Intelligent cable temperature on-line monitoring system

A monitoring system and smart cable technology, applied in the directions of thermometers, signal transmission systems, thermometer components, etc., can solve the problems of increased fire accidents, economic losses, cable burning, etc., and achieve ideal operating characteristics, convenient use, and improved The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

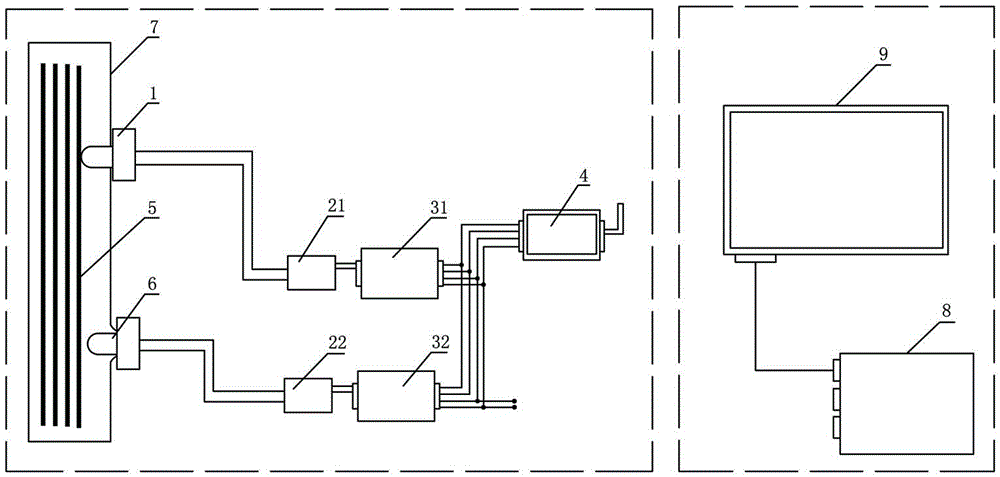

[0018] Such as figure 1 Shown, a kind of intelligent cable temperature on-line monitoring system comprises temperature sensor 1, first signal conditioner 21, first bus collector 31, GPRS data transmitter 4 and monitoring center; The input end of described temperature sensor 1 is connected to The cable body 5 at the cable joint or section monitoring, the output end of the temperature sensor 1 is connected to the first signal conditioner 21, and the temperature data is collected by the first bus after being processed by the first signal conditioner 21 Collected by the device 31, then uploaded to the monitoring center by the GPRS data transmitter 4. Due to the permanent and online nature of GPRS data transmission, it is possible to predict the fault trend of the cable head or the cable body 1, provide cable fault location and maintenance gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com