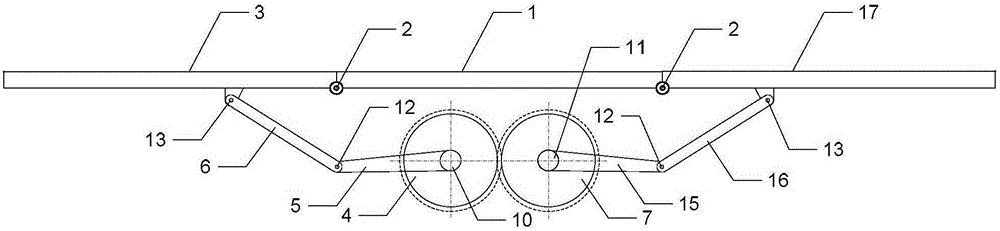

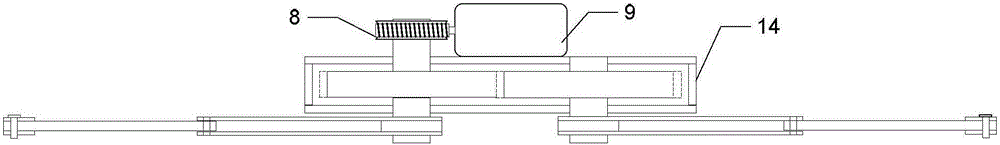

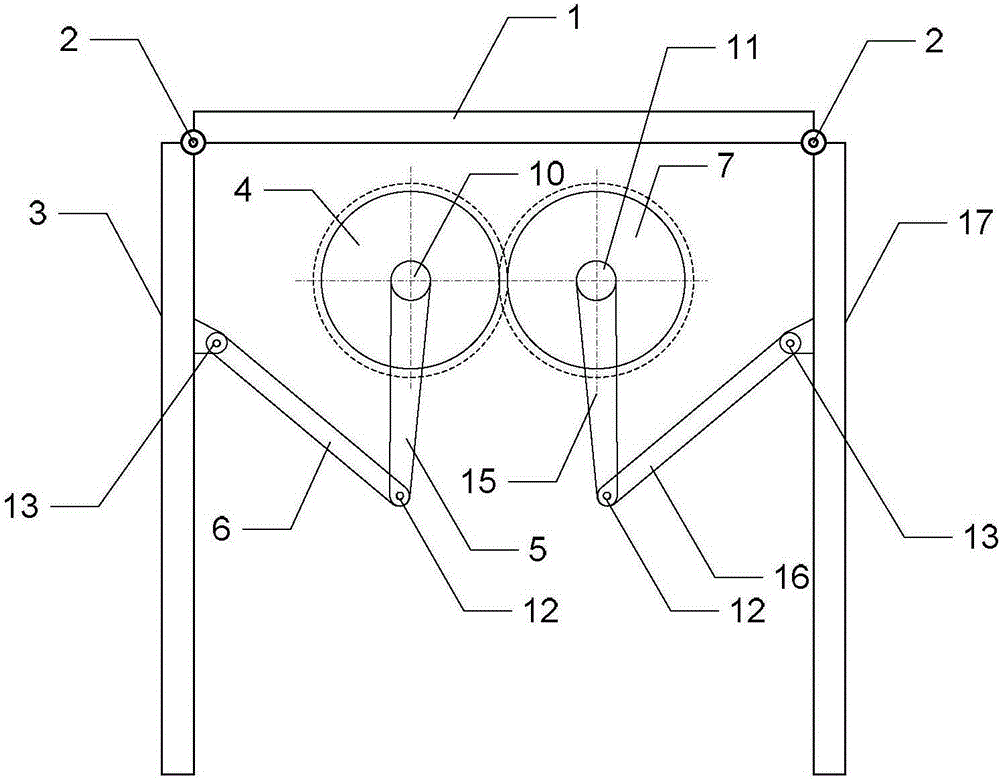

[0011] Specific implementation mode 1: the following combination Figure 1-Figure 3 To explain this embodiment, the solar panel carrying mechanism based on the crank and rocker deployment structure in this embodiment includes a battery panel support 1, a support shaft 2, a first battery panel side plate 3, a driving gear 4, and a driving wheel drive. Support arm 5, driving wheel driven arm 6, driven gear 7, worm gear 8, drive motor 9, driving gear shaft 10, driven gear shaft 11, driving arm coupling 12, side plate coupling 13, gear Box 14, driven wheel driving arm 15, driven wheel driven arm 16, and second battery plate side plate 17;

[0012] The driving motor 9 drives the worm gear 8 to rotate. The gear of the worm gear 8 meshes with the driving gear 4, and the driving gear 4 rotates along the driving gear shaft 10; the driving gear 4 drives the driving wheel driving arm 5, and the driving wheel driving arm 5 pushes the driving wheel The driven arm 6 rotates with the driving a...

specific Embodiment approach 2

[0013] Specific implementation manner 2: the following combination figure 1 To illustrate this embodiment, this embodiment will further explain the first embodiment, the driving gear 4 rotates in a clockwise direction along the driving gear shaft 10.

specific Embodiment approach 3

[0014] Specific implementation manner three: the following combination figure 1 This embodiment will be described. This embodiment will further explain the second embodiment. The driven gear 7 rotates in a counterclockwise direction along the driven gear shaft 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com