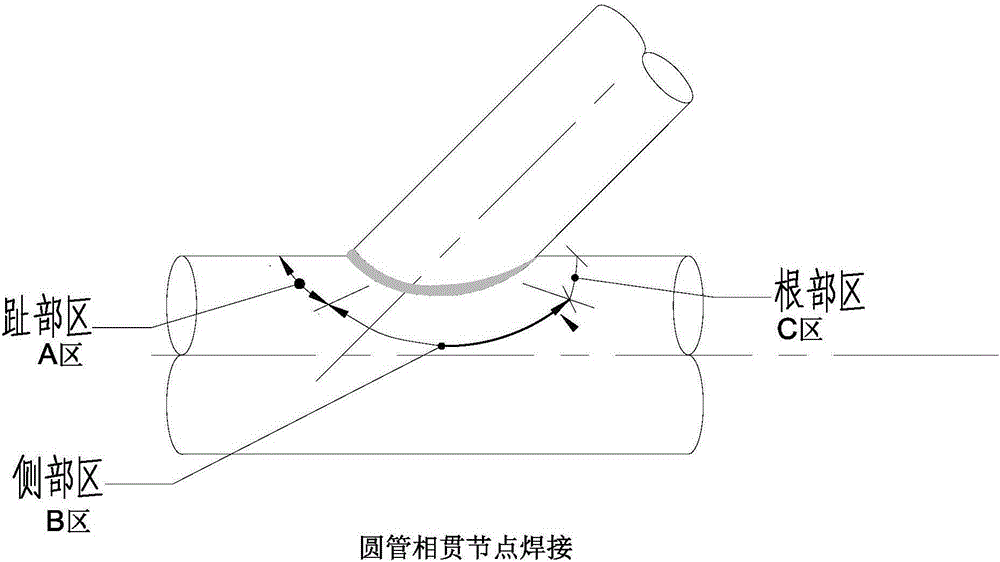

Whole plate thick penetration welding method for intersection joint of circular tube

A technology of intersecting joints and penetration welding, which is applied in the field of steel pipe welding, can solve the problems that special-shaped intersecting line welds cannot achieve full plate thickness penetration, and achieve the effects of shortening the production period, improving competitiveness, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

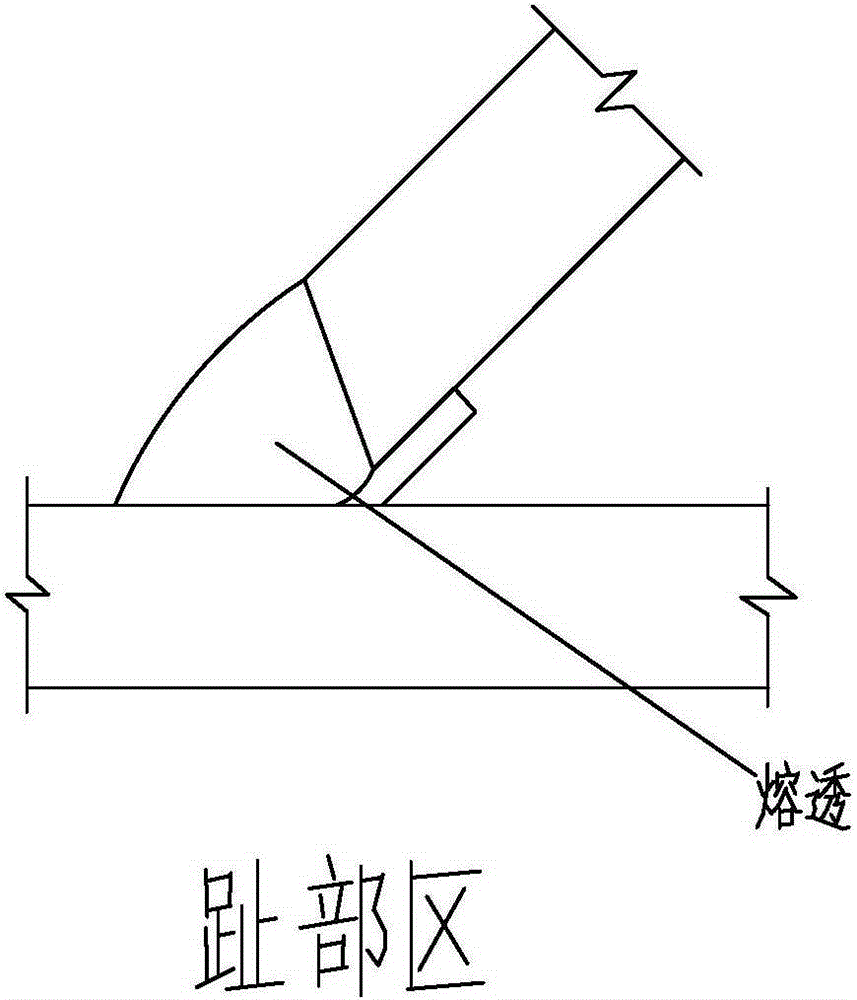

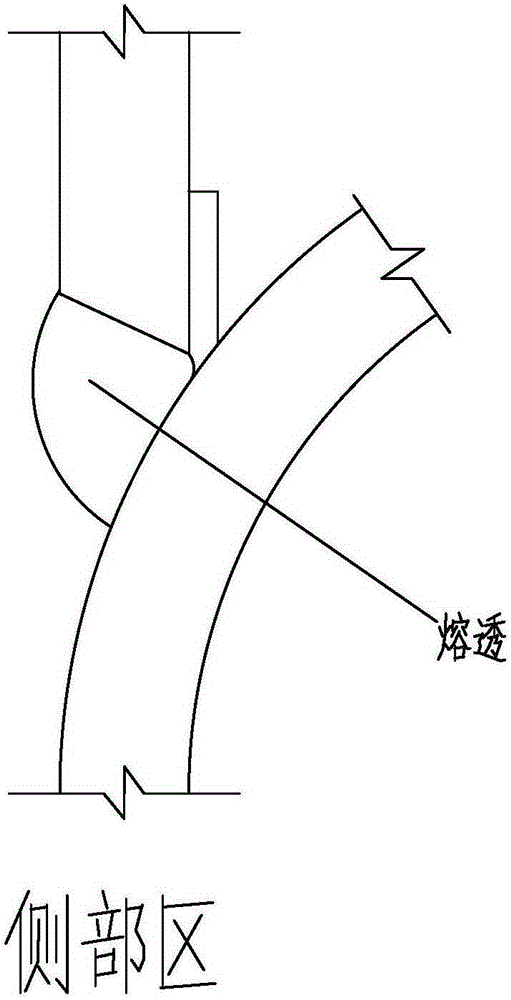

[0015] Such as Figure 1-4 As shown, what the present invention discloses is a full-plate thickness penetration welding method for intersecting joints of circular pipes, which specifically includes the following steps: a. Cutting the intersecting circular pipes with the intersecting line, marking the position of the cutting point, and vertically Draw a reference line 100mm behind the axis, and the cut-off point is at the same position as the cut-off point of the backing plate;

[0016] b. To program the special-shaped intersecting line backing plate, it is required that the starting point position of the backing plate is consistent with the starting cutting position of the intersecting circular pipe, and draw the installation reference line on the outside of the backing plate based on the starting cutting point;

[0017] c. Assemble the intersecting round pipe according to the conventional process to ensure the dimensional accuracy of the round pipe installation;

[0018] d. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com