A multi-purpose vegetable shredding device

A technology for shredding and vegetables, applied in metal processing and other directions, can solve the problems of unevenness, labor-intensive, easy to hurt fingers, etc., and achieve the effect of low technical requirements and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

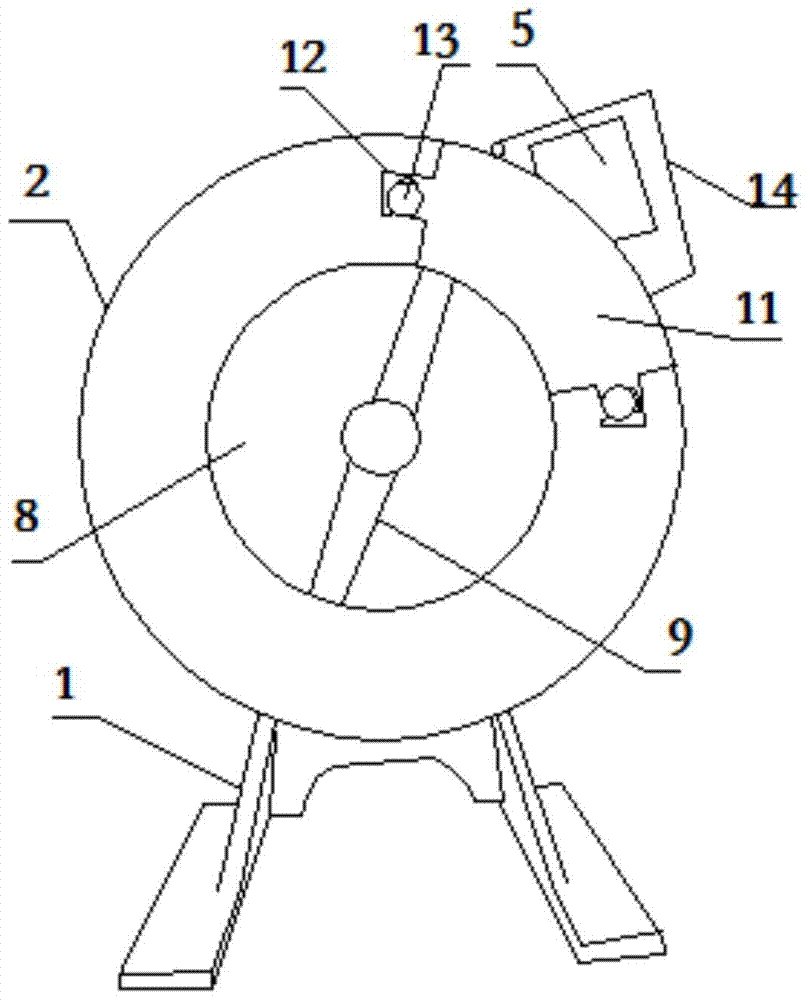

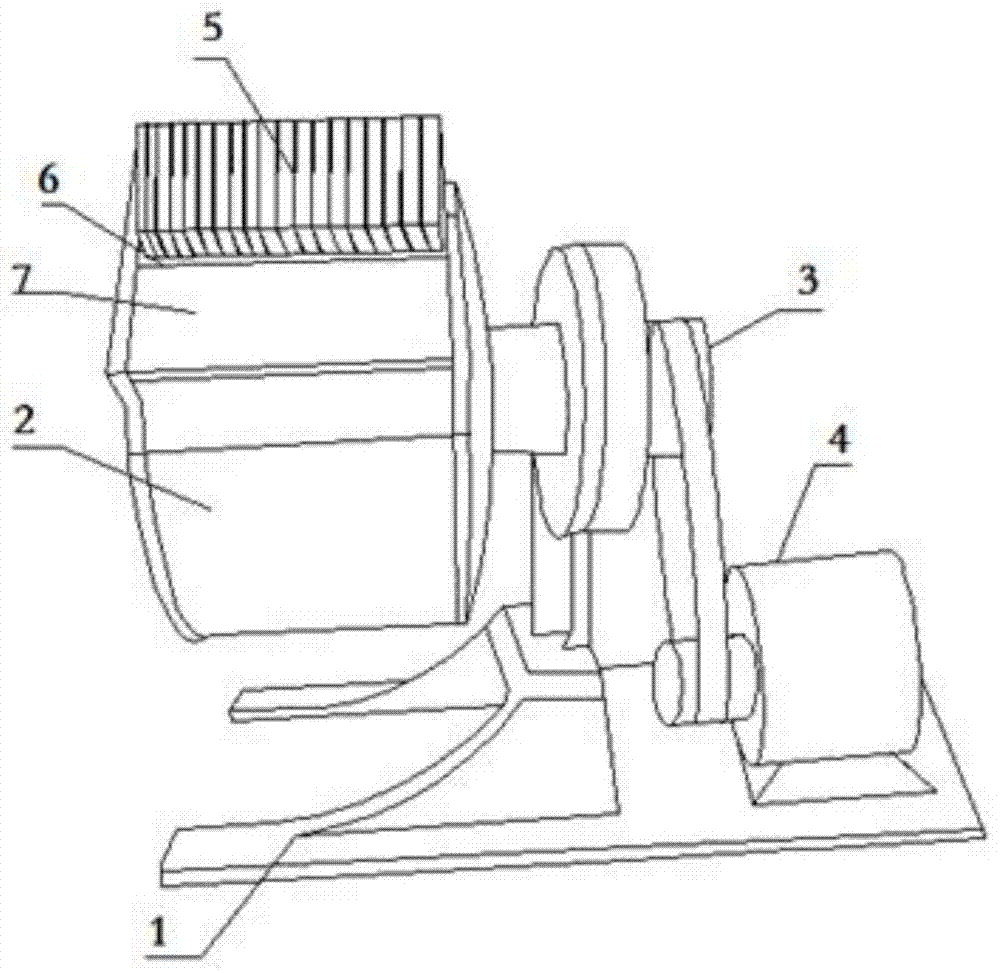

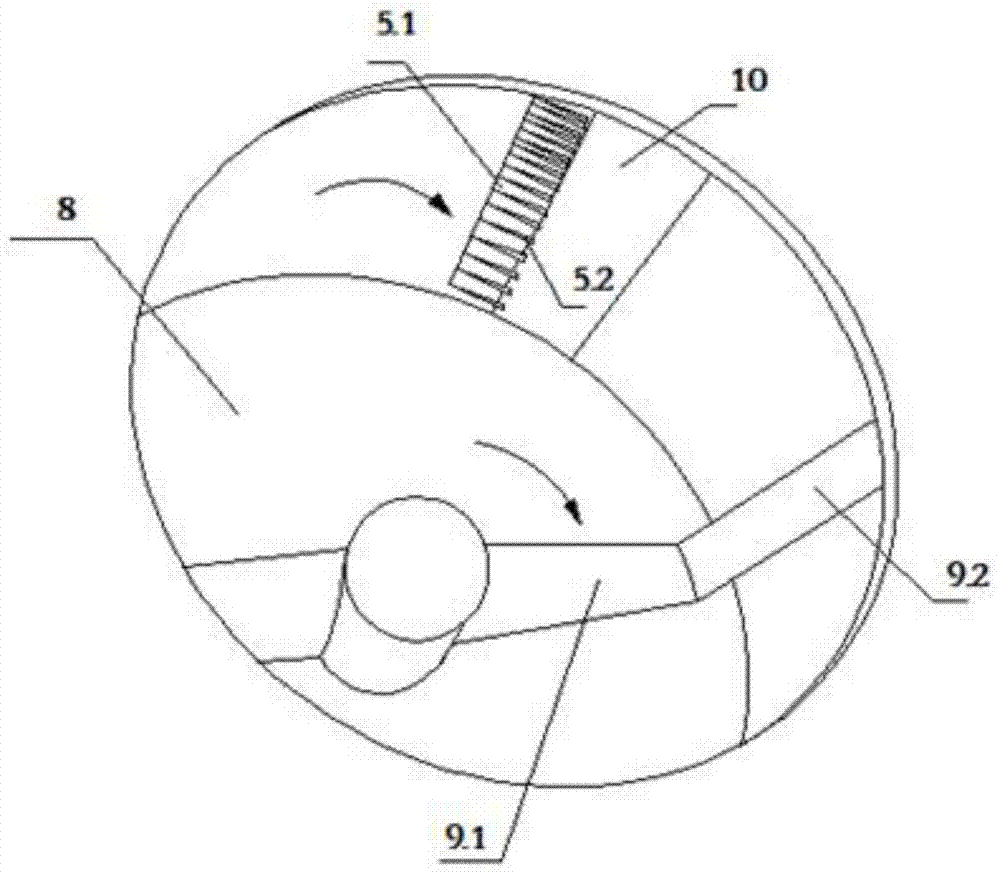

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0022] A multi-purpose vegetable shredding device of the present invention has a structure such as Figure 1-Figure 4 As shown, including a base 1, a cylindrical shredding cylinder 2 is horizontally arranged on the base 1, the interior of the shredding cylinder 2 is hollow and a feed port 8 is provided on the left end surface, and a center of the right end surface of the shredding cylinder 2 is provided with an axial Rotating rotating shaft, the right end of the rotating shaft passes through the right end surface of the shredded barrel 2 and is connected with a pulley 3, and the pushing arm 9 arranged in the shredded barrel 2, the pushing arm 9 includes a radial rod 9.1 and an axial rod 9.2, the radial rod 9.1 and the axial rod 9.2 The rod 9.1 is connected to the rotating shaft, the axial rod 9.2 is connected to the end of the radial rod 9.1 and is close to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com