Pipe bending device

A technology of a pipe bending device and an eccentric wheel, which is applied in the field of pipe processing, can solve the problems of small application range, low efficiency, complicated procedures for replacing molds, etc., and achieves the effect of convenient replacement and easy operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

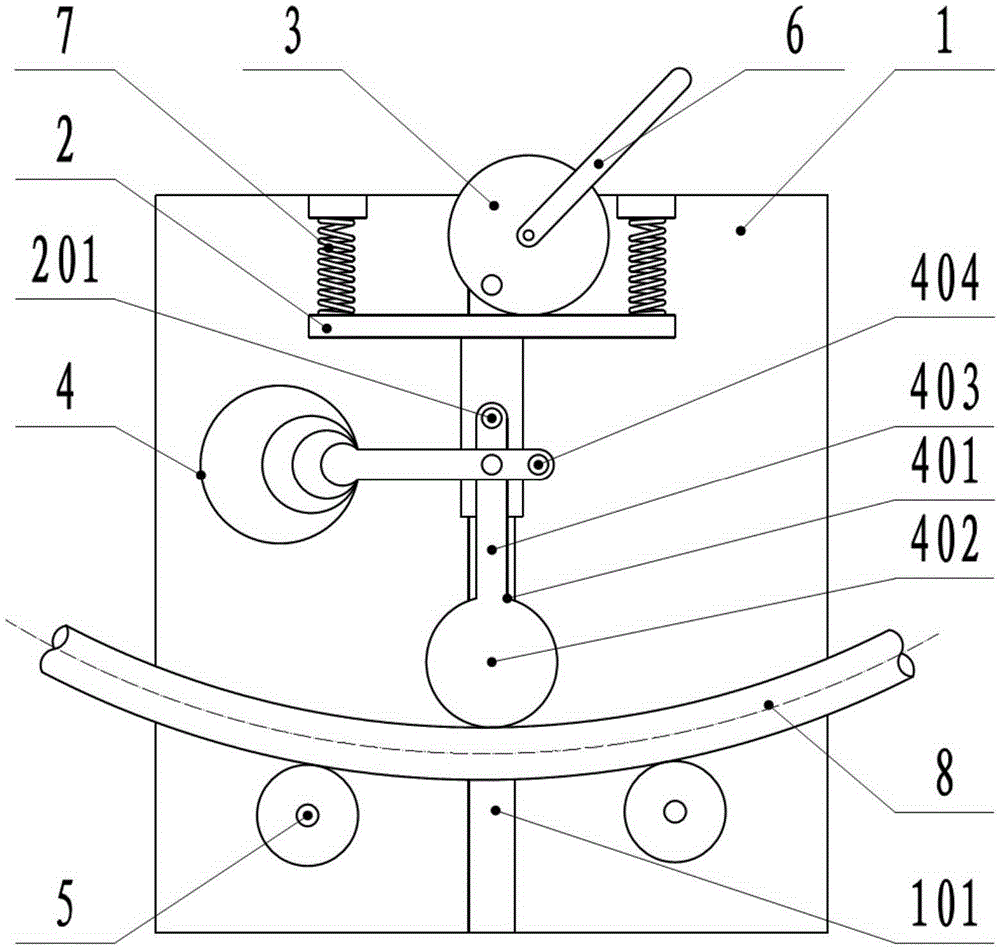

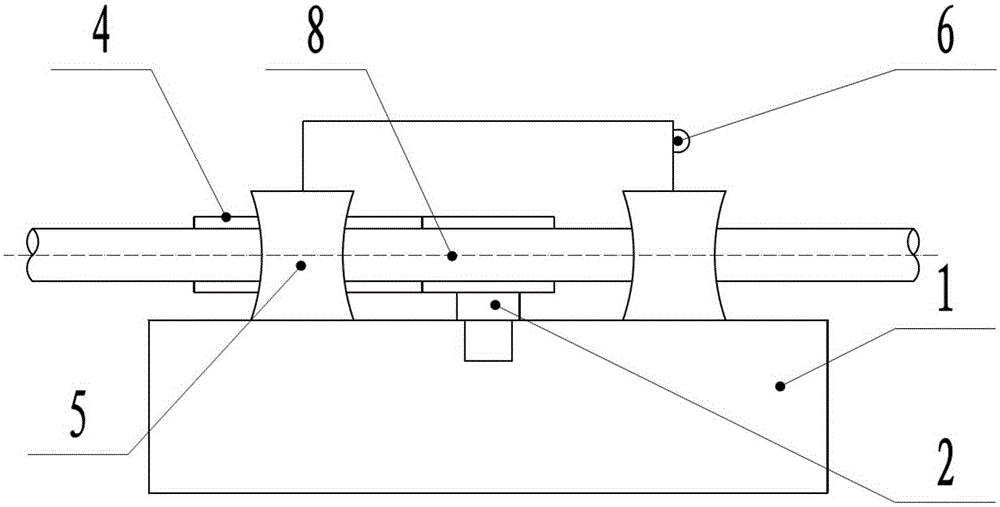

[0015] A pipe bending device, comprising a base 1, the base 1 is fixed horizontally, and a slideway 101 is provided on the upper surface; a sliding part 2 is arranged in the slideway 101, and the sliding part 2 is slidably connected with the slideway 101; one end of the sliding part 2 is connected to the eccentric wheel 3 contacts, and the other end is connected with a group of bending molds 4 in rotation, and the bending mold 4 includes molds 401 different from five sizes, and the mold 401 includes an arc 402 and a connecting rod 403; one end of the connecting rod 403 is connected to the arc 402 Fixed connection, the other end is rotationally connected with the slider 2.

[0016] Two guide wheels 5 are evenly distributed on both sides of the slideway 101, and the two guide wheels 5 are located on the side away from the eccentric wheel 3, and are connected to the base 1 in rotation; the eccentric wheel 3 is fixedly connected with a handle 6; The sliding part 2 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com