Two-position three-way reversing valve

A two-position three-way, reversing valve technology, applied in the direction of fluid pressure actuators, servo meter circuits, servo motor components, etc., can solve the problems of low working pressure, small flow control, cumbersome reversing, etc., and achieve simple structure Reasonable, simple reversing method, stable working pressure and flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

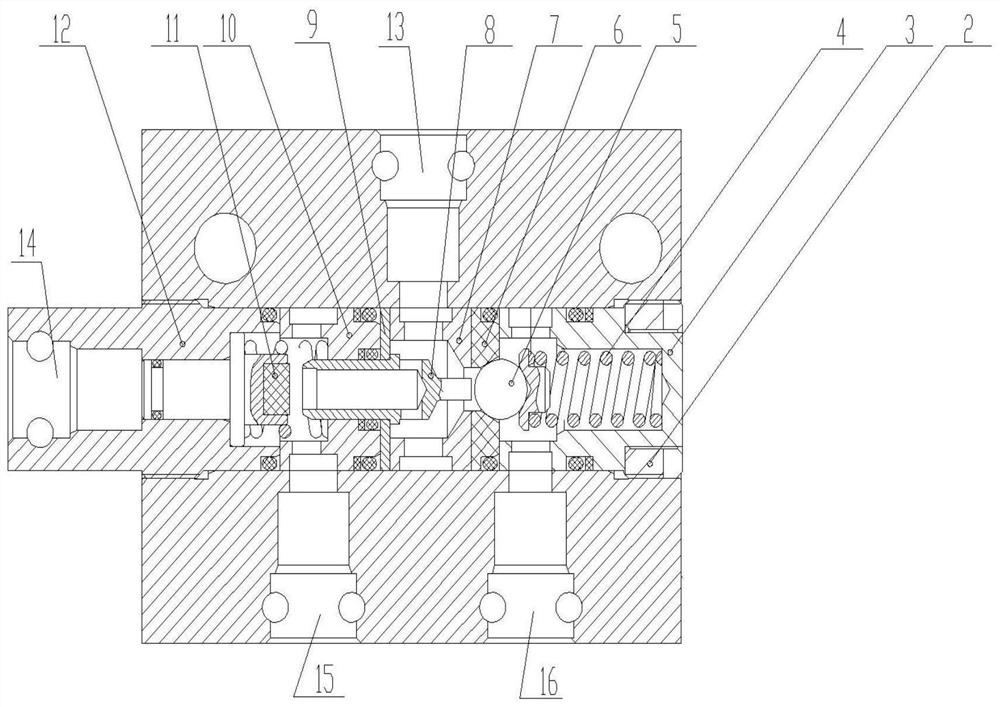

[0021] A two-position three-way reversing valve as shown in the accompanying drawings includes a valve body 1 and a positioning sleeve 12 arranged in the valve body 1. One end of the positioning sleeve 12 is provided with a control port 14, and one end of the control port 14 is provided with There is a valve stem assembly 11, one end of the valve stem assembly 11 is provided with a spool 8 cooperating with it, the valve body 1 is also provided with a middle valve sleeve 7, and one side of the middle valve sleeve 7 is provided with a valve seat 6, And the valve seat 6 is provided with a limit opening, and the limit opening is provided with a limit device that can be pushed back by the spool 8 .

[0022] Wherein, the middle and lower part of one end of the positioning sleeve 12 is provided with a protruding part, and the port of the other end is provided with a concave part, and the concave part is provided with an end sleeve 3 and a compression screw 2 for fastening the end slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com