Fluid phase analysis apparatus and fluid phase analysis method

An analysis device and fluid phase technology, applied in the field of fluid phase state analysis devices, can solve problems such as inability to guarantee sample volume, difficulty in sampling, inability to meet test requirements, etc., and achieve the effects of saving on-site sampling operation costs, being convenient to carry, and having a small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

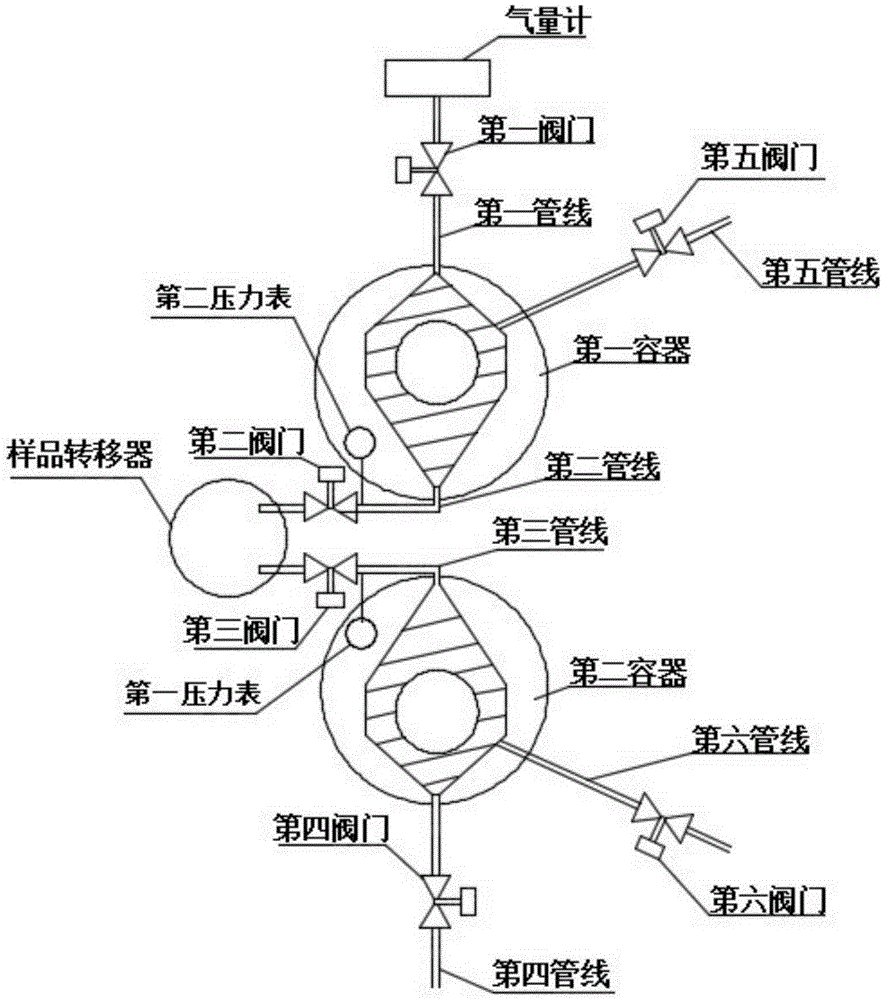

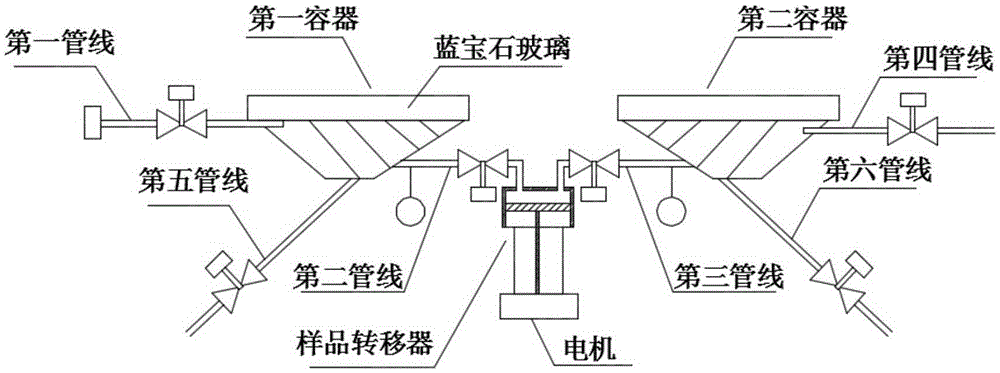

[0045] This embodiment provides a fluid phase analysis device. The device includes three groups of analysis units, which are respectively the first analysis unit ( figure 1 is the front view of the first analysis unit, figure 2 is the side view of the first analysis unit), the second analysis unit and the third analysis unit;

[0046] Each analytical unit includes: a first container, a second container and a sample transfer device:

[0047] The volume of the first container is the same as that of the second container, which is 5mL, and the top material of both containers is sapphire glass;

[0048] The top of the first container is provided with a first pipeline. The first pipeline is provided with a first valve and a gas meter sequentially along the direction extending outward. The middle of the first container is provided with a second pipeline communicating with the sample transfer device. The second pipeline is provided with a second pressure gauge and a second valve i...

Embodiment 2

[0053] This embodiment provides the process of using the fluid phase analysis device in Embodiment 1 to perform P-V test.

[0054] The process of performing P-V test on the first analysis unit is:

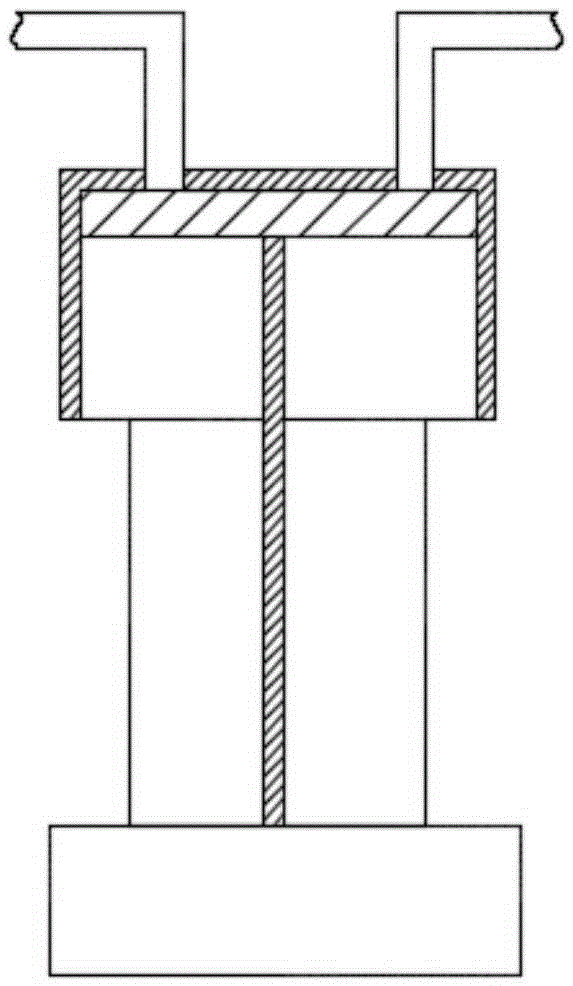

[0055] (1) Roughly measure the bubble point pressure P of crude oil A b0 to 6.7MPa, the temperature of the first container, the second container, and the sample transfer device is kept constant until the formation temperature T of crude oil A is 83.08°C, each valve is kept closed, and the motor drives the movable parts of the sample transfer device to keep the internal space in a state of minimum volume (such as image 3 shown);

[0056] (2) Open the fourth valve to introduce pressurized crude oil, and continue pressurizing and injecting after the crude oil is full of the second container until the pressure P in the second container 0 =32MPa, close the fourth valve;

[0057] (3) Open the third valve, and the motor drives the movable parts of the sample transfer device to gradual...

Embodiment 3

[0066] This embodiment provides the process of using the fluid phase analysis device in Embodiment 1 to perform a flash test.

[0067] The process of flash test using the first analysis unit is:

[0068] (1) Constantly temperature the first container, the second container and the sample transfer device to the formation temperature T (83.08°C) of the crude oil A, keep all valves closed, and move the movable parts of the sample transfer device to keep the internal space in a state of minimum volume;

[0069] (2) Open the fourth valve to introduce pressurized crude oil. When the crude oil is full of the second container, open the third valve to move the movable parts so that the internal space of the sample transfer device gradually changes from the state of minimum volume to the state of maximum volume. After the internal space, continue to pressurize and inject until the pressure in the second container reaches the formation pressure P (18.33MPa) of crude oil, then close the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com