Movement and pose adjusting platform for large member

A technology for large-scale components and pose adjustment, applied in the mechanical field, can solve the problems of difficult alignment and positioning, unbalanced movement of large-scale equipment components, etc., to achieve convenient installation and positioning, improve assembly accuracy and assembly efficiency, and efficient movement and alignment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

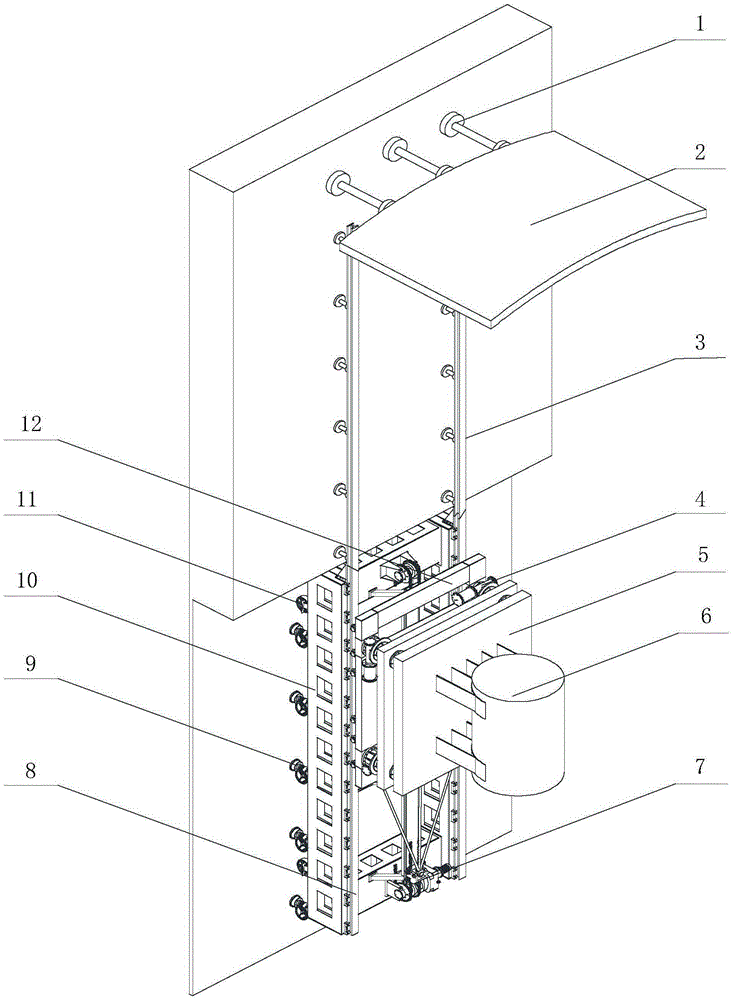

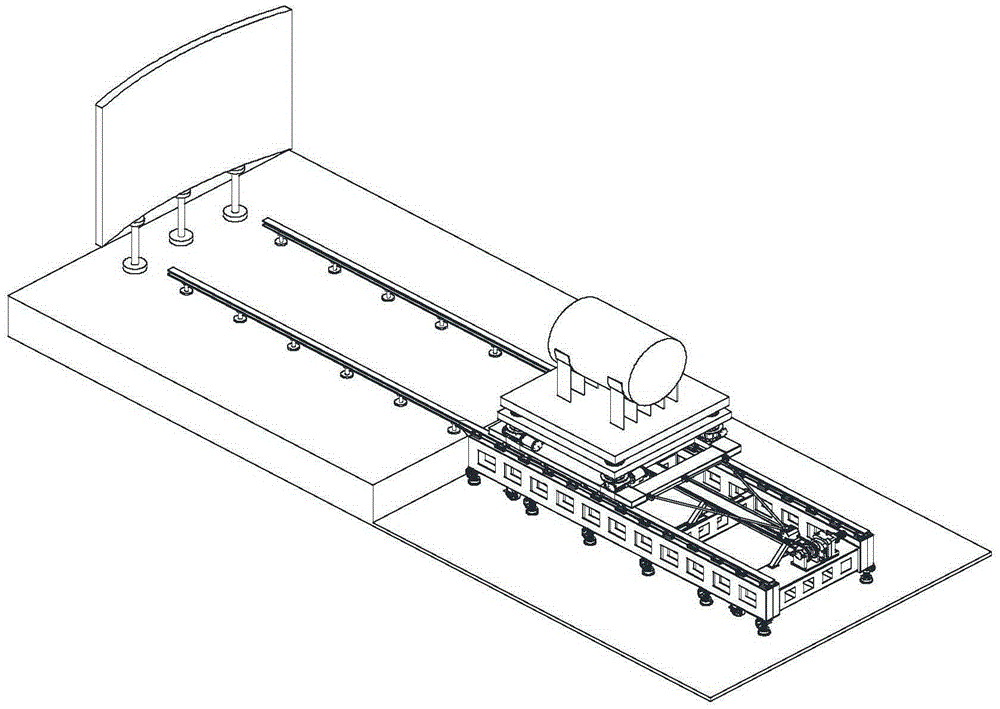

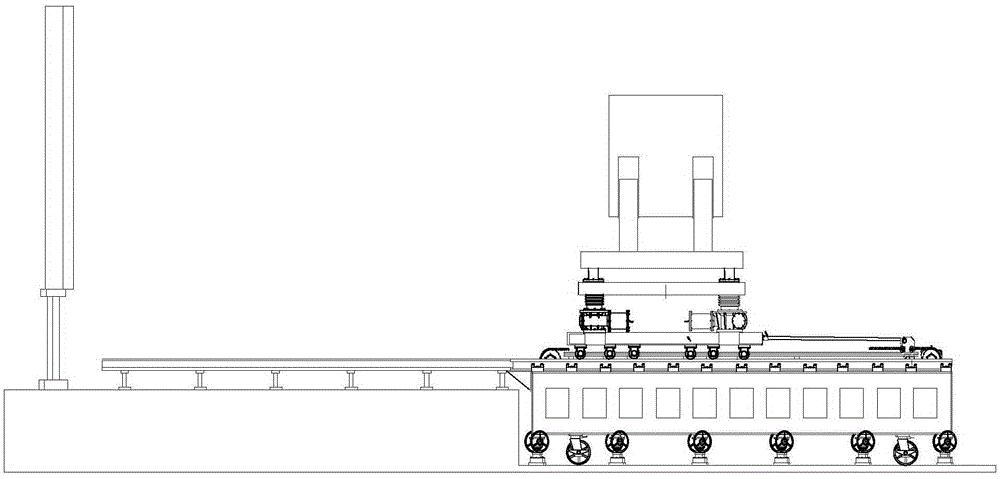

[0042] Embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

[0043] As shown in the accompanying drawings, a platform for horizontal movement and posture adjustment of a large slewing mechanism includes: a test piece trolley 12 as a movable bearing platform; a track docking carriage 10 for moving the rail docking carriage; The power trolley 12 uses the motor 23 as the power source, decelerates through the reducer, and finally pushes the specimen trolley through the chain transmission; the horizontal posture adjustment mechanism adopts the working principle of four-point posture adjustment method to realize the test specimen trolley and the carrier. horizontal pose adjustment.

[0044] The test piece trolley 12 includes: the test piece trolley frame 31, the track wheel 32 and the track wheel bearing, etc., the test piece trolley frame 31 is welded by box girders, and is connected to the horizontal posture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com