Splitting machine for slip shaft of double gas circuits

A slip shaft, double air path technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of not being able to connect tightly, differential motion, affecting production efficiency and slitting quality, and achieve improved end faces Poor uniformity, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

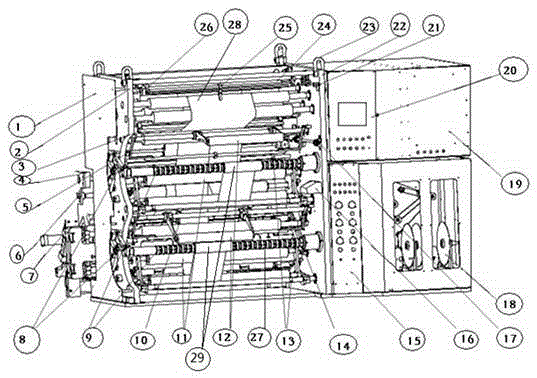

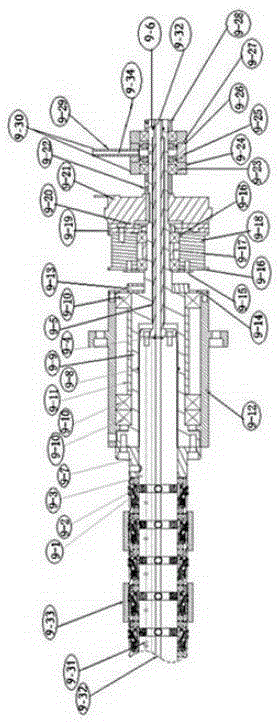

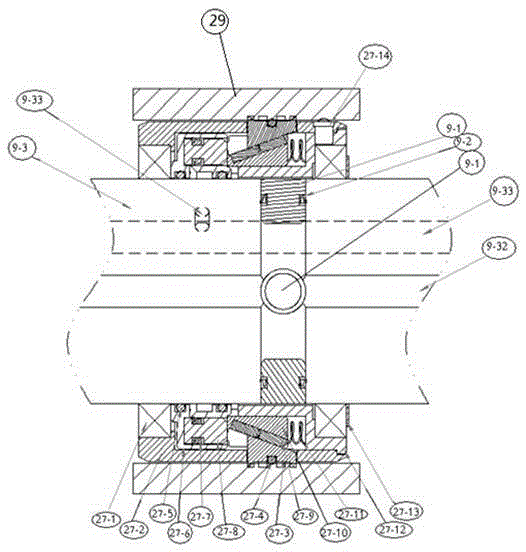

[0013] Embodiment, with reference to the accompanying drawings, a dual-air path slip shaft slitting machine includes a frame composed of side baffles 1, side wall panels 2 and main wall panels 22, and is installed on the upper right side of the main wall panels 22. Main control panel 20 and electrical control cabinet 19 are arranged, and automatic crimping machine 18 and instrument panel 15 are housed in the lower right side of main wallboard 22; Cutter 25 and main driving pressure roller 24 are housed on knife rest 26; Below main driving pressure roller 24, lower pressing roller 11 and upper pressing roller 12 are housed, and the middle part between side wall panel 2 and main wall panel 22 and The lower part is equipped with a dual air path slip shaft 9, which is installed on the main wallboard 22; the dual air path slip shaft 9 is composed of an air intake mechanism 9-30, a synchronous pulley 9-18 and an electromagnetic clutch 9-21 composition; it is characterized in that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com