Modular passenger car body

A modularized bus technology, applied to the upper structure of the bus, vehicle parts, upper structure, etc., can solve the problems of long assembly time, heavy body weight, and fixed specifications, and achieve simple assembly process, shorten assembly time, and reduce the number of parts. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

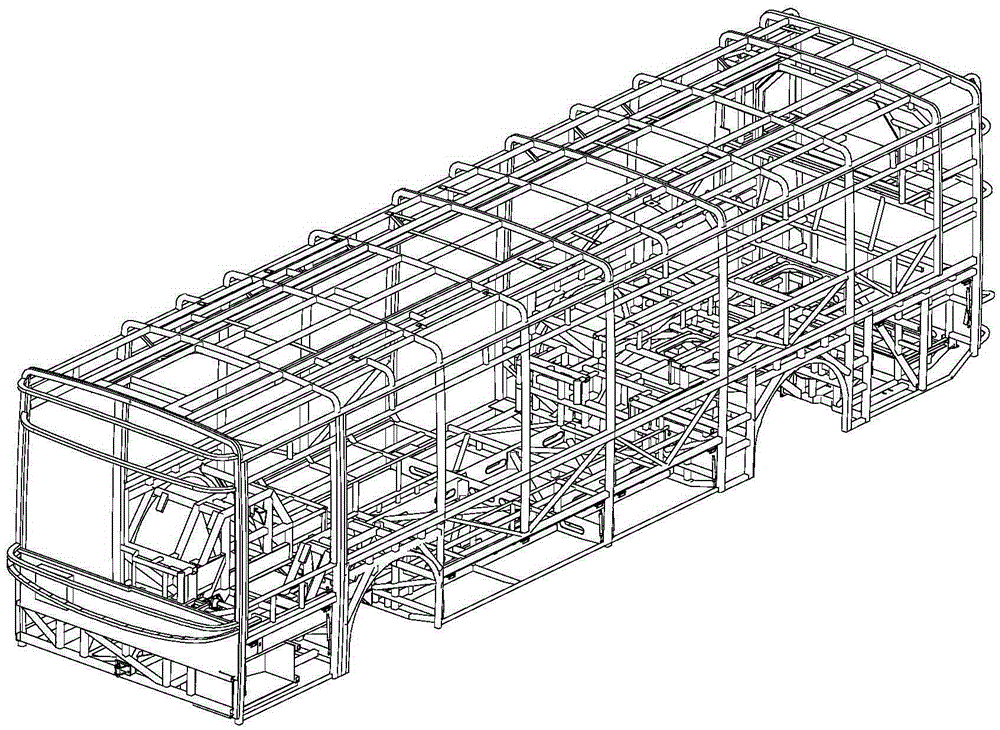

Image

Examples

Embodiment 1

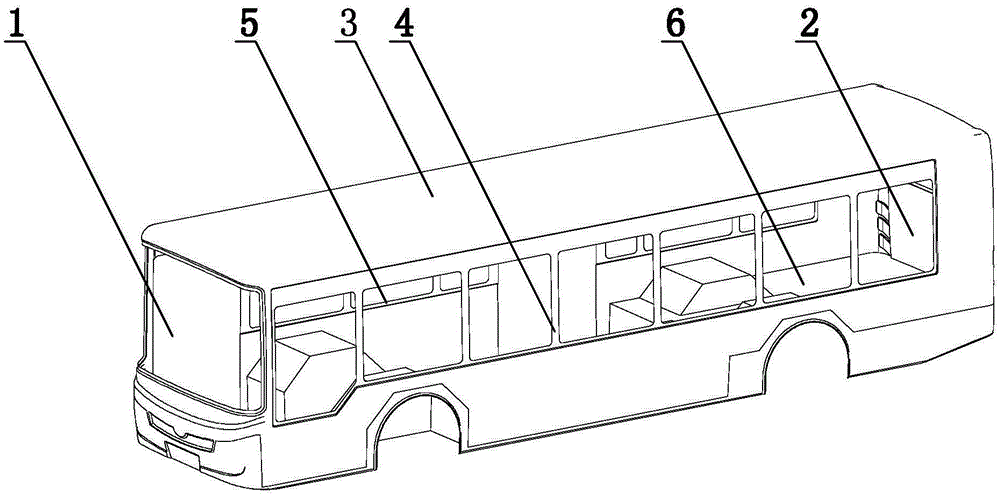

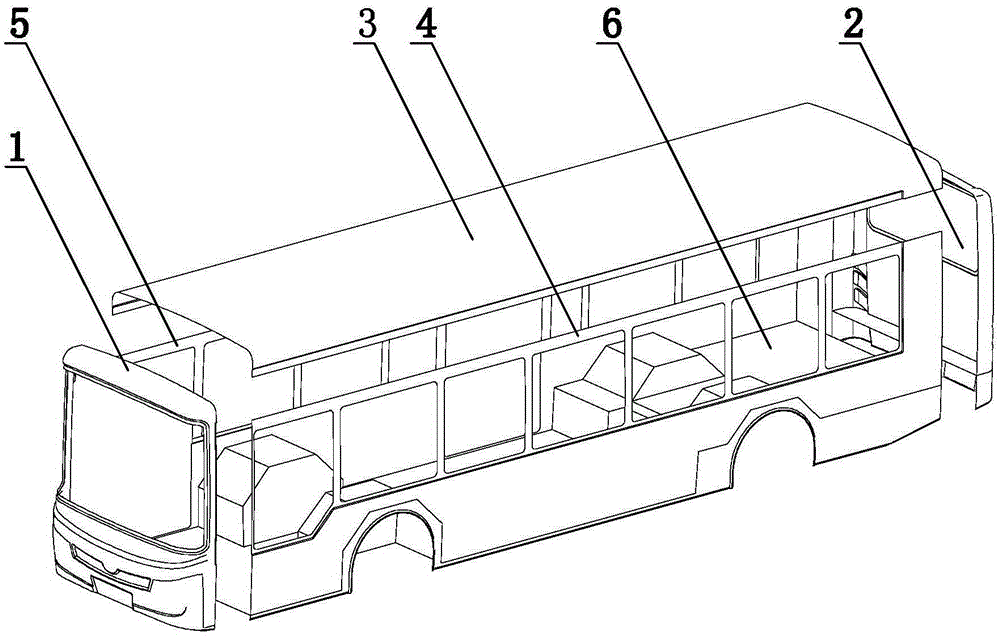

[0027] A kind of modular passenger car of present embodiment, combines figure 2 and image 3 As shown, it is composed of a front wall module 1, a rear wall module 2, a top cover module 3, a left wall module 4, a right wall module 5 and a floor module 6, and the left wall module 4 and the right wall module 5 pass through The top cover module 4 is connected to the floor module 6, and one end of the quasi-rectangular cylindrical structure formed by the left side wall module 4, the top cover module 3, the right side wall module 5 and the floor module 6 is connected with the front wall module 1, and the other One end is connected to the rear wall module 2, and between the front wall module 1 and the top cover module 3, between the front wall module 1 and the left wall module 4, between the front wall module 1 and the right wall module 5, and between the front wall module Between module 1 and floor module 6, between rear wall module 2 and left wall module 4, between rear wall modu...

Embodiment 2

[0033] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference lies in: combining Figure 5 , the connector 7 is composed of a section one 71, a section two 72 and a zigzag connecting layer 73 and a reinforcing rib 74. It is connected by a zigzag connection layer 73, and the zigzag connection layer 73 passes through the gap between the first section 71 and the second section 72 from the outer wall of the top cover module 3 where section one 71 is located, and then extends to the left side surrounding module where section two 72 is located. 4 inner side walls, thus, combined with Figure 6 , a parallel zone 731 is formed on the outer wall of the module where section one 71 is located, a broken line zone 732 is formed between section one 71 and section two 72, parallel zone two 733 is formed on the inner wall of the module where section two 72 is located, parallel zone one 731 , the folding line area 732 and the first parallel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com