Calibration method and device for laser marking

A technology of laser marking and calibration method, applied in the field of laser marking, can solve the problems of difficulty in measuring the number of points, time-consuming, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

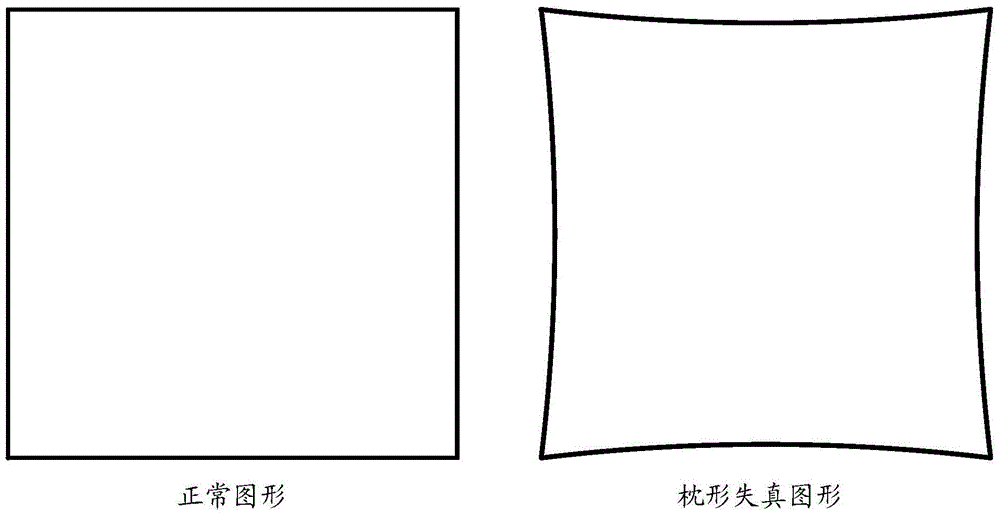

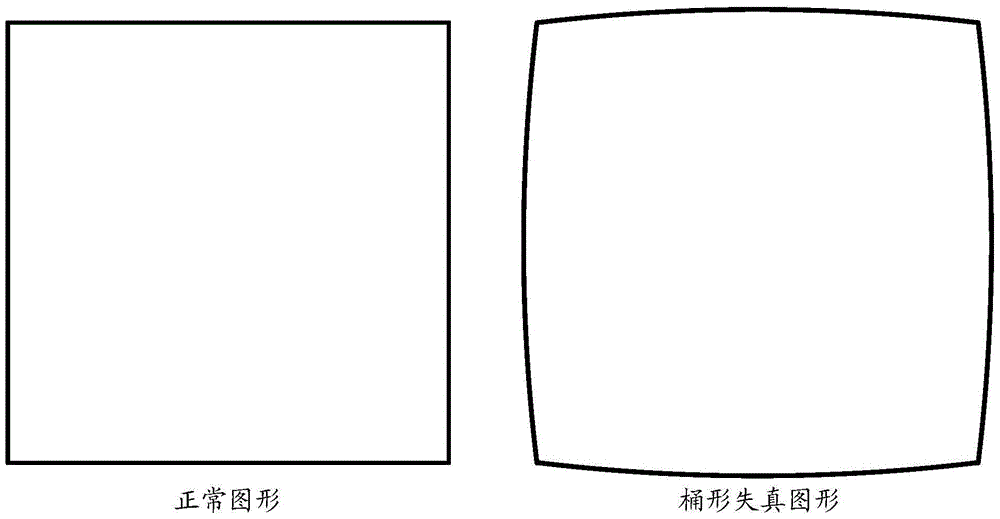

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

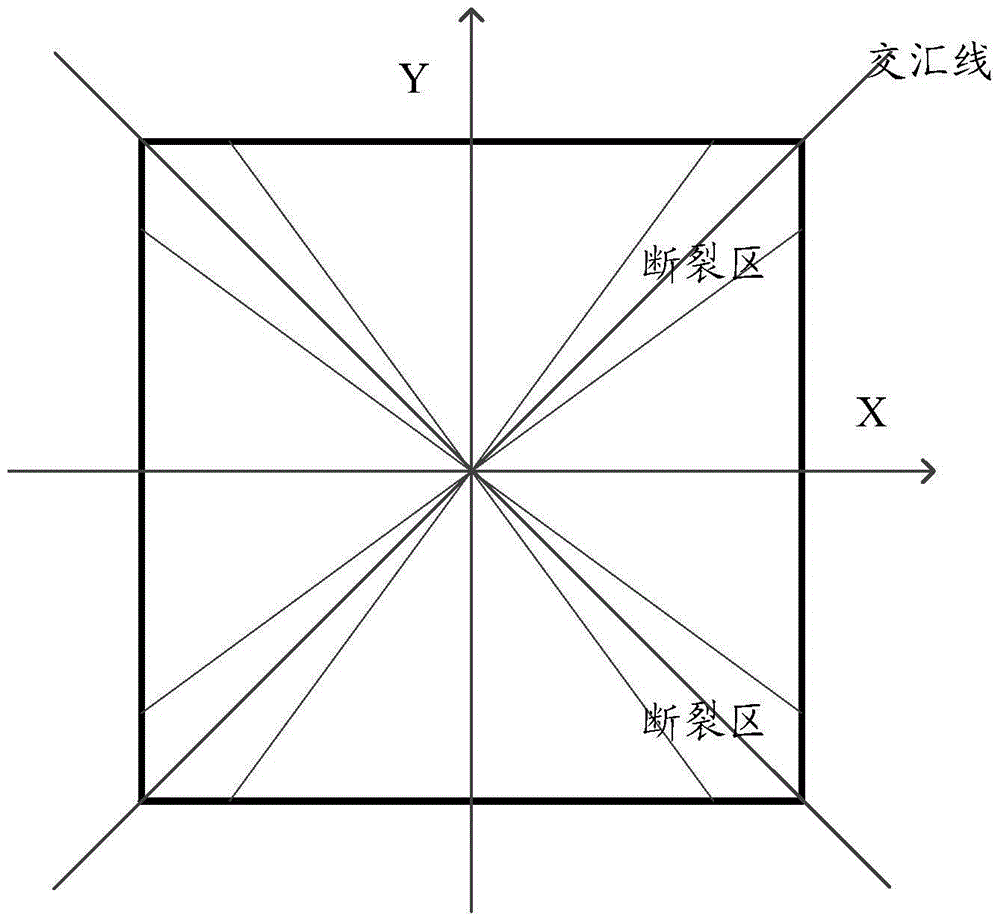

[0050] like image 3 As shown, when printing a square using the formula method, first intercept N points on the uncorrected marking image, measure the deviation between the actual coordinates of these N points and the ideal coordinates, and use the fitting method, Fit these N points into a curve equation, which is the deviation equation of each marking point coordinate after distortion. In this way, the four curve formulas of the four sides will be obtained. After the formula is obtained, the deviation value of each point on the marking plane can be known. When actually marking, the deviation of each coordinate point is first calculated, and the The deviation of the coordinates is added to the actual co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com