Combined pot base and manufacturing method

A manufacturing method and bonding technology, applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve the problems of troublesome manufacturing, inability to adopt cold extrusion molding, and high cost, and achieve low manufacturing cost, increased firmness and The effect of stability and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

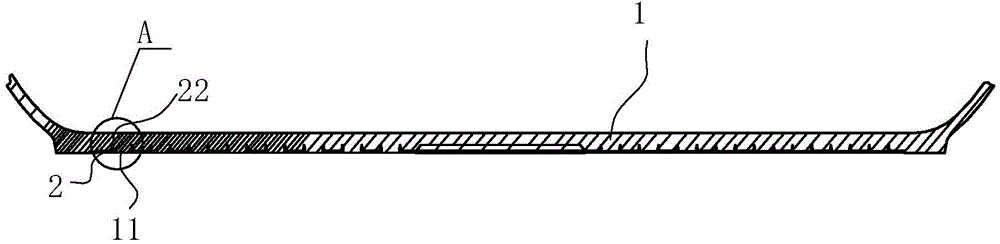

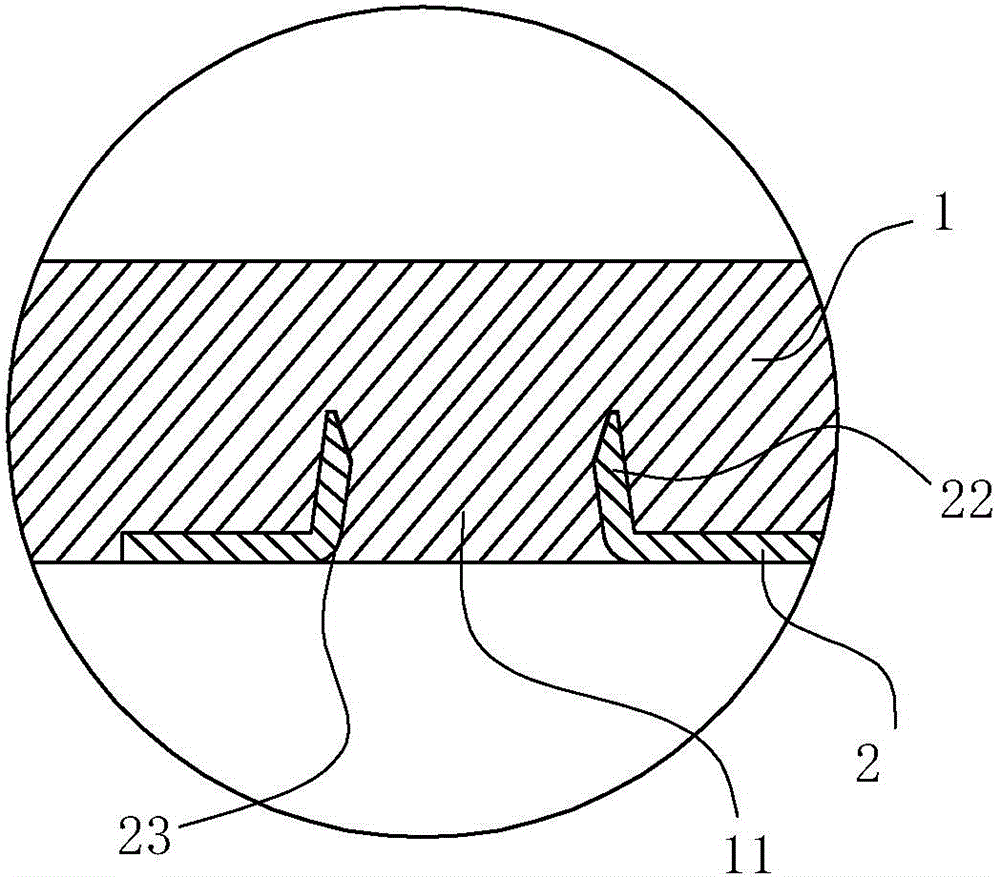

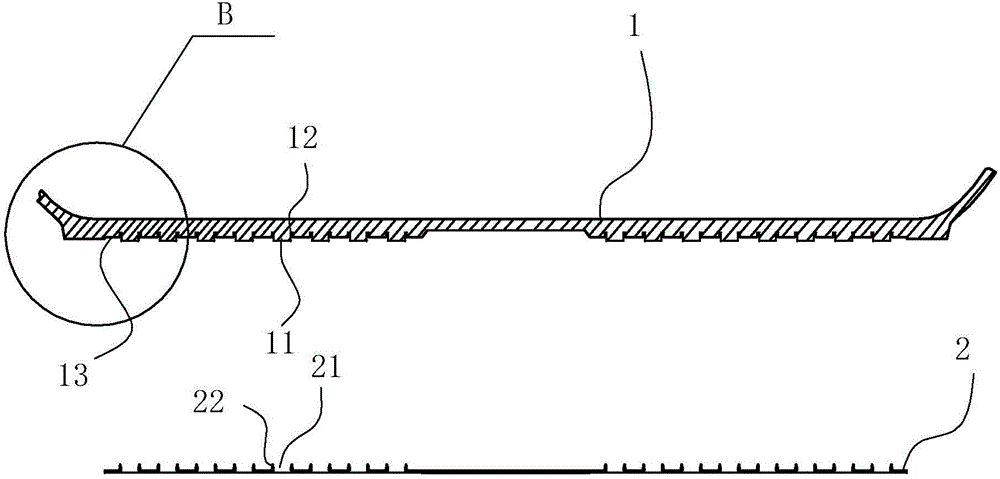

[0033] Such as Figure 1~5As shown, the composite pan bottom of the present embodiment includes an aluminum pan bottom 1, and the bottom of the pan bottom 1 is compositely fixed with a magnetically conductive heating plate 2, and the bottom of the pan bottom 1 is preformed with the shape and shape of the magnetically conductive heating plate 2. The circular sinking platform 13 with matching thickness makes the lower surface of the magnetic conduction heating plate 2 substantially flush with the plane of the bottom of the pot 1 after compounding, and basically flush requires that the distance between the two sides be controlled within 0.1mm, preferably smooth and flush At the same time, it is beneficial to the beautiful appearance and reduces the processing difficulty of the subsequent process; the circular sinking platform 13 at the bottom of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com