A method for correcting optical distortion of a line scan camera

A line-scan camera and optical distortion technology, applied in the field of three-dimensional measurement, can solve the problems that area-scan cameras are not suitable for line-scan cameras, etc., and achieve the effects of good correction effect, convenient and simple preparation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

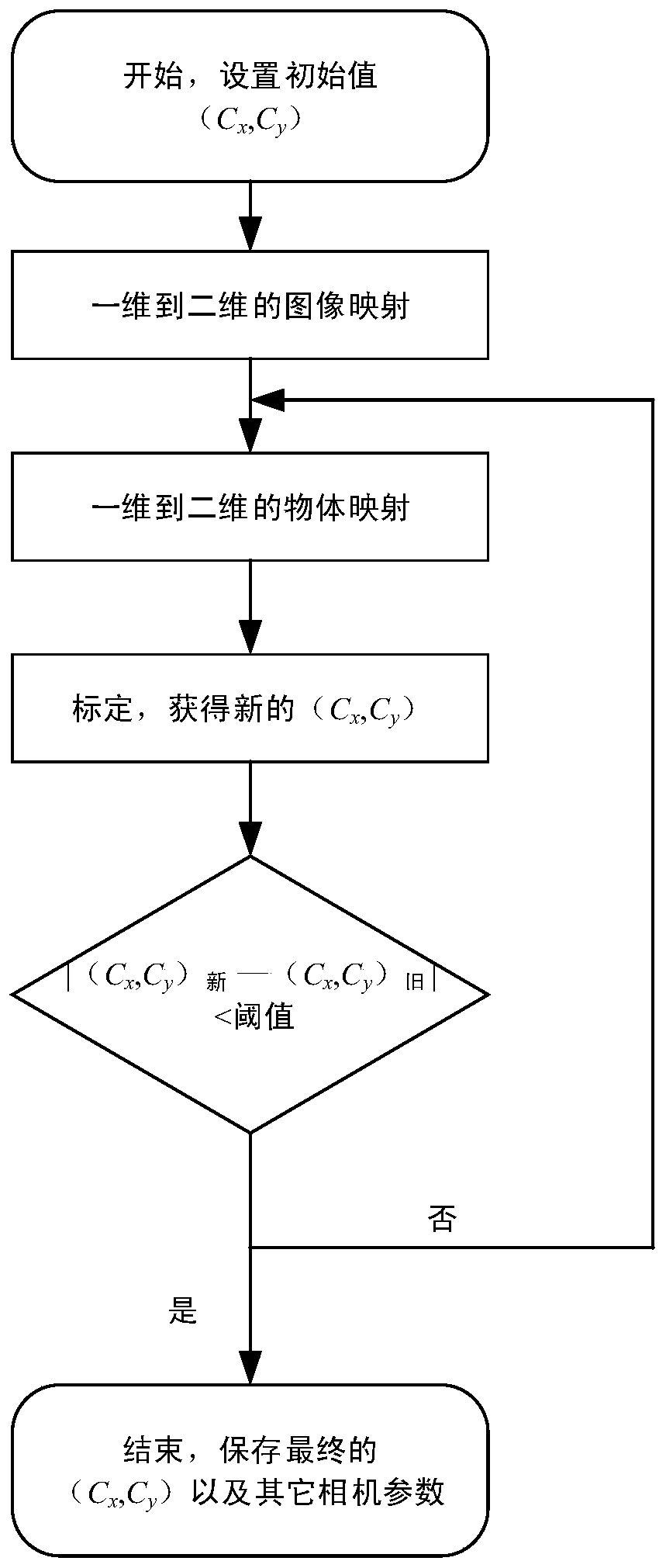

[0039] The invention provides a method for correcting optical distortion of a line array camera, the specific implementation steps are as follows:

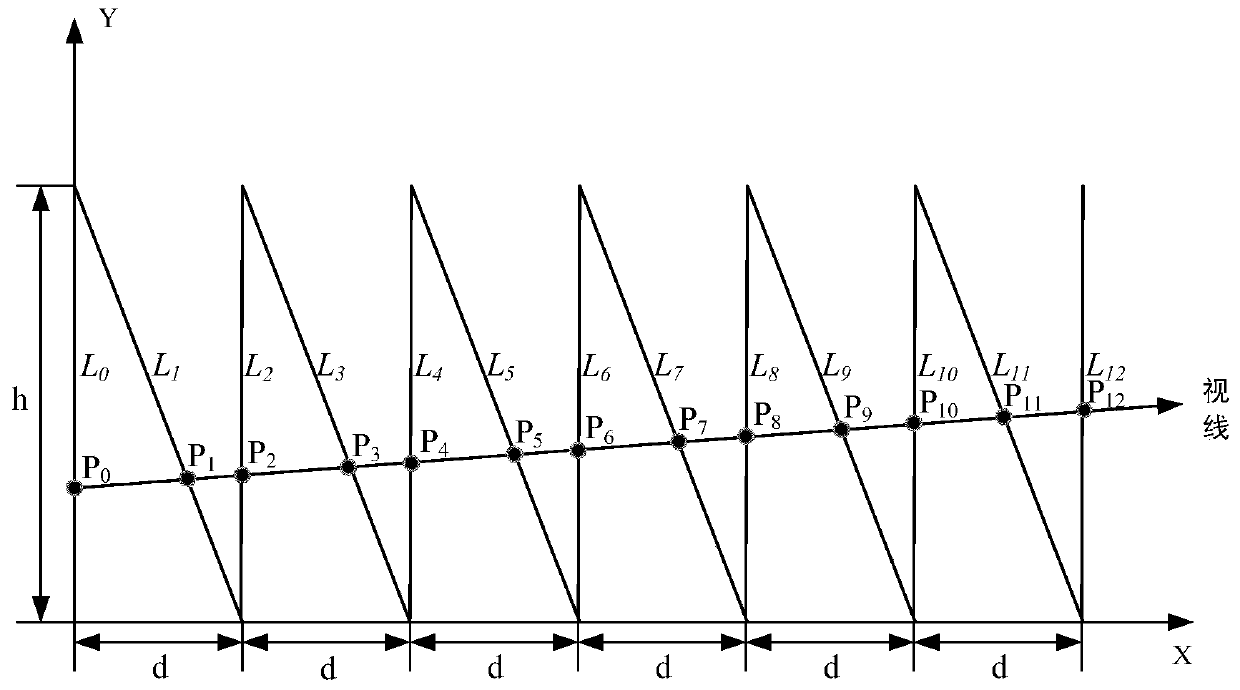

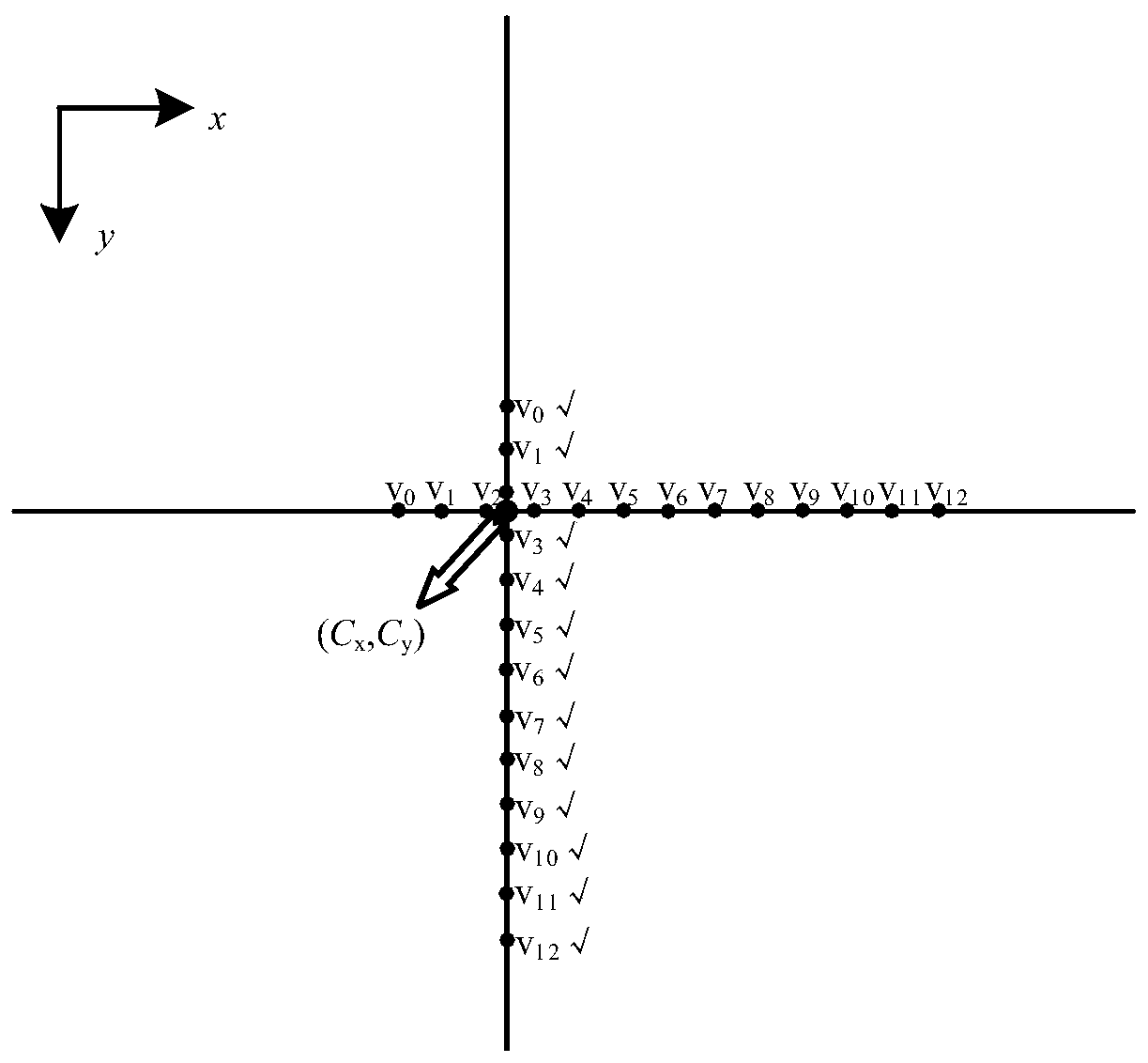

[0040] 1. Make the calibration board: such as figure 1 As shown, the calibration board is drawn with an X-Y coordinate system, 6 oblique lines and 7 straight lines, one of which is coincident with the Y axis and intersects at the origin of the coordinate axis, and the rest of the straight lines are set parallel to the Y axis and Intersecting on the X-axis, the distance between every two adjacent straight l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com