Pairing device for cone yarns

A technology of package yarn and conveying device, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of reducing work efficiency, increasing mechanical loss, increasing the length of production workshop, etc., and achieves the effect of increasing matching efficiency and increasing production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

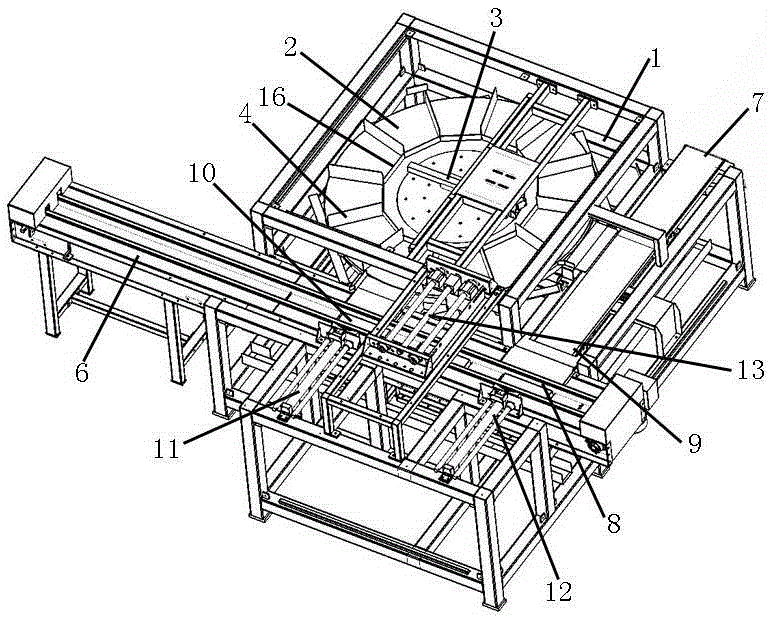

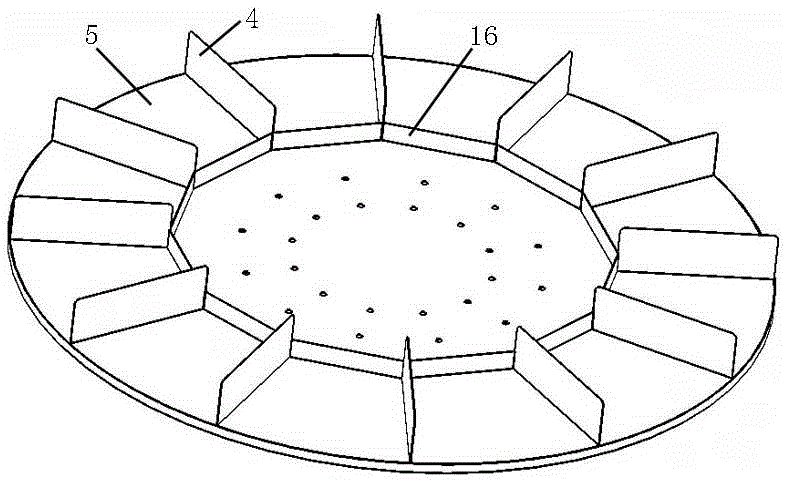

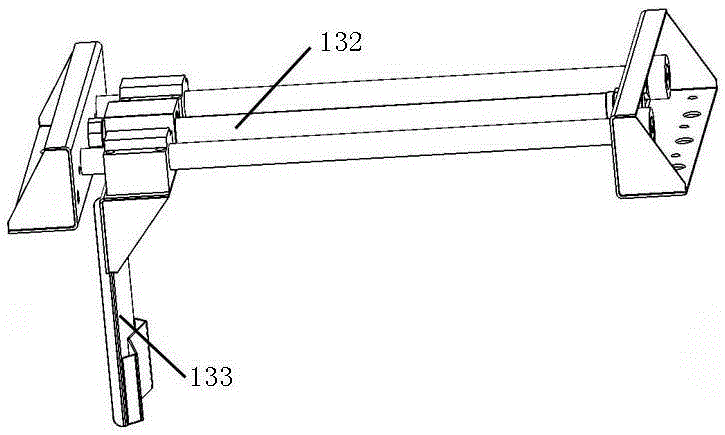

[0021] Such as Figure 1-4 As shown, a cheese pairing device includes a fixed frame 1 and a material conveying device. A material tray 2 is rotatably mounted on the fixed frame 1. A pushing device I3 is installed above the material tray 2. The pushing device I3 Installed on the fixed frame 1 through a fixed seat, at least 4 baffles 4 are installed on the material tray 2, and a cheese storage area 5 is formed between the baffles 4, and the material conveying device includes a The material conveying device I6 and the material conveying device II7 at the side end, the discharge end 8 of the material conveying device I6 is communicated with the feed end 9 of the material conveying device II7, and a weighing device 10 is installed on the conveying platform of the material conveying device I6, The side end of the material conveying device I6 where the weighing device 10 is located is equipped with a pushing device II11, the pushing device II11 reciprocates toward the cheese storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com